Risk Assessments

Disclaimer: This information provides general information about risk assessment practices. It is not intended to be legal or safety advice and must not replace consultation with qualified safety professionals or reference to applicable legislation, standards, or organisational procedures.

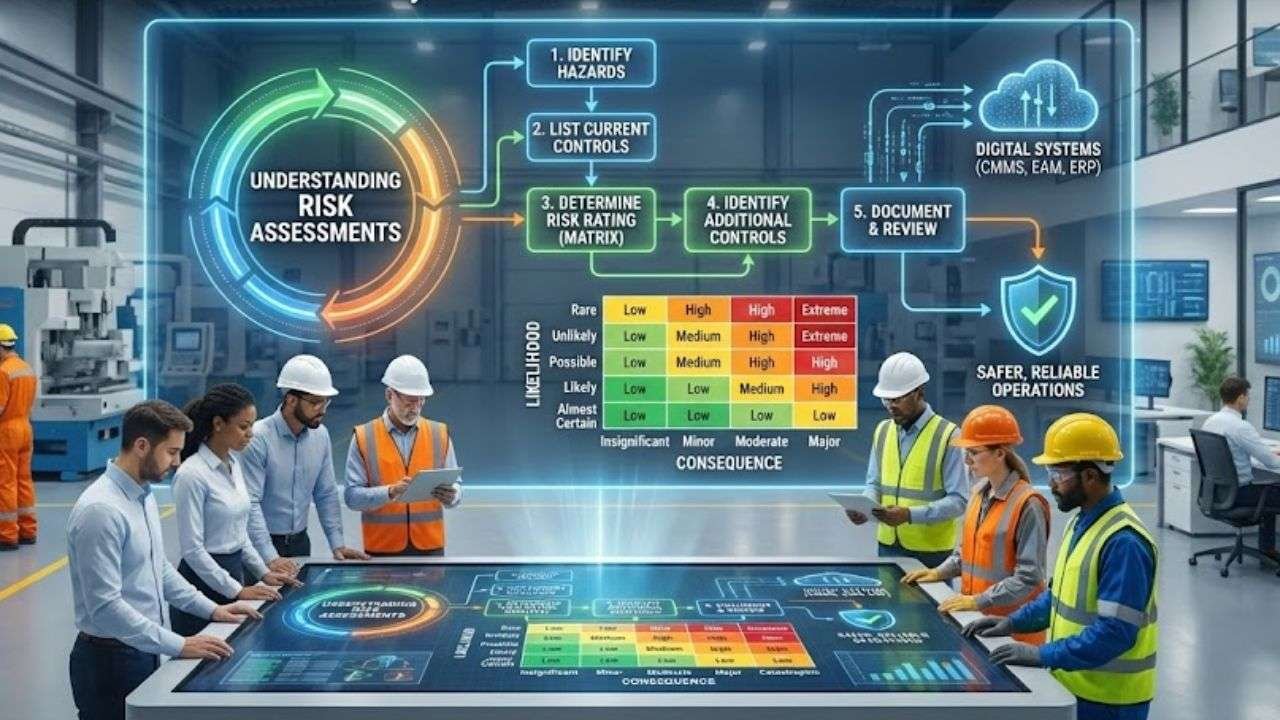

Understanding Risk Assessments.

Risk assessment is one of the foundational activities in any safety‑conscious organisation.

Whether the setting is heavy industry, mining, manufacturing, construction, or even an office environment, the logic remains the same: identify what could go wrong, understand how serious it could be and control it before harm occurs.

It is a structured, evidence‑based method for protecting people, equipment and operations.

A typical risk assessment form captures background information, hazard identification, existing controls, a risk rating and additional controls.

When paired with a risk matrix and standard definitions of likelihood and consequence, it becomes a comprehensive tool for evaluating and managing workplace hazards.

What Is A Risk Assessment?

