Maintenance Planning

Maintenance planning is the disciplined, forward‑looking practical process that ensures maintenance work is executed safely, efficiently and predictably.

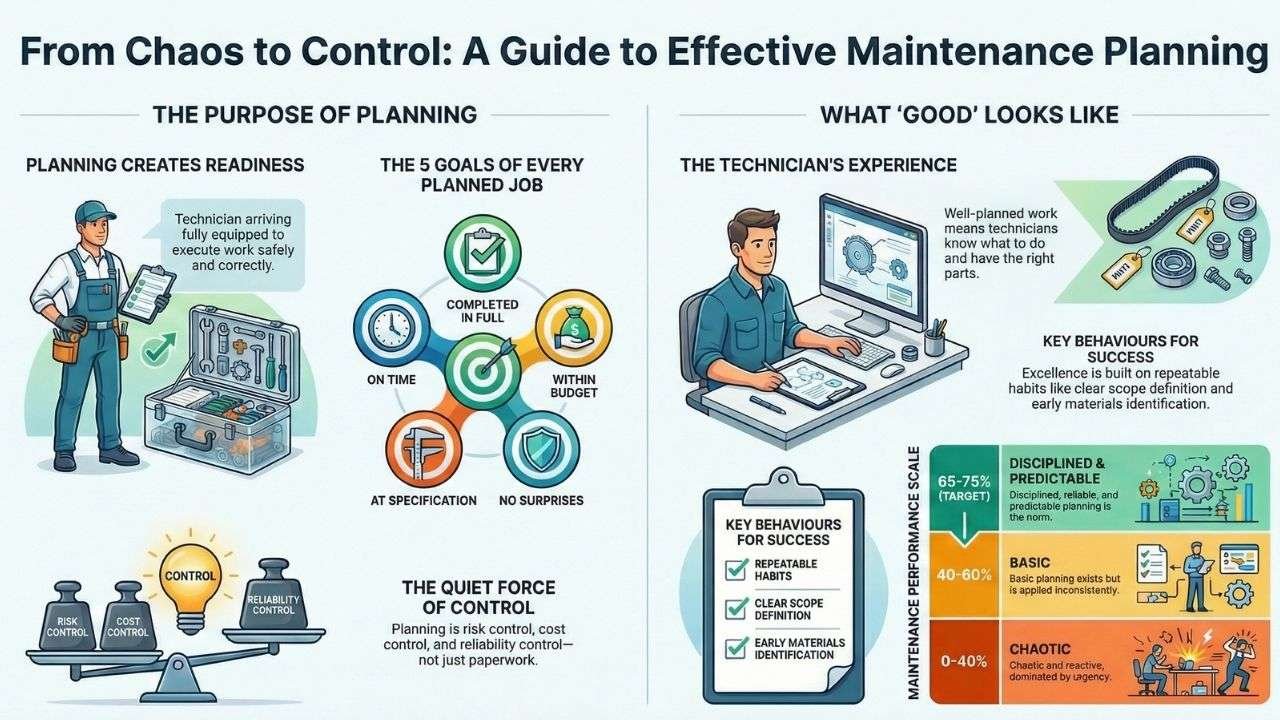

At its simplest, maintenance planning exists to ensure that every approved job on the schedule is completed in full, on time, within budget, with no surprises and at specification.

But beneath that simple statement sits a deeper operational truth: good planning is the mechanism that turns organisational intent into predictable, repeatable results. It is the discipline that converts a work order into a controlled, well‑executed maintenance activity.

Achieving this level of consistency requires more than generating work orders and attaching documents. It depends on a series of interconnected behaviours and controls that prevent the common failure modes found in reactive environments.

When planning is functioning well, each job moves through a structured preparation process that eliminates ambiguity, aligns resources and ensures that technicians arrive at the job site fully equipped to execute the work safely and correctly.

To understand what this looks like in practice, it helps to break the idea into its core components:

- In full: The entire scope is completed as intended, with no missing steps, no deferred tasks and no unplanned scope changes.

- On time: The job is ready before the scheduled window, materials are available and execution proceeds without avoidable delays.

- Within budget: Labour, materials and services align with expected cost ranges because planning prevented waste, rework and procurement surprises.

- No surprises: Risks were identified early, access constraints were resolved, and the job unfolds as expected rather than becoming a firefight.

