Downtime Reduction

Downtime reduction is one of the most powerful levers any organisation can pull to improve reliability, productivity, safety and cost performance.

Across industries, from small workshops to refineries, mining operations, manufacturing lines and service-based businesses, downtime directly affects the ability to deliver work, meet customer expectations and maintain profitability.

Reducing downtime is not about eliminating every stoppage. It is about understanding why assets stop, controlling the causes and building systems that keep equipment available, predictable and safe.

At its core, downtime reduction is the discipline of minimising the time assets spend unable to perform their required function.

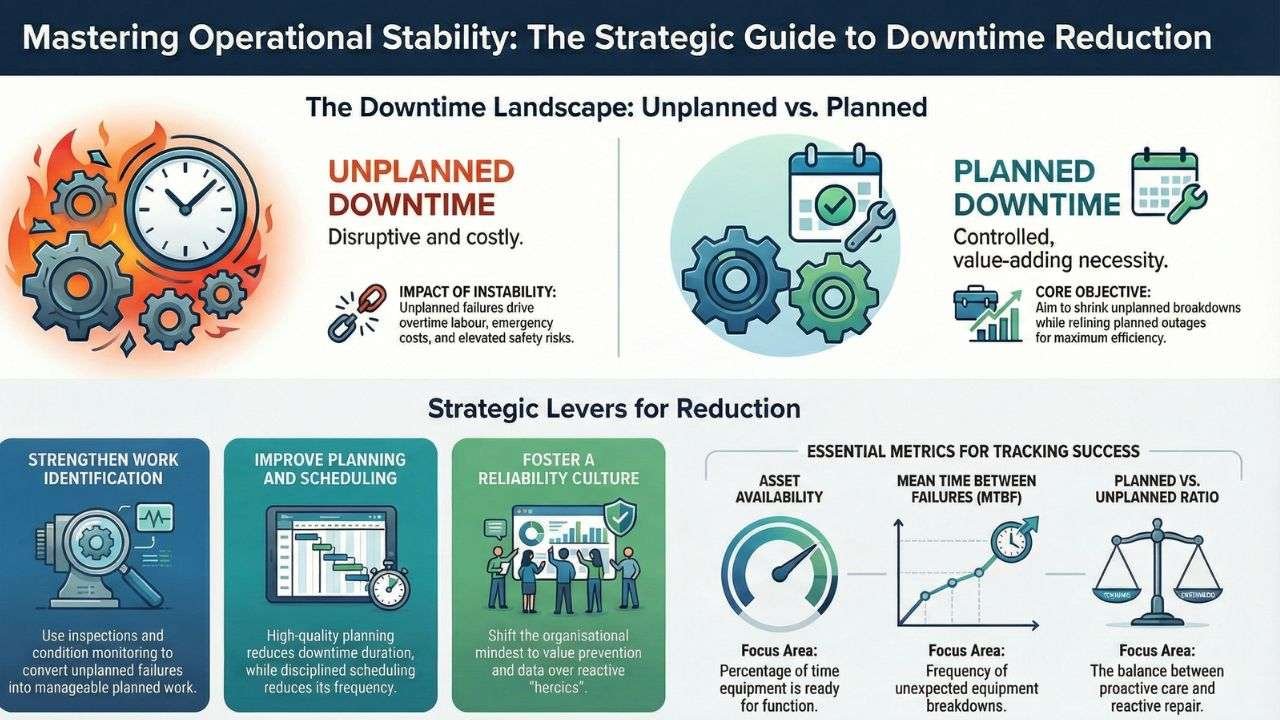

This includes both unplanned downtime (breakdowns, failures, unexpected stoppages) and planned downtime (scheduled maintenance, inspections, changeovers). While unplanned downtime is the most disruptive and costly, both forms must be managed strategically to achieve operational stability.

Importantly, downtime reduction is not a single activity. It is the outcome of coordinated, cross-functional effort spanning maintenance, operations, planning, scheduling, supply chain and leadership.

When an organisation strengthens work identification, improves maintenance strategies, enhances planning and fosters a reliability-focused culture, downtime reduction becomes a long-term competitive advantage.

Understanding the Types of Downtime.

Before downtime can be reduced, organisations must understand the two core forms it takes.

Unplanned Downtime.

Unplanned downtime occurs when an asset fails unexpectedly and can no longer perform its intended function.

Examples include:

- A pump seizing due to lack of lubrication.

- A conveyor belt tearing.

- A vehicle failing to start.

- A circuit breaker tripping repeatedly.

This form of downtime is highly disruptive. It derails schedules, forces reactive work, elevates safety risks and often leads to secondary damage.

It also consumes resources inefficiently, technicians are pulled from planned work, parts may be unavailable and operations may be forced to slow or stop.

Planned Downtime.

Planned downtime is scheduled, controlled and predictable. It includes:

- Preventive maintenance.

- Component replacements.

- Shutdowns and turnarounds.

- Calibration and testing.

Planned downtime is necessary and value-adding when executed well.

The objective is not to eliminate it, but to optimise it so tasks are performed at the right time, with the right scope and with minimal operational disruption.

Effective downtime reduction aims to shrink unplanned downtime and refine planned downtime so it is efficient, coordinated and aligned with operational priorities.

Why Downtime Reduction Matters.

Downtime reduction is more than a maintenance objective. It is a business imperative with measurable impacts across performance, cost and safety.

Productivity and Output.

