Process Improvement

Process improvement is one of the most powerful levers available to any organisation. It sits at the intersection of efficiency, resilience and operational maturity.

When done well, process improvement creates stability, reduces waste, strengthens reliability and builds a culture where teams continuously refine how work gets done.

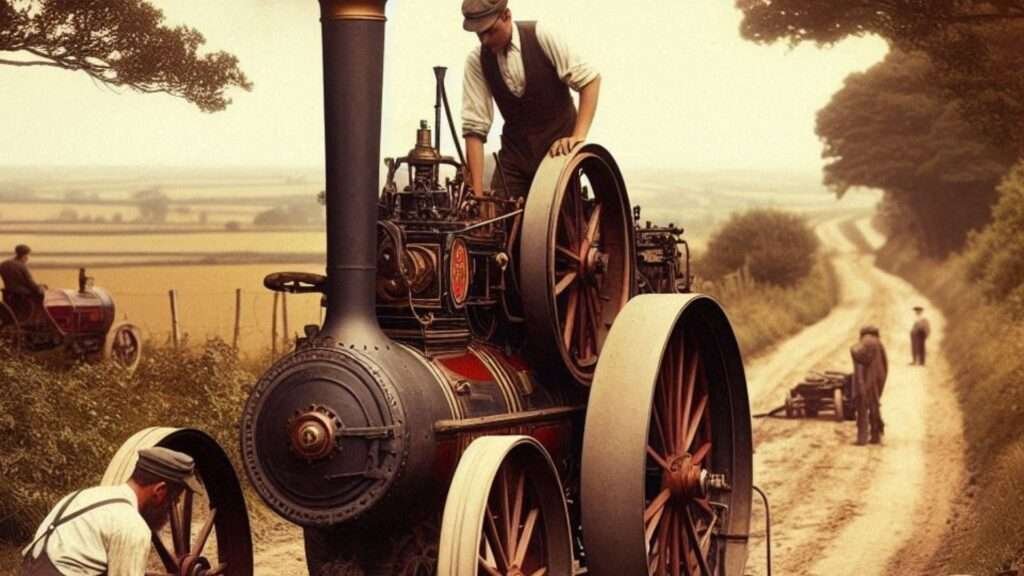

In heavy industry, process improvement is not a theoretical exercise.

It is a practical discipline that shapes safety, productivity, cost and asset health.

It determines whether an organisation operates with clarity and control, or whether it relies on firefighting, heroics and luck.

This information explores what process improvement really means, why it matters and how organisations can use proven tools such as Lean, Six Sigma, TPM, TQM and waste elimination to build stronger, more predictable operations.

What Does Process Improvement Really Mean?

Process improvement is the systematic effort to make work more effective, more efficient and more reliable.

It focuses on understanding how work actually flows, not how it is imagined to flow and then removing barriers, waste, variation and failure points.

At its core, process improvement is built on three principles:

