Operational Resilience

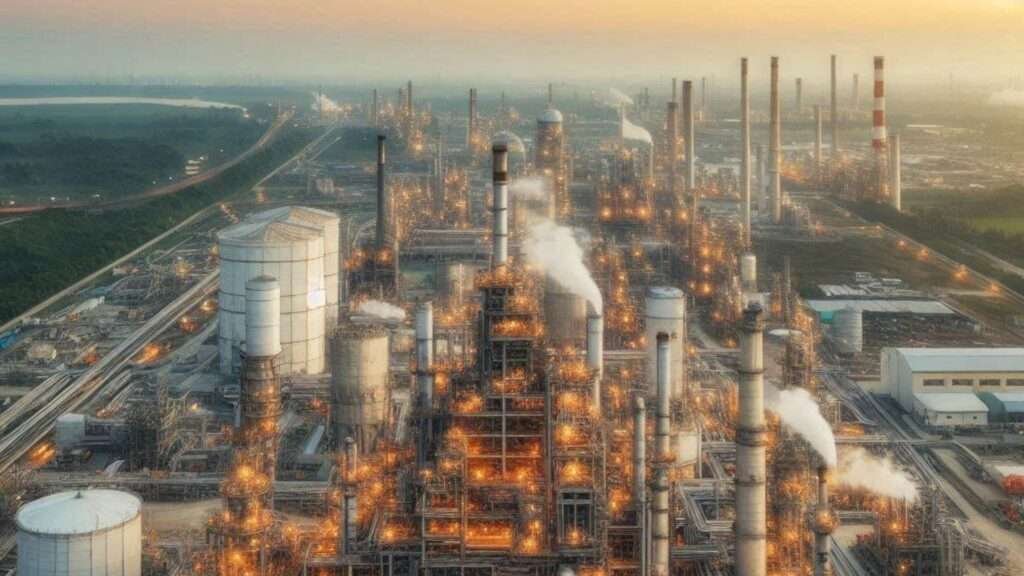

Operational resilience is one of the defining capabilities of modern processing and refining industries.

It’s not a niche concept reserved for risk managers or business continuity teams.

Marked by supply chain volatility, climate extremes, workforce shortages, ageing assets and rising stakeholder expectations, operational resilience is a core requirement for safe, reliable and sustainable operations.

Where operational efficiency focuses on optimising performance in stable conditions, operational resilience focuses on maintaining performance when conditions are unstable. It is the organisation’s ability to absorb shocks, recover quickly and adapt to new realities without losing control of safety, reliability, or service delivery.

A resilient organisation doesn’t simply survive disruption. It uses disruption as a catalyst for learning, improvement and long‑term strength.

1.0 What Does Operational Resilience Means?

Many definitions of operational resilience are somewhat vague or overly academic and although there’s a place for those somewhere in this world, in heavy industry, resilience is not an abstract concept, it is a practical capability built into assets, processes, people and organisational systems.

At its core, operational resilience is made up of three interlocking abilities:

1.1 Absorption.

The ability to take a hit without catastrophic failure.

A resilient operation can withstand variability, unexpected conditions and sudden shocks because it has:

- Robust maintenance strategies.

- Redundant or fail‑safe equipment.

- High‑quality data enabling early detection.

- Operators trained to stabilise processes under pressure.

- Clear escalation pathways.

- Asset designs that include margin, not just minimum compliance.

Absorption is the first line of defence. It prevents small disturbances from becoming major events.

1.2 Recovery.

The ability to restore operations quickly and safely.

Recovery is not just about speed, it is about control, coordination and clarity. Effective recovery depends on:

- Accurate CMMS history and asset intelligence.

- Well‑structured planning and scheduling.

- Spare parts availability and supply chain resilience.

- Cross‑functional response teams.

- Clear communication channels.

- Leadership that prioritises safety and stability over haste.

Recovery capability determines how long a disruption lasts and how much it costs.

1.3 Adaptation.

The ability to learn, adjust and improve after disruption.

Adaptation is where resilience becomes a long‑term strategic advantage. It includes:

- Root cause analysis that leads to real change.

- Updating maintenance strategies based on new evidence.

- Learning loops between operations, maintenance, engineering and leadership.

- Cultural norms that reward transparency, not blame.

- Scenario planning and continuous improvement.

Adaptation ensures that the same disruption does not happen twice.

2.0 The Relationship Between Efficiency and Resilience.

Operational efficiency and operational resilience are often treated as separate goals, but they are deeply interconnected.

- Operational Efficiency Doing things right in stable conditions. Reducing waste, improving flow, optimising utilisation and maximising value.

