Industrial Safety

Industrial safety has always been the defining measure of operational excellence in mining, after all, equipment can be replaced, production can be recovered, but people cannot.

Yet despite enormous investment in safety programs, many operations still rely on manual processes, disconnected systems and inconsistent communication to manage critical safety information.

The result is predictable: delays, blind spots, duplicated effort and preventable incidents.

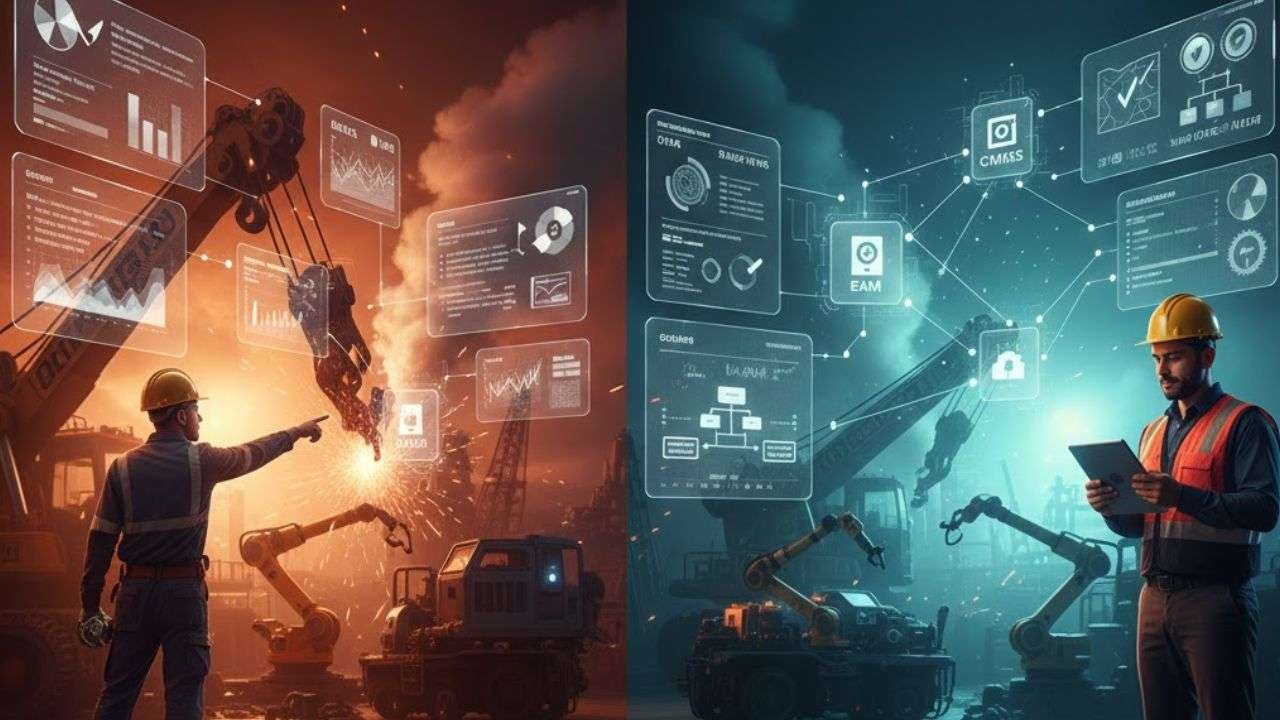

Modern digital systems, CMMS, EAM, ERP platforms, integrated data environments and workflow automation, are transforming this landscape.

They don’t replace safety culture or leadership, but they provide the structure, visibility and reliability that high‑risk environments demand.

When implemented well, they elevate safety from a reactive compliance function to a proactive, intelligence‑driven capability embedded in every operational decision.

This article explores how these systems work together to create a higher standard of industrial safety across the mining value chain.