A risk assessment is a systematic process used to:

- Identify hazards that could cause injury, illness, environmental harm, or equipment damage.

- Evaluate the likelihood and consequence of those hazards.

- Determine the level of risk.

- Decide on appropriate controls to eliminate or reduce the risk.

- Document findings and ensure follow‑up actions are completed.

Risk assessment is both a legal requirement in most jurisdictions and a practical necessity for safe, reliable operations.

In high‑risk industries, it also becomes a cultural expectation, teams rely on it to make informed decisions and avoid preventable incidents.

Why Do Risk Assessments Matter?

Effective risk assessment enables organisations to:

- Prevent injuries and fatalities by identifying hazards before harm occurs.

- Reduce downtime, equipment failures and emergency callouts.

- Improve communication between maintenance, engineering and production.

- Support compliance with legislation, standards and internal procedures.

- Strengthen safety culture by encouraging proactive behaviour.

- Guide investment in training, equipment and engineering controls.

- Enable continuous improvement as risks evolve over time.

Collaboration between maintenance, engineering and production is essential, particularly in heavy industry, where risks are dynamic and interdependent.

Who Conducts Risk Assessments?

Risk assessments are typically carried out by the people involved with performing work and could/would include and not limited to:

- The people involved (those who will have risks exposed to them when conducting the work) and whose practical experience is invaluable.

- Supervisors and frontline leaders familiar with day‑to‑day operations and have received formal training in this process.

- Other maintenance and engineering staff who understand equipment and task hazards.

- Health and Safety Representatives or OHS professionals.

- Subject matter experts for specialised knowledge on particular equipment or processes.

In high‑risk work, these assessments are collaborative exercises that combine technical expertise and operational insight.

How Is A Risk Assessment Done?

