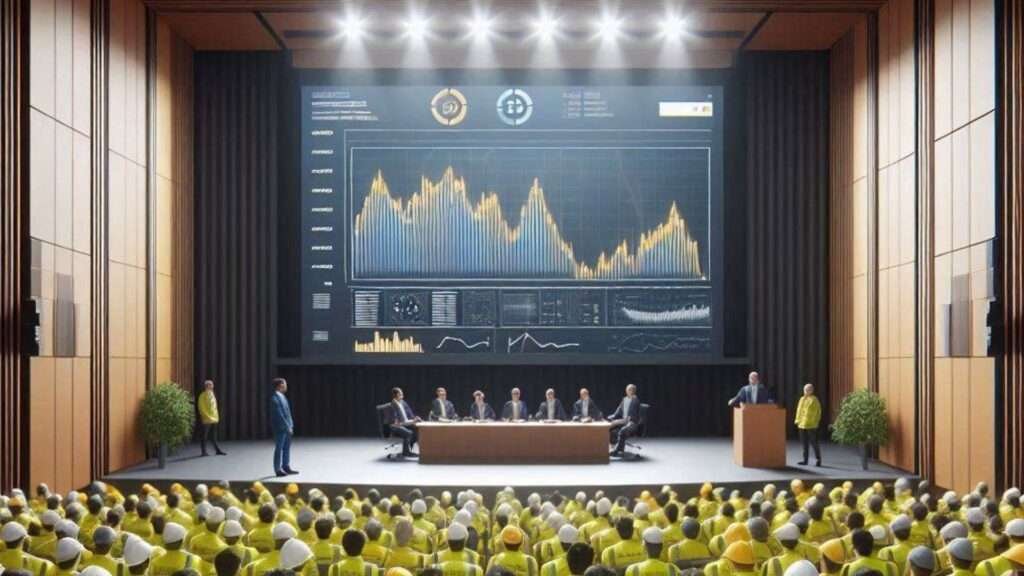

Performance Benchmarking

Performance benchmarking in the context of CMMS, EAM, and ERP systems has always been one of the most quietly powerful levers for organisational improvement. Yet, it seems to have faded from common practice.

Many years ago, it wasn’t unusual for maintenance planners, supervisors, reliability engineers, IT analysts and even maintenance managers to jump in a car, drive to a peer organisation and spend the best part of a day comparing how each team used the same system.

Those sessions were informal but incredibly rich: people shared tips and tricks, experienced stories, debated configuration choices and walked away with practical insights they could apply immediately (at least discuss with their group).

Today, the technology we have out our disposal makes this easier than ever, but the habit has withered. Re‑establishing this could possibly be transformative.

Performance Benchmarking Meaning – CMMS/EAM/ERP Environment.

At its core, performance benchmarking is the structured comparison of processes, data quality, system usage, and outcomes between organisations that operate similar systems or face similar operational challenges.

It’s not just about metrics; it’s about understanding how those metrics are achieved. In asset‑intensive industries, the value lies in seeing how others configure work management, preventive maintenance, materials management, failure coding, reporting and integration with finance or operations.