- At specification: The work meets technical, safety and quality requirements, ensuring the asset returns to service in the condition intended.

When these outcomes occur consistently, the organisation operates in the 65–75% excellence band—a level where maintenance is stable, predictable and aligned with operational priorities.

This performance level is not achieved through heroics or last‑minute effort. It is achieved through repeatable planning behaviours, including:

- Clear scope definition so technicians know exactly what must be done.

- Risk‑based planning effort that matches the complexity and criticality of the job.

- Early materials identification to prevent procurement delays.

- Accurate work packs that technicians trust and rely on.

- Coordination with operations to secure access, permits and isolation windows.

- Verification of readiness before the job is released to scheduling.

When these elements are consistently applied, the maintenance schedule becomes more than a list of intentions—it becomes a reliable operational plan.

This is the essence of mature maintenance planning: a disciplined, structured process that ensures work is executed exactly as the organisation expects, without the chaos, reactivity or uncertainty that characterise lower‑maturity environments.

It is the quiet force that keeps maintenance predictable, safe and aligned with the organisation’s definition of “what good looks like.”

Maintenance Planning bridges the gap between identifying a maintenance need and performing the work. Without planning, maintenance becomes reactive, inconsistent and vulnerable to delays, safety exposures and unnecessary cost.

At its core, maintenance planning is about creating readiness.

It ensures that when a technician arrives at a job, everything required, scope, materials, tools, permits, drawings, risk controls and instructions, is already in place. Planning removes uncertainty so that execution can focus on doing the work, not figuring out what the work is.

To fully understand maintenance planning, it helps to anchor it to a broader performance concept: the “What Does Good Look Like?” scale.

The “What Does Good Look Like?” Scale Applied to Maintenance Planning.

Every organisation sits somewhere on a continuum of maintenance performance:

- 0–20%: Chaotic, reactive, unsafe, unplanned.

- 20–40%: Some structure, but still dominated by urgency.

- 40–60%: Basic planning exists, but inconsistently.

- 65–75%: Disciplined, reliable, repeatable planning that avoids. unacceptable outcomes.

- 75–90%: High‑performing, optimised and continuously improving.

- 90–100%: Industry‑leading, benchmark‑setting excellence.

At 65–75% excellence, maintenance planning typically looks like this:

- Work is clearly defined before execution.

- Planning effort is proportionate to risk and complexity.

- Preventive maintenance is strategy‑controlled, not improvised.

- Corrective work is vetted, prioritised and bundled intelligently.

- Work packs are complete, consistent and trusted by technicians.

- Materials and services are identified early, avoiding delays.

- Urgent work is handled with controlled responsiveness, not chaos.

- Long‑term forecasting provides visibility and stability.

- Financial oversight ensures predictability and alignment.

This is what “good” looks like: not perfection, but disciplined reliability.

A Multi‑Layered Explanation: What Good Maintenance Planning Looks Like.

To make the concept tangible, here is a layered breakdown of what good maintenance planning looks like in practice.

Layer 1: The Purpose Layer , Why Planning Exists.

Good planning exists to:

- Prevent avoidable downtime.

- Reduce safety risk.

- Ensure compliance.

- Improve reliability.

- Optimise labour and materials.

- Support predictable operations.

Planning is not paperwork, it is risk control, cost control and reliability control.

Layer 2: The Process Layer , What Planning Actually Does.

Good planning:

- Defines the work clearly.

- Confirms technical requirements.

- Identifies materials, tools and services.

- Coordinates with operations.

- Prepares documentation and work packs.

- Ensures readiness before scheduling.

It is the structured preparation that makes execution smooth and predictable.

Layer 3: The Decision Layer , How Planning Effort Is Determined.

Planning effort is influenced by:

- Asset criticality.

- Risk exposure.

- Task complexity.

- Regulatory requirements.

- Operational impact.

- Material lead times.

- Strategy maturity.

Good planning adapts its depth and rigour according to these variables.

Layer 4: The Execution Layer , What Technicians Experience

When planning is done well, technicians:

- Know exactly what they are doing.

- Have the right parts and tools on hand.

- Understand the risks and controls.

- Follow clear instructions.

- Complete work efficiently.

- Avoid rework and delays.

Execution becomes safe, efficient and repeatable.

Layer 5: The Governance Layer , How Planning Improves Over Time.