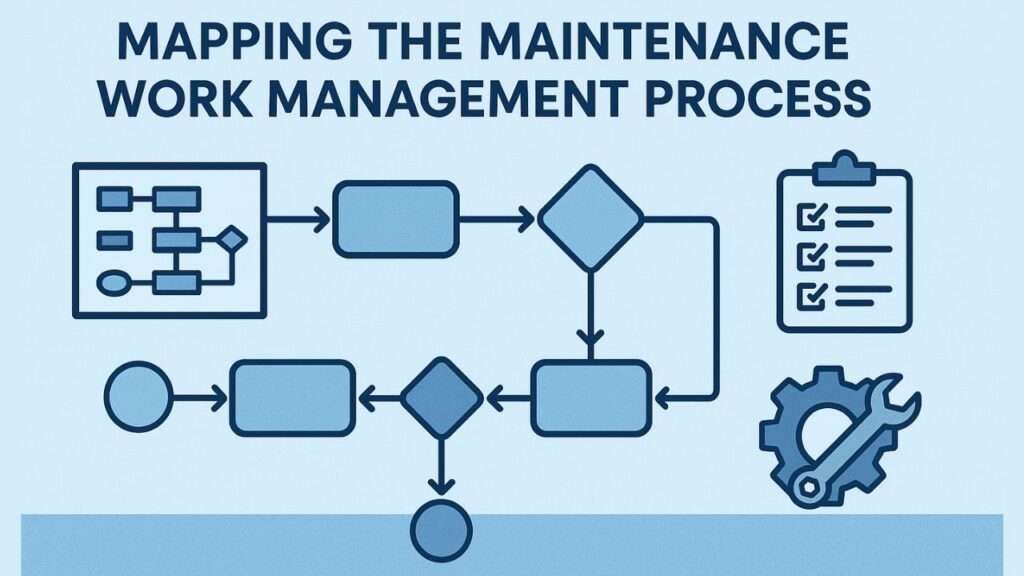

- Clarity: You cannot improve what you cannot see. Process improvement begins with mapping workflows, understanding roles, identifying bottlenecks and revealing hidden complexity.

- Consistency: A process must be repeatable before it can be optimised. Standardisation, documentation and clear responsibilities create the foundation for improvement.

- Continuous Learning: Processes evolve. Teams learn from failures, refine methods and adapt to new conditions. Improvement is not a project, it is a habit.

These principles underpin every major improvement methodology, from Lean to TPM to Six Sigma.

Why Does Process Improvement Matter?

Process improvement is not just about efficiency. It strengthens every dimension of operational performance:

- Safety: Clear, stable processes reduce human error and unsafe improvisation.

- Reliability: Better processes reduce variation, improve asset care and prevent failures.

- Cost: Waste elimination reduces unnecessary work, rework and downtime.

- Quality: Consistent processes produce consistent outcomes.

- Culture: Teams become more engaged when they can influence how work is done.

- Resilience: Strong processes hold up under pressure and recover faster from disruption.

In many organisations, poor processes are the root cause of most recurring problems. Process improvement provides the structure to fix them permanently.

The Major Process Improvement Methodologies.

There are many improvement frameworks, but most share common DNA. Below are the major methodologies used across industry, along with how they contribute to operational maturity.

Lean: Eliminating Waste and Improving Flow.

Lean focuses on maximising value by eliminating waste and improving the flow of work. It originated in manufacturing but is now used across every sector.

Lean identifies eight types of waste:

- Defects – Errors, rework and quality failures.

- Overproduction – Making more than needed.

- Waiting – Delays, idle time, bottlenecks.

- Non‑utilised talent – Underusing people’s skills.

- Transportation – Unnecessary movement of materials

- Inventory – Excess stock, spares, or WIP.

- Motion – Unnecessary movement of people.

- Extra processing – Doing more work than required.

Lean is especially powerful in maintenance and operations because it exposes hidden inefficiencies that accumulate over time, poor job planning, excessive travel time, unclear work instructions and duplicated effort.

Six Sigma: Reducing Variation and Improving Quality.

Six Sigma focuses on reducing variation and improving process capability. It uses statistical tools to identify root causes and eliminate defects.

The core Six Sigma cycle is DMAIC:

- Define the problem.

- Measure current performance.

- Analyse root causes.

- Improve the process.

- Control the new standard.

Where Lean improves flow, Six Sigma improves precision.

Together, they form Lean Six Sigma, a powerful combination used across mining, manufacturing, energy and utilities.

Total Productive Maintenance/Manufacturing (TPM).

TPM is a process improvement methodology focused on equipment reliability and operator engagement. It aims to eliminate the “six big losses” that reduce equipment effectiveness:

- Equipment failures.

- Setup and adjustment losses.

- Idling and minor stops.

- Reduced speed.

- Defects and rework.

- Startup losses.

TPM empowers operators to take ownership of basic maintenance tasks, cleaning, inspection, lubrication, while maintenance teams focus on higher‑value work such as strategy optimisation and reliability engineering.

TPM strengthens both asset resilience and process stability.

Total Quality Management (TQM).

TQM is a holistic approach that embeds quality into every part of the organisation. It emphasises:

- Customer focus.

