System Integration

Mining is a complex, capital‑intensive, risk‑laden industry where operational excellence isn’t a competitive advantage, it’s a requirement for survival.

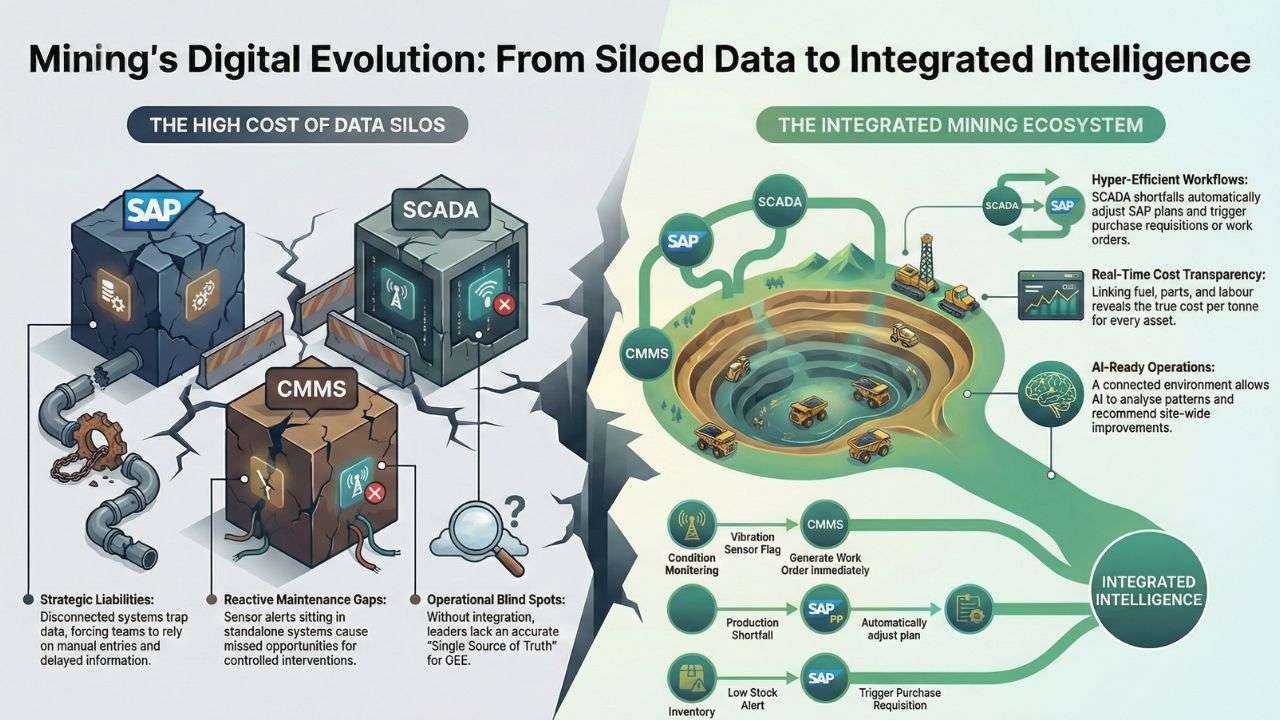

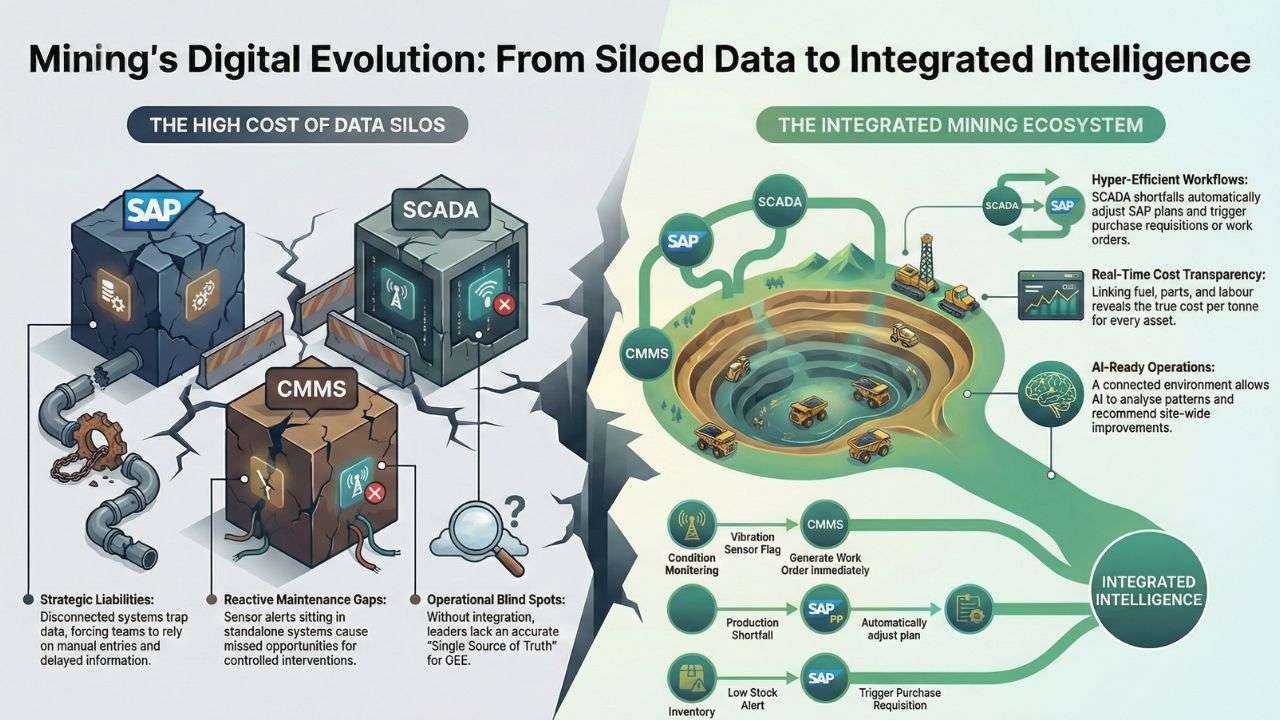

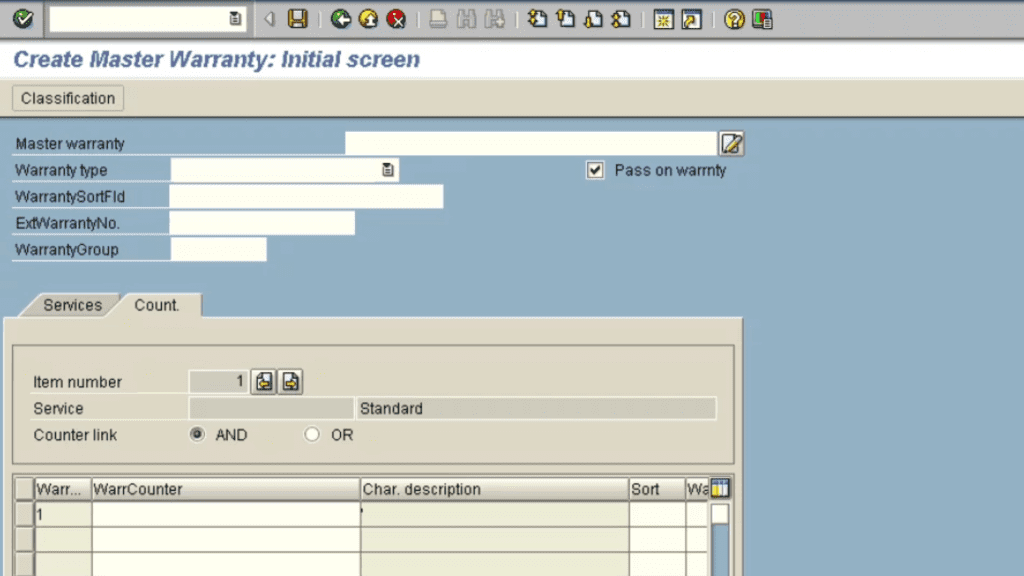

Yet many operations still rely on a patchwork of powerful but disconnected systems: ERP platforms like SAP, specialised EAM or CMMS tools, production SCADA systems, condition monitoring suites and standalone solutions for HR, finance, safety and environmental management.

