Site Maintenance Strategy

Every mining operation depends on the reliability, availability and safe performance of its equipment.

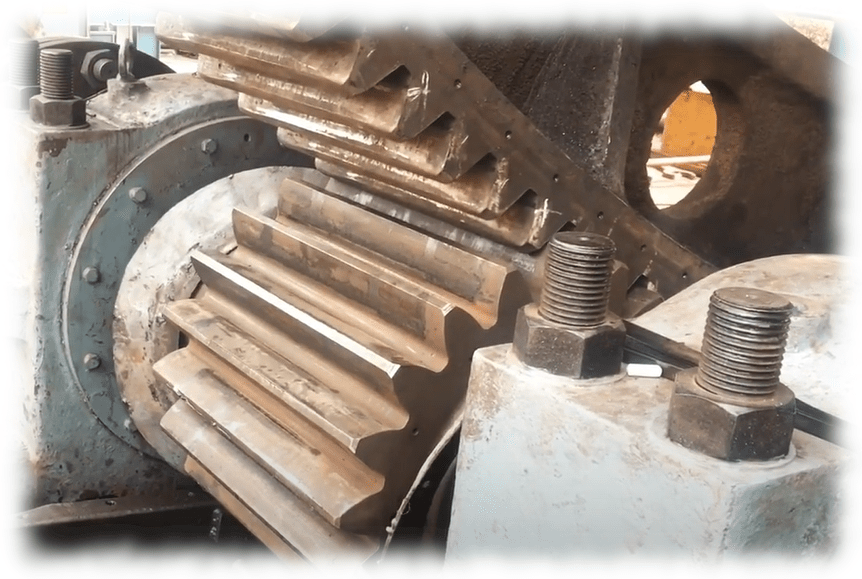

From haul trucks to crushers, pumps to conveyors and electrical systems to mobile plant, every asset plays a crucial role in the value chain.

Yet many sites talk about a “Site Maintenance Strategy” as if it were a single equipment‑level plan.

In reality, it’s something far broader, a site‑wide framework that governs how every maintainable asset is managed, maintained and continuously improved.

A Strategy For The Whole Site.

A Site Maintenance Strategy isn’t a list of maintenance tasks; it’s a philosophy, a framework and a standard.

It defines how the site approaches reliability, risk, cost and performance.

You can think of it as the end result of a site‑wide reliability program, the foundation that ensures all maintenance decisions share a common logic and standard of quality.

It sets expectations for how asset strategies are created, reviewed, monitored, improved and measured so that every asset, from the largest shovel to the smallest pump, is managed with the same level of discipline and consistency.

The Parent Framework.

When a site says, “We need a maintenance strategy,” what it often needs is the parent strategy, the governing framework that defines:

- How asset strategies are developed.

- What quality standards they must meet.

- How risk is assessed and controlled.

- How tasks are selected and justified.

- How performance is measured.

- How strategies are reviewed and improved over time.

This parent framework sits above all individual asset strategies.

