Preventive Maintenance Optimization

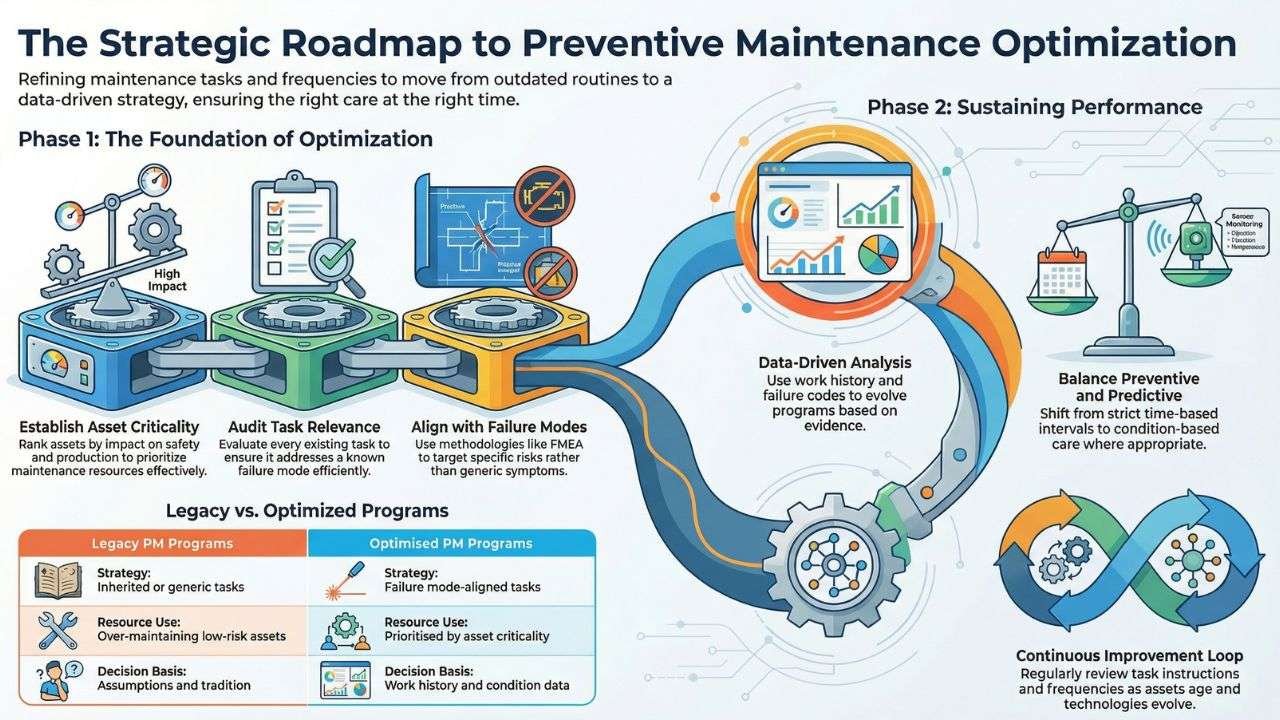

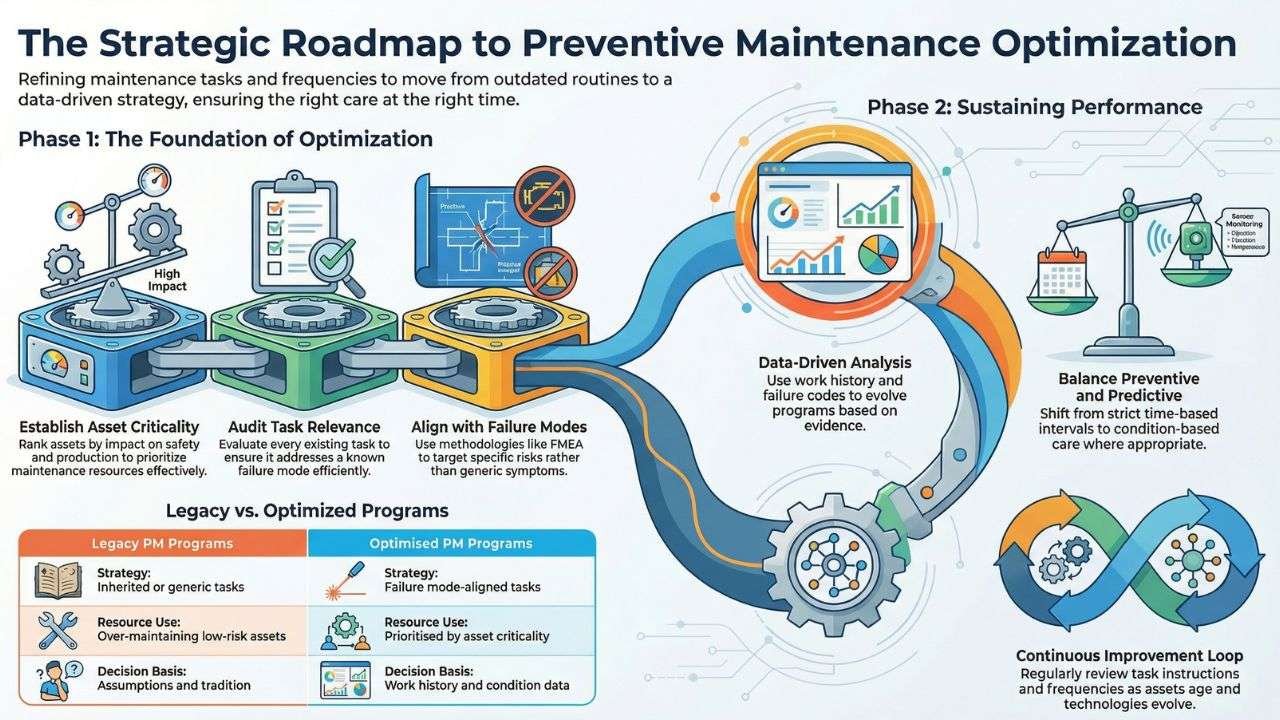

Preventive Maintenance Optimization is the disciplined process of refining maintenance tasks, frequencies, and workflows to ensure that assets receive the right care at the right time with minimal waste.

It is a cornerstone of modern maintenance management because it directly influences reliability, cost control, safety, and operational stability.

When organizations optimize their preventive maintenance (PM) programs, they reduce unplanned downtime, extend asset life, and create a predictable, efficient maintenance environment that supports long‑term asset performance.

At its simplest, preventive maintenance is scheduled work performed to prevent failures. In practice, however, many PM programs become bloated, outdated, or misaligned with current operational needs.

Organizations often inherit maintenance routines from manufacturers, consultants, or previous staff without validating whether those tasks remain effective.

Over time, this leads to inefficiencies such as over‑maintaining low‑risk assets, under‑maintaining critical ones, or performing tasks that add little or no value. Preventive Maintenance Optimization addresses these issues by systematically reviewing, analyzing, and improving the PM program.

Establishing Asset Criticality.

