Supply Chain Optimization ERP Functionality

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »

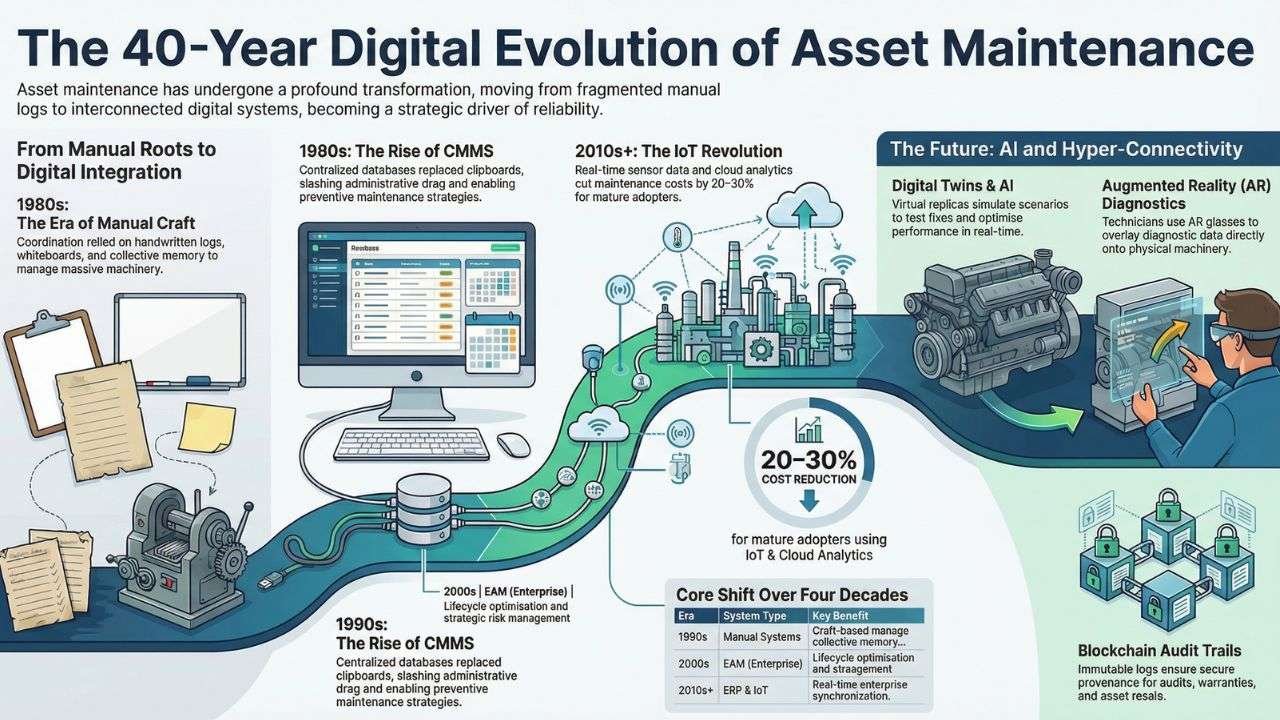

Over the past four decades, asset maintenance management has undergone a profound digital transformation, evolving from fragmented, manual processes into interconnected digital ecosystems that predict failures, optimize lifecycles and drive strategic decisions.

This shift has reshaped maintenance culture, raising expectations for precision, efficiency and data-driven insights across mining, manufacturing, utilities, oil & gas and other asset-intensive sectors.

While core craft skills remain timeless, the digital revolution has unlocked unprecedented scale and reliability.

Early Manual Practices in Mining Maintenance.

Forty years ago, mining maintenance delivered high-quality outcomes through disciplined, hands-on expertise, despite lacking modern digital tools.

Preventive maintenance (PM) routines were religiously followed, condition monitoring via vibration checks, oil analysis and thermography was standard on critical fixed and mobile plant and breakdowns triggered rapid, 24/7 responses from tradespeople with intimate plant knowledge.

Coordination relied on analog methods: parts ordered by phone or fax from suppliers, shift handovers via handwritten logs and job cards, status updates on chalkboards or whiteboards and troubleshooting fueled by conversations and local knowledge.

Work orders, spare parts inventories and equipment histories lived in physical folders, pigeonholes, filing cabinets and crucially, the collective memory of the team. These teams routinely stripped down, repaired and rebuilt massive mining machines, shovels, drills, crushers, to OEM-equivalent standards under tight deadlines, matching today’s rebuild quality.

Special technical instructions, oil analysis reports and other technical information from OEMS, laboratories and technical companies were received via mail and were usually managed very well.

The real constraints were time-intensive processes: meticulous note-taking, cross-referencing files and long hours chasing paper trails.

As assets grew larger, more automated and complex, manual systems strained under the volume, paving the way for digital evolution.

Dawn of Computerized Maintenance Management Systems (CMMS).

The 1980s-1990s introduced CMMS as the first digital bridge from paper systems. Early platforms digitized work orders, PM schedules, asset registers and spares tracking, replacing clipboards with central databases.

On-premises installations demanded IT overhead but slashed administrative drag, enabling reactive teams to shift toward preventive strategies.

Maturing features, automated PM triggers, asset hierarchies, cost capture and rudimentary dashboards, boosted visibility.

Planners were able to sequence jobs more efficiently, compliance reporting became far easier and leaders finally had access to meaningful performance metrics.

Downtime began to decline and assets appeared to last longer, although it’s difficult to attribute this solely to the introduction of CMMS software.