Individually, these systems are strong. In isolation, they become strategic liabilities.

When data is trapped in silos, leaders lose visibility, decisions slow down and the business absorbs unnecessary cost and risk.

System integration is not a luxury, it is the foundation of a truly intelligent, responsive and profitable mining operation.

The High Cost of Data Silos.

When your SAP PP module doesn’t communicate with AVEVA Plant SCADA and condition monitoring insights don’t automatically feed into maintenance strategies or predictive models, your CMMS work orders are never as accurate or timely as they should be.

This forces teams to operate through manual gaps, delayed information, duplicated entry and avoidable errors.

The consequences ripple across the entire value chain.

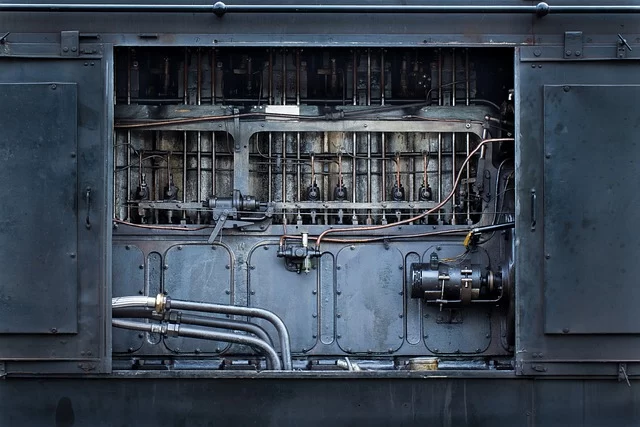

Reactive Instead of Predictive Maintenance.

A vibration sensor on a critical shovel flags an impending failure.

If that alert sits in a standalone system waiting for manual review, the opportunity for a controlled intervention disappears.

The result: unplanned downtime, production loss and inflated maintenance cost.

Integrated systems turn condition monitoring into automated action, triggering work orders, adjusting schedules and protecting asset availability.

Fragmented Operational Intelligence.

SCADA holds real‑time production data. ERP holds cost, labour and inventory data. Without integration, leaders are making decisions with half the picture.

You can’t measure OEE accurately, understand the cost impact of bottlenecks, or align production performance with financial outcomes. Integration creates a single source of truth that links physical activity to commercial reality.

Compliance And Safety Blind Spots.

Many sites underutilise SAP’s HSEC or QM modules, relying instead on point solutions. When incidents occur, disconnected data slows reporting, obscures root‑cause analysis and hides systemic contributors like maintenance delays or production pressure.

Integrated safety and environmental data strengthens compliance, improves transparency and supports proactive risk management.

The Tangible Benefits Of A Connected Ecosystem.

System integration transforms raw data into operational intelligence. When your systems speak the same language, the entire business accelerates.

- Hyper‑Efficient Workflows:

- A production shortfall in SCADA can automatically adjust the plan in SAP PP.A low inventory alert can trigger a purchase requisition.

- A condition monitoring event can generate a work order.

- This eliminates swivel‑chair processes and frees your workforce to focus on value, not data entry.

- Real‑Time Cost Transparency:

- Mining margins are tight and to control cost, you must understand it in real time.

- Integration links runtime, fuel burn, parts usage, labour hours and production output, revealing the true cost per tonne for every asset, shift and circuit.

- This empowers precise budgeting, exposes waste and strengthens commercial discipline.

- Optimised Asset Lifecycle Management:

- Tyre wear, load cycles, service history and production demand all live in different systems.

- Integrated, they form a complete asset health profile.

- This enables smarter maintenance planning, better procurement timing and capital replacement decisions based on total cost of ownership, not guesswork.

- Faster, Better Decision‑Making:

- Integrated dashboards give leaders a unified view of production, maintenance, safety and financial KPIs.

- Patterns become visible.Risks become predictable.Decisions become faster and more confident.

