Productivity Enhancement

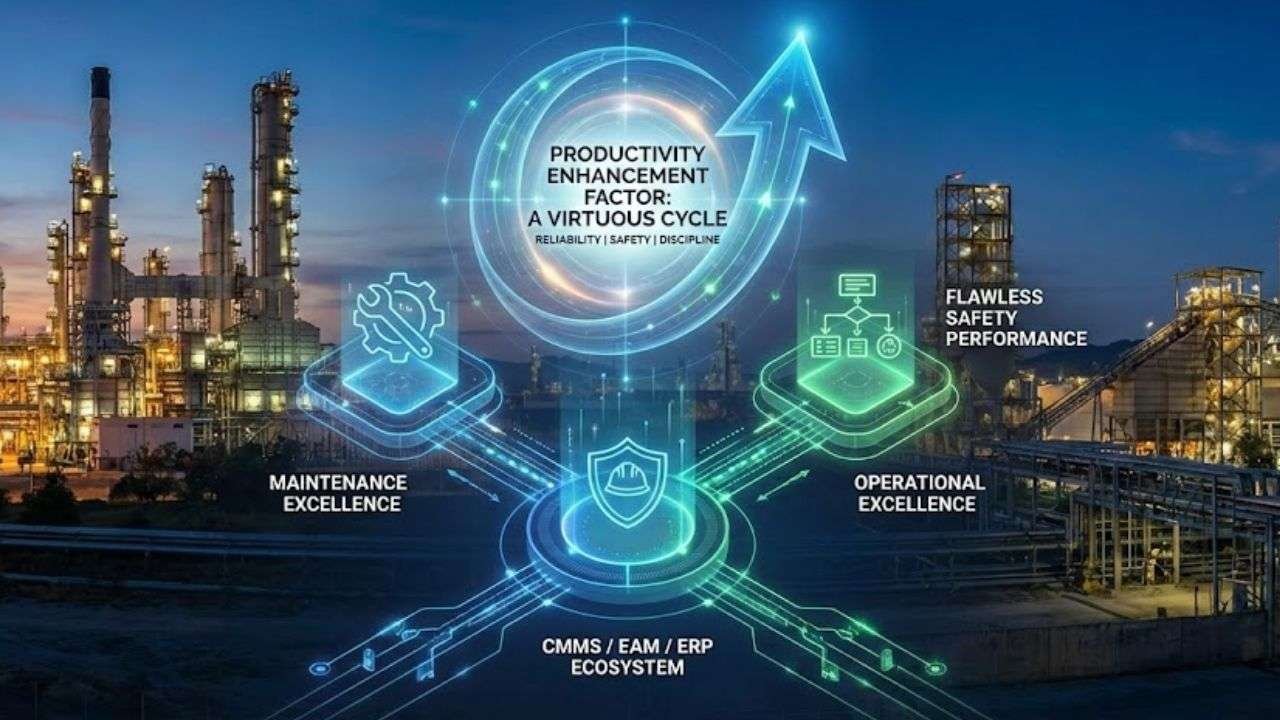

In refineries, chemical plants and mineral processing facilities, productivity enhancement is often mistakenly reduced to simply accelerating processes, optimizing labor, or slashing costs.

In truth, sustainable productivity in heavy industry emerges from a system that prioritizes reliability, safety and operational discipline. Facilities don’t achieve high productivity by chasing it directly, they do so by cultivating predictability.

