Operational Efficiency

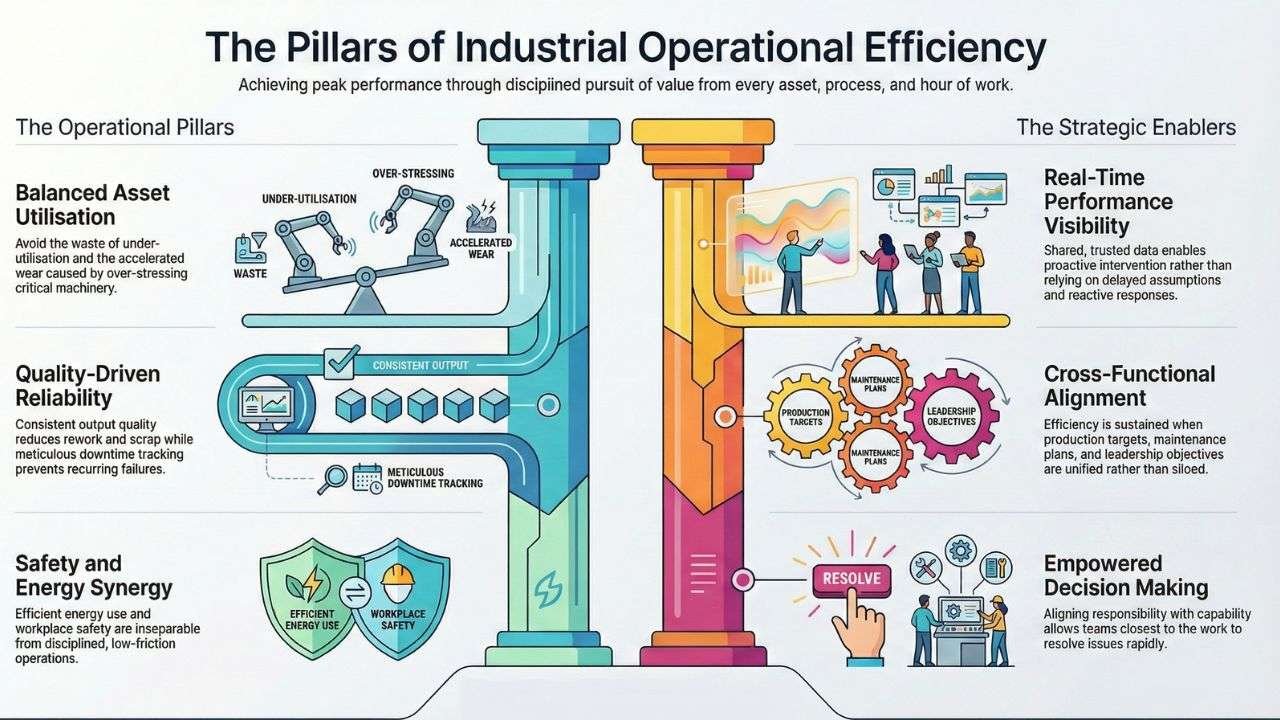

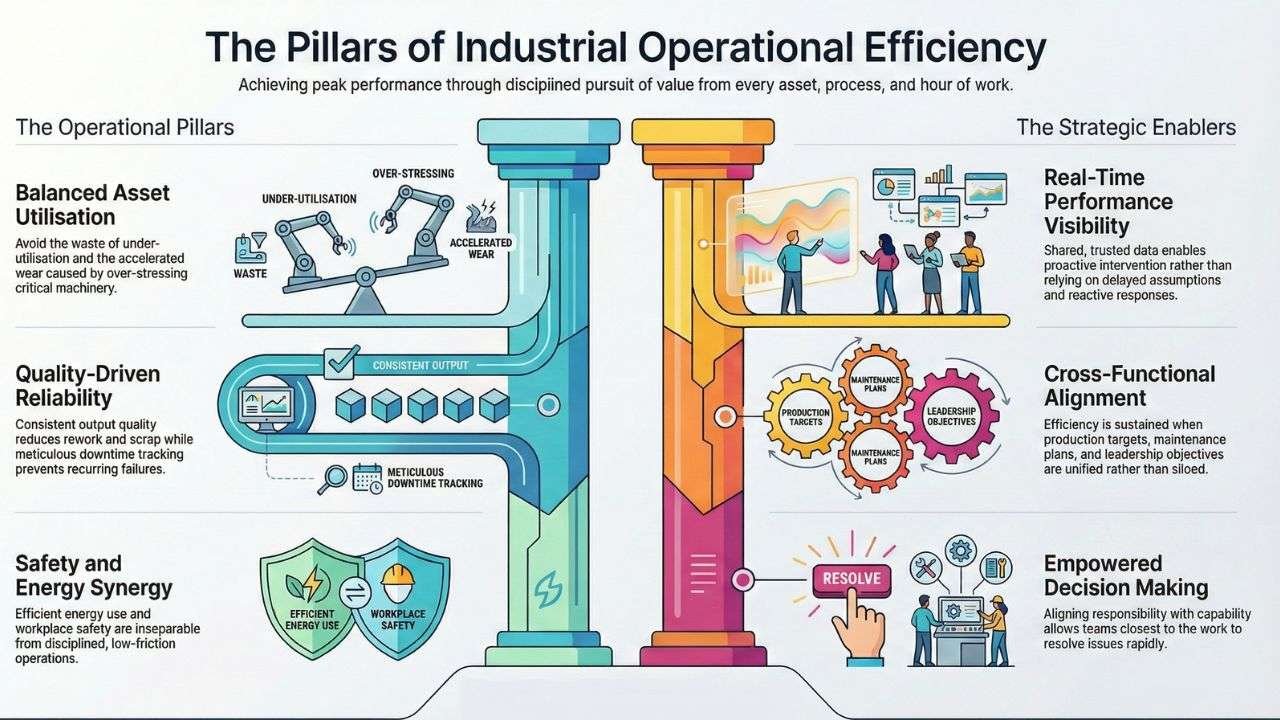

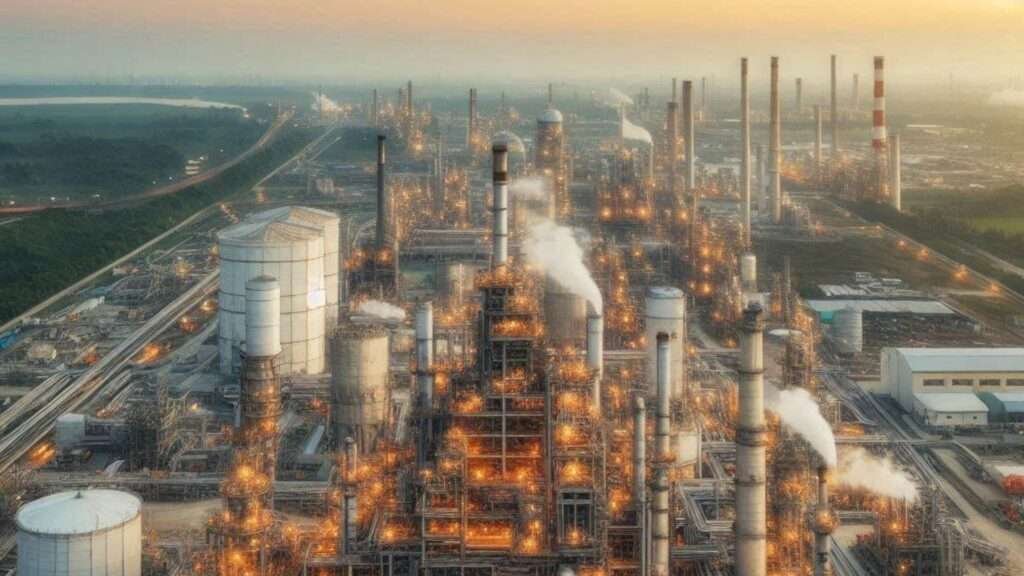

Operational efficiency, in the context of asset‑intensive processing or refining industries, is the disciplined pursuit of getting the highest possible value from every asset, process and hour of work while minimising waste, risk and unnecessary cost.

It is not a single metric but a system-wide condition: assets must run reliably, people must work safely and processes must convert inputs into outputs with as little friction as possible.

When operational efficiency is strong, organisations experience fewer disruptions, lower operating costs and more predictable performance. When it is weak, inefficiencies compound, downtime increases, quality drops and costs escalate.

