The Maintenance Planning Skill Set

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

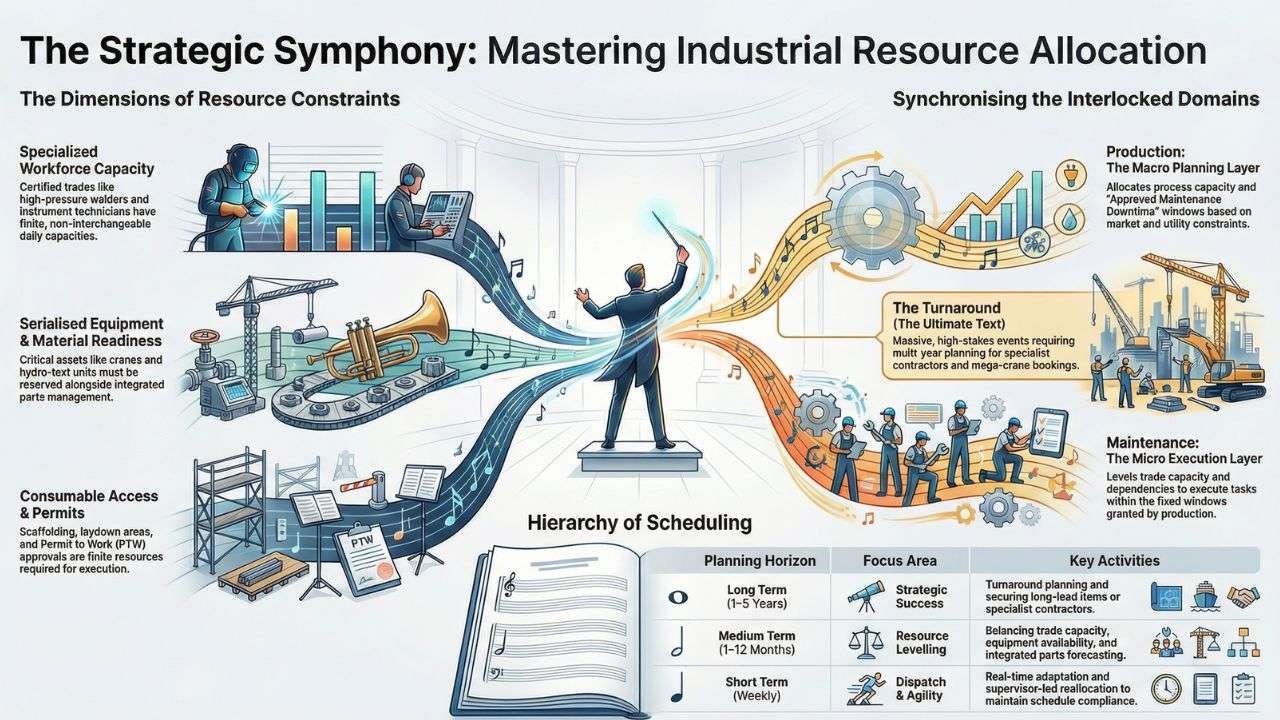

In the often complex and capital‑intensive ecosystem of a refinery or heavy processing plant, scheduling is the central nervous system of execution.

It converts strategic intent, production targets, reliability campaigns, turnaround objectives, into hour‑by‑hour operational reality.

Far from being a simple sequence of tasks, industrial scheduling is a continuous, high‑stakes exercise in multidimensional constraint management, where the precise allocation of people, equipment, materials and access determines the difference between profitability and catastrophic loss.

When resources are misaligned, the consequences are immediate and severe: bottlenecks, safety compromises, exponential cost overruns and missed production opportunities.

Effective scheduling is therefore not just coordination, it is risk control, cost control and performance control.

The Critical Nature of Resources in an Industrial Environment.

Resources in heavy industry are not often interchangeable, they are more often than not specialised, limited and deeply interdependent:

People.

Certified welders, boilermakers, instrument technicians, mechanical fitters, machinists, tool makers, scaffolders and operations teams all bring particular qualifications such as high‑pressure and exotic materials welding tickets, confined space certification, electrical licensing and are often subject to finite daily capacity.

Equipment.

Scissor lifts, non-slew cranes, ewp’s (cherry pickers), fork lifts, skid steer loaders, telescopic handlers, hydro‑test units, torque tools, compressors, welder/generators etc. Many of these are serialized or there might be only one of them.

Materials & Spare Parts: This could very well be a mixture of internal (managed inventory) and externally purchased parts as well as materials readily available from what’s known as a Free-Issue store (minor parts that don’t need to be micro-managed.

Space & Permits.

Scaffolding, laydown areas, access platforms and Permit‑to‑Work (PTW) approvals are themselves consumable resources. Without them, work cannot proceed.