- Leadership commitment.

- Employee involvement.

- Process‑based thinking.

- Continuous improvement.

- Data‑driven decision‑making.

TQM is less about tools and more about culture. It creates the environment where Lean, Six Sigma and TPM can thrive.

How Does Process Improvement Support Operational Maturity?

Process improvement is not a standalone activity, it is a core component of organisational maturity.

At low maturity, processes are inconsistent, undocumented and dependent on individuals.

Improvement efforts focus on stabilising workflows and reducing chaos.

At medium maturity, processes are standardised and measured.

Improvement efforts focus on waste elimination, flow and reliability.

At high maturity, processes are optimised, predictable and continuously refined.

Improvement efforts focus on innovation, resilience and strategic alignment.

Process improvement is the mechanism that moves organisations up the maturity curve.

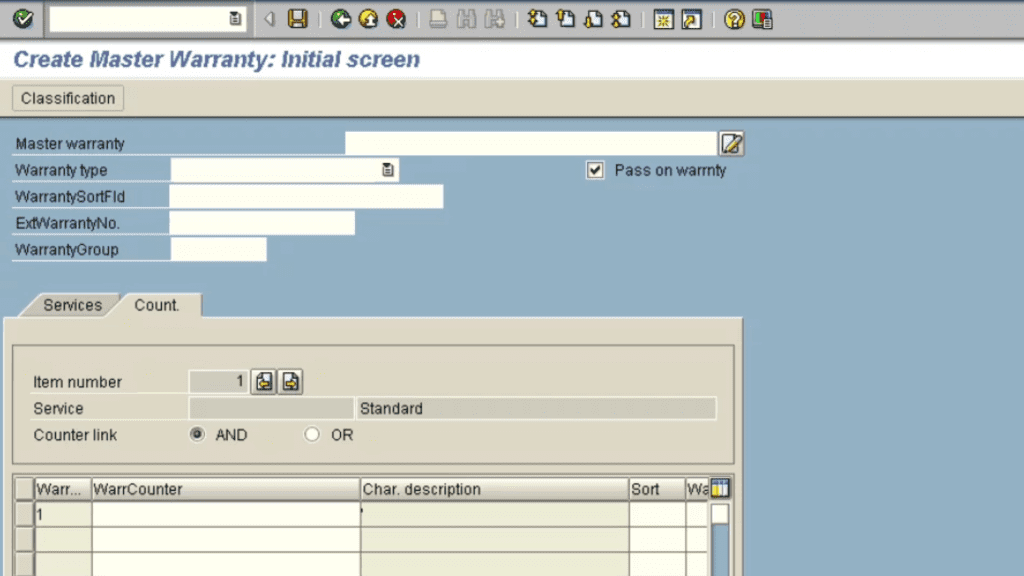

The Role of CMMS/EAM/ERP in Process Improvement.

