Supply Chain Optimization ERP Functionality

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »

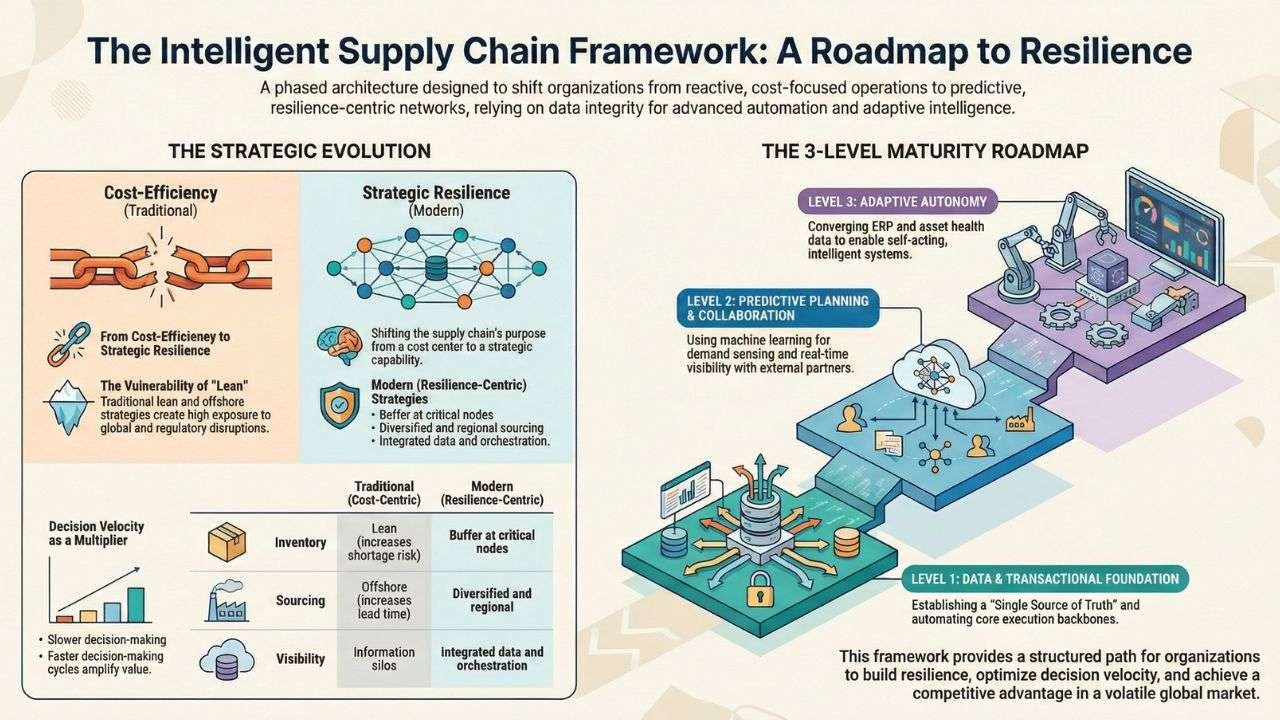

The Intelligent Supply Chain Framework is a structured approach for transforming traditional, cost‑centric supply chains into resilient, data‑driven and adaptive networks.

It recognises that modern supply chains operate in an environment defined by volatility, regulatory pressure and global interdependence.

To remain competitive, organisations must shift from reactive decision‑making to predictive, coordinated and intelligence‑enabled operations.

The framework provides a phased architecture that guides this transition, ensuring that advanced technologies such as machine learning, predictive analytics and agent‑based automation are built on a foundation of accurate data and integrated processes.

The Intelligent Supply Chain Framework is typically organised into three major components:

Together, these elements create a supply chain that can sense changes, evaluate options and act with minimal delay.

The Strategic Pivot: From Cost Efficiency to Resilience.

Historically, supply chains were designed primarily to minimise cost.

Organisations focused on lean inventory, offshore sourcing and transactional efficiency. These strategies reduced expenses but created vulnerability.

When disruptions occurred, whether geopolitical, environmental, or regulatory, supply chains lacked the flexibility to respond quickly.

The Intelligent Supply Chain Framework begins by redefining the purpose of the supply chain.

Instead of treating it as a cost centre, the framework positions the supply chain as a strategic capability that protects continuity, supports compliance and enables competitive advantage.

Traditional Cost‑Centric Approaches.