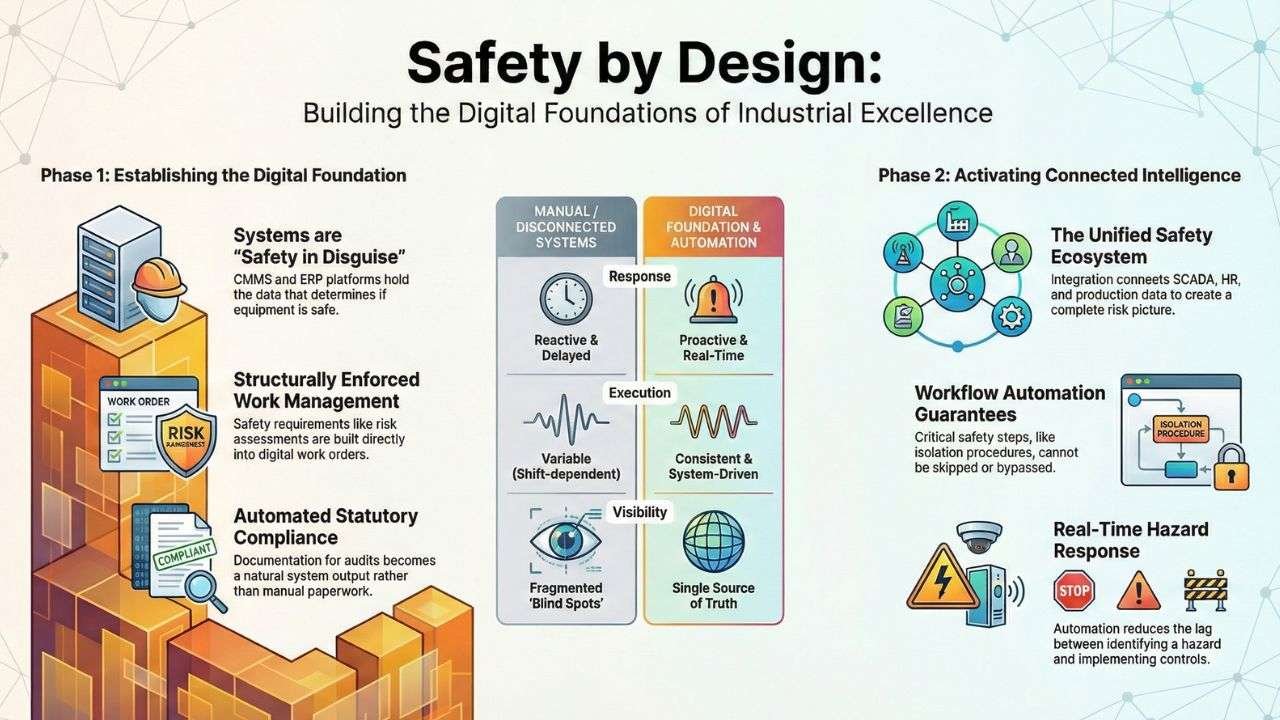

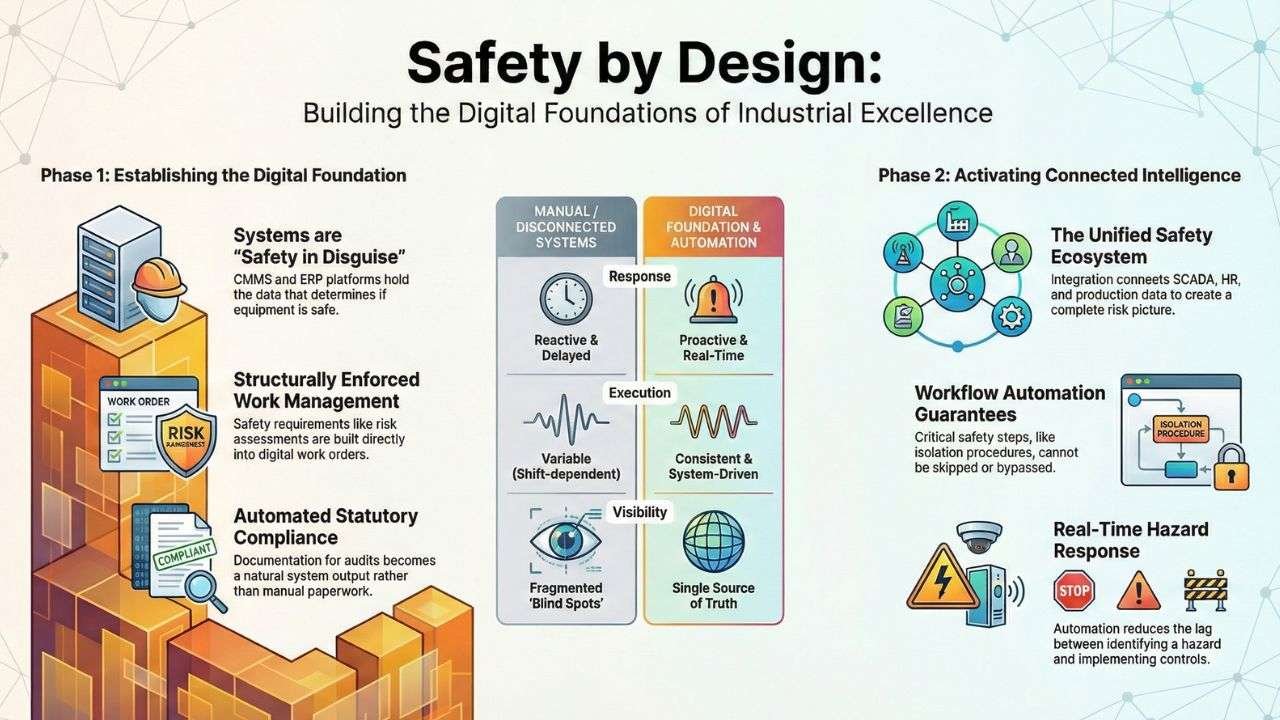

The Foundation: A Quality CMMS, EAM, or ERP System.

A strong safety environment begins with strong operational systems. CMMS, EAM and ERP platforms are often seen as maintenance or business tools, but in reality, they are safety systems in disguise. They hold the data that determines whether equipment is safe to operate, whether inspections are completed, whether hazards are controlled and whether people are working within safe limits.

Ensuring Equipment Reliability and Safe Operation.

Unreliable equipment is one of the most common contributors to safety incidents. A quality CMMS/EAM system:

- Tracks asset condition and failure history.

- Ensures inspections are completed on schedule.

- Manages statutory compliance tasks.

- Flags overdue or high‑risk work.

- Provides visibility into equipment health.

When equipment is maintained consistently and predictably, operators face fewer unexpected failures, fewer emergency repairs and fewer hazardous conditions.

Embedding Safety into Work Management.

Modern CMMS/EAM systems allow safety requirements to be built directly into work processes:

- Mandatory risk assessments before work orders can be released.

- Automated checks for isolation procedures.

- Integration of JHAs, SOPs and permits into job plans.

- Competency verification before assigning tasks.

- Safety-critical steps embedded into digital workflows.

This ensures safety is not an optional add‑on, it is structurally enforced.

Strengthening Compliance and Assurance.

ERP and EAM systems provide the backbone for statutory compliance:

- Tracking of regulated inspections.

- Evidence of maintenance on safety-critical equipment.

- Documentation for audits and investigations.

- Traceability of who approved what and when.

Compliance becomes a natural output of the system, not a scramble to assemble paperwork.

The Power of System Integration in Safety.

A CMMS or ERP alone cannot deliver full safety visibility. Safety is inherently cross‑functional, it touches production, maintenance, HR, environment, training and supply chain. When these systems operate in isolation, safety information becomes fragmented and slow.

System integration changes this by creating a unified safety ecosystem.

Real-Time Hazard Awareness.

When systems are integrated, safety teams gain immediate visibility into emerging risks:

- SCADA detects abnormal operating conditions.

- Condition monitoring identifies early signs of failure.

- Production systems flag bottlenecks or overloads.

- HR systems track fatigue, rosters and competencies.

- Environmental systems detect dust, vibration, or gas exceedances.

Individually, these signals are useful. Integrated, they form a complete risk picture, enabling earlier intervention and more informed decisions.

Eliminating Communication Gaps.

