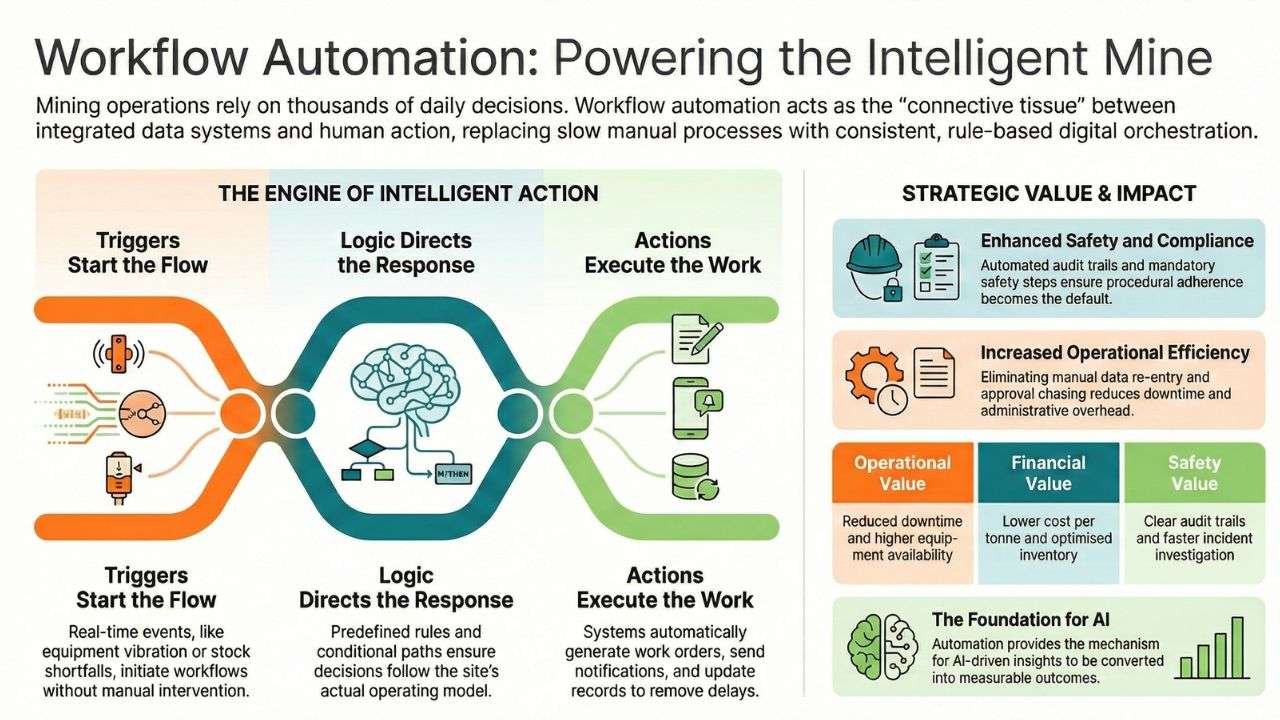

Workflow Automation

Mining operations are built on thousands of decisions, approvals, handovers and checks that occur every single shift/day.

From maintenance planning to production reporting, from safety management to procurement, every process relies on people moving information from one system to another, interpreting it and acting on it.

When these workflows are manual, slow, or inconsistent, the entire operation absorbs unnecessary cost, risk and delay.

Workflow automation changes this. It transforms integrated data into coordinated action, ensuring that the right information reaches the right people at the right time, automatically, consistently and with full traceability.

For mining operations striving for efficiency, safety and cost control, workflow automation is no longer optional. It is a foundational capability for modern, high‑performance operations.

What Is Workflow Automation?

Workflow automation is the use of digital tools to orchestrate and execute business processes without manual intervention.

Instead of relying on emails, spreadsheets, phone calls, or memory, automated workflows use predefined rules, triggers and logic to move tasks through a sequence of steps.

In practical terms, workflow automation:

- Routes information automatically.

- Ensures approvals happen in the correct order.

- Triggers actions based on real‑time data.

- Eliminates manual re‑keying.

- Standardises processes across teams and shifts.

- Creates a complete audit trail of every decision.

It is the bridge between integrated systems and operational excellence. Integration connects your data; workflow automation puts that data to work.

How Workflow Automation Functions.

At its core, workflow automation relies on three components: triggers, logic and actions.

Triggers.

A trigger is an event that starts the workflow. In mining, triggers can come from any integrated system:

- A vibration threshold exceeded on a haul truck.

- A stock level falling below a minimum.

- A safety incident logged in the field.

- A production shortfall detected in SCADA.

- A contractor arriving on site without required competencies.

Triggers ensure workflows begin instantly and consistently, without waiting for someone to notice a problem or manually escalate it.

Logic.

Logic defines what should happen next and this includes:

- Decision rules.

