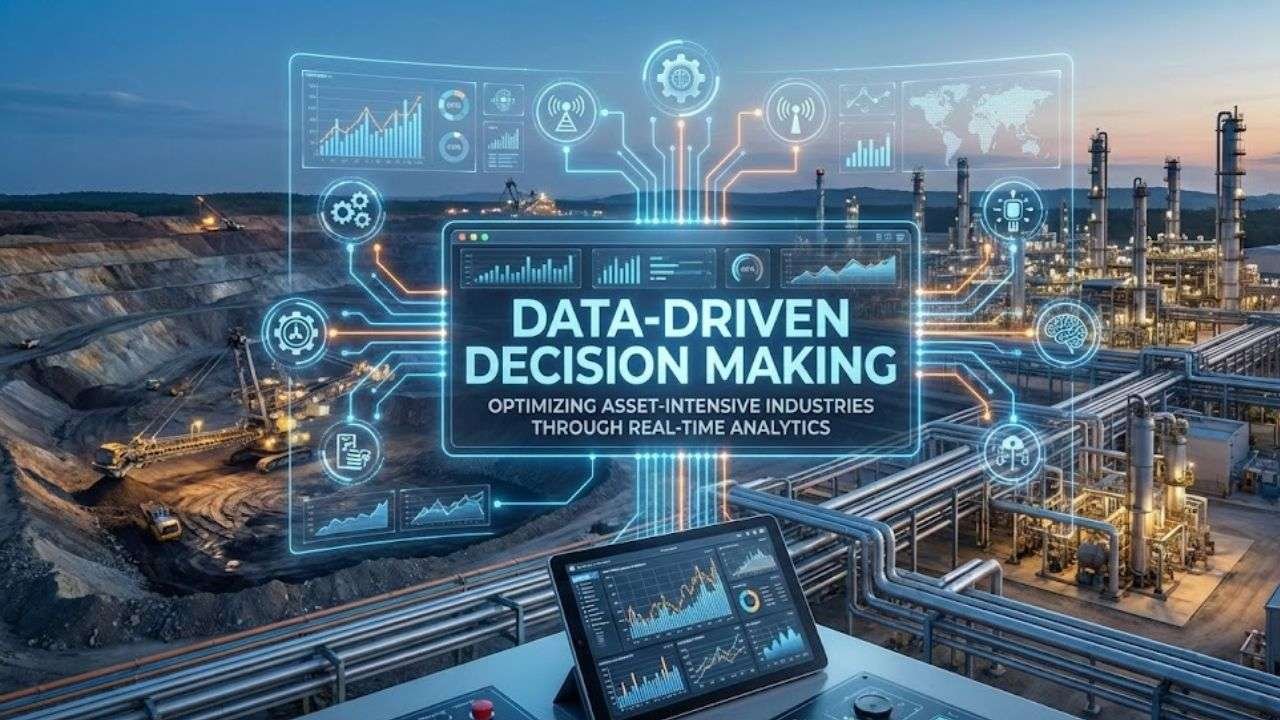

Data Driven Decision Making

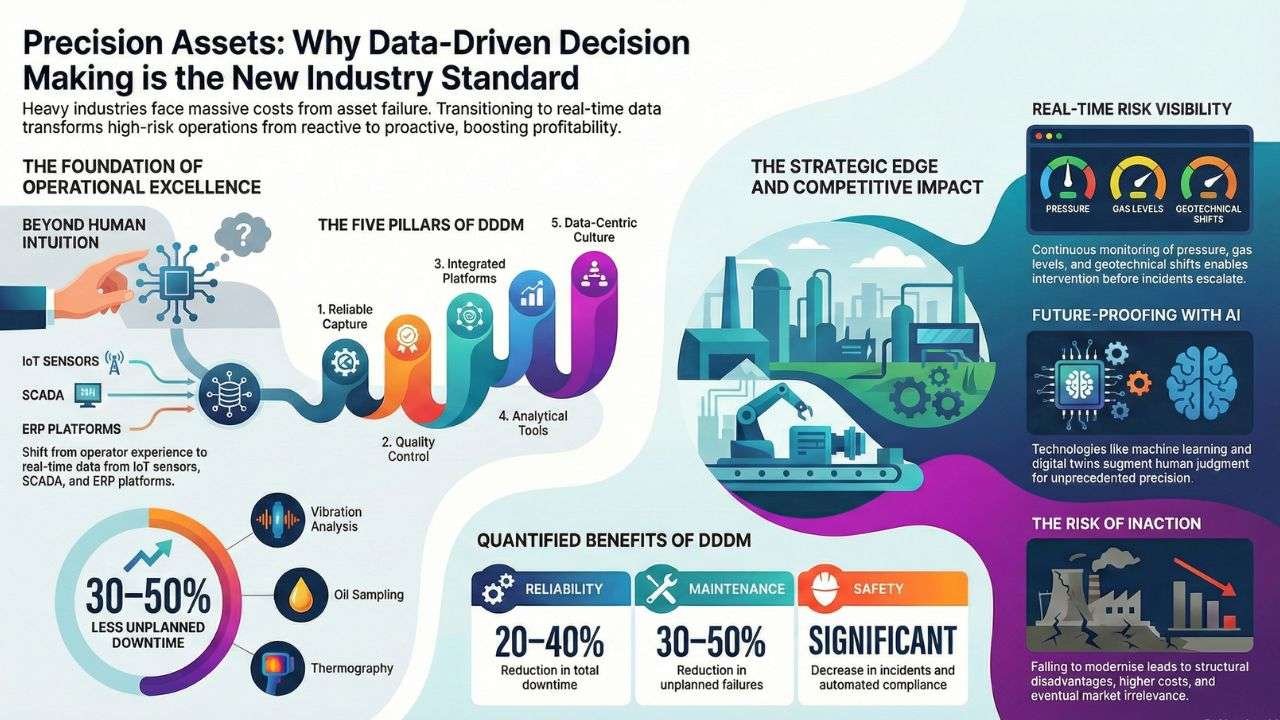