Modern Resilience‑Centric Approaches.

This strategic shift sets the stage for the technical and operational pillars that follow.

The Five‑Pillar Optimisation Framework.

The Intelligent Supply Chain Framework is built on a hierarchical, five‑pillar model.

Each pillar represents a maturity stage that must be stabilised before progressing to the next.

This ensures that advanced analytics and automation are supported by accurate data and reliable processes.

Pillar 1: Foundational Data Integrity (Single Source of Truth).

This pillar addresses the most common cause of supply chain failure: inconsistent or inaccurate data.

When item masters, supplier records, or bill‑of‑materials structures differ across systems or sites, planning errors and execution delays occur.

Key capabilities include:

Outcomes include:

Without this foundation, higher‑level optimisation cannot function correctly.

Pillar 2: Core Transactional Efficiency (Execution Backbone).

This pillar focuses on the daily operational transactions that drive procurement, production, warehousing and distribution.

Manual processes create delays, errors and information gaps.

The Intelligent Supply Chain Framework requires these processes to be automated and integrated.

Key capabilities include:

Outcomes include:

This pillar ensures that the operational backbone is efficient and reliable.

Pillar 3: Planning and Predictive Analytics (From Forecasting to Foresight).

Traditional planning relies on historical data and fixed assumptions. In volatile markets, this approach is insufficient.

The Intelligent Supply Chain Framework introduces predictive analytics and machine learning to anticipate changes before they occur.

Key capabilities include:

Outcomes include:

This pillar shifts the organisation from reactive planning to predictive foresight.

Pillar 4: Networked Collaboration (Visibility Beyond Borders).

Supply chains extend beyond the organisation. Suppliers, logistics providers, regulators and customers all influence performance.

The Intelligent Supply Chain Framework requires real‑time collaboration across this network.

Key capabilities include:

Outcomes include:

This pillar ensures that external partners operate with shared visibility and coordinated workflows.

Pillar 5: Adaptive Intelligence (ERP as the Cognitive Core).

The final pillar introduces adaptive intelligence, the ability of the system to sense, decide and act with minimal human intervention.

This is where the supply chain becomes truly intelligent.

Key capabilities include:

Outcomes include:

This pillar represents the convergence of ERP flow optimisation and EAM asset‑health optimisation.

Integrative Data Architecture: The Engine Behind Intelligence.

The Intelligent Supply Chain Framework depends on a robust data architecture.

Even the most advanced algorithms cannot compensate for poor data quality.

The phrase “Optimised Garbage In, Optimised Garbage Out” reflects the reality that AI will amplify errors if the underlying data is flawed.

Key architectural requirements include:

Taxonomy Alignment.

A unified language for products, locations and financial dimensions ensures that planning and reporting are consistent across the organisation.

Event‑Driven Architecture.

Static data models are no longer sufficient. Modern supply chains require real‑time signals from:

These signals allow the ERP to update plans immediately when conditions change.

Data Quality Governance.

Leadership must enforce:

Without governance, data quality deteriorates and optimisation efforts fail.

Implementation Strategy: Readiness and Governance.

Transitioning to an intelligent supply chain requires more than technology.

Process alignment, organisational readiness and governance culture determine success.

Key readiness dimensions include:

Common pitfalls include:

A phased rollout with pilot implementations reduces risk and builds confidence.

Measuring Strategic Impact.

The Intelligent Supply Chain Framework delivers value across both quantitative and qualitative dimensions.

Hard metrics include:

Soft metrics include:

Decision velocity acts as a multiplier: faster decisions amplify the value of all other improvements.

The Future State: The Autonomous Enterprise Supply Chain.

The ultimate goal of the Intelligent Supply Chain Framework is an autonomous enterprise where systems sense, decide and act with minimal human intervention.

Emerging pillars include:

ERP–EAM Convergence.

The future supply chain requires a shared data model between ERP (flow optimisation) and EAM (asset‑health optimisation).

Production plans must always reflect asset capability and condition.

Summary.

The Intelligent Supply Chain Framework is a structured, maturity‑based approach for transforming traditional supply chains into resilient, predictive and adaptive networks.

It integrates data integrity, transactional efficiency, predictive analytics, collaboration and adaptive intelligence into a unified architecture.

Supported by strong data governance and phased implementation, the framework enables organisations to navigate volatility, improve operational performance and build long‑term resilience.

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »