There are numerous possibilities for cutting-edge software available for any activity in any business. With so many options available, it is understandable that you will need to spend your time studying the features and benefits of each option before you can best select the most appropriate software solution for your organisation.

Choosing the right software and utilising its possibilities could help your company thrive. The usability of a software product is just as important as its technical impressiveness; it’s easy to envisage the vast majority of workers being discouraged and even fatigued from attempting to understand software that makes no sense to them.

Furthermore, if there are too many upgrades and modifications, employees may start to dread the idea of turning the computer on. If you purchase software that is still in development, you may end up spending more much time learning about the new changes than the base functions according to your role. Stability must be a significant consideration while purchasing software.

Choosing the best software solution for your organisation is a difficult task no matter how you slice it. You’ll want a solution that can handle company expansion and does everything you’ve outlined in your business procedures, but I’m sure you don’t want to subject your employees to software that’s difficult to learn, unfit for purpose, riddled with errors, and unstable, as this will limit everyone’s effectiveness.

Software can help you develop and succeed in many ways, but if you are careless with your choice, it can come back to bite you and even send you backwards. It is just not worth throwing time and money at something that proves to be the wrong choice within 12 months from implementation, so be sure to include a wide selection of your people when selecting asset management software.

It will be difficult to achieve a decent return on your software investment if you are unable to fully utilise the new system. The newly deployed system may have been hyped up extensively during the project period, but sometimes they can fall short of expectations in every manner. Poor adoption undercuts the promise and premise of delivering improved workflows and becomes a barrier to transformation success.

Excessive expenditures emerge from poor installation or ineffective use of new systems. While the cost of system ownership is the most immediate and obvious price, the expenses of customisation, implementation and configuration, maintenance, support, and training all add to the overall costs of deploying any new system.

The actual costs associated with implementing a CMMS

You must account for the costs associated with inappropriate usage of new systems, blunders, and inefficiencies uncovered as your staff progress along their learning curve; some of this is difficult to quantify.

Even so, you would have budgeted for a notional cost for all of this. All too often, the actual costs of implementing a new system exceed your expectations, casting doubt on your budget assumptions. As a result, any organisation should prioritise assuring adoption success.

Problems are more frequently caused by a lack of planning, organisation, effort, and time in the software adoption process than by accepting the shift in technology. A successful CMMS implementation process entails much more than merely installing software and then sitting back and hoping that your staff might learn its capabilities & fully adopt it.

Managing the change process introduced by your CMMS

A software implementation is also a business transformation project and can frequently succeed or fail owing to a lack of sufficient and adequate training and assistance. When employees are unable to properly utilise new systems, organisations do not enjoy the anticipated benefits. Before you intend to train your staff on the technology, get their cultural support for the implementation process. To ensure readiness, inform workers about the overall process and secure early buy-in. Information sharing gatherings, videos, and surveys are all pretty good ways to spread the word about impending change. Build momentum and time it properly. Make it a simple and straightforward process to reduce tension and frustration.

Remember that while leadership makes the decision to buy a system and marks the beginning of an implementation process, end users ultimately decide if the system will ever be considered a successful undertaking. Don’t undervalue the significance of your training program despite the tireless efforts of software developers to make software more understandable and user-friendly.

Have an early commitment from the leadership and a clear, comprehensive training plan. Use a methodical, well-thought-out design approach for creating software training. Employees remember material when it is relevant to them and effective training can even be entertaining when it is relevant. We learn and retain more when we feel this knowledge can be applied very quickly. Overly lengthy manuals, classroom or online sessions will not be welcomed by all employees; while some may relish the prospect of learning all day, others will begin to drift off after a couple of hours.

We learn best when we are engaged and it is sometimes difficult to keep people engaged for more than 2 hours. To guarantee successful engagement and retention, you must balance the ‘learn it’ and ‘do it’ components.

Introduce & Sustain new CMMS information

When your employees have a lot to learn and absorb while also having hectic work schedules, training may appear to take too long. If you schedule training sessions when your employees are most likely to be busy, you will have a lot of resistant learners who are distracted by all manner of other things. You’ll win no support from your employees by forcing them to learn a new system fast by scheduling the training right before or right after its rollout.

Employees will need time to ask questions and seek advice from their supervisor, co-workers, and subject matter experts. They will also require time to read the training manual you have given. Poor training decisions result in increased expenses and longer delays due to the overall loss of productive time. Although technology is intended to reduce inefficiencies, when quality training is lacking, it has the opposite impact.