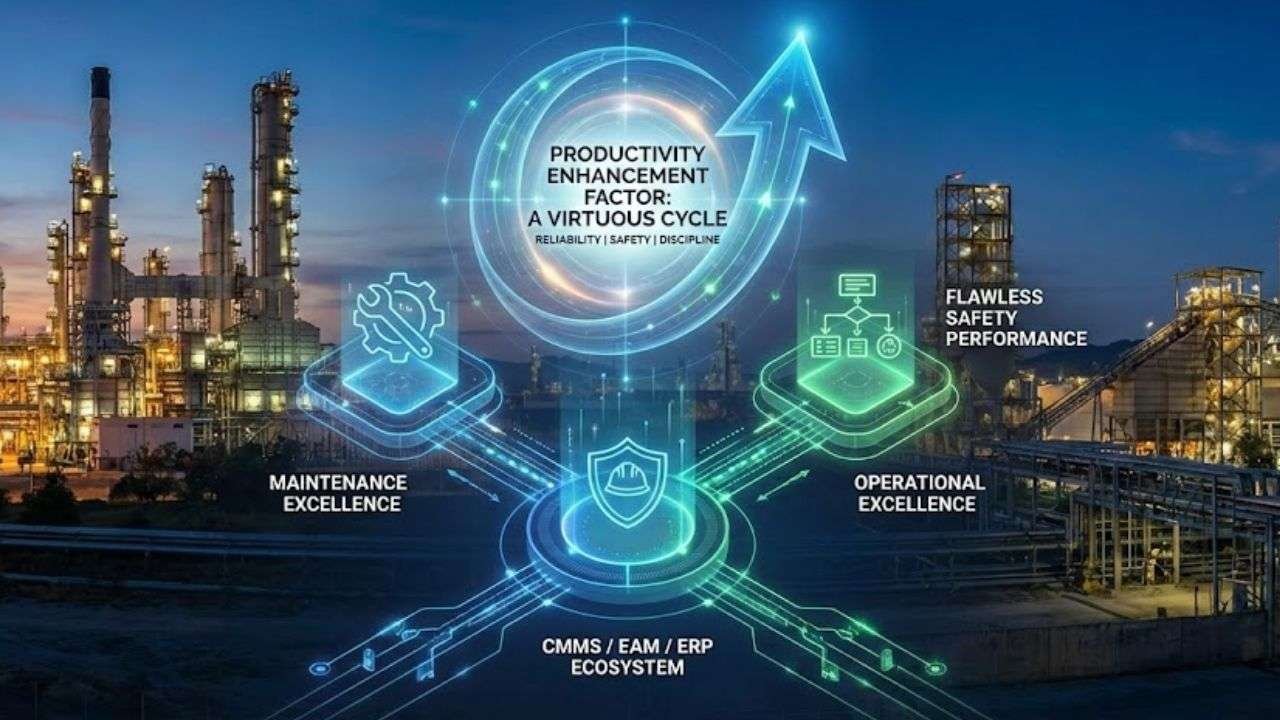

This predictability arises from the powerful interplay of three core pillars: maintenance excellence, operational excellence and flawless safety performance, each amplifying the others.

When digitally unified through a modern CMMS, EAM, or ERP ecosystem, these elements create a self-sustaining productivity engine that safeguards profit margins, minimizes operational volatility and optimizes returns on capital-intensive assets.

At its core, this is the Productivity Enhancement Factor: a virtuous cycle in which reliability, safety and disciplined execution compound to deliver world-class results.

