Equipment Reliability

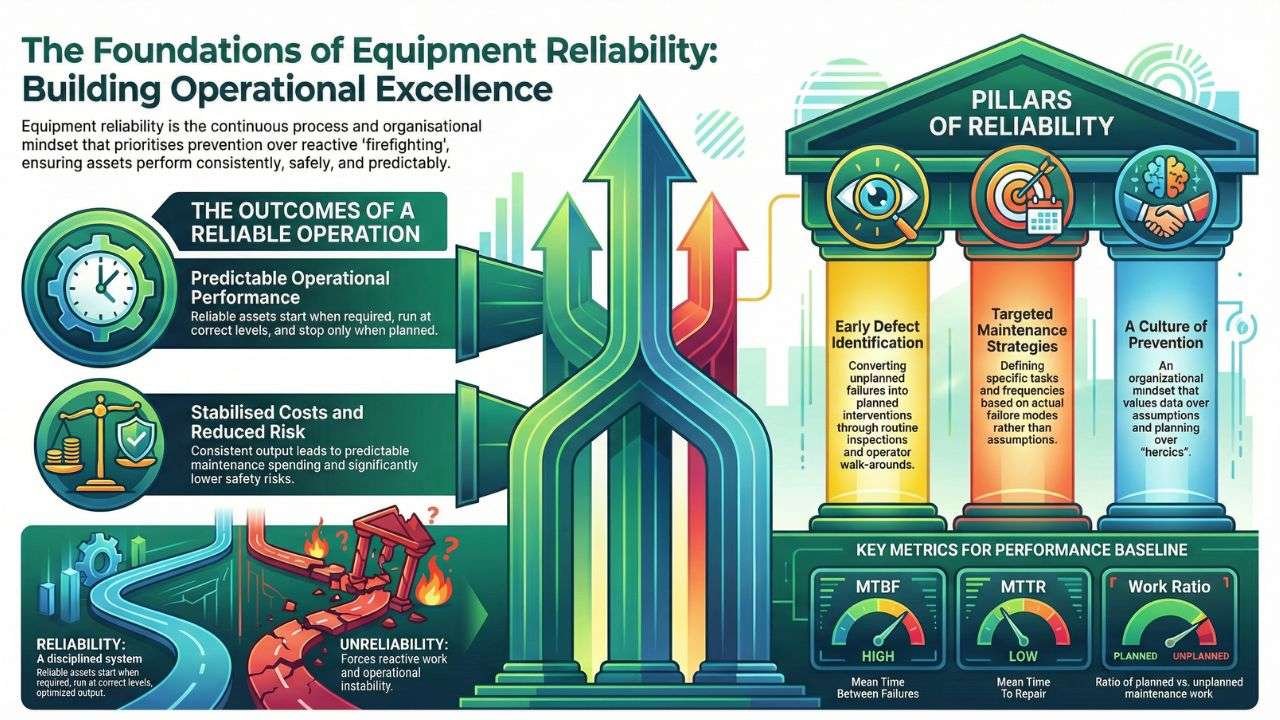

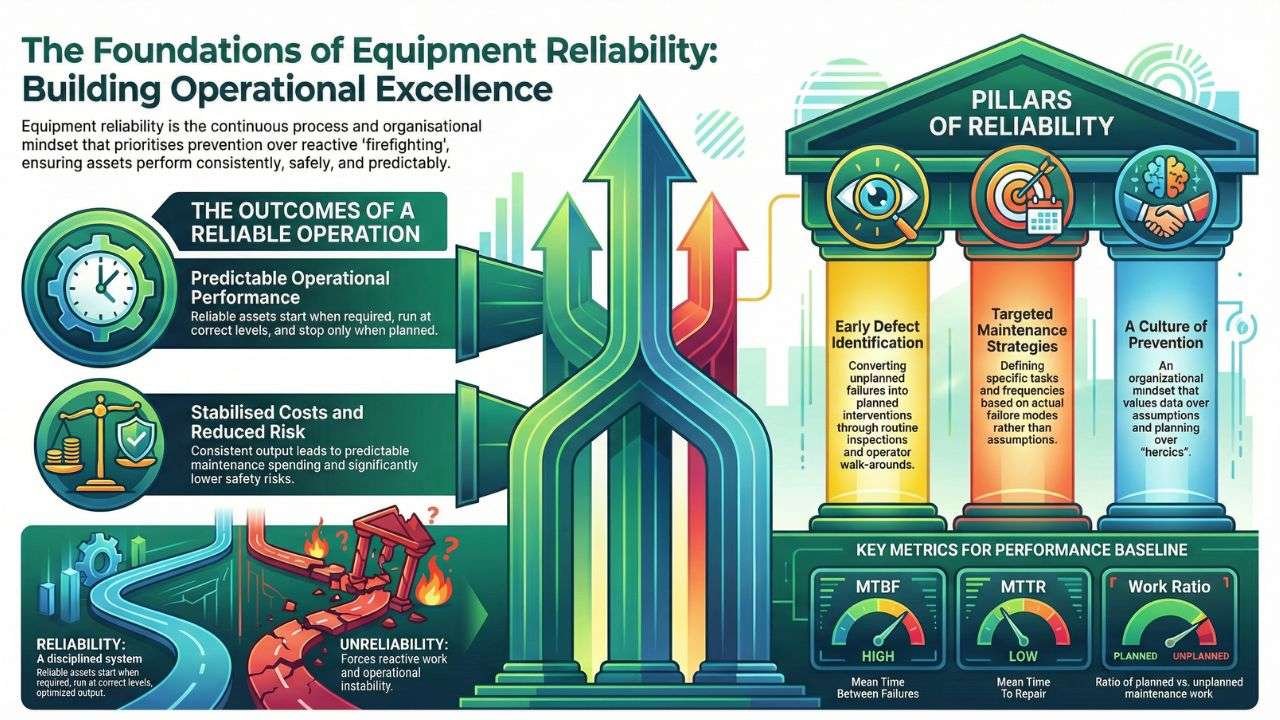

Equipment reliability is the ability of assets to perform their required function consistently, safely and predictably over time.

It is the foundation of stable operations in every industry, whether the asset is an underground haul truck carrying ore through a decline or a high‑speed blow‑moulding machine producing thousands of plastic bottles per hour.

Reliable equipment enables organisations to meet production targets, control costs, protect people and maintain confidence in their operational capability.

At its core, equipment reliability is about predictability. Reliable assets behave as expected. They start when required, run at the correct performance level and stop only when planned.

Unreliable assets behave unpredictably, forcing organisations into reactive work, unplanned downtime and operational instability. The difference between the two is not luck, it is the result of disciplined systems, strong maintenance practices and a culture that values prevention over reaction.

What Does Equipment Reliability Mean?

Equipment reliability means that assets:

- Perform their intended function without unexpected failure.

- Operate within safe and controlled parameters.

- Deliver consistent output at the required quality.

- Require minimal unplanned intervention.

- Support predictable production schedules.

- Maintain performance throughout their expected lifecycle

In practical terms, reliability is the outcome of good design, correct operation, effective maintenance and disciplined management.

It is not a single activity but a continuous process of understanding how equipment fails, preventing those failures and learning from every event.