Keep the learning relevant and interesting. A framework based on roles or functions keeps the user from being overburdened with information. When training is organised into targeted modules with well-defined learning objectives, users can enjoy and better absorb the essential training. Continuous training programs are required for effective training. When there is no attempt to retrain, information is lost over time.

A training plan should contain ‘boost sessions’ at regular intervals to guarantee that the training sticks in the minds of your staff over time. Seek employee input on what those ‘boost sessions’ might look like. When done appropriately, these can be effective methods of reinforcing the initial time and money spent of training.

A computerised maintenance management system (CMMS) can be utilised to increase equipment uptime and maximise asset lifecycles while lowering costs and enhancing overall efficiency.

A CMMS is capable of automating and centralising maintenance procedures and data. It will help to improve the efficiency and usability of your company’s assets including mobile machinery, plant infrastructure, communications, and other assets.

If you’re looking to buy a CMMS, the first step is to create a software requirements statement outlining all of the objectives you want to achieve. The following are some pretty normal reasons for wanting to purchase and deploy a CMMS.

1. Manage, analyse & minimize equipment downtime

2. Develop a better understanding of all your production related costs

3. Holistic inventory management

4. Transform your Asset Maintenance from reactive to proactive.

5. Capture & action Health, Safety & Environment incidents

Prior to signing off on your Software Requirements Statement (SRS), it is critical to understand all of the “real” costs associated with obtaining a CMMS. While you may initially shop around based on product price, there are many rather large costs associated with successfully commissioning a well-built CMMS that will be well-utilized by your users.

Considerations – Step 1

ROI, cost savings (short, medium, and long term), how to maximise tool time, waste reduction (muda), production efficiency gains, integration of operating system software, compliance requirements, downtime reduction, plan and execute outage events, master data objectives, safety enhancements (integration of the safety and maintenance modules), inventory management, and develop and manage preventive maintenance activities should all be defined.

Considerations – Step 2

Standard Functionality & Optional Extras, Ease of Use, 24/7 Customer Support? Training (before, during, and after implementation), Mobile Compatibility, Typical Queries and Reports Future Software Developments / Frequency of Expected Upgrades, SAAS (Software as a Service) option, the annual subscription fee (what do you get) & what are the options for integration with other software, either now or later on.

Considerations – Step 3

Can you bind the provider to a set price for software purchase or rental fees? Is the cost of pre-configuration included or not? If not, they must present you with a detailed breakdown of the estimated costs as well as hourly/daily rates for the resources they intend to use. Is training included in the final configuration and implementation costs? If not, acquire a complete breakdown; you might decide to undertake the training yourself. Is post-installation help, both onsite and remotely, included in the ‘Final configuration and implementation costs?’ If it isn’t, it should be! This should be their warranty policy. Charges connected with providing quotes for future adjustments you may desire, will they supply free quotations or will the software developer’s costs be passed on to you?

Be very detailed with your Software Requirements Statement prior to tender process. Find out who else is using their software products and contact them and see if you can visit, see it in action and talk to users. Don’t just go off the product reviews or the client feedback stories they publish online as I doubt they are going to boost and bad reviews etc.

How many people they state will be involved

during implementation etc? Do you

actually have anywhere for these people to sit during the implementation

process? Workstations, office real

estate space etc. Last but not least,

look at meeting room capacity impacts as your meeting rooms will be pretty much

booked solid during this entire process.

Collaboration is essential when working on a CMMS project, such as a system deployment or upgrade.

These projects must be managed in a specific manner, and they will necessitate collaboration from the entire group; any identified sub-group ‘silos’ must be eliminated as soon as possible.

You will be able to achieve your key objectives with little to no conflict if you have a cohesive team.

Make a detailed action plan and encourage your team to work together.

To be effective and efficient, as well as to reduce or eliminate project cost overruns, teamwork concepts must be accepted.

A good team is made up of interdependent individuals who work together to achieve a common goal.

