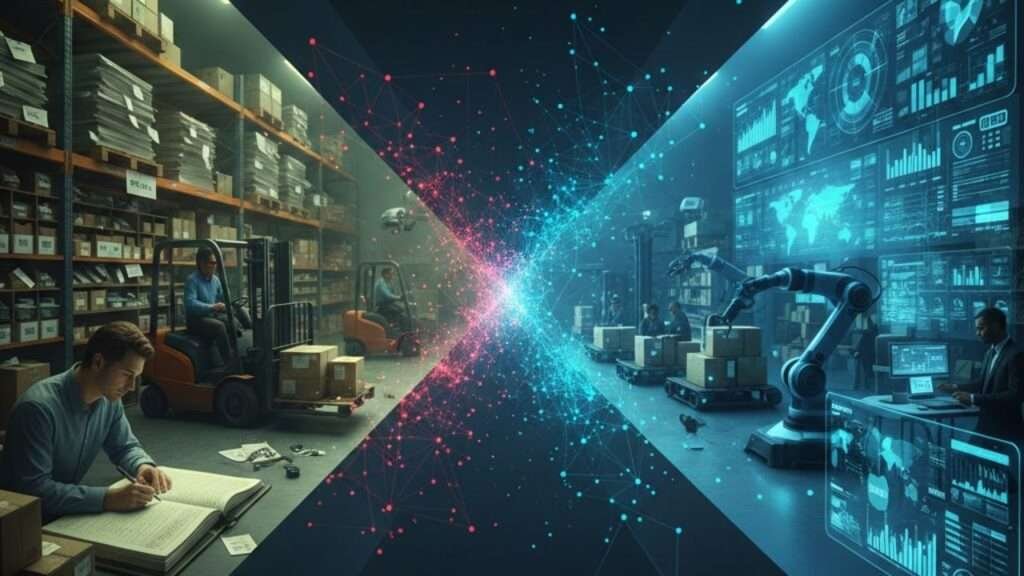

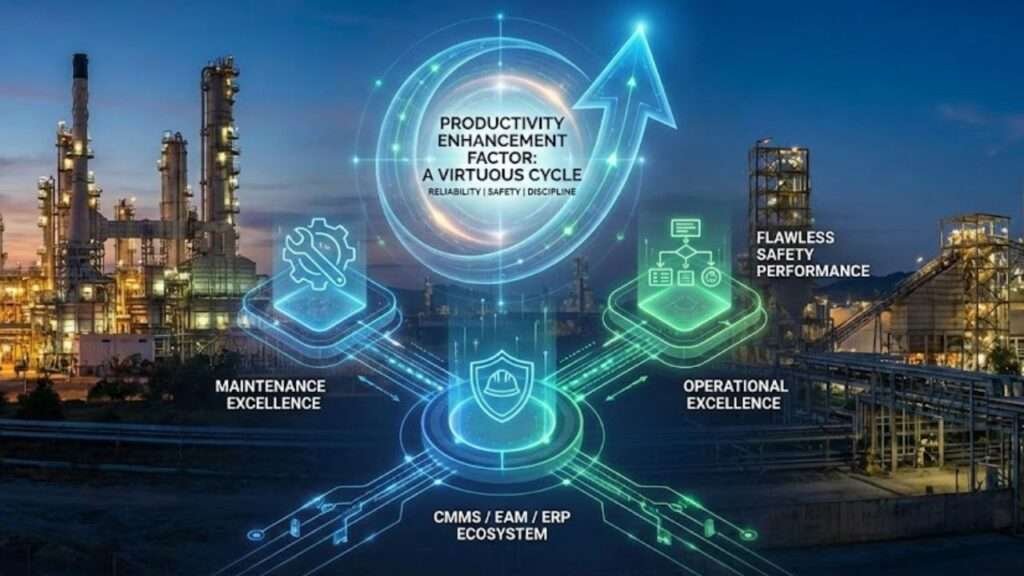

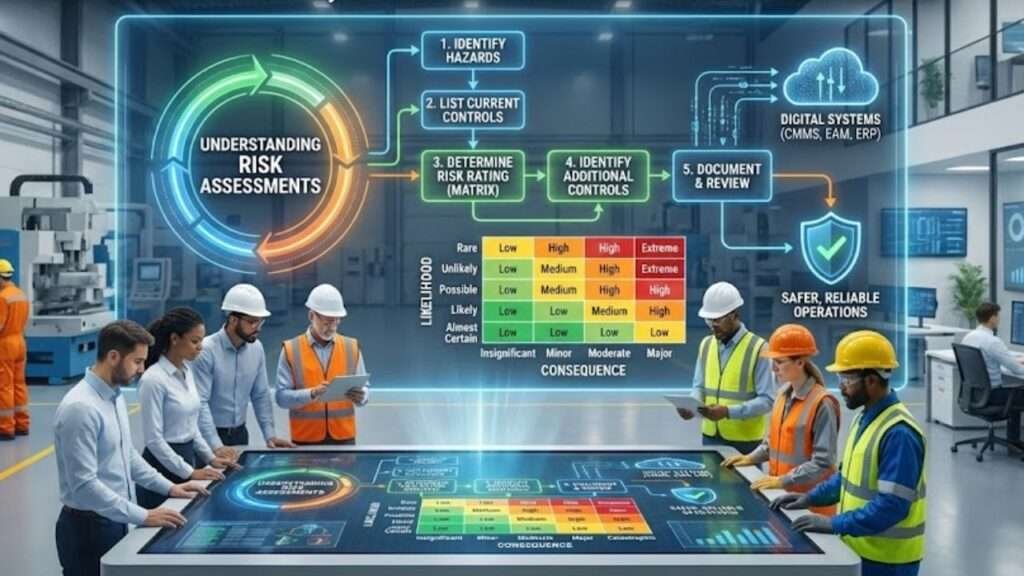

Unleash the full potential of your Asset Management System

CMMS Success is possible.

Navigating the CMMS Success Journey.

You Can Contact Us

We're Ready, Let's Talk.

Contact Info

Address

PO Box 784, Muswellbrook, NSW, Australia

Email Us

admin@cmmssuccess.com

Call Us

0448 687 451