How Is Equipment Reliability Achieved?

Achieving high equipment reliability requires a coordinated approach across maintenance, operations, engineering, supply chain and leadership.

The most reliable organisations focus on the following pillars:

- Strong Work Identification

Reliability begins with the early detection of defects. Small issues, heat, vibration, leaks, noise, misalignment, contamination, must be identified before they escalate into failures and this is achieved through:

- Routine inspections.

- Operator walk‑arounds.

- Condition monitoring.

- Clear reporting channels.

- Defined defect standards.

Early identification converts unplanned failures into planned interventions.

- High‑Quality Maintenance Strategies

Every asset requires a strategy that defines:

- What tasks must be done.

- How often they must be done.

- What failure modes they prevent.

- What skills, tools and parts are required.

These strategies may include preventive maintenance, predictive tasks, lubrication routines, calibrations, component replacements and condition‑based triggers. A strong strategy ensures maintenance effort is targeted, effective and aligned with actual failure behaviour.

- Effective Planning and Scheduling.

Reliability improves when maintenance work is:

- Properly scoped.

- Supported with the right parts and tools.

- Sequenced logically.

- Assigned to the right people.

- Executed at the right time.

Good planning reduces the duration of downtime. Good scheduling reduces the frequency of downtime. Together, they create a stable, predictable maintenance environment.

- Competent and Engaged Operators.