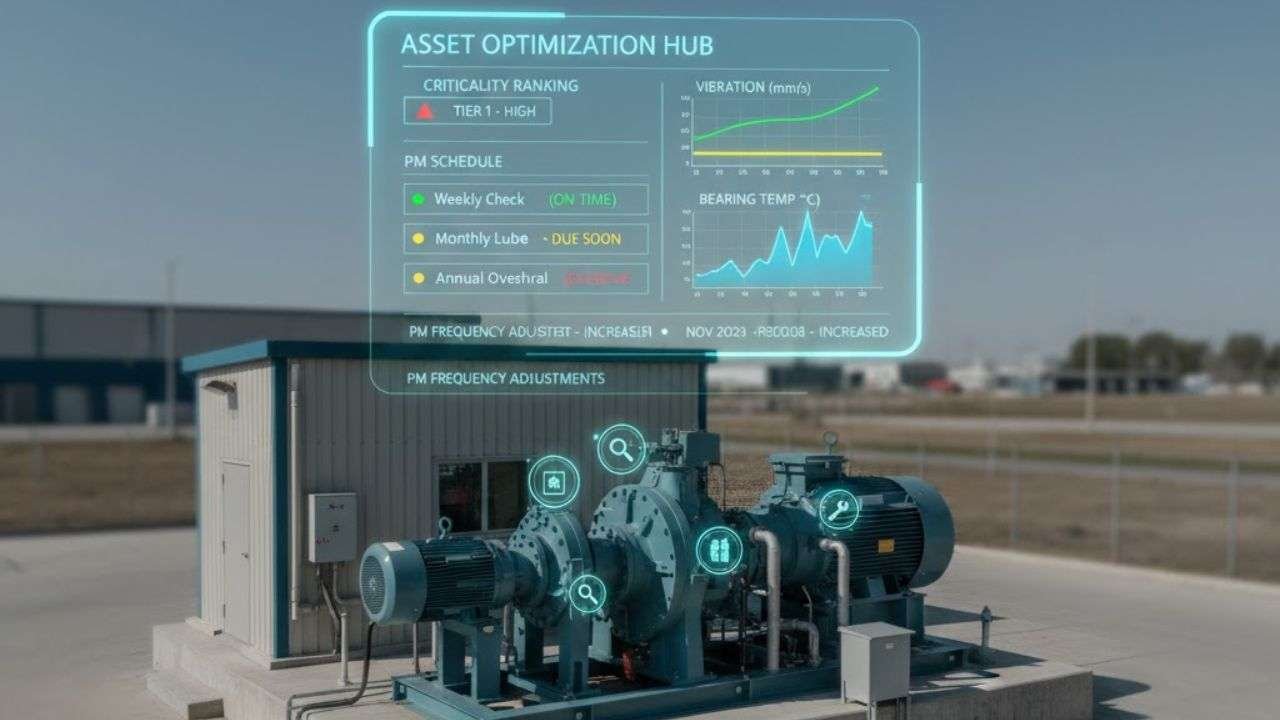

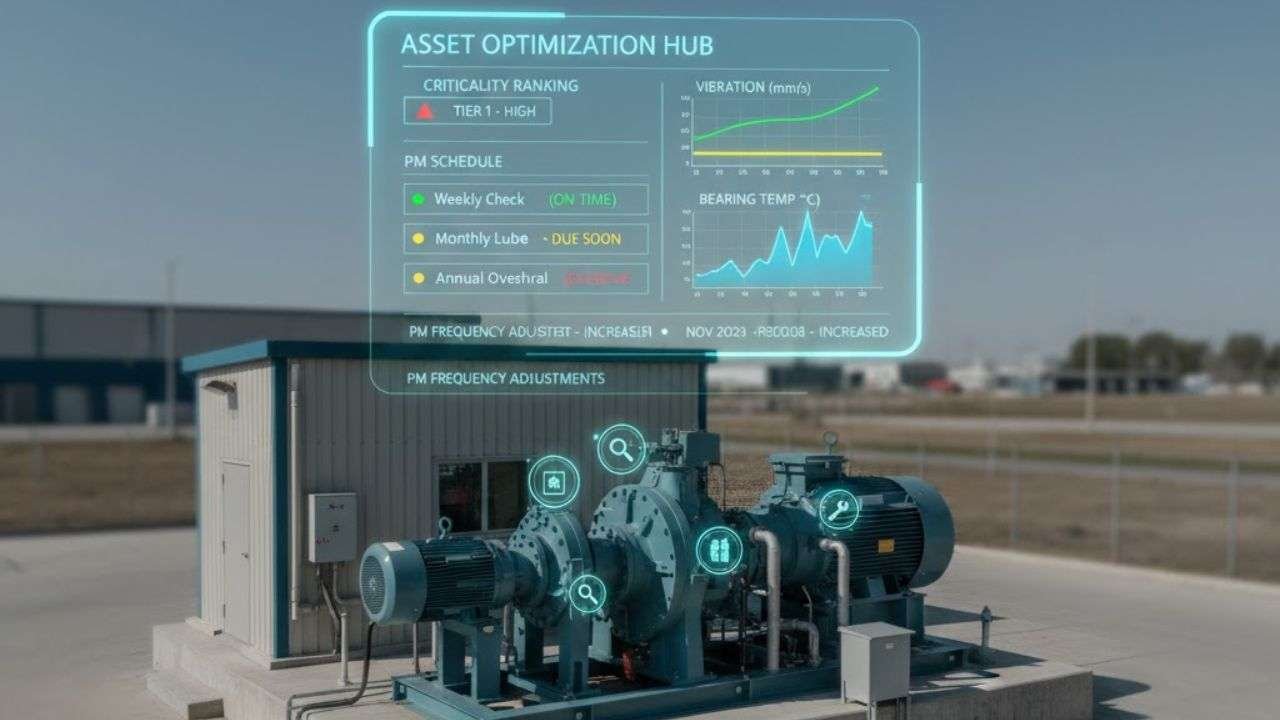

Optimization begins with a clear understanding of asset criticality. Not all assets contribute equally to safety, production, or service delivery.