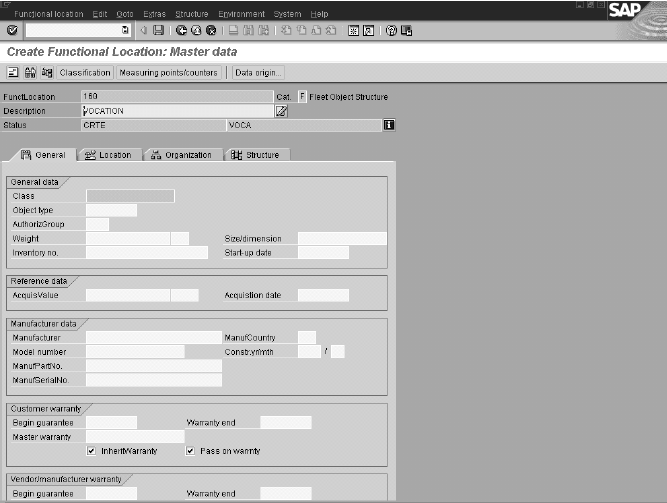

SAP is an acronym that stands for Systems, Applications, and Products in Data Processing (in German: Systemanalyse und Programmentwicklung). It is the name of a German software company as well as the name of their Enterprise Resource Planning programme (ERP).

SAP was founded in 1972 by five ex-IBM employees. The company’s headquarters are in Walldorf, a town in the Rhein-Neckar-Kreis district of the German state of Baden-Württemberg.

SAP is without a doubt the world’s most popular ERP system. It is a comprehensive software suite that helps organisations integrate all parts of their operations, including maintenance, manufacturing, project management, cost accounting, sales, distribution, and marketing.

SAP began with a single client and a tiny team; their narrative is extraordinary and their path would not only revolutionise the information technology industry, but would also permanently change the way businesses run. SAP is still driven by the pioneering spirit that drove its founders, 50 years later and with over 400,000 clients, they still constantly redefine the IT sector and will no doubt continue to do so for as long as they exist.

SAP is one of the world’s largest firms in terms of revenue, the fourth largest publicly traded software company in terms of revenue, and the second largest German company in terms of market capitalisation.

In addition to their well-known ERP software, the company sells database software and technologies, cloud designed systems, and a variety of additional ERP software solutions.

Despite the fact that I have no idea what Release 1 (R/1) was like, SAP delivered Release 2 (R/2) to the market in 1981. However, R/2 did not dramatically improve until between 1985 and 1990. SAP introduced R/3 in 1992, a game-changing release of their software that would propel them to the top of the ERP sector.

SAP would go on to develop and release a large number of R/3 versions in the coming years. By the mid-1990s, SAP had followed in the footsteps of mainframe computing companies and had nearly completely revamped their software, launching the new SAP ERP Central Component ‘ECC 5.0’ in 2004.

Improvements were developed to accommodate an enterprise service design in order to transition clients to a services-oriented architecture and it paid off beyond imagination. SAP ECC 6.0 was released some years later and in my opinion, is the gold standard for others to follow. Their most recent product, to the best of my knowledge, is S/4 Hana, I’ve had the privilege of using S/4 Hana a few times now and it’s so hard to imagine how we ever did maintenance without such incredible software.

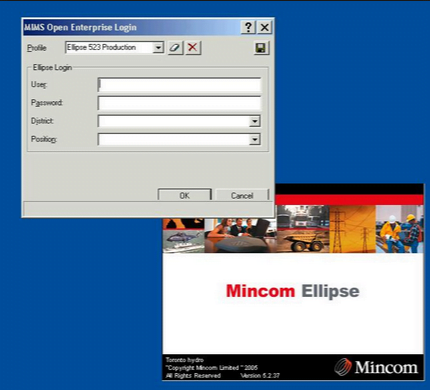

Mincom was an amazing Australian Company established in 1979 in Brisbane, Australia, when five computer specialists in the mining industry agreed to pool their abilities and write better mining software. These five developers felt that the numerous software applications used in mining at the time were a little inadequate, unable to connect all areas of the organisation and necessitating continual updating.

MIMS (Mincom Information Management System) was a very successful enterprise asset management software solution developed by Mincom.

MIMS was a modular application with four sub-systems: maintenance, materials, finance, and human resources. It was built on a three-tiered architecture; the user interface, the application, and the database. It functioned as separate and replaceable units linked by standard network and inter-process protocols.

Through their MIMS software, Mincom became the largest software firm in Australia in the early 90’s as well as the world’s largest supplier of mining software.

Mincom was the fourth oldest ERP Company globally prior to the Mincom moniker no longer existing.