- Conditional paths.

- Approval sequences.

- Escalation thresholds.

- Time‑based reminders.

For example, if a critical asset fails, the workflow may automatically:

- Notify the maintenance supervisor.

- Generate a work order.

- Check parts availability.

- Escalate to planning if downtime exceeds a threshold.

- Alert production if output will be affected.

Logic ensures that workflows reflect the site’s actual operating model, not the informal shortcuts that creep in over time.

Actions.

Actions are the automated steps the workflow performs. These can include:

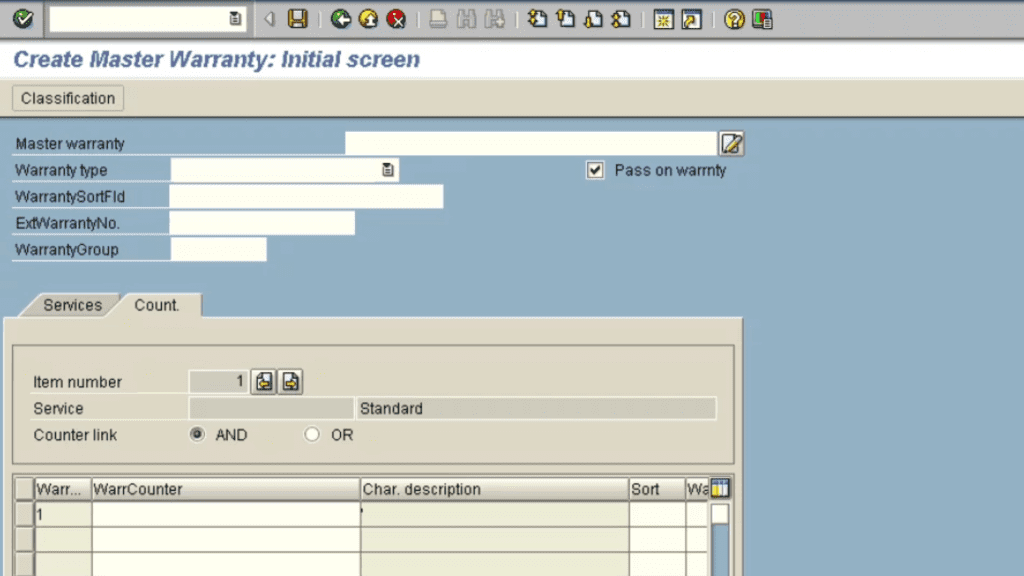

- Creating work orders.

- Sending notifications.

- Updating records.

- Triggering procurement.

- Scheduling inspections.

- Logging decisions.

- Generating reports.

Actions remove manual effort and ensure processes move forward without delay.

How Workflow Automation Helps Mining Operations.

Workflow automation delivers value across every part of the mining value chain. Its impact is both operational and strategic.

Streamlining Decision‑Making.

Mining is full of time‑sensitive decisions: whether to shut down equipment, reroute a haul fleet, adjust a production plan, or escalate a safety concern. When decisions rely on manual communication, delays are inevitable.

Workflow automation accelerates decision‑making by:

- Presenting the right information at the moment it’s needed.

- Ensuring decisions follow the correct approval path.

- Escalating automatically when deadlines are missed.

- Reducing ambiguity about who is responsible for what.

- Removing bottlenecks caused by unavailable personnel.

Instead of chasing information, leaders receive structured, timely prompts that guide them through the decision process.

Creating a Visible, Auditable Trail of Decisions.

Mining operations are heavily regulated, safety‑critical environments. Every decision, from maintenance deferrals to safety approvals, must be traceable.

Workflow automation provides:

- A timestamped record of every action.

- A clear chain of responsibility.

- Evidence of compliance with procedures.

- Visibility into delays, bottlenecks and deviations.

- A defensible audit trail for regulators, insurers and internal reviews.

This level of transparency is impossible with manual processes. Automated workflows make governance effortless.

Reducing Risk and Improving Safety.

Many safety incidents stem from communication breakdowns, missed handovers, or incomplete processes.

Typically, workflow automation reduces these risks by:

- Ensuring safety steps cannot be skipped.

- Automatically escalating overdue actions.

- Triggering alerts when hazards are identified.

- Enforcing competency checks for contractors.

- Standardising incident reporting and investigation workflows.

When safety workflows are automated, compliance becomes the default, not an aspiration.

Increasing Operational Efficiency.

Manual workflows consume enormous time:

- Chasing approvals.

- Re‑entering data.

- Searching for information.

- Following up on overdue tasks.

- Coordinating between departments.

Workflow automation eliminates this waste. Processes that once took hours or days can be completed in minutes. Teams spend less time administering work and more time doing work.

Examples include:

- Automatically generating maintenance work orders from condition monitoring.

- Routing purchase requisitions through the correct approval chain.