Many incidents occur not because people don’t care, but because information doesn’t flow:

- A hazard identified in the field doesn’t reach maintenance.

- A critical part shortage isn’t communicated to operations.

- A safety alert isn’t linked to affected equipment.

- A contractor’s expired competency isn’t flagged before they start work.

Integration ensures that safety‑critical information moves automatically between systems, without relying on manual handovers.

Linking Safety to Operational Reality.

Safety performance cannot be understood in isolation. Integrated systems allow leaders to correlate safety data with:

- Production pressure.

- Maintenance backlog.

- Equipment utilization.

- Workforce fatigue.

- Environmental conditions.

This reveals patterns that would otherwise remain hidden, such as increased near misses during high‑output periods or rising equipment failures when maintenance is deferred.

Creating a Single Source of Truth.

When safety data is scattered across spreadsheets, emails and standalone tools, leaders cannot trust the information. Integration creates a unified, reliable safety record:

- One version of each incident.

- One version of each inspection.

- One version of each competency.

- One version of each risk control.

This reduces confusion, improves accountability and strengthens decision‑making.

Workflow Automation: Turning Safety Processes Into Safety Guarantees.

If integration connects the data, workflow automation ensures the right actions happen, consistently, promptly and traceably. In mining, where safety depends on timely decisions and strict adherence to process, automation is a game‑changer.

Enforcing Safety Procedures.

Automated workflows ensure that critical steps cannot be skipped:

- Permits cannot be issued until risk assessments are completed.

- Work orders cannot be closed without required inspections.

- Isolation procedures must be confirmed before work begins.

- Incident investigations must follow defined stages.

This removes variability between shifts and supervisors, ensuring safety processes are followed every time.

Accelerating Safety Response.

When hazards emerge, speed matters. Workflow automation:

- Sends instant alerts to supervisors.

- Escalates overdue actions.

- Triggers follow‑up inspections.

- Notifies affected departments.

- Initiates corrective actions automatically.

This reduces the lag between hazard identification and hazard control.

Strengthening Incident Management.

Automated workflows guide teams through the entire incident lifecycle:

- Initial report.

- Immediate controls.

- Root cause analysis.

- Corrective actions.

- Verification of effectiveness.

Every step is timestamped, assigned and tracked, creating a defensible, transparent record.

Enhancing Contractor and Workforce Safety.

Automation ensures that:

- Competencies are verified before access is granted.

- Inductions are completed before work begins.

- Fatigue risks are flagged based on rosters.

- High‑risk work requires mandatory approvals.

This reduces administrative burden while strengthening frontline safety.

Providing a Clear Audit Trail.

Every decision, approval and action is recorded automatically:

- Who approved a permit.

- When a hazard was escalated.

- Which controls were applied.

- How long corrective actions took.

- Whether follow‑up checks were completed.

This level of traceability is invaluable for audits, investigations and continuous improvement.

Seek A Higher Standard of Industrial Safety.

When CMMS/EAM/ERP systems, integration and workflow automation operate together, they create a safety environment that is:

- Proactive: Risks are identified early through real‑time data and predictive insights.

- Consistent: Safety processes are executed the same way every time, regardless of shift or supervisor.

- Transparent: Leaders have full visibility into hazards, controls and compliance.

- Accountable: Every action is assigned, tracked and auditable.

- Connected: Safety is no longer a standalone function, it is embedded in production, maintenance, HR and planning.

- Intelligent: Data is used not just to record incidents, but to prevent them.

This is the future of industrial safety: a system‑driven, intelligence‑enabled, operationally integrated approach that supports, rather than replaces, human judgment and leadership.

Conclusion: Safety as a System, Not a Slogan.

Industrial safety in mining cannot rely on posters, slogans, or good intentions.

It must be engineered into the operation through reliable systems, integrated data and automated workflows that ensure the right actions happen at the right time.

A quality CMMS, EAM, or ERP provides the foundation. System integration provides the visibility. Workflow automation provides the discipline.

Together, they create a safety environment where risks are controlled, decisions are informed and people are protected, not by chance, but by design.