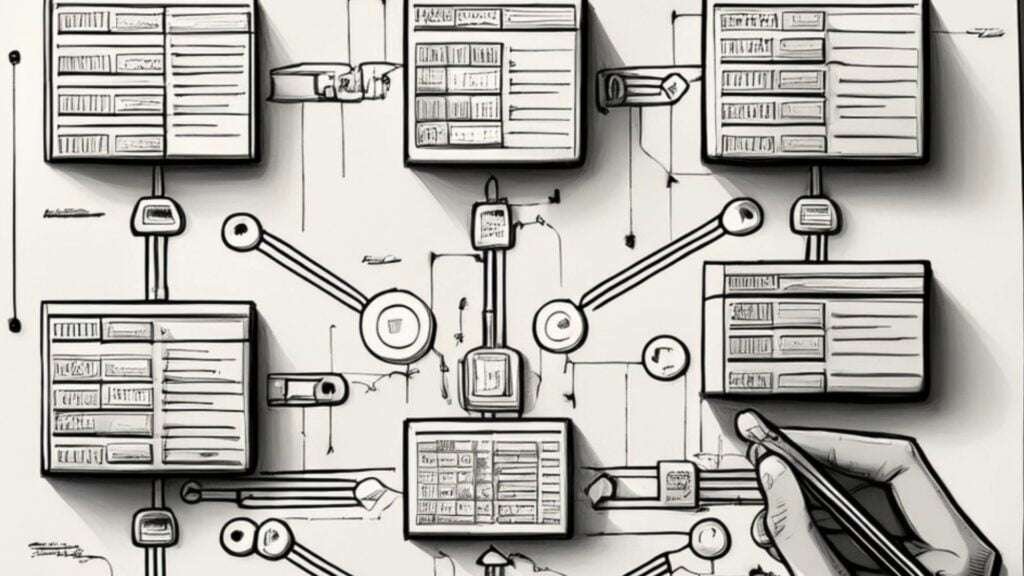

A CMMS/EAM/ERP is not just a work management tool, it is a process improvement engine.

When used well, it supports:

- Standardised workflows.

- Accurate data for analysis.

- Visibility of backlog and bottlenecks.

- Identification of waste and rework.

- Measurement of process performance.

- Continuous improvement cycles.

- Poor data creates blind spots.

- Strong governance creates insight.

Process improvement and system maturity reinforce each other.

Below is a practical roadmap organisations can use to begin improving processes in a structured, sustainable way.

- Map the Current State: Document how work actually happens, not how it is supposed to happen. Use tools like value stream mapping, SIPOC, or simple flowcharts.

- Identify Waste, Variation and Failure Points: Look for delays, rework, handoff issues, unclear responsibilities and unnecessary steps.

- Engage the People Who Do the Work: Operators, maintainers, planners and supervisors know where the real problems are. Improvement is most effective when it is co‑created.

- Standardise the Process: Create clear, repeatable steps. Define roles, responsibilities and decision points.

- Improve the Process Using the Right Tools: Lean for waste Six Sigma for variation TPM for equipment losses TQM for culture 5S for workplace organisation Kaizen for rapid improvement RCA for problem solving.

Measure Performance (What Gets Measured, Gets Managed).

Use KPIs that reflect flow, quality, reliability and stability.

Use KPIs that reflect flow, quality, reliability, and stability. The goal is not to measure everything—it’s to measure the few things that reveal whether the system is healthy, predictable, and improving.

Examples are:

- Schedule Compliance – A leading indicator of planning discipline and workflow stability.

- Scheduled Work Percentage – Shows whether the team is operating proactively or being consumed by reactive work.

- Safety Observations – A behavioural indicator of safety culture maturity and leadership engagement.

- Contractor Hours Capture – Ensures data completeness so KPIs reflect reality, not assumptions.

- Daily Work Order Completion & Actual Hours Accuracy – Protects data integrity and prevents backlog distortion.

- RCA / 5 Whys Completion Rate – Demonstrates whether the organisation is learning from failures or repeating them.

These above 6 KPIs tell you whether maintenance is creating the conditions for stable, predictable operations.

- Overall Equipment Effectiveness (OEE) – The clearest measure of how well assets convert time into value across availability, performance, and quality.

- Throughput / Tonnes per Hour (TPH) – A direct indicator of flow stability and process bottlenecks.

- Production Plan Adherence – The operational equivalent of schedule compliance; shows how reliably the plant meets its planned output.

- Unplanned Downtime – A lagging indicator of system fragility and a mirror of reactive maintenance.

- First Pass Yield (FPY) – Measures quality at the source and reflects process stability.

- Energy Intensity (kWh per tonne) – A sensitive indicator of equipment health and process efficiency.

- Utilisation Rate – Shows how effectively available production time is being used.

- Inventory Turns / WIP Stability – Reveals flow consistency and the presence of hidden variability.

- Process Cycle Efficiency (PCE) – Measures how much of the total process time is value‑adding.

These above 9 KPIs show whether operations are stable, efficient, and capable of meeting demand without excessive cost, waste, or variability.

Why These KPIs Matter.

Together, these metrics create a balanced view of system performance. Maintenance KPIs reveal whether the organisation is doing the right work at the right time. Production KPIs reveal whether that work is translating into stable output. When both sets trend in the right direction, you get:

- Higher reliability.