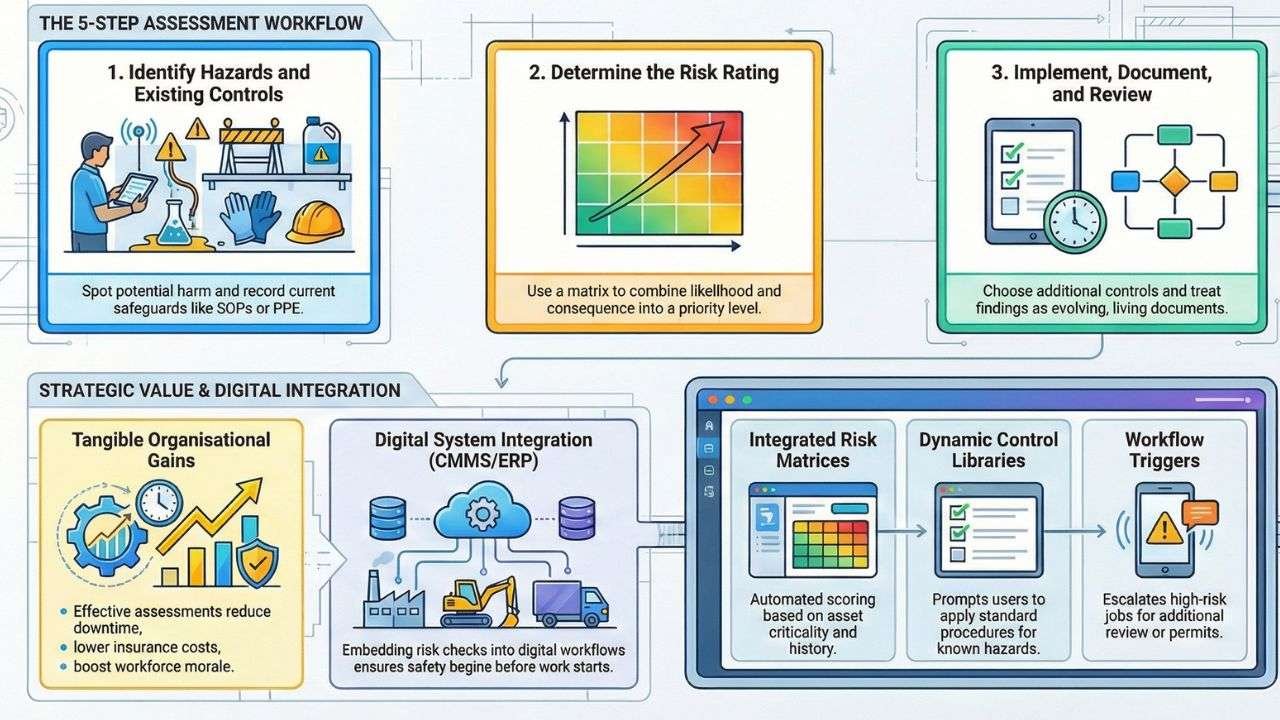

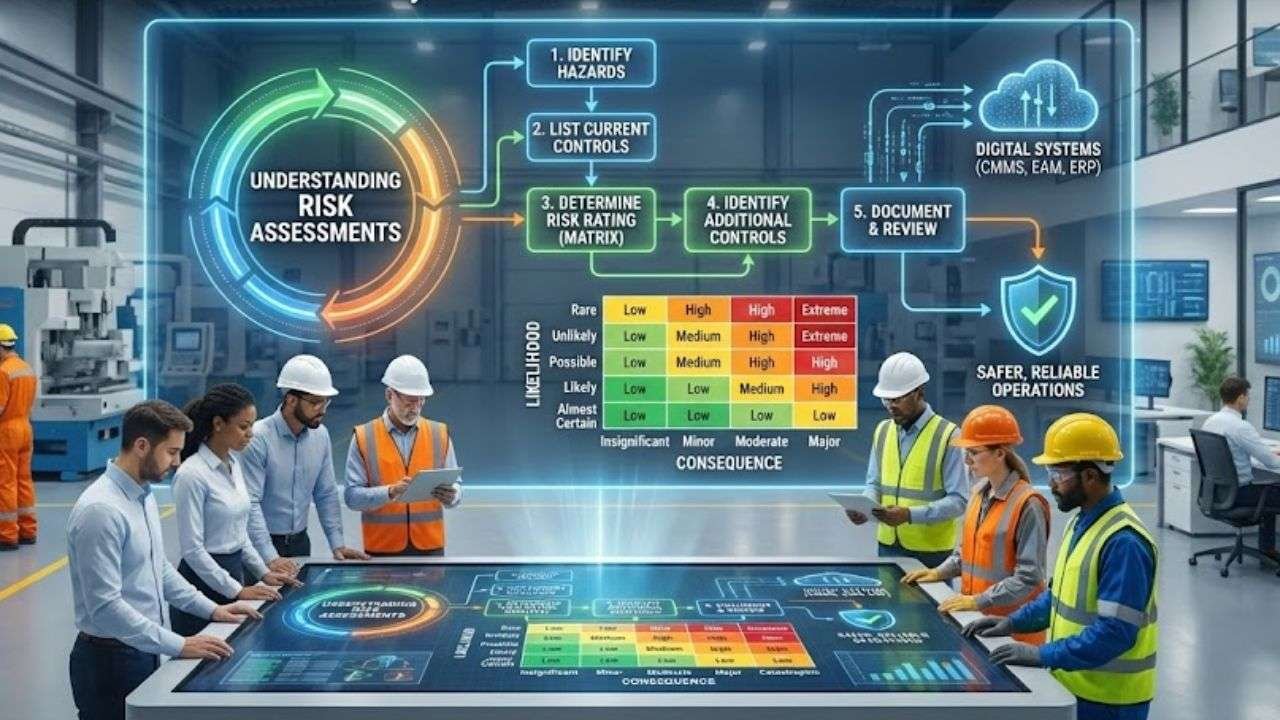

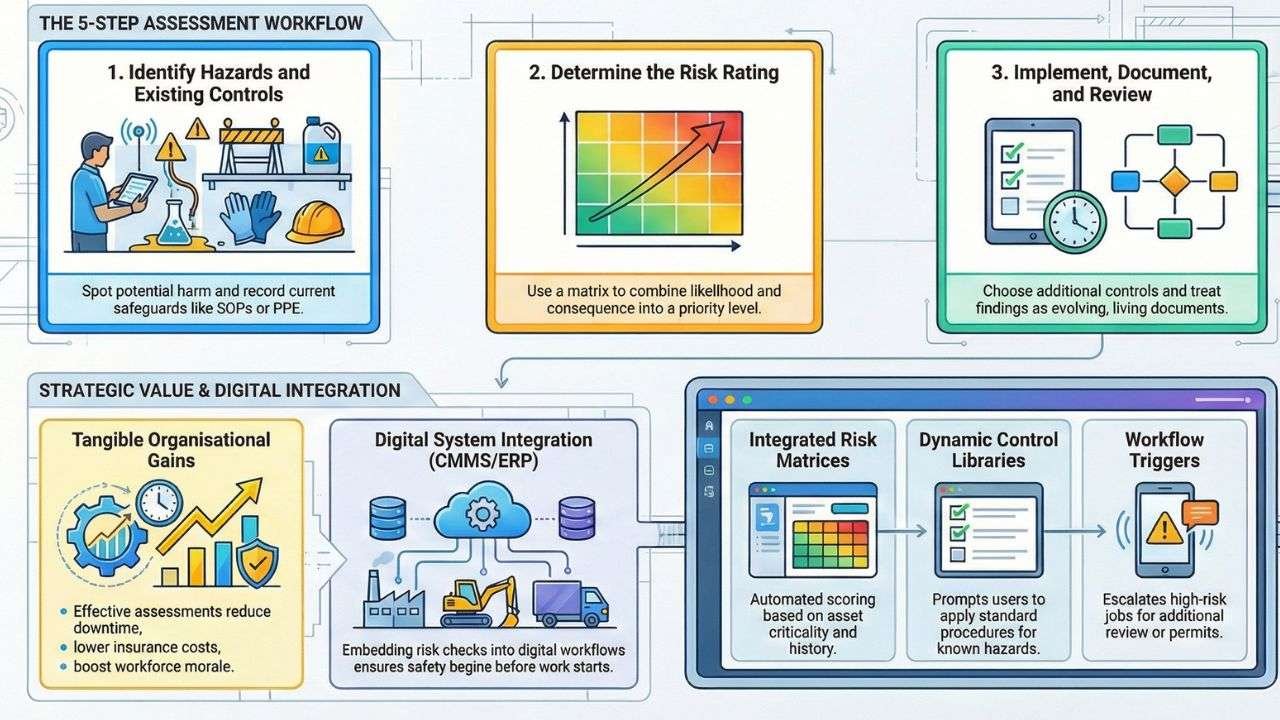

The process generally follows five structured steps:

Step 1: Identify Hazards: Anything with the potential to cause harm, mechanical, electrical, chemical, physical, environmental, or human factors. Emergency or reactive maintenance increases risk due to fatigue, poor visibility and time pressure.

Step 2: List Current Controls: Record controls already in place (SOPs, lockout/tagout, PPE, training, engineering safeguards, maintenance routines). This helps assess their adequacy.

Step 3: Determine the Risk Rating: Use the risk matrix to combine likelihood and consequence, producing a rating (Low, Medium, High, or Extreme).

This rating determines how urgently corrective action is needed.

Step 4: Identify Additional Controls: If risk remains too high, choose new controls, such as engineering modifications, additional training, improved supervision, or fatigue‑management scheduling.

Step 5: Document and Review: Record findings, communicate them to affected personnel, monitor implementation and periodically review.

Risk assessments are living documents that must evolve with changing conditions, equipment, or processes.