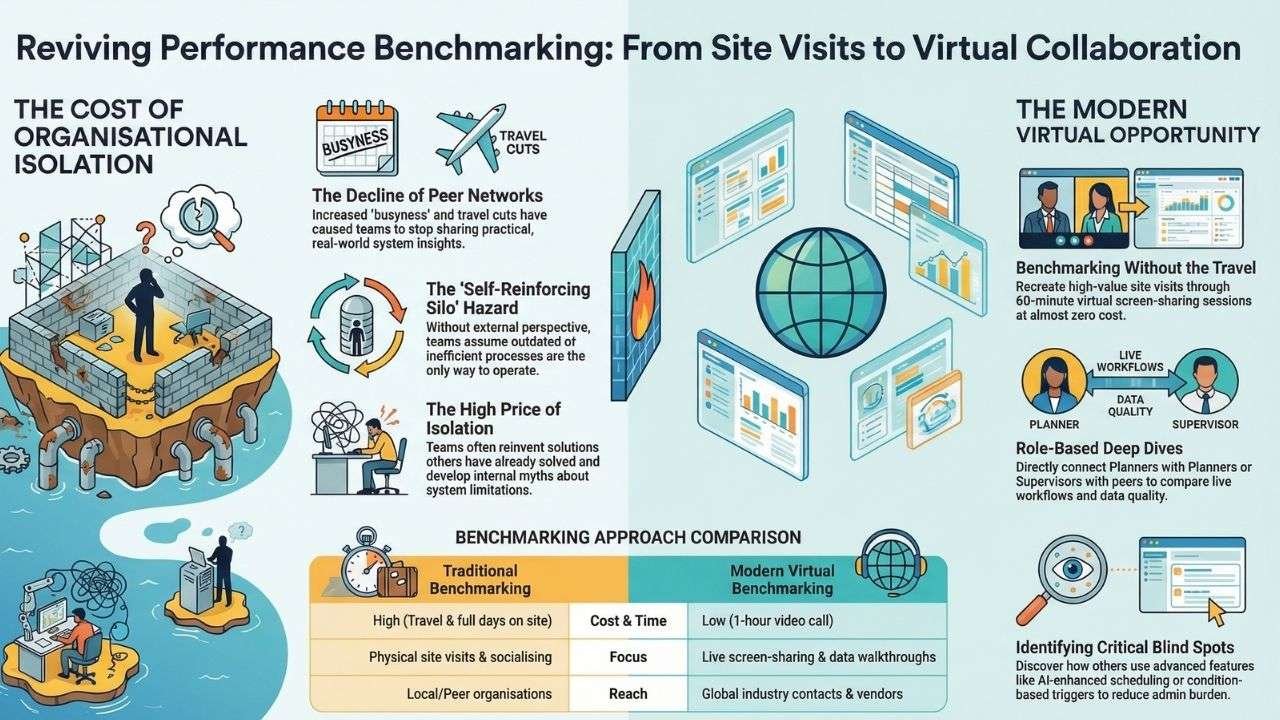

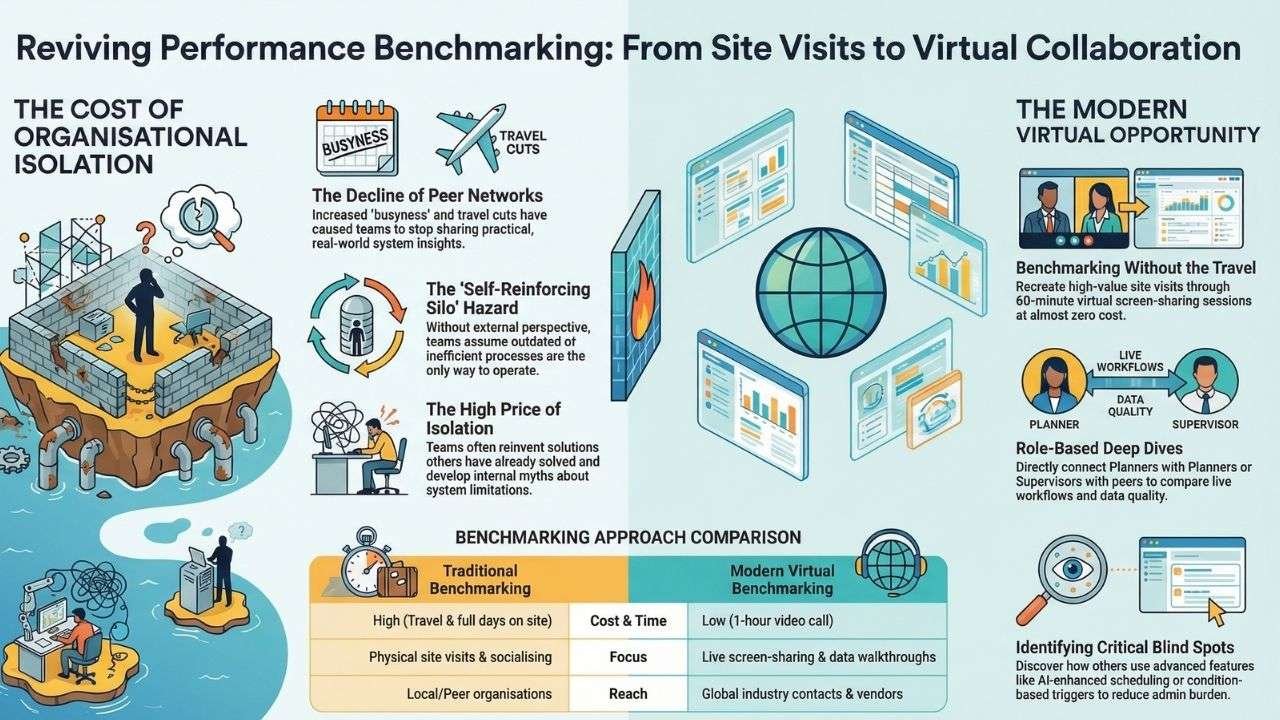

Benchmarking helps organisations break out of the self‑reinforcing silo that forms when teams only look inward.

Over time, people assume their way is “the way,” even if it’s inefficient, outdated, or misaligned with modern system capabilities.

Benchmarking reintroduces external perspective, which is essential for continuous improvement. As the old saying goes, “You don’t know what you don’t know.”