Some of the improvement undoubtedly came from the evolution of the assets themselves. What did change decisively was the role of maintenance: it shifted from a perceived cost centre to a genuine reliability enabler.

These early systems demonstrated the strategic value of data and laid the groundwork for broader digital integration across the organisation.

Enterprise Asset Management (EAM): Holistic Lifecycle Optimisation.

By the 2000s, CMMS limitations surfaced amid expanding asset portfolios.

EAM emerged to orchestrate the full lifecycle, acquisition, commissioning, operations, maintenance, decommissioning, beyond mere work execution.

Integrating with finance, procurement, engineering and reliability, EAM embedded reliability-centered maintenance (RCM), risk-based inspections, lifecycle costing and advanced analytics.

This mindset pivot elevated maintenance as a profit driver.

Cross-functional teams shared a “single source of truth,” curbing silos, errors and duplicated effort.

Capital planning aligned with ops; regulatory demands streamlined.

Modern EAM’s mobility and cloud roots further empowered field access, cementing its role in operational excellence.

ERP Integration: Enterprise-Wide Synchronization.

ERP systems now fuse CMMS/EAM with finance, HR, supply chain and ops for seamless data flows.

A planner’s overhaul schedule auto-triggers procurement, budget checks and inventory adjustments, eliminating silos and lag.

Operations sync shutdowns with production; finance tracks costs live; procurement optimizes spares.

This unification yields holistic dashboards: asset health, capex forecasts, ROI projections.

In mining, it coordinates fleet utilization with pit plans, slashing unplanned stops. ERP’s backbone ensures maintenance fuels, not fights, business goals.

Key Technological Accelerators.

IoT sensors revolutionized monitoring, streaming vibration, temperature and wear data into platforms for predictive alerts, averting failures pre-symptom.

Cloud deployments cut infrastructure costs, auto-scale and enable remote/global access. Mobile apps let technicians update jobs, scan histories and log photos on-site, closing the field-office loop.

Real-time analytics sift petabytes for failure precursors, prescribing optimal interventions.

From reactive “run-to-fail” to prescriptive “fix-before-break,” these tools compound uptime, slashing costs 20-30% in mature adopters.

| Evolution Milestone | Core Shift | Key Gains |

| Manual (1980s) | Paper/logs/whiteboards | Craft reliability, but slow coordination |

| CMMS (1990s) | Digital work orders/PM | Visibility, reduced admin |

| EAM (2000s) | Lifecycle/RCM integration | Strategic alignment, risk mgmt |

| ERP+IoT (2010s+) | Real-time enterprise sync | Predictive, cross-dept optimization |

Future Horizons: AI, Twins and Beyond.

Tomorrow’s platforms will pulse with AI: self-learning models refining predictions from fleet-wide data, auto-prioritizing jobs amid constraints.

Digital twins, virtual asset replicas, will simulate scenarios, test fixes virtually and optimize in real-time.

Blockchain secures provenance: immutable logs for audits, warranties, resale. Edge computing processes IoT at-source for instant decisions.

Augmented reality overlays diagnostics on machinery via glasses. Interoperable APIs will weave CMMS/EAM/ERP into “asset operating systems,” hyper-personalized per site.

Overcoming Implementation Hurdles.

Cyber threats loom large in connected ecosystems, IoT vulnerabilities, cloud breaches demand zero-trust architectures, encryption and AI threat-hunting.

Change management tackles ingrained habits: phased pilots, role-based training, quick wins build buy-in. Leadership must evangelize ROI, tying digital maturity to KPIs like MTBF and cost-per-tonne.

Legacy data cleansing and integration roadmaps prevent “garbage-in, garbage-out.” Vendor-agnostic standards ensure flexibility.

Strategic Imperative for Asset Leaders.

Digital transformation isn’t optional, it’s now part of how we work and live.

In Australian mining, where remoteness amplifies downtime pain, CMMS/EAM/ERP solutions being utilized to their fullest are what helps keep operations optimal and costs under control.

Forward-thinking, digital transformation embracing teams will almost certainly thrive the most.

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »

Maintenance Business Process Mapping & Software. Disclaimer. This article provides general information about maintenance process mapping and software tools based

Maintenance Business Process Mapping Software Tools Read More »

Purchase Asset Management Software Solutions Asset management software is essential for businesses in the manufacturing, commodity extraction, material processing, and

Purchasing Asset Management Software Read More »

SAP Cross Application Time Sheet (CATS). The SAP Cross-Application Time Sheet (CATS) is a vital component of the SAP ERP

SAP Cross Application Time Sheet Solution Read More »

The Dream Of Designing The Ultimate Asset Management Software Product. Asset management software is one of the most significant investments

Designing The Ultimate Asset Management Software Product Read More »

Interfacing Disparate Systems Data With Your CMMS Via AVEVA PI. Interfacing disparate systems across your organization with a Computerised Maintenance

Interface Disparate Systems Data With A CMMS Via AVEVA PI Read More »

The Intriguing History and Success of LinkOne EPC. What we now know and enjoy as LinkOne Software began as a

LinkOne Electronic Parts Catalogue Read More »

Oracle E-Business Suite-IBM’s Maximo Suite and Hitachi’s Ellipse. Streamlining business processes for enhanced efficiency and effectiveness is entirely possible via

Oracle-Maximo-Ellipse software Read More »

Computers Powering Australian Businesses. Disclaimer. This article is provided for general informational purposes only. It does not constitute financial, legal,

Computers Powering Australia Read More »

Will AI improve Asset Management Software? Profitability depends on a number of variables, including the size and grade of the

Will AI Make Asset Management Better Read More »