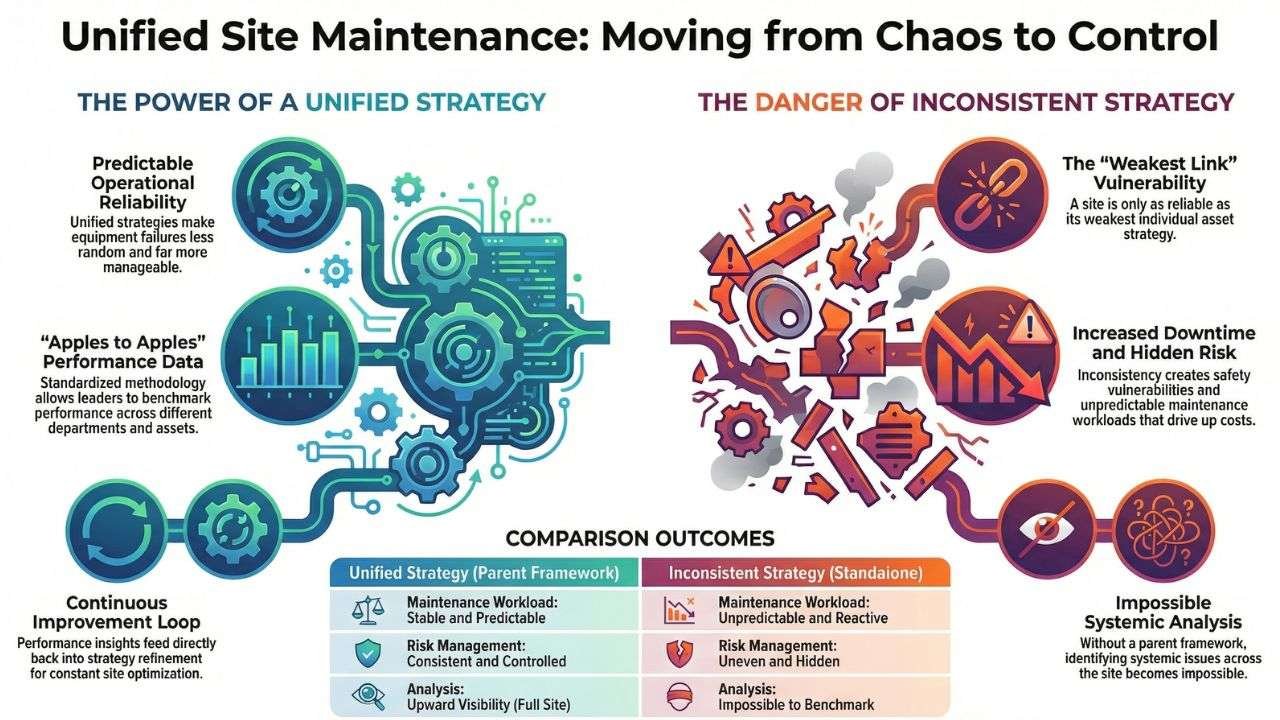

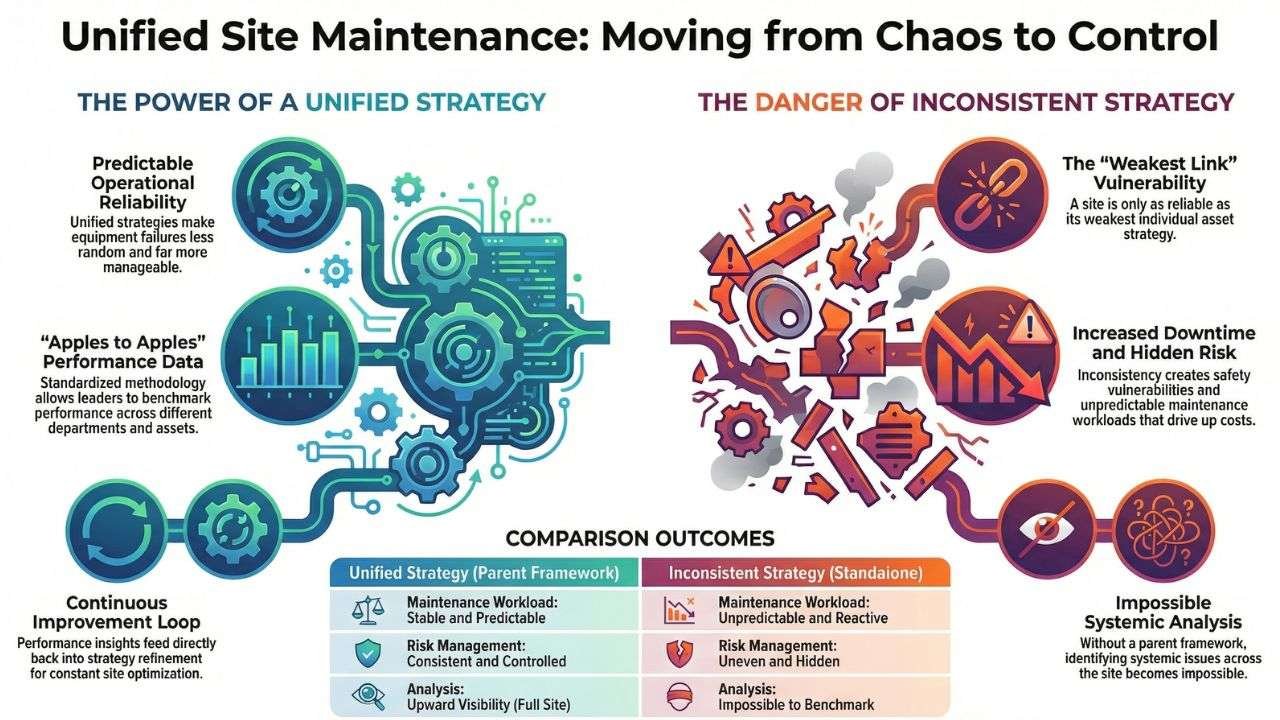

Without it, each asset plan becomes a standalone effort shaped by local habits or personal preferences, leading to uneven quality, unpredictable reliability and unmanaged risk.

A site‑wide maintenance strategy eliminates this variability and ensures consistent performance across the entire operation.

Why Asset‑Level Strategies Must Align.

Every maintainable asset has its own:

- Failure modes.

- Operating context.