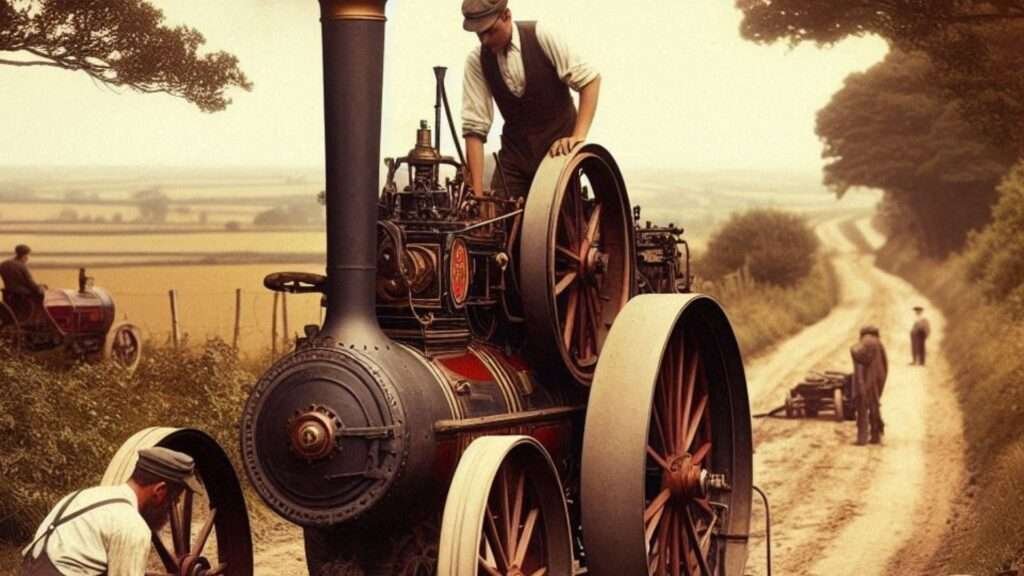

At its core, operational efficiency depends on how well assets are managed across their entire lifecycle.

This includes maintenance quality, utilisation rates, energy consumption and the organisation’s ability to prevent failures before they occur.

Efficient operations ensure that assets are neither under‑used nor over‑stressed, both of which create hidden costs.

Under‑utilisation wastes capital investment, while over‑utilisation accelerates wear, increases breakdowns and shortens asset life.

Striking the right balance requires accurate data, disciplined scheduling and a clear understanding of production demands.

Another pillar of operational efficiency is output quality. Assets must consistently produce goods or services that meet required standards.

Poor quality leads to rework, scrap, customer dissatisfaction and regulatory consequences. High-quality output, on the other hand, reduces waste and strengthens the organisation’s reputation.

This is why quality metrics, testing procedures and continuous monitoring are essential components of efficient operations.

Downtime, especially unplanned downtime, is one of the most visible threats to operational efficiency. Every unexpected outage disrupts production, increases costs and strains resources.

Efficient organisations track downtime meticulously, analyse root causes and implement corrective actions that prevent recurrence. Over time, this builds a more resilient operation where failures become rarer and easier to manage.

Energy efficiency also plays a significant role. Energy is often one of the largest controllable costs in industrial operations.

Efficient energy use reduces expenses, supports sustainability goals and extends equipment life. Modern metering, benchmarking and energy management systems help organisations identify waste and optimise consumption.

Operational efficiency is inseparable from safety as a safe workplace reduces incidents, protects people and prevents costly disruptions.

Strong safety performance also reflects disciplined processes, an essential ingredient of efficiency.

In essence, operational efficiency is the outcome of well‑maintained assets, reliable processes, informed decision‑making and a culture committed to continuous improvement.

It enables organisations to operate predictably, competitively and sustainably. If you want, I can also shape this into a more formal definition or adapt it for a specific audience.