Misallocation in any of these categories cascades quickly, as such, quality scheduling is critical and is about balancing utilization against resilience.

The Two Interlocked Domains: Production and Maintenance Scheduling.

Resource allocation unfolds across two inseparable domains: production scheduling and maintenance scheduling. Each has its own logic, but both must operate in harmony.

Production scheduling is the macro‑planning layer, typically weeks or months ahead. Its purpose is to maximize revenue by converting feedstock into finished products within market, logistics and utility constraints.

Resources Allocated.

The primary resource is process unit capacity and time. Schedulers allocate operating windows:

“Crude Unit A runs sweet crude from the 1st–15th.”

“Polymer Line B produces Grade X for the next 72 hours.”

The Optimization Challenge.

A high‑margin product may consume disproportionate utilities, limiting what other units can run simultaneously.

The Maintenance Handoff.

Production scheduling will allocate the most precious resource of all, ‘Approved Maintenance Downtime’.

Maintenance teams need approved outage windows for preventive maintenance, to rectify defects, perform inspections and do shutdown maintenance (tasks that cannot be done during ‘running plant’ situations.

Commercial Needs and Wants: These teams want maximum runtime but more importantly, they need production predictability.

As such, the production planner’s forecast/schedule formalises the much needed maintenance windows, making them immovable anchors for all downstream planning.

Maintenance Scheduling: Allocating Execution Capacity.

Maintenance scheduling is the micro‑planning layer, where resource constraints become most acute.

It determines what work can be executed within the downtime windows granted by production.

The Hierarchy of Scheduling.

Long‑Term Scheduling.

This is what’s often referred to as rough cut scheduling and is looking as far out into the future as you can. It typically involves creating a schedule that is 1–5 years minimum out into the future.

These are essential for Turnaround/Outage Planning Success.

Turnarounds require the booking of specialist contractors (sometimes from overseas), ordering long‑lead items, securing ‘hard to get machines’ such as the mega‑cranes that require multiple years in advance bookings.

This is the largest resource allocation event in the plant lifecycle.

Medium‑Term Scheduling (1–12 months).

This is the core arena for resource levelling. Schedulers will typically consider:

Trade Capacity: Are enough of the right types of tradespeople going to be available at the right times.

Equipment availability: Will we have the right amount of support equipment on site at the right times and would take into account tools that require certification or calibration etc.

Parts availability: Given that there is hardly a single maintenance task that can be executed without parts, it’s very important that the maintenance forecast is integrated with the materials management functionality.

Dependencies: What types need to be done before another, what tasks can be done at the same time, what tasks must be finished by no later than. These are some of the typical dependencies. An example is removal of cladding prior to a tasks, the task is performed and then the cladding must be reinstalled.

Short‑Term Scheduling (Often Weekly): Dispatch and Adaptation.

Even the best schedule meets reality from time to time, even if schedule compliance is a key KPI. Supervisors will need to reschedule jobs that were not able to be done for a particular reason. They may also reallocate people during the approved maintenance execution window (if a job was to finished early).

Real life situations aside though, the emphasis is for the short term schedule to be as accurate as possible. There will naturally be some allowance or ‘wiggle room’ for things not to go exactly as scheduled but this is more about controlled agility, not an excuse for resource chaos.

The Ultimate Test: Turnaround Resource Allocation.

Turnarounds are the most complex resource allocation challenge in heavy industry. They involve trying to get a lot of work done in a small amount of time. Production has allocated a finite, high‑cost maintenance downtime window (e.g., 2 days).

Within this, maintenance will often attempt to execute a plethora of interdependent tasks.

These events face a number of challenges such as drop zones, crane interactions, space availability, peak resource load management, critical path protection and dealing with the weather conditions (hopefully the weather bureau’s predictions were spot on).

Turnaround/Outage/Shutdown events tend to reveal the true maturity of a plant’s scheduling discipline.

The Enabling Technology: CMMS/EAM, ERP and Advanced Scheduling Tools.

Manual (old school) scheduling is just about impossible at the largest end of the scale and is why sites rely so heavily on their CMMS/EAM/ERP.

Skills & qualifications registry ensures only certified personnel are assigned.

Tool & equipment tracking reserves specialized tools and support equipment automatically.

Parts availability checks & Procurement Visibility prevent short and possibly mid-term scheduling of work to happen work without materials and would also look at any insurance, high criticality parts and make sure their provision is ‘locked in’ at the time of completing the long range schedule. Overall, it provides site confidence in material readiness.

Historical labour data with regular planned task reviews helps improve duration estimates and overall planning accuracy.

Budget controls helps prevent excessive overtime or contract resource spending.

Procurement visibility informs confidence in material readiness

Labour rules integration ensures compliance with union and payroll constraints.