Every minute an asset is offline reduces production capacity. In asset-intensive industries, even marginal improvements in uptime can translate into significant output gains.

Cost Control.

Unplanned downtime drives:

- Overtime labour.

- Emergency callouts.

- Expedited parts.

- Secondary equipment damage.

- Production losses.

Reducing downtime stabilises maintenance costs and redirects budget from reactive activities to proactive improvement.

Safety and Risk Reduction.

Breakdowns often occur under deteriorating conditions such as heat, vibration or overload, conditions that increase risk.

Stable, predictable equipment reduces exposure to hazardous failure scenarios.

Operational Stability.

Reduced downtime improves:

- Schedule adherence.

- Customer delivery performance.

- Workforce morale.

- Planning accuracy.

- Inventory control.

When assets behave predictably, the entire organisation becomes more stable and efficient.

Asset Life Extension.

Frequent failures accelerate wear. Reducing downtime through better care and earlier intervention extends the life of equipment and delays capital expenditure.

Root Causes of Downtime.

Downtime rarely results from a single cause. It is typically the outcome of multiple systemic weaknesses, including:

- Poor work identification, small issues go unnoticed until they become failures.

- Weak maintenance strategies, inconsistent or inappropriate tasking leads to unpredictable performance.

- Inadequate planning and scheduling, poorly scoped or unsequenced work increases downtime duration.

- Lack of spare parts or tools, waiting for parts extends outages unnecessarily.

- Operator error or misuse, overloading or incorrect operation triggers preventable failures.

- Poor communication between operations and maintenance, symptoms go unreported and asset condition is not shared.

- Reactive culture, firefighting becomes normalised and prevention is neglected.

Understanding these drivers enables organisations to target improvements that address root causes rather than treating symptoms.

Strategies for Reducing Downtime.

High-performing organisations apply a combination of technical, procedural and cultural practices to reduce downtime. The most effective strategies include:

- Strengthen Work Identification.

Early detection is the foundation of downtime reduction. High-performing sites use:

- Routine inspections.

- Operator walk-arounds.

- Basic condition monitoring (temperature, vibration, noise, leaks).

- Clear distinctions between corrective and breakdown work.

Early identification converts unplanned downtime into planned downtime.

- Build High-Quality Maintenance Strategies.

Every maintainable asset requires a strategy that defines:

- Required tasks.

- Appropriate intervals.

- The failure modes those tasks prevent.

- Required skills, parts and tools.

Strong strategies reduce failure likelihood and ensure maintenance is effective.

- Improve Planning and Scheduling.

Planned downtime becomes shorter and more predictable when:

- Work is validated.

- Scope is clear.

- Parts are available.

- Labour is coordinated.

- Tasks are logically sequenced.

Good planning reduces downtime duration; good scheduling reduces downtime frequency.

- Implement Basic Condition Monitoring.

Advanced sensors are helpful but not essential. Many failures can be prevented through simple checks, heat, vibration, noise, smell and pressure, supported by operator feedback and photographic evidence.

- Strengthen Spare Parts Management.

A well-managed inventory ensures critical spares are readily available and non-critical items are procured proactively. Many downtime events are extended unnecessarily due to missing parts.

- Improve Operator Training.

Operators are the first line of defence. When they understand:

- How assets should sound and behave.

- What symptoms to report.

- How to avoid misuse.

- How to conduct basic checks.

Downtime decreases significantly.

- Analyse Failures and Learn From Them.

Every failure is a source of insight. High-performing organisations:

- Document failures.

- Identify root causes.

- Update strategies.

- Improve inspections.

- Adjust training.

This creates a feedback loop that continuously reduces downtime.

- Foster a Reliability-Focused Culture.

Downtime reduction is not a maintenance initiative. It is an organisational mindset. Leaders must value:

- Prevention over reaction.

- Planning over heroics.

- Data over assumptions.

- Collaboration over silos.

Culture determines whether improvement efforts stick or fade.

Measuring Downtime Reduction.

You cannot improve what you do not measure. Key metrics include:

- Asset availability, percentage of time equipment can perform its required function.

- Mean Time Between Failures (MTBF), higher MTBF indicates fewer failures.

- Mean Time to Repair (MTTR), lower MTTR means issues are resolved faster.

- Planned vs unplanned work ratio, a high ratio reflects a proactive maintenance environment.

- Schedule compliance, measures execution discipline.

- Downtime hours by asset, identifies chronic offenders.

These metrics enable organisations to track progress, pinpoint weaknesses and drive continuous improvement.

The Business Case for Downtime Reduction.

The benefits of downtime reduction compound over time and include:

- More predictable operations.

- Lower maintenance costs.

- Higher asset availability.

- Improved safety outcomes.

- Better customer service.

- Reduced stress on staff.

- Longer asset life.

For small businesses, downtime reduction often separates survival from success. For larger operations, it becomes a strategic advantage that boosts competitiveness and profitability.

Downtime Reduction as a Continuous Improvement Journey.

Downtime reduction is not a one-off project. It is a continuous improvement journey that evolves as assets age, operations grow and technology advances. Organisations that excel are those that:

- Review their strategies regularly.

- Learn from failures.

- Invest in training.

- Maintain discipline in planning and scheduling.

- Use data to guide decisions.

- Encourage collaboration between operations and maintenance.

Over time, downtime becomes more predictable, more controllable and far less disruptive, enabling a safer, more stable and more profitable operation.