- Operational Resilience Continuing to do things right in unstable conditions. Maintaining safety, reliability and service delivery when the environment becomes unpredictable.

Efficiency without resilience creates fragility. Resilience without efficiency creates waste.

The most mature organisations build efficient systems that remain stable under stress. They understand that resilience is not the opposite of efficiency, it is the extension of efficiency into real‑world conditions.

3.0 The Four Pillars of Operational Resilience.

To make resilience practical and actionable, it helps to break it into four pillars. These pillars align with how real operations function and how CMMS maturity develops over time.

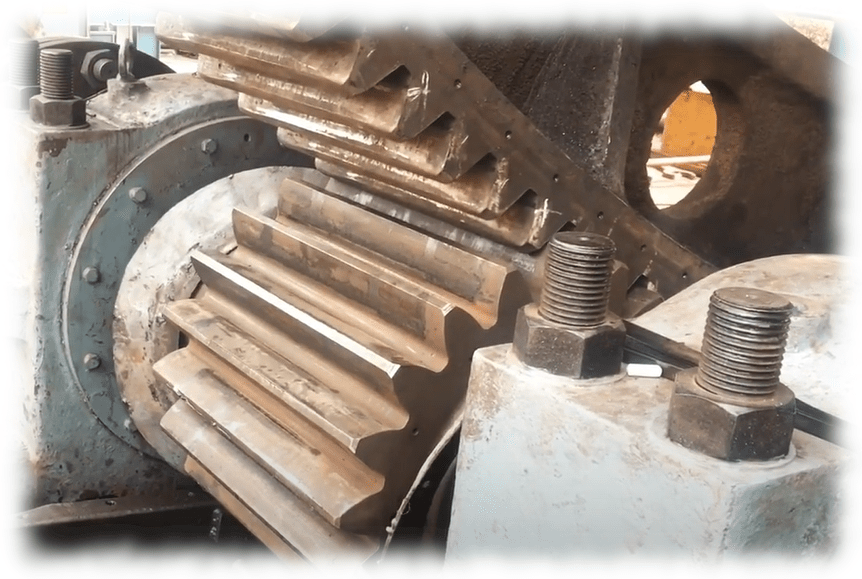

Pillar 1: Asset Resilience.

Asset resilience is the ability of physical equipment to withstand variability, wear and unexpected conditions.

It includes:

- Reliability engineering.

- Condition monitoring and predictive analytics.

- Strategy optimisation (RCM, FMEA, PMO).

- Understanding failure modes and degradation patterns.

- Redundancy and design margin.

- Effective lubrication, alignment and precision maintenance.

Asset resilience is the foundation. Without it, even the best processes and people cannot maintain stability.

Pillar 2: Process Resilience.

Process resilience is the ability of workflows and systems to hold up under pressure.

It includes:

- Planning and scheduling discipline

- Clear roles and responsibilities

- Standard operating procedures

- Change management

- Work management maturity

- CMMS data quality and governance

- Documented escalation pathways

Process resilience ensures that when something goes wrong, the organisation does not rely on improvisation or heroics.

Pillar 3: People Resilience.

People resilience is the ability of teams to respond effectively to stress, uncertainty and rapid change.

It includes:

- Competency and cross‑training

- Psychological safety

- Decision‑making under pressure

- Leadership behaviours

- Communication clarity

- Fatigue management

- Cultural norms that support transparency

People resilience is often the difference between a controlled recovery and a cascading failure.

Pillar 4: Organisational Resilience.

Organisational resilience is the ability of the broader system, governance, strategy, resources and culture, to support stability and adaptation.

It includes:

- Risk management

- Supply chain resilience

- Business continuity planning

- Scenario modelling

- Investment in asset health

- Leadership alignment

- A culture of learning and continuous improvement

Organisational resilience ensures that resilience is not dependent on individuals, it is built into the system.

4.0 What Causes Fragility.

Fragility is the opposite of resilience. It is the condition where small disturbances create large consequences.

Fragile organisations often share the same patterns:

- Over‑reliance on heroic individuals.

- Poor CMMS data quality.

- Deferred maintenance and backlog bloat.

- Siloed teams with poor communication.

- Underinvestment in training and competency.

- Short‑term cost cutting that erodes long‑term stability.

- Lack of scenario planning.

- Inconsistent leadership signals.

- Ageing assets with no renewal strategy.

- Supply chains with single points of failure.

These patterns are not random, they are symptoms of deeper systemic issues. Many of them overlap with what you’ve described as Heroic Load Syndrome, where organisations rely on extraordinary individual effort instead of building resilient systems.