Advanced Scheduling Engines & Simulation.

These tools provide the cognitive layer:

This transforms scheduling from reactive juggling to proactive optimization.

The Human Element: The Scheduler as Conductor.

Despite advanced tools, scheduling will (at this stage) need substantial human discipline. The scheduler is the negotiator, analyst and communicator who typically aligns at least:

They continuously reallocate resources as priorities shift, especially when safety‑critical work emerges or a change of direction with regards to production is about to happen (a period of reduced or increased production).

Conclusion: The Symphony of Resource Constraints.

Resource allocation is the disciplined orchestration of finite, specialized elements under the pressure of keeping production at the optimum level.

It helps shape plant safety, reliability and profitability.

Excellence in scheduling is not about marking out maintenance days on a calendar hanging on the wall. Rather, it is about synchronizing people, tools, equipment, materials and access into a resilient, data‑driven execution model.

By leveraging the data integrity of CMMS/EAM/ERP systems and the predictive power of advanced scheduling engines, sites can move from reactive resource shuffling to proactive, optimized orchestration.

The result is a schedule that is not merely a plan, but a strategic model of the future, one where every hour, every tool and every technician is positioned to deliver maximum value when the window for action opens.

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

Maintenance Business Process For A Gold Mine. Disclaimer. This article draws on general gold mining industry knowledge, common CMMS principles

Setting Up A Maintenance Business Process For A New Gold Mine Read More »

Maintenance Business Process Mapping & Software. Disclaimer. This article provides general information about maintenance process mapping and software tools based

Maintenance Business Process Mapping Software Tools Read More »

Build Audit Systems That Reveal Truth and Improve Performance Disclaimer. This article provides general guidance, frameworks, and examples to support

Building Your Maintenance Audit Framework Read More »

Purchase Asset Management Software Solutions Asset management software is essential for businesses in the manufacturing, commodity extraction, material processing, and

Purchasing Asset Management Software Read More »

SAP Cross Application Time Sheet (CATS). The SAP Cross-Application Time Sheet (CATS) is a vital component of the SAP ERP

SAP Cross Application Time Sheet Solution Read More »

Understanding Asset Registers in Asset Management. This article explores the crucial role of asset registers for a typical industrial organisation

Asset Registers in Modern Asset Management Read More »

Getting In Control Of Truck Tyre Maintenance Costs. When it comes to managing the expenses of earthmoving and transport companies,

The Hidden Costs Of Tyre Maintenance Read More »

Highway Dump Truck Maintenance Manual / CMMS Guide Disclaimer. This content is for informational and educational purposes only. It reflects

Truck Maintenance Management Read More »

Framework for Developing Truck Asset Management Plans Disclaimer This article is provided for general informational and educational purposes only. The

Highway Truck Asset Management Plan Read More »

The Dream Of Designing The Ultimate Asset Management Software Product. Asset management software is one of the most significant investments

Designing The Ultimate Asset Management Software Product Read More »

A Guide To Achieving A Masters Degree In Maintenance Management. In today’s competitive industrial landscape, the reliance on sophisticated and

Master Of Maintenance Management Guide Read More »

Interfacing Disparate Systems Data With Your CMMS Via AVEVA PI. Interfacing disparate systems across your organization with a Computerised Maintenance

Interface Disparate Systems Data With A CMMS Via AVEVA PI Read More »

Setting Up Maintenance & Operations Systems At A New Facility. With this article I have put together a comprehensive framework

Set Up Maintenance And Operations Systems Read More »

Understanding Enterprise Resource Planning Systems. ERP systems are critical for businesses with complex operations, high-value assets, and stringent regulatory requirements.

Enterprise Resource Planning Systems Read More »

Understanding The Asset Management Process. One should never undervalue the significance of creating an asset management strategy for businesses that

The Asset Management Process Read More »

Effective Work Scheduling Process & Your CMMS. When it comes to managing a high-risk heavy industrial business, one of the

Maintenance Work Scheduling Read More »

The Intriguing History and Success of LinkOne EPC. What we now know and enjoy as LinkOne Software began as a

LinkOne Electronic Parts Catalogue Read More »

Materials Management Quality Is A Common Concern. Materials management is a critical component of the supply chain that contributes significantly

Materials Management Quality Read More »

How Software Helps Shire Councils Deliver Essential Tasks. This article explores the critical role of software solutions in enabling shire

Essential Tasks of a Shire Council Read More »

Using Road Maintenance Improvement Methodologies. The use of sophisticated management techniques in the field of road maintenance can greatly extend

Road Maintenance Improvements Read More »

The Importance of Mining Industry Regulation Guidelines. Regulation guidelines for the mining industry are critical to ensuring worker and environmental

Mining Industry Regulation Guidelines Read More »