What Do Risk Assessment Enable?

A well‑executed risk assessment empowers organisations to make smarter, safer decisions.

It improves work planning, strengthens collaboration and reduces operational disruptions.

Documented assessments also demonstrate due diligence and regulatory compliance, a key requirement in audits and investigations.

Organisational Benefits.

Risk assessments deliver tangible benefits:

- Fewer injuries and incidents.

- Lower insurance and compensation costs.

- Improved equipment reliability and uptime.

- Higher workforce morale and trust.

- A proactive, resilient safety culture.

In high‑risk industries, risk assessments are not just paperwork, they are critical operational tools that link safety, reliability and productivity.

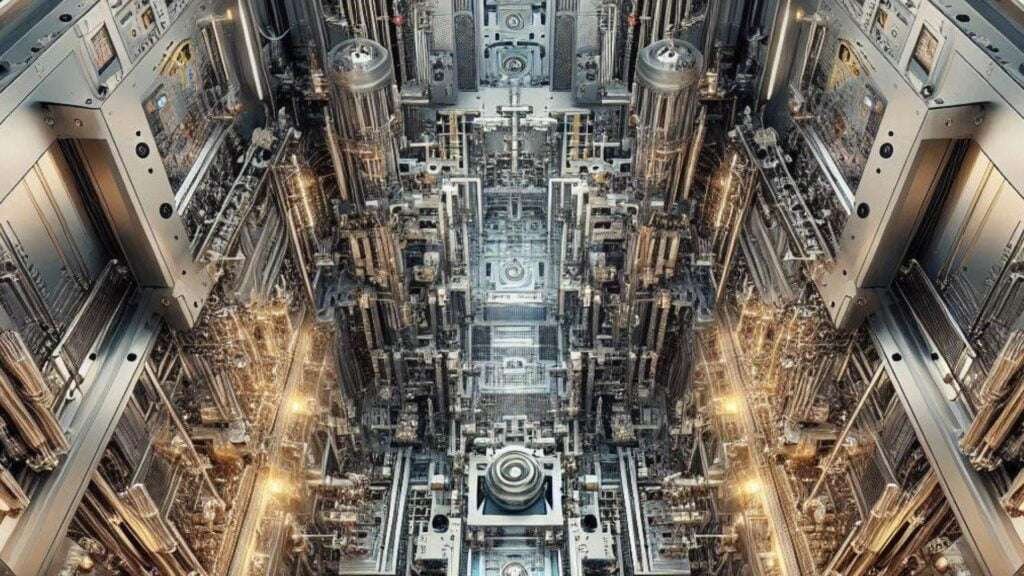

Risk Assessment and Digital Systems (CMMS, EAM, ERP).

Modern Computerised Maintenance Management Systems (CMMS), Enterprise Asset Management (EAM) and Enterprise Resource Planning (ERP) platforms increasingly include risk assessment functionality as a standard feature. Examples include IBM Maximo, Infor EAM, SAP PM and IFS Cloud.

These systems can embed risk analysis directly into the work identification and job request stage, allowing users to assign a preliminary risk level to each task or asset.

Typically, the key capabilities include:

- Integrated risk matrices linked to asset criticality and work order types.

- Automated risk scoring based on historical incidents or asset condition data.

- Dynamic control libraries that prompt users to apply standard procedures for known hazards.

- Workflow triggers that escalate high‑risk jobs for additional review or permit‑to‑work controls.

- Audit trails proving compliance and due diligence.

Embedding risk assessment at the job identification stage is powerful because it ensures that risk thinking begins before work even starts, not after planning or during job execution.

It supports better decision‑making, reduces exposure to hazards and aligns maintenance practice with corporate risk management frameworks.

This digital integration also streamlines compliance reporting, enabling organisations to automatically link risk data with incident management, asset reliability and safety performance metrics, turning risk assessment from a manual form into a living, data‑driven process.