Effective planning systems:

- Distinguish between approved and unapproved PMs.

- Maintain controlled job plans for repeatable work.

- Use engineering validation for strategy changes.

- Track materials performance and procurement delays.

- Review work pack quality.

- Improve continuously through feedback and failure data.

Planning becomes a continuous improvement engine for reliability.

A Single Comprehensive Table: The Entire Planning Function at a Glance.

| Category |

Explanation |

| What |

Maintenance planning is the structured preparation of all maintenance work, preventive, corrective and urgent. It defines scope, identifies risks, prepares documentation, coordinates resources and ensures readiness before execution. |

| Why |

To eliminate ambiguity, reduce delays, prevent safety incidents, support compliance, optimise labour and materials and ensure maintenance activities directly reinforce asset reliability and operational goals. |

| Who |

Planners (primary role), supported by tradespeople, supervisors, reliability engineers, operations, procurement, materials management, safety teams and finance for cost alignment. |

| When |

Applied continuously: during backlog review, PM generation cycles, corrective work vetting, materials planning, work pack development, engineering review, scheduling preparation and long‑term forecasting. |

| How |

Through structured work order review, job site validation, consultation with technical experts, readiness checks, development of work packs, identification of materials and services, coordination with operations and alignment with risk and strategy maturity. |

| Risk Influence |

High‑risk or complex tasks demand deeper planning, engineering input and detailed documentation. Low‑risk or repeatable tasks rely on standard job plans and readiness checks. |

| Materials Influence |

Long‑lead items trigger early procurement and schedule protection. Routine materials follow standard processes. |

| Strategy Influence |

Approved PMs require readiness checks; unapproved PMs require technical review and engineering validation. |

| Operational Influence |

Planning aligns maintenance with production windows, shutdowns, access constraints and resource availability. |

| Excellence Scale (65–75%) |

Planning is disciplined, consistent and proportionate. Work packs are reliable, materials are identified early, corrective work is vetted, urgent work is controlled, long‑term forecasting is active and financial oversight is integrated. |

Maintenance planning transforms maintenance from reactive firefighting into a structured, predictable and reliability‑driven discipline.

It ensures every job, regardless of type, enters execution with clarity, preparation and control. Good planning isn’t about producing paperwork; it’s about creating the conditions for safe, efficient and repeatable maintenance.

At the 65–75% excellence level, planning becomes a stabilising force. It prevents unacceptable outcomes, supports operational continuity and forms the foundation for continuous improvement. It is one of the most powerful levers an organisation can use to improve reliability, reduce cost and protect people and assets.

Shutdown Maintenance Planning.

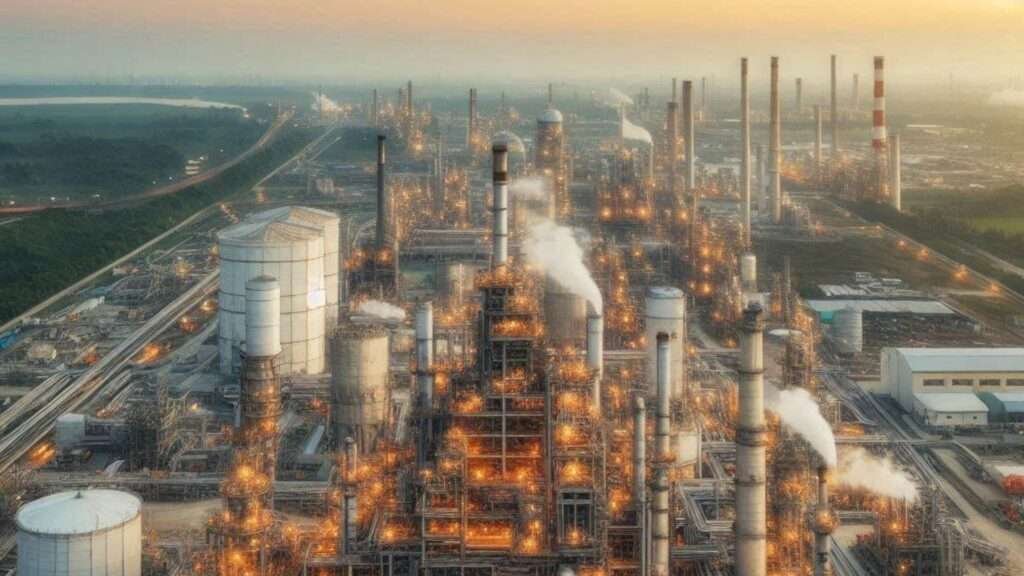

Shutdown maintenance planning coordinates planned maintenance outages with production schedules in industrial processing plants to perform essential tasks like overhauls and inspections that require halting operations.