- Strategic Agility:

- When commodity prices shift, integrated systems allow rapid scenario modelling, fleet availability, crew schedules, maintenance constraints, consumable

- Planning becomes dynamic, not monthly. Strategy becomes data‑driven, not intuition‑driven.

What Does Good System Integration Look Like in Practice?

Modern integration is not about replacing systems, it’s about connecting them. Practical enablers include:

- API‑based data exchange for seamless communication

- Event‑driven triggers that automate workflows

- Standardised data models that ensure consistency

- Middleware/iPaaS platforms that simplify connectivity

- Real‑time dashboards that unify operational and financial insight

Integration is now achievable through phased, use‑case‑driven implementation, not multi‑year transformation programs.

Preparing for AI‑Enabled Operations.

As the mining industry moves toward more automated and data‑driven operations, integrated systems become the foundation for adopting site‑wide AI.

Whether your current platforms already include AI features or not, a connected environment ensures you can take advantage of emerging capabilities without major rework.

When data flows freely across ERP, EAM, CMMS, production, and monitoring systems, AI can begin to analyse patterns, highlight risks, and recommend improvements across the entire operation.

Over time, this can extend from advisory insights—such as identifying bottlenecks or predicting equipment issues, to automated actions like generating work orders, adjusting plans, or optimising resource use.

The goal isn’t to replace people, but to remove friction, reduce delays, and support faster, more confident decision‑making.

By building an integrated ecosystem today, you create the conditions for AI to enhance operations, streamline maintenance, and strengthen performance across the site as capabilities continue to evolve.

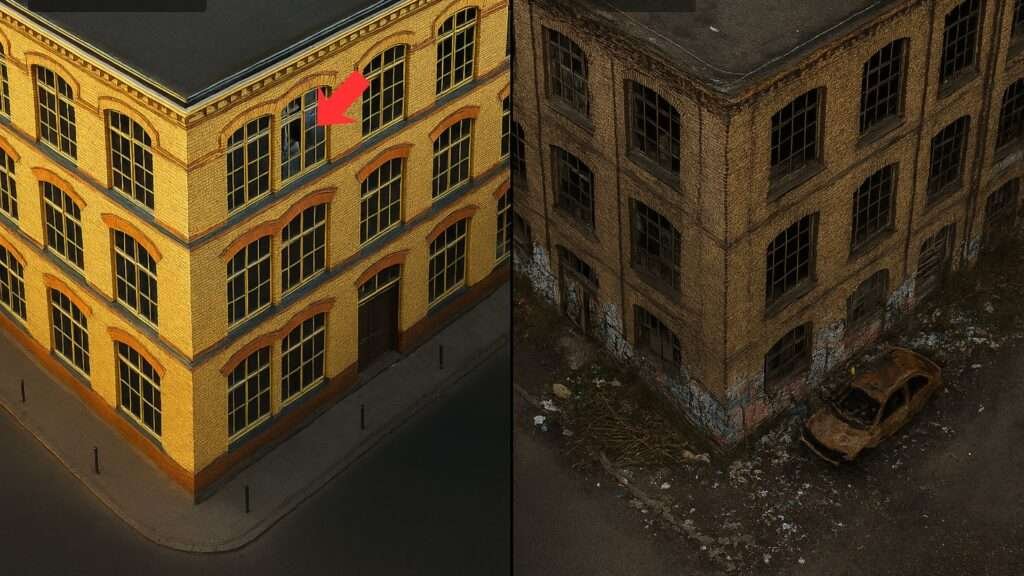

Conclusion: From Fragmented to Fused.

Running a mine with disconnected systems is like operating a haul fleet where every truck is on a different radio channel. You can still move material, but coordination breaks down. Safety risks increase, delays multiply, confusion spreads, and countless small issues compound. By the end of the shift, you’ve wasted time, burned money, and taken risks no one needed to take.

The mining operations that will lead the next decade are those that treat data as a strategic resource, one as valuable as the ore they extract.

By integrating ERP, EAM, CMMS, production and all specialist systems, you move from managing isolated functions to managing a unified enterprise.

You shift from collecting data to leveraging it. You reduce cost, strengthen safety, improve productivity and build a durable competitive advantage.

The seam is there, the value is real, so it’s time to start digging.