In 1992, it had 320 employees, including 50 in the United States and various abroad branches. It was turning over roughly $35 million each year, with 40% of that coming from exports, and earning annual profits of $3-4 million, all of which was reinvested back into the business.

Over the 4 years since 1988, Mincom had been growing at an astounding rate of approximately 40% every year.

The MIMS software would go through a lot of baseline versions over the years and was also re-branded to what a lot of use now know as ‘Ellipse’.

Mincom also created another remarkable software product, now known as ‘Linkone.’ It began as a product called ‘Image Link,’ and the majority of the development effort was done by just two people in the early days. The early version of Image Link included a Komatsu D375 dozer and an Army Camp Trailer.

ABB sold Ellipse too Hitachi in Feb 2019 and the latest version I’m aware of is Ellipse9

Maximo is an Enterprise Asset Management (EAM) software solution that IBM purchased from MRO Software a company that was formerly known as Project Software & Development Inc (PSDI). .

PSDI’s original product was called PROJECT/2 (p/2) and had its first commercial version release in 1985. It was a project management scheduling system that ran on IBM mainframes. It was very popular and as much as 75% of the nuclear power plants in the US used P/2 for outage management.

In the latter half of 2000, PSDI would change their directive following the changes they would make to the setup of their business; they changed their name to MRO Software.

They stopped offering P/2 (a project management product) and came up with two products they would produce, one would be a Enterprise Asset Management solution, the other would be an internet procurement focused product. Maximo was the EAM software product they would then offer.

IBM purchased MRO Software around 2005/6 branded the product as IBM Maximo Asset Management.

Once the transfer to IBM was completed, MRO Software would cease to exist.

IBM Maximo is an integrated modular Asset Management solution for managing asset operations and business processes. It provides visibility into all of your enterprise assets, their conditions, and work processes, enabling better planning and control. Maximo enables firms to manage inventory, resources, and personnel. It also allows you to manage a variety of physical assets such as plant, manufacturing, transportation, infrastructure, facilities, and communications. Its six modules are Asset Management, Work Management, Contract Management, Service Management, Inventory Management, and Procurement Management.

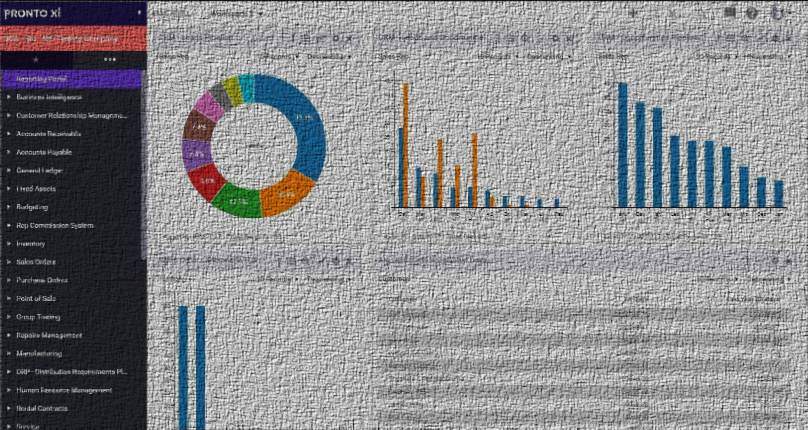

Pronto Software is an Australian Enterprise Resource Planning software solution. The company was originally known as “Prometheus Software,” of which was purchased by Sausage Software in 1999. Following a management buyout in 2002, the name was changed to ‘Pronto Software.’

The company employs roughly 420 employees and is headquartered in Melbourne, Victoria, Australia, where they also have their main development centre. They have a large amount of support offices and consultants, as well as a global network of Resellers and Solution Partners.

Pronto Xi, the company’s latest software version offering, is an Enterprise Resource Planning (ERP) system that was released in 2018. The way organisations operate and receive information will change thanks to this highly intelligent ERP solution. The new edition meets crucial market needs, such as providing instant visibility into company performance to enable quicker, more informed decision-making for all employees. It is also quick and easy to incorporate. Modules include financial, retail, CRM, supply chain, warehouse, manufacturing, and facilities management. Businesses can monitor and manage every aspect of their operations from top to bottom thanks to Pronto Xi.

Pronto Xi will provide you with the knowledge about what is helping and hurting your business, it will highlight your biggest opportunities to improve and it will equip you with the means to increase productivity, customer satisfaction, inventory accuracy, and many other factors.