- Maintenance requirements.

- Risk profile.

- Cost impact.

But the approach to managing these differences must be consistent. When all asset strategies are built using the same methodology, the site gains:

- Comparable performance data.

- Predictable workloads.

- Consistent risk management.

- Standardised task quality.

- Clear visibility of gaps and weaknesses.

This consistency allows performance to be rolled up logically, from asset, to system, to department, to site level.

Without standardisation, you can’t compare like for like, benchmark performance, or identify systemic improvement opportunities.

You don’t have a unified maintenance strategy, just a collection of tasks.

What Does A High‑Quality Site Maintenance Strategy Look Like?

A high‑quality strategy, whether for one asset or the entire site, shares several defining traits:

- Risk‑based: Effort is proportional to criticality, high‑risk assets get more attention.

- Failure‑mode driven: Tasks address real failure modes, not guesswork or habit.

- Justified: Every task has a clear purpose, cost‑benefit and link to risk reduction or compliance.

- Standardised: One consistent methodology applies across all assets.

- Integrated: The strategy lives in the CMMS/EAM system, not in spreadsheets or PDFs.

- Measurable: KPIs and metrics are tied directly to strategy execution.

- Dynamic: Strategies evolve via review, feedback and performance analysis.

When every asset strategy meets these standards, the site’s maintenance system becomes far more reliable, predictable and easy to improve.

The Problem With Inconsistent Individual Maintenance Strategy Quality.

A site is only as reliable as its weakest asset maintenance strategy.

If one department operates with best‑practice strategies and another with outdated or ineffective ones, performance will always drift toward the weaker areas.

Inconsistent individual maintenance strategy quality tends to create:

- Uneven reliability.

- Unpredictable workloads.

- Hidden risks.

- Uncontrolled costs.

- Confusion among maintainers.

- Poor planning accuracy.

- Increased downtime.

- Safety vulnerabilities.

A parent maintenance strategy prevents this by enforcing a consistent minimum standard.

How Is A Site‑Wide Maintenance Strategy Structured?

A mature site-wide maintenance framework forms a clear hierarchy:

- Parent Strategy (Site Level), defines the methodology (e.g. RCM, FMEA, PMO), quality standards, approvals, review cycles, risk framework, documentation requirements, CMMS integration and KPIs.

- Asset Class Strategies (System Level), address groups of similar assets such as pumps, conveyors, crushers, mobile plant, electrical systems, HVAC and dewatering.

- Individual Asset Strategies (Asset Level), detail the specific tasks, frequencies and failure‑mode controls for each maintainable item.

- Task Lists and Job Plans (Execution Level), the actionable instructions used by maintainers.

When this hierarchy is in place, the site gains clarity, consistency and control at every level.

Performance Visibility And Continuous Improvement.

When all asset strategies align under a single framework, performance data “rolls up” seamlessly.

You can track and compare:

- Task compliance and PM completion.

- Failure frequency, MTBF, MTTR.

- Cost per asset class.

- Risk exposure and backlog health.

- Condition monitoring results.

- Defect elimination trends.

This allows leaders to pinpoint where risk is rising, where strategies need review and where cost or effort are misaligned, turning raw data into actionable improvement.

A Strategic Advantage.

A unified maintenance strategy gives a mining operation clear advantages:

- Predictable reliability.

- Lower maintenance costs.

- Stronger planning and scheduling.

- Improved safety performance.

- Faster onboarding of new personnel.

- Better capital planning and data confidence.

- Continuous improvement through consistent governance.

A site without a unified strategy is constantly reacting. A site with one is constantly improving.

The Role of Integration and Automation.

A maintenance strategy must live within integrated systems, not on a standalone shelf.

System integration:

- Condition monitoring triggers maintenance tasks

- Production data informs task timing

- Inventory data aligns with work orders

- Safety systems tie into maintenance controls

Workflow automation:

- Strategy reviews occur on schedule

- Approvals follow the correct process

- Updates and revisions are controlled

- Performance insights automatically drive action

Integration and automation keep the strategy alive, ensuring it remains current, measurable and aligned with site operations.

A Site Maintenance Strategy Is a System, Not An Individual Task.

Creating a Site Maintenance Strategy isn’t about writing a single reliability plan, it’s about building a structured, disciplined and measurable system that governs every maintainable asset.

High‑quality asset strategies roll up into a high‑quality Site Maintenance Strategy.

Inconsistent and/or poor quality strategies roll up into inconsistent performance across the site.

A unified approach ensures:

- Consistency

- Reliability

- Safety

- Cost control

- Predictability

- Continuous improvement

It’s one of the most powerful and yet sometimes overlooked, levers for improving mining performance.