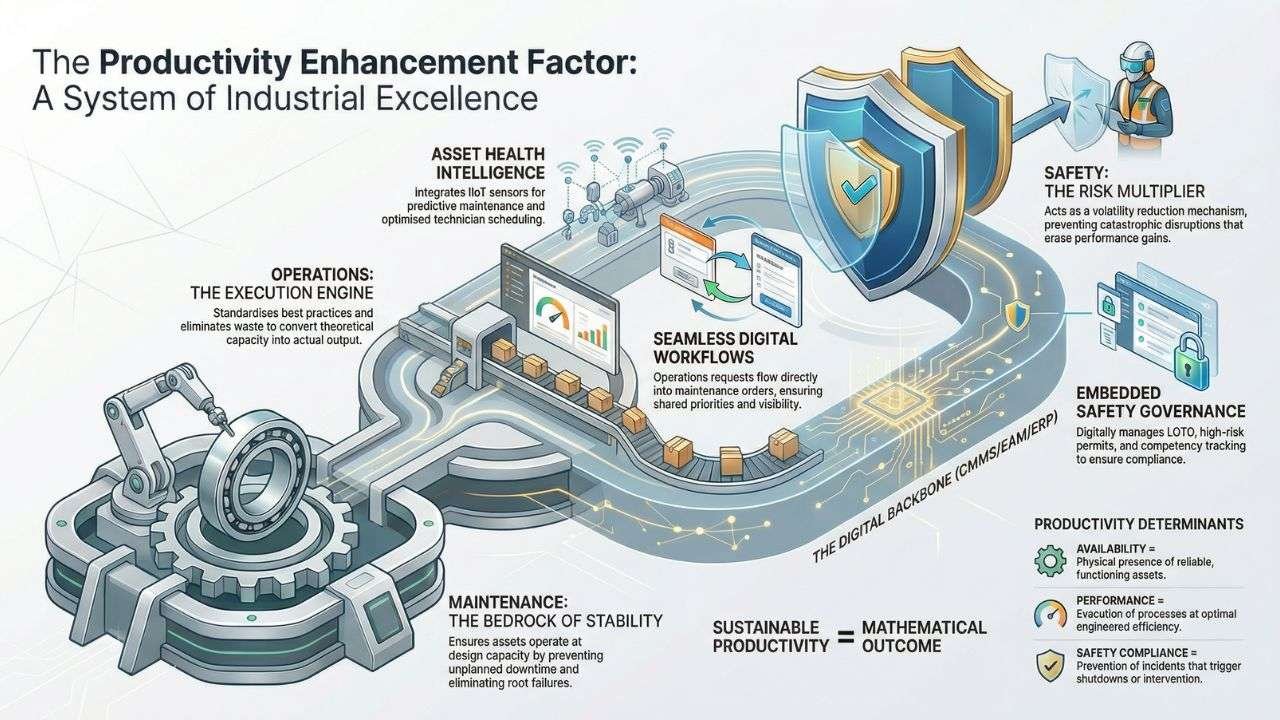

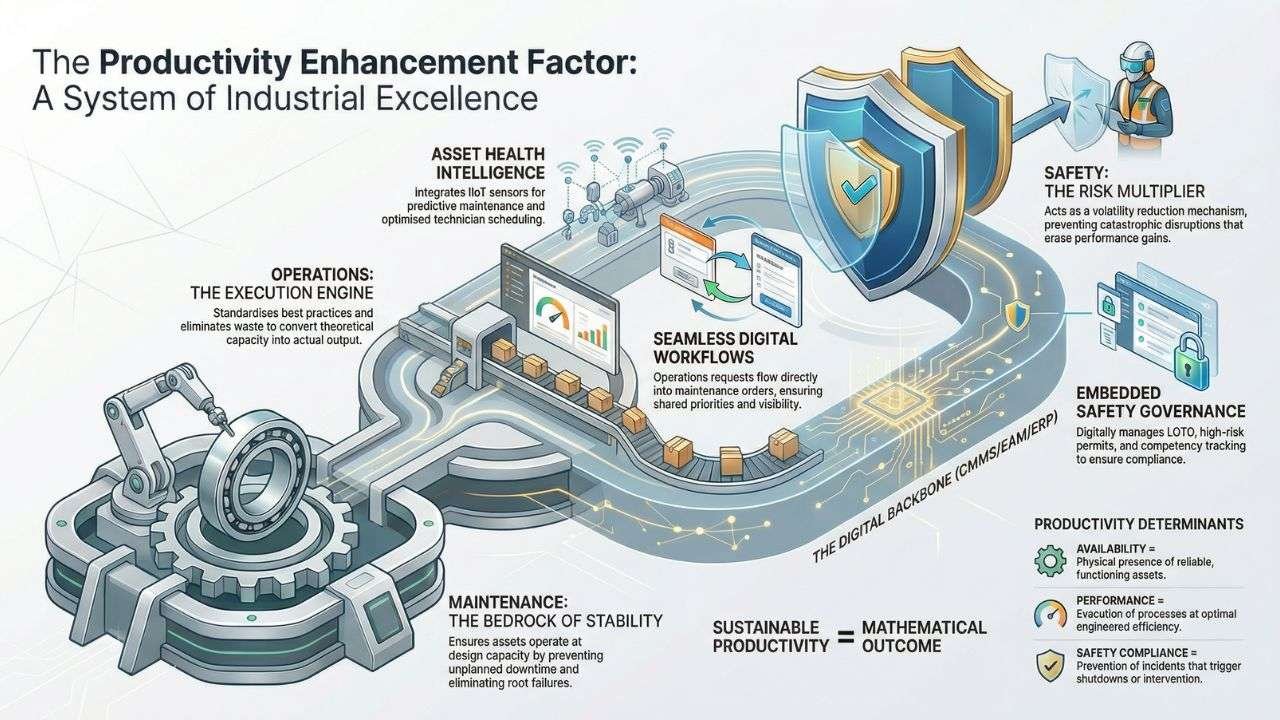

Rethinking Productivity: A System, Not a Speed Setting.

In high‑hazard, capital‑intensive industries, productivity is not about working faster or squeezing more out of people. It is the mathematical outcome of:

- Assets operating at design capacity.

- Processes executed consistently.

- Risks controlled and minimized.