5.0 How to Build Operational Resilience.

Building resilience is not a single project, it is a long‑term capability that grows through deliberate investment and disciplined execution. The following actions form a practical roadmap for organisations at any maturity level.

- Strengthen Maintenance Strategies: Move from time‑based tasks to evidence‑based strategies. Use real failure data, condition monitoring and reliability engineering to refine PMs and eliminate unnecessary work.

- Improve Planning and Scheduling Discipline: A resilient organisation does not rely on reactive work. Planning and scheduling create stability, predictability and control, especially during disruption.

- Invest in Condition Monitoring and Early Warning Systems: Early detection is one of the most powerful resilience tools. It turns surprises into manageable events.

- Build Cross‑Functional Response Teams: Resilience is a team sport. Operations, maintenance, engineering and supply chain must respond as a coordinated unit.

- Train Operators and Maintainers Together: Shared understanding reduces errors, improves communication and accelerates recovery.

- Improve CMMS Accuracy and Governance: Resilience depends on reliable data. Poor data quality creates blind spots that become vulnerabilities.

- Conduct Scenario‑Based Drills: Practice builds confidence and competence. Teams that rehearse disruption recover faster and more safely.

- Strengthen Supply Chain Visibility: Know where your vulnerabilities are. Identify single points of failure, critical spares and alternative suppliers.

- Reward Transparency, Not Firefighting: A resilient culture values early reporting, not heroic recovery. It celebrates prevention, not last‑minute saves.

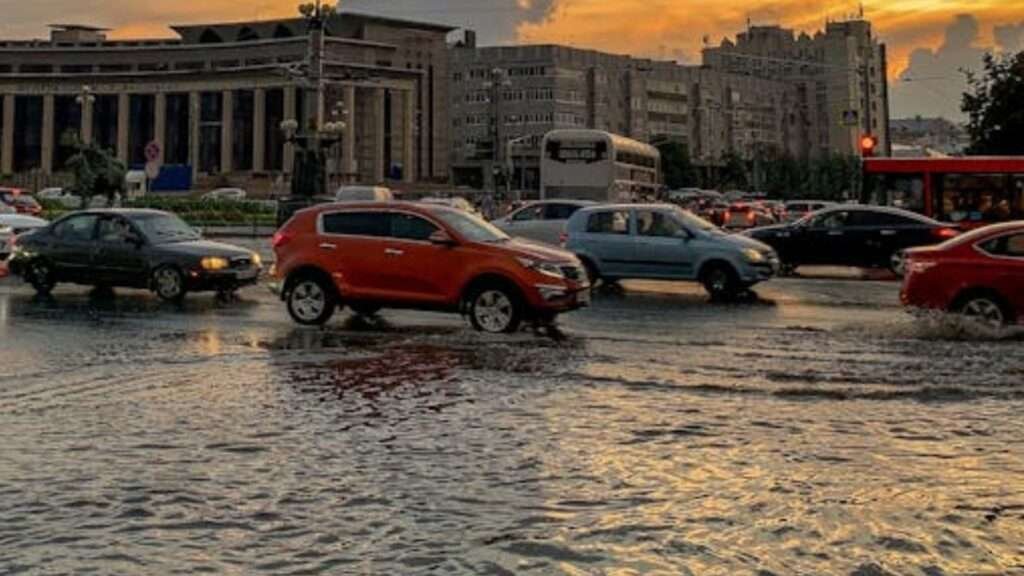

6.0 Why Operational Resilience Matters Now.

The world is becoming more volatile, not less. Organisations face a convergence of pressures:

- Climate whiplash and extreme weather.

- Global supply chain instability.

- Workforce shortages and skill gaps.

- Ageing infrastructure.

- Rising regulatory expectations.

- Increasing digital complexity.

- Higher stakeholder scrutiny.

In this environment, operational resilience is not optional. It is a competitive advantage, a safety requirement and a survival strategy.

Resilient organizations typically:

- Experience fewer catastrophic failures.

- Recover faster from disruptions.

- Maintain safer, more stable operations.

- Make better long‑term decisions.

- Build trust with regulators, communities and investors.

- Attract and retain skilled people.

- Spend less on unplanned downtime and emergency work.

Resilience is not a cost, it is an investment in continuity, capability and confidence.

7.0 Conclusion.

Operational resilience is the true test of organisational maturity. It reveals whether systems are built on stable foundations or held together by heroic effort.

Efficiency shows how well you perform when everything is stable. Resilience shows how well you perform when nothing is.

The organisations that thrive in the next decade will be those that build both.