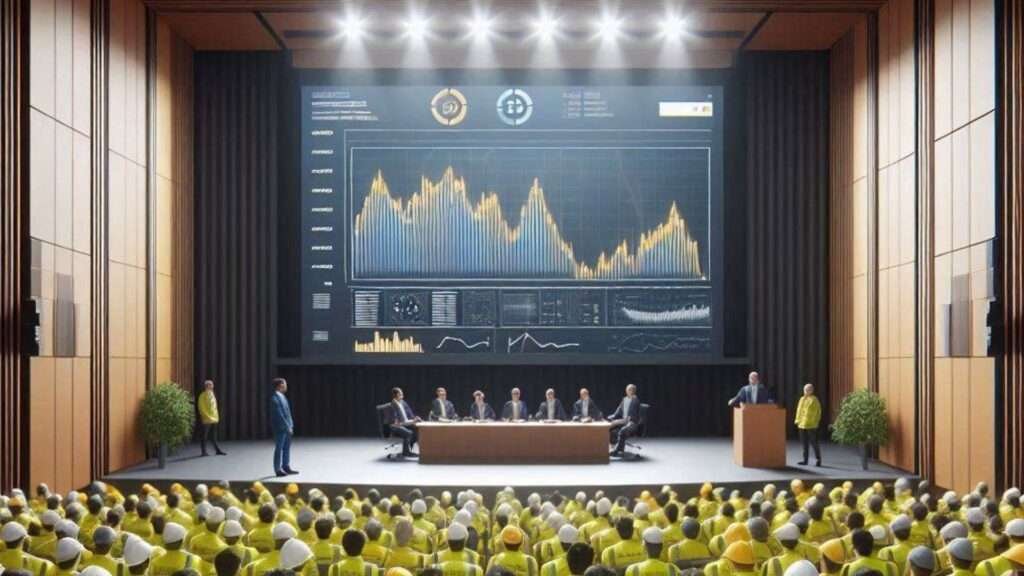

Data Driven Decision Making and Organisational Alignment.

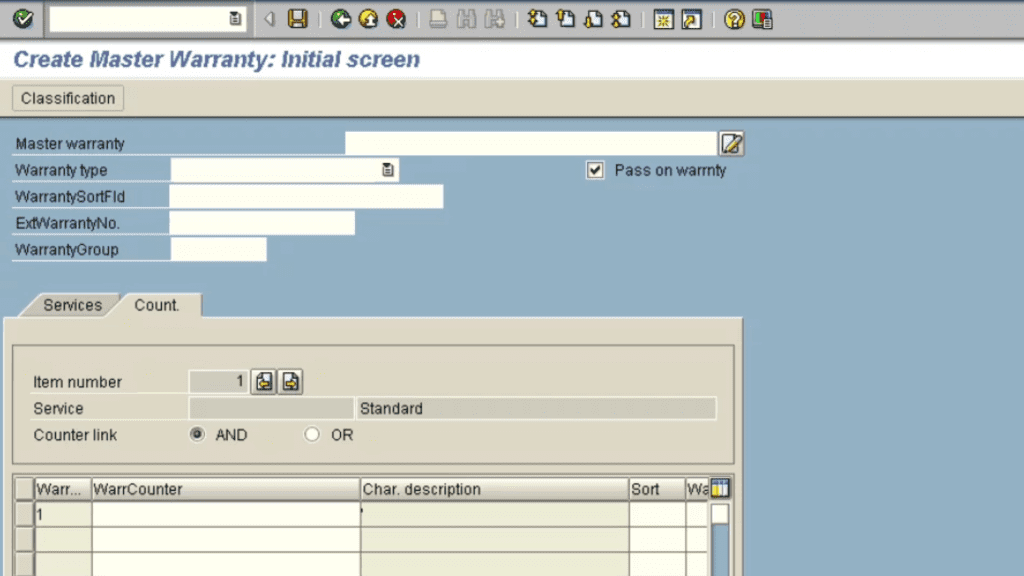

Operational efficiency is ultimately shaped by the quality of decisions made every day across the organisation.

In processing or refining operational environments with a substantial amount of maintenance intensive assets, these decisions must be informed by accurate, timely and trusted data.

Without this, even well-designed processes and capable assets cannot deliver consistent performance.

Efficient operations establish clear performance visibility across the entire site.

This includes real-time production data, asset health indicators, maintenance backlogs, energy consumption trends and quality metrics.

When information is fragmented, delayed or unreliable, teams are forced to rely on assumptions and reactive responses, which erodes efficiency over time.

Conversely, shared and transparent data enables proactive intervention, better prioritisation and faster problem resolution.

Decision-making authority and accountability also matter. Operational efficiency suffers when roles are unclear, approvals are slow or decisions are escalated unnecessarily.

High-performing operations align responsibility with capability, allowing teams closest to the work to act quickly within defined boundaries. This reduces delays, prevents small issues from becoming major failures and supports continuous improvement at the operational level.

Just as important is alignment between operational, maintenance, engineering and leadership objectives.

Efficiency cannot be achieved in silos. Production targets that ignore asset health, maintenance plans that conflict with operational demands or cost-cutting initiatives that undermine reliability all create friction.

Efficient organisations ensure that goals, incentives and performance measures are aligned across functions, reinforcing behaviours that support long-term asset performance rather than short-term gains.

In this way, operational efficiency becomes not only a technical outcome but a managerial and cultural one. When data, decision-making and organisational alignment work together, efficiency is sustained rather than periodically recovered after failures occur.