- Failures prevented before they occur.

- People working in a safe, stable environment.

A refinery or processing plant is a tightly coupled system. A single failure, mechanical, procedural, or safety‑related, can dramatically reduce availability, performance and quality simultaneously.

That is why productivity is often expressed as:

Productivity = (Theoretical Capacity) × (Availability) × (Performance) × (Quality) × (Safety Compliance)

Traditional OEE models omit safety, but in heavy industry, safety behaves exactly like a multiplier. A single incident can erase months of performance gains, trigger regulatory intervention and impose long‑term reputational and financial damage.

Thus, productivity enhancement is fundamentally a risk‑reduction and margin‑protection strategy, not a speed strategy.

Maintenance Excellence: The Foundation of All Productivity.

Maintenance excellence is the bedrock of productivity because it ensures the physical plant can operate at its intended capability. Without reliable assets, no amount of operational discipline or safety focus can compensate.

- Preventing Unplanned Downtime: Unplanned shutdowns in refineries or processing plants routinely cost millions per day. Predictive and preventive maintenance, driven by data, condition monitoring and disciplined planning, keeps assets available and stable.

- Ensuring Design Capacity: Equipment that is clean, calibrated, lubricated and aligned performs at its engineered efficiency. Heat exchangers transfer heat at the intended rate. Pumps deliver their rated flow. Compressors maintain pressure. When equipment degrades, throughput drops and energy consumption rises.

- Reducing the Cost of Quality: Reliable equipment produces product within specification. Poorly maintained assets generate off‑spec batches, rework, blending losses and waste, all of which erode margins.

- Enabling Root Cause Elimination: Maintenance excellence is not just about fixing failures; it is about eliminating them. Systematic RCA, supported by accurate failure codes and work history, prevents recurrence and steadily improves asset performance.

In a nutshell, maintenance excellence creates the physical stability that makes operational excellence and safety excellence possible.

Operational Excellence: The Execution Engine of Productivity.

If maintenance excellence ensures the plant can run, operational excellence ensures the plant does run, consistently, efficiently and in alignment with best practice.

- Standardising Best Practices: SOPs, checklists and procedural discipline ensure that operators run processes at their optimal parameters. Variability is the enemy of productivity; standardisation eliminates it.

- Optimising Throughput: Operational excellence uses data to balance flows, temperatures, pressures and cycle times to maximise yield from available assets. This is where the plant’s theoretical capacity becomes real capacity.

- Eliminating Waste: In the Lean/TPM sense, waste includes:

- Unnecessary motion.

- Inefficient changeovers.

- Poor communication.

Operational excellence removes these friction points, freeing capacity without additional capital expenditure.

- Strengthening Cross‑Functional Coordination: Operations and maintenance must function as a single system. Clear work requests, accurate feedback and shared priorities prevent misalignment that otherwise erodes productivity.

Operational excellence is the discipline that converts asset capability into actual output.

Excellent Safety Performance: The Non‑Negotiable Enabler.

Safety is often framed as a moral or regulatory obligation and it is, but in heavy industry, it is also a productivity strategy.

- Preventing Catastrophic Disruption: A major safety incident can shut down a plant for weeks or months. Investigations, regulatory scrutiny and remediation efforts consume enormous resources. Safety failures are productivity failures.

- Creating a Culture of Attention: A safety‑first culture is a procedure‑following culture. People who consistently follow LOTO, PTW and confined space protocols are the same people who follow SOPs, report abnormalities early and prevent operational errors.

- Protecting Critical Assets: Safety systems, relief valves, shutdown valves, fire suppression systems, protect both people and equipment. Their reliability is essential to preventing catastrophic loss.

- Reducing Operational Variability: Incidents, near misses and unsafe behaviours introduce volatility. A stable, safe environment is a productive environment.

Safety is not a cost centre; it is a volatility‑reduction mechanism that protects availability, performance and quality.