Why Benchmarking Was So Strong Decades Ago.

In the early days of digital maintenance management systems, implementations were expensive, complex and often customised.

Because of this, organisations seemed to naturally form peer networks with others using the same platform. Possibly due to the world just simply being a lot more sociable back then but it could also have been that for a company running on a very small budget, learning a lot from another company ‘for free’ simply seemed like a great idea.

These relationships were practical and valuable: people met face‑to‑face, built trust and shared openly. Vendors encouraged it, user groups were active, email groups were used to share tips. The culture of collaboration was strong.

Those site visits created:

- Shared understanding of system capability: People learned what was possible beyond their own configuration.

- Healthy comparison of processes: Teams could see how others structured PMs, managed backlog, or handled shutdown planning.

- Real‑world problem solving: Users exchanged tips, shortcuts, and lessons learned that never appear in manuals.

- Cross‑pollination of ideas: Innovations spread organically across organisations.

This was benchmarking at its best, practical, relational, and grounded in real work.

Why Did It Decline?

It would be fair to say that several factors contributed to the decline:

- Increased digital maturity: As systems became more standardised, organisations assumed they no longer needed to compare notes.

- Vendor‑driven training models: Companies leaned more on official training and less on peer learning.

- Organisational busyness: Travel budgets shrank, workloads increased, and benchmarking was seen as optional.

- Silo reinforcement: Ironically, as systems became more capable, teams became more isolated in how they used them.

The result is that many organisations now operate their CMMS/EAM/ERP in ways that are outdated, inefficient (time and money), or misaligned with best practice, without realising it.

Why Benchmarking Matters More Now Than Ever.

Modern systems evolve quickly. Updates, new modules, analytics capabilities, mobile tools, and integration options appear constantly. Without external reference points, organisations fall behind. Benchmarking helps teams stay aware of:

- New features and updates.

- Emerging best practices.

- Process improvements others have already tested.

- Data structures that support better reporting.

- Configuration choices that reduce administrative burden.

It also helps organisations identify blind spots. For example, a team may believe their preventive maintenance program is mature until they see how another organisation uses condition‑based triggers, tradespeople provide ‘red pen markups’ on PM work orders for the smallest corrections required, AI enhanced scheduling (MEX, Prometheus, OptiScheduleAI etc), or AI assisted reliability‑centred templates.

The Modern Opportunity: Benchmarking Without the Travel.

The irony is that benchmarking is easier now than it has ever been.

With Microsoft Teams & Google Meet, Zoom etc, screen sharing, shared whiteboards, and collaborative documents, organisations can recreate the old site‑visit experience with almost no cost.

A one‑hour virtual session would surely deliver the same insights that once required a full day of travel back and forth on top of the time on site.

Modern benchmarking could as a minimum include:

- Live system walkthroughs: Each organisation shows how they manage their new work processing, Creating Maintenance Strategies & Improvements, PM Management, materials management, or reporting/maintenance analysis dashboards.

- Role‑based deep dives: Planners meet planners, supervisors meet supervisors, reliability engineers meet reliability engineers.

- Configuration comparisons: Teams compare fields, workflows, statuses, and coding structures. Discuss any mods they may have paid for recently.

- Data quality reviews: Organisations examine how others maintain master data, naming conventions, and hierarchies.

- Process mapping sessions: Teams align on how work flows through the system and identify improvement opportunities.

This approach eliminates the biggest historical barrier, ‘travel’, while preserving the value of shared learning.

How Benchmarking Prevents Organisational Isolation.

When teams operate in isolation, they often:

- Reinvent solutions others have already solved.

- Maintain outdated processes because “that’s how we’ve always done it.”

- Underuse system features that could save time or improve accuracy.

- Develop internal myths about what the system can or cannot do.

- Lose sight of industry standards and maturity expectations.

Benchmarking breaks this cycle. It reconnects organisations to the broader ecosystem of users, ideas, and innovations.

It also builds confidence: when teams see how others operate, they gain clarity about where they excel and where they need to improve.

The Cultural Value: Rebuilding Community Among System Users.

One of the most underrated benefits of benchmarking is the sense of community it creates. When people talk to peers who understand their challenges, they feel supported and energised.

This is especially important in maintenance and asset management, where roles can be demanding and often under‑recognised.

Rebuilding these networks digitally could help:

- Strengthen professional identity.

- Encourage continuous learning.

- Reduce frustration with system limitations.

- Create informal channels for troubleshooting.

- Foster a culture of improvement rather than stagnation.

A Practical Way Forward.

Organisations don’t need a formal program to restart benchmarking.

They simply need to reach out to peers, other sites, similar companies, vendors, or industry contacts and propose a short virtual session.

Even a single conversation can spark meaningful change.