- Lower unplanned downtime.

- Better quality.

- More predictable throughput.

- Lower energy use.

- Safer operations.

- A more resilient organization.

When they diverge, it’s a sign that processes are unstable, data is incomplete, or improvement efforts are not being sustained.

Sustain the Gains You Achieve.

Document the new standard. Train teams. Audit regularly. Use visual management to keep the process visible.

Build a Culture of Continuous Improvement.

Celebrate improvements. Encourage experimentation. Reward transparency. Make improvement part of everyday work.

The Link Between Process Improvement and Operational Resilience.

Process improvement strengthens resilience by:

- Reducing reliance on heroic individuals.

- Creating predictable workflows.

- Improving asset health.

- Reducing variation and uncertainty.

- Strengthening cross‑functional coordination.

- Building learning loops.

- Improving recovery speed after disruptions.

A resilient organisation is one where processes hold up under pressure and recover quickly when they don’t.

Process improvement is the mechanism that makes this possible.

Push Versus Consolidate – Process Improvement Phases.

One of the most overlooked elements of process improvement is the rhythm between Push and Consolidate.

Many organisations are excellent at pushing, launching new initiatives, debottlenecking processes, rolling out new tools, and driving rapid change.

However, far fewer are disciplined at consolidating, stabilising the change, validating the results, updating master data, and ensuring the improvement becomes part of the organisation’s DNA.

Without this rhythm, process improvement becomes a cycle of enthusiastic starts followed by quiet decay.

The Push Phase: Introducing Change and Creating Momentum.

The Push phase is where energy is highest. Teams introduce new processes, eliminate waste, redesign workflows, or implement new technologies.

This phase is essential for breaking inertia and moving the organisation forward.

But Push is inherently destabilising. It introduces new behaviours, new data requirements, new responsibilities, and new expectations.

Even when the change is positive, it creates temporary uncertainty and variation.

That’s why Push must never stand alone.

The Consolidate Phase: Turning Change into Stability.

Consolidation is where improvement becomes real.

It is the disciplined process of embedding the change, validating its impact, and ensuring the organisation is ready for the next step.

A strong Consolidate phase answers four critical questions:

- How well did the change actually work? Not how well we think it worked, but what the data shows. Did the bottleneck disappear? Did cycle time improve? Did backlog reduce? Did quality increase?

- Do we need to adjust or revisit anything? Early assumptions are often incomplete. Consolidation allows teams to refine the process, correct unintended consequences, and close gaps.

- What is the proof that the improvement is real and repeatable? Evidence matters. Without measurable results, the improvement is just a hypothesis.

- Was everything documented, standardised, and embedded into master data? This is the most critical step, and the one most often skipped. If asset strategies, job plans, BOMs, workflows, responsibilities, and CMMS data are not updated, the improvement will erode over time.

Why Consolidation Protects Site Quality.

When organisations rush from one Push phase to the next without consolidation, they accumulate hidden fragility:

- Master data becomes outdated or inconsistent.

- Workflows drift away from documented standards.

- Operators and maintainers revert to old habits.

- Improvements fail to sustain.

- New initiatives are built on unstable foundations.

This is how sites end up with poor data quality, unreliable planning, and processes that look good on paper but fail in practice.

The Rhythm That Builds Maturity.

The most mature organisations treat Push and Consolidate as a deliberate cycle:

Push → Consolidate → Prove → Standardise → Push Again

This rhythm ensures that each improvement becomes a stable platform for the next. It prevents organisational debt, protects data integrity, and builds long‑term capability rather than short‑term excitement.

Conclusion.

Process improvement is not a toolkit. It is not a project. It is not a one‑off initiative. It is a mindset and a discipline.

Organisations that embrace process improvement build safer, more reliable, more efficient and more resilient operations.

They reduce waste, strengthen asset health, empower their people and create a culture where excellence is the norm, not the exception.

In a world where volatility is increasing and expectations are rising, process improvement is not optional. It is the foundation of operational maturity and long‑term success.