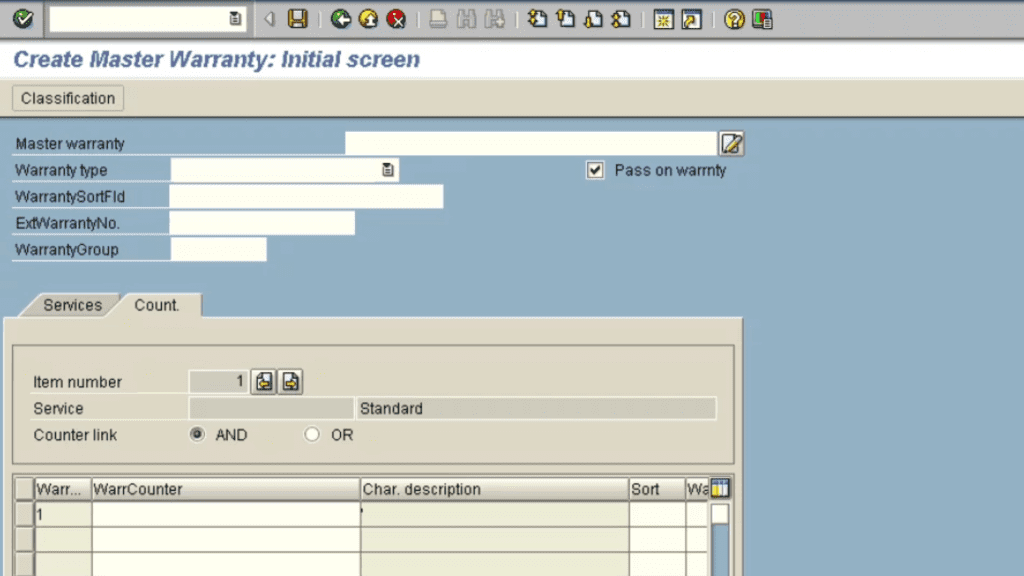

The Digital Backbone: CMMS/EAM/ERP as the Central Nervous System.

The synergy between maintenance, operations and safety only becomes scalable when supported by integrated digital systems.

A modern CMMS/EAM/ERP ecosystem provides the data, workflows and governance needed to execute the strategy consistently.

- Maintenance Excellence Through CMMS/EAM.

- Asset Health Intelligence: Full lifecycle history, specifications, warranties and performance data.

- Predictive Maintenance: Integration with IIoT sensors for vibration, temperature and pressure monitoring.

- Optimised Scheduling: Coordinated planning of technicians, permits, tools and parts.

- Inventory Optimisation: Ensures critical spares are available without excessive carrying costs.

- RCA Enablement: Structured failure codes and history enable systemic problem elimination.

- Operational Excellence Through EAM/ERP Integration.

- Seamless Workflows: Operations requests flow directly into maintenance work orders.

- Regulatory Compliance: Digital management of inspections, certifications and audits.

- Energy and Material Tracking: Identifies inefficiencies that may be equipment‑related.

- Turnaround Management: Budgeting, scheduling and resource coordination for major shutdowns.

- Safety Excellence Embedded in the System.

- Digital LOTO: Ensures isolations are verified before work begins.

- Permit‑to‑Work: Hot work, confined space and high‑risk permits managed electronically.

- Critical Device Management: Proof testing and calibration of SIS and relief devices.

- Incident Reporting: Near misses and incidents logged, investigated and actioned.

- Competency Management: Ensures only qualified personnel perform high‑risk tasks.

- The Integrated Data Platform.

The real power emerges when CMMS/EAM and ERP systems share data:

- Finance ↔ Maintenance: Work order costs flow to cost centres.

- Procurement ↔ Inventory: Parts requisitions align with budgets and stock levels.

- Production ↔ Reliability: Production schedules inform maintenance windows; downtime explains production losses.

This integration eliminates blind spots and enables leading indicators instead of lagging ones.

The Virtuous Cycle: How the Productivity Enhancement Factor Works.

When maintenance, operations and safety are aligned and digitally integrated, a self‑reinforcing cycle emerges:

- Reliable assets reduce failures.

- Stable operations reduce variability.

- Safe behaviours reduce disruptions.

- Integrated data improves decision‑making.

- Improved decisions enhance reliability.

Round and round it goes, each improvement amplifying the next.

This is the Productivity Enhancement Factor: a multiplier effect where excellence in one domain strengthens the others, producing sustainable, high‑margin productivity.

Enhanced Productivity: The Outcome of Pursuing Excellence

Productivity is not a standalone initiative. It is the mathematical and operational outcome of a system where:

- Assets are healthy.

- Processes are disciplined.

- People are protected.

- Data flows seamlessly.

- Decisions are evidence‑based.

A modern CMMS/EAM/ERP ecosystem is not an optional tool, it is the digital infrastructure that makes this system possible.

It transforms philosophy into execution and execution into predictable, safe, profitable output.