- Triggering production plan adjustments based on real‑time data.

- Automating onboarding and competency checks for new personnel.

Efficiency gains compound across shifts, departments and sites.

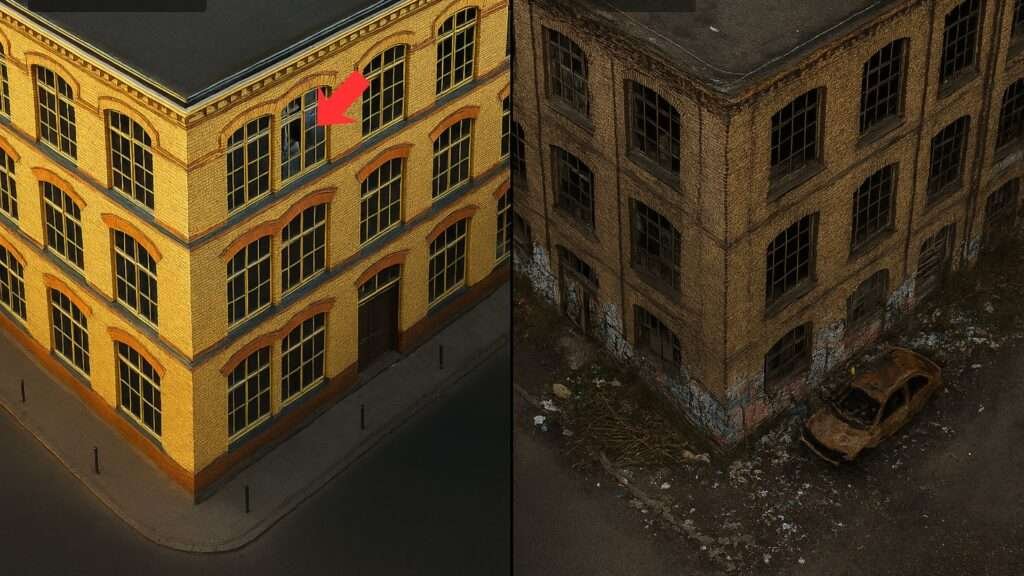

Enhancing Consistency and Standardisation.

Mining operations often struggle with variability between shifts, crews and supervisors. Manual processes rely on individual habits, experience and interpretation.

Workflow automation enforces:

- Standard operating procedures.

- Consistent approval paths.

- Uniform data capture.

- Repeatable decision logic.

- Predictable outcomes.

This reduces variability, improves quality and ensures the operation runs the same way every day, regardless of who is on shift.

Enabling Proactive, Not Reactive, Operations.

When workflows are automated and data is integrated, the operation becomes predictive rather than reactive.

Examples include:

- Automatically escalating rising equipment temperatures before failure.

- Triggering procurement before stockouts occur.

- Adjusting production plans when bottlenecks emerge.

- Alerting supervisors when leading indicators of safety risk appear.

Automation turns early signals into early action.

How Workflow Automation Adds Value.

The value of workflow automation is both measurable and strategic.

1. Operational Value:

- Reduced downtime.

- Faster turnaround on approvals.

- Lower administrative overhead.

- Improved maintenance planning.

- Fewer errors and rework.

- Higher equipment availability.

2. Financial Value:

- Lower cost per tonne.

- Reduced overtime.

- Optimised inventory.

- Better capital planning.

- Stronger cost control.

3. Safety and Compliance Value:

- Fewer incidents.

- Stronger procedural adherence.

- Clear audit trails.

- Faster reporting and investigation.

- Reduced regulatory exposure.

4. Strategic Value:

- Greater agility.

- More informed leadership.

- Stronger cross‑department alignment.

- A foundation for AI‑driven operations.

Workflow automation is not just a tool, it is a capability that reshapes how the entire mine operates.

Why Workflow Automation Matters More as AI Emerges.

As mining systems become more integrated and data‑rich, workflow automation becomes the mechanism through which AI insights turn into action.

AI can:

- Detect anomalies.

- Predict failures.

- Identify bottlenecks.

- Recommend optimizations.

But without automated workflows, these insights sit idle.

Workflow automation ensures AI outputs:

- Trigger actions.

- Reach the right people.

- Follow the right process.

- Drive measurable outcomes.

It is the connective tissue between intelligence and execution.

Conclusion: The Future of Mining Is Automated, Connected and Intelligent.

Workflow automation is the natural evolution of system integration. Once your systems are connected, automation ensures your processes are connected too.

It removes friction, accelerates decisions, strengthens safety and creates a transparent, auditable and efficient operating environment.

In a world where margins are tight, risks are high and expectations are rising, workflow automation is not a luxury, it is a strategic necessity.

It transforms how work flows, how decisions are made and how value is created across the entire mining operation.

The mines that embrace workflow automation today will be the ones that operate safer, leaner and smarter tomorrow.