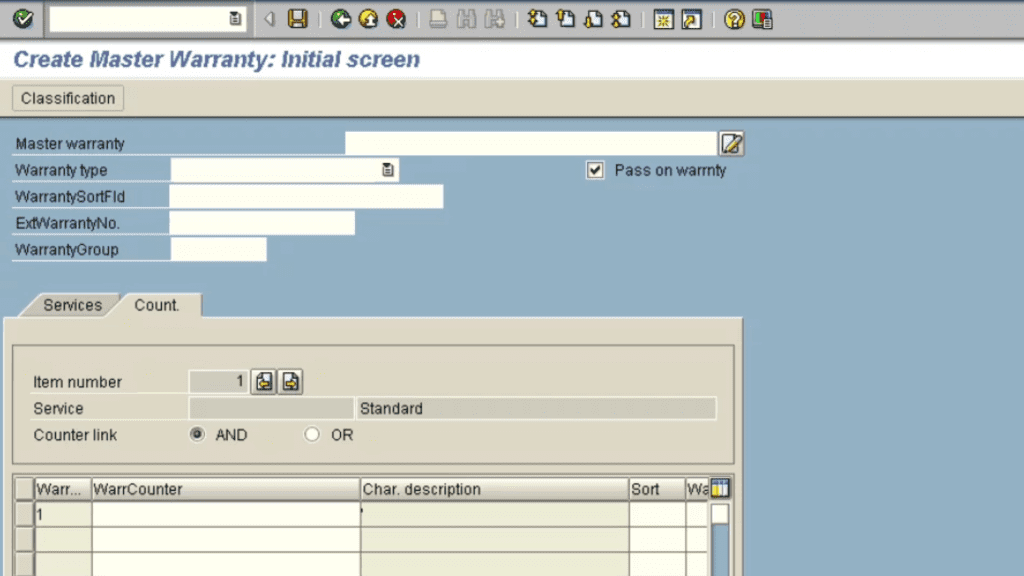

It integrates tools such as enterprise systems (e.g., ERP like SAP) and operational forecasting models to predict impacts, minimize downtime costs, and align with business goals.

Effective planning prioritizes cross-departmental collaboration, data accuracy, and risk assessment for sustainable output and profitability.

Core Elements.

Periodic shutdowns target equipment or process interruptions that stop material flow, analyzing factors like asset criticality, upstream/downstream effects, and losses (e.g., forgone production vs. repair expenses). Plans support end-to-end operations from raw material intake to final product, merging maintenance and production inputs into unified forecasts for reliable reporting and timelines.

Key Goals.

- Eliminate time on unplanned outages.

- Deliver on-time, specification-compliant output.

- Reduce production costs per unit.

- Ensure zero harm to personnel or environment.

- Enhance efficiency and productivity.

- Minimize waste for higher margins.

- Optimize assets for market demands.

Planning Process.

- Task identification: Capture needs via notifications/work orders from condition monitoring, strategies, projects, or regulations.

- Review meetings: Joint production/maintenance evaluations of backlogs, probing duration, costs, viability (e.g., “Online feasible? Scope valid?”).

- Coding/scheduling: Tag tasks for outages, gain approvals, feed into production models.

- Plan assembly: Sequence via templates, verify resources/materials (e.g., availability indicators).

- Work packages: Include risks, isolations (tagged visuals), materials lists, test plans, hazard analyses.

- Capacity evaluation: Assess labor (internal/external), logistics, training; lock scope 3-4 weeks ahead.

- Execution/tracking: Release, monitor via scheduling software; review outcomes.

Excellence Indicators.

- 85%+ planned work (90% PM-driven); full resource utilization.

- Reliability-centered prioritization, low stock-outs, failure audits.

- Advance procurement for long-lead items; precise timings (prep/execution/restart).

- Strict budgeting, target adherence, stakeholder confidence.

- Skill-building and data refinement for uptime gains.