A structured criticality assessment ranks assets according to their impact on operations, cost, safety, and compliance.

This ranking forms the foundation for PM prioritization. High‑criticality assets receive more rigorous preventive strategies, while low‑criticality assets may be maintained less frequently or even allowed to operate to failure where appropriate. Without clear prioritization, resources are easily wasted on non‑critical equipment while critical assets remain exposed to risk.

Evaluating Existing PM Tasks.

The next step involves evaluating existing PM tasks for relevance, effectiveness, and efficiency.

Key questions include:

- Does the task prevent a known failure mode.

- Is the frequency appropriate.

- Is the task measurable and clearly defined.

- Does it require specific skills or tools.

Many PM tasks fail these tests. For instance, a monthly inspection may be excessive if the asset’s condition changes slowly, while a lubrication task might be too infrequent for equipment operating in harsh environments.

Optimization ensures every task serves a defined purpose and delivers measurable outcomes.

Aligning with Failure Modes.

A core principle of PM Optimization is aligning maintenance activities with actual failure modes. This is where methodologies such as Failure Mode and Effects Analysis (FMEA) are invaluable.

By identifying how assets fail and what causes those failures, organizations can design targeted PM tasks that address real risks rather than generic symptoms. This alignment increases both the effectiveness and predictability of maintenance.

Leveraging Data and Insights.

Data plays a central role in successful optimization. Work order history, failure codes, condition monitoring data, and technician feedback provide critical insights into asset performance.

Analyzing this data reveals patterns such as recurring failures, ineffective PM tasks, or excessive corrective work.

For example, if an asset continues to fail despite regular PM, the task may be insufficient or incorrectly executed.

Conversely, if an asset exhibits prolonged stability, PM frequency may be safely reduced. Data‑driven analysis ensures that PM programs evolve based on evidence rather than assumptions.

Balancing Preventive and Predictive Maintenance.

Optimization often involves striking the right balance between preventive and predictive maintenance.

While preventive maintenance relies on time‑based intervals, predictive maintenance uses condition data to determine when work is truly required.

For example, instead of replacing a bearing every six months, vibration analysis may indicate when replacement is actually necessary.

This shift reduces unnecessary work and premature component replacement, improving both cost efficiency and asset reliability.

Standardization and Consistency.

Optimized PM programs depend on standardization. Clear, consistent task instructions help ensure reliability in execution.

Procedures should define required measurements, tolerances, safety precautions, and documentation standards.

Standardization reduces variability, improves data quality, and ensures consistency across teams and sites. Without it, even the best‑designed PM plans may deliver inconsistent results.

Cross‑Functional Collaboration.

Effective optimization requires strong collaboration between departments.

Operations teams provide insight into asset behavior and production constraints; procurement supports parts availability and vendor performance; reliability engineers analyze data and refine strategies; and technicians contribute hands‑on feedback about asset condition and task effectiveness.

When these disciplines work together, PM programs become more accurate, realistic, and aligned with organizational goals.

Continuous Improvement.

PM Optimization is an ongoing process. As assets age, operating conditions evolve, and new technologies emerge, maintenance programs must adapt. Regular reviews and feedback loops enable continuous refinement of task instructions and frequencies.

Advances in condition monitoring and analytics further enhance program effectiveness.

This continuous improvement cycle keeps preventive maintenance dynamic, evidence‑based, and aligned with organizational objectives.

Conclusion.

Preventive Maintenance Optimization is a structured approach to ensuring assets receive the right care at the right time.

It integrates criticality analysis, failure mode identification, data‑driven decision‑making, standardization, and cross‑functional collaboration.

When applied effectively, it transforms maintenance from a reactive necessity into a strategic advantage, improving reliability, safety, and long‑term asset performance.