Across roughly 1,700 customers, Pronto has been in helping businesses get in control of their assets, resources and people in Australian and around the world for more than 40 years.

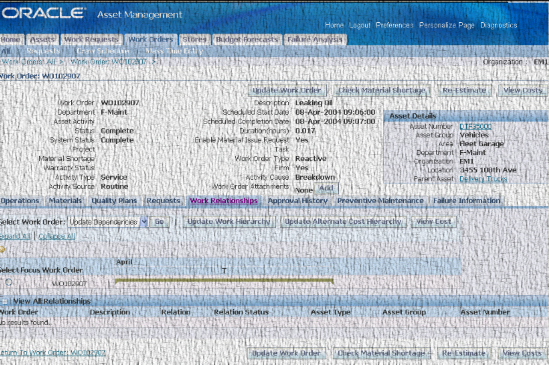

Oracle Enterprise Asset Management software provides organisations with the tools they need to optimise asset performance through sophisticated planning, tracking, and execution features. Its vast condition-based maintenance plans for buildings, infrastructure, and public facilities, as well as an integrated asset repository, ensure best practises and high performance standards all around the world. Oracle Enterprise Asset Management (eAM) promotes environmental, health, and safety standards, as well as the reduction of excess and obsolete spare part inventories and the improvement of production and maintenance schedule synchronisation.

With Oracle eAM, businesses can better manage asset and inventory maintenance processes and it assists users with a variety of tasks, including scheduling and optimising maintenance activities, extending the life of assets, streamlining work orders, and keeping track of all actions involving assets.

Additionally, it takes the place of spreadsheets, gathers data from many data sources, and enables proactive rather than reactive maintenance. Incorporating Oracle Inventory, Oracle Purchasing, Oracle Property Management, Oracle Quality, Oracle Human Resources, Oracle Financials, Oracle Fixed Assets, Oracle Manufacturing, and Oracle Projects, Oracle EAM is a part of the Oracle E-Business suite.

To maximise asset use and overall business success, businesses can create and implement maintenance strategies for assets as well as certain types of inventory items. A company’s overall asset lifecycle management system is dependent on quality maintenance strategies.

With Oracle eAM, you can schedule and organise maintenance work with the least amount of disruption to an organization’s operations or output. It also tracks labour history, improves maintenance quality, and keeps track of all maintenance costs.

Oracle eAM tracks the performance of assets like repairable and rotable inventory items using meters, quality plans, and condition monitoring systems. Monitoring an asset’s operational status effectively allows for the execution of effective preventative maintenance approaches. In addition to creating preventative maintenance plans, users can set up alternative maintenance strategies for seasonal or production capacity changes.

The processing, mining, manufacturing, pulp/paper, petrochemical, industrial facilities, and educational sectors can all benefit from Oracle eAM’s features. It enables enterprises to manage reactive, scheduled, and preventive maintenance as well as build a central, proactive strategy for managing asset maintenance throughout an organisation, reducing the need for spreadsheets and disparate data repositories. By capturing defects and managing their resolution, corrective and improvement plans may be carried out and assessed to make sure your maintenance department shines.

Believe it or not, there are four pretty good-looking free maintenance management software packages. I won’t go into depth about all four because I’d prefer to focus on one of them, but the four are: MaintainX, Fiix, Upkeep, and eMaint.

They all have free and paid versions, but the free ones are 100% free. Sure, the free options are restricted, but for a very small business, you can’t help but believe any of these four would be excellent to at least try out.

This cloud based CMMS platform MaintainX has got at sack of capabilities including infinite work orders, asset categorisation, managing spare parts, and team communication. With the free membership offered by the provider, a limited number of work order templates, maintenance checklists, and standard operating procedures can be created. The main benefits of MaintainX’s free plan include the ability to make, assign, and track work orders; to keep an unlimited number of asset entries in a database; to facilitate team communication via chat; and to design customised API interfaces with your other business software programmes.

MaintainX is available on desktop computers as well as mobile apps for Android and iOS smartphones. There is 2 levels of the software’s paid versions and they offer many additional features for the market’s lowest entry-level pricing of around US $10 per user/monthly. MaintainX’s ease of use, customer service, and team chat capabilities has received very high ratings from users.

CONTACT US

Address

PO Box 784, Muswellbrook, NSW, Australia

Email Us

admin@cmmssuccess.com

Call Us

0448 687 451