Operators are the first line of defence. They interact with equipment every day and are best positioned to detect early signs of deterioration. Reliability improves when operators:

- Understand how equipment should sound and behave.

- Know what symptoms to report.

- Avoid misuse and overloading.

- Perform basic checks and care tasks.

A well‑trained operator can prevent more failures than a well‑trained technician can repair.

- Reliable Spare Parts and Supply Chain Support.

Many failures are extended, or made worse, by missing parts, incorrect parts, or long lead times.

A reliable operation ensures:

- Critical spares are available.

- Inventory levels match operational risk.

- Parts are stored correctly.

- Procurement processes support maintenance needs.

A strong supply chain is a reliability enabler, not an administrative function.

- Learning From Failures.

Every failure contains information. High‑reliability organisations:

- Document failures clearly.

- Identify root causes.

- Update maintenance strategies.

- Improve inspections.

- Adjust training.

- Strengthen procedures.

This creates a feedback loop that continuously improves asset performance.

- A Culture That Values Reliability.

Reliability is not a maintenance initiative, it is an organisational mindset. Leaders must reinforce:

- Prevention over reaction.

- Planning over heroics.

- Data over assumptions.

- Collaboration over silos.

Culture determines whether reliability practices are sustained or abandoned under pressure.

What Does Equipment Reliability Typically Look Like?

High equipment reliability is visible, measurable and felt across the organisation. When reliability is strong:

- Assets run consistently with minimal unplanned stoppages.

- Production targets are met without last‑minute recovery efforts.

- Maintenance teams spend most of their time on planned work.

- Operators trust their equipment.

- Safety risks decrease.

- Costs stabilise and become predictable.

- Inventory levels are controlled.

- Stress levels drop across the workforce.

In a plastic bottle plant, this might look like blow‑moulders running at full speed without jams, leaks or temperature faults.

In an underground mine, it might look like loaders and trucks completing their cycles without breakdowns, overheating or hydraulic failures.

The context might change, but the principles remain the same.

What Are The Steps To Attaining Improved Equipment Reliability?

Organisations that want to improve reliability follow a structured path:

Step 1: Establish a Clear Baseline.

Measure current performance using metrics such as:

- Asset availability.

- Mean Time Between Failures (MTBF).

- Mean Time to Repair (MTTR).

- Planned vs unplanned work ratio.

- Defect backlog.

- Downtime hours by asset.

You cannot improve what you do not measure.

Step 2: Strengthen Work Identification.

Improve inspections, operator care and reporting systems. Ensure defects are captured early and consistently.

Step 3: Build or Update Maintenance Strategies.

Develop strategies based on actual failure modes, not assumptions. Use RCM principles where appropriate.

Step 4: Improve Planning and Scheduling Discipline.

Ensure work is planned properly, scheduled realistically and executed with precision.

Step 5: Address Chronic Issues.

Identify assets with recurring failures and eliminate root causes through engineering, redesign, or improved procedures.

Step 6: Build Capability.

Train operators, technicians and planners. Reliability improves when people understand their role in preventing failure.

Step 7: Create a Reliability Culture.

Reinforce behaviours that support long‑term stability. Celebrate prevention, not firefighting.

What Are The Signs That Equipment Reliability Is Not as Good as It Should Be?

Unreliable equipment leaves a trail of symptoms.

Common indicators include:

- Frequent unplanned breakdowns.

- High levels of reactive maintenance.

- Technicians constantly pulled off planned work.

- Operators reporting recurring issues.

- Excessive overtime or emergency callouts.

- Long waits for parts.

- Rising maintenance costs.

- Production targets missed or barely achieved.

- Safety incidents linked to equipment condition.

- Low morale among operators and maintenance teams.

- Large and growing defect backlogs.

- Equipment that never seems to run right.

These symptoms appear in every industry. Whether it’s a moulding machine that keeps jamming or a loader that keeps overheating, the underlying issue is the same: the asset is not being managed in a way that supports reliability.

A Universal Discipline Across All Industries.

Equipment reliability is not industry‑specific. The same principles that keep a mine running safely and efficiently also keep a manufacturing line stable and productive. The assets differ, but the behaviours, systems and disciplines required to maintain them are remarkably consistent.

Reliable equipment is the foundation of operational excellence. It reduces cost, increases output, improves safety and builds confidence across the organisation.

When reliability becomes a shared priority, operations become smoother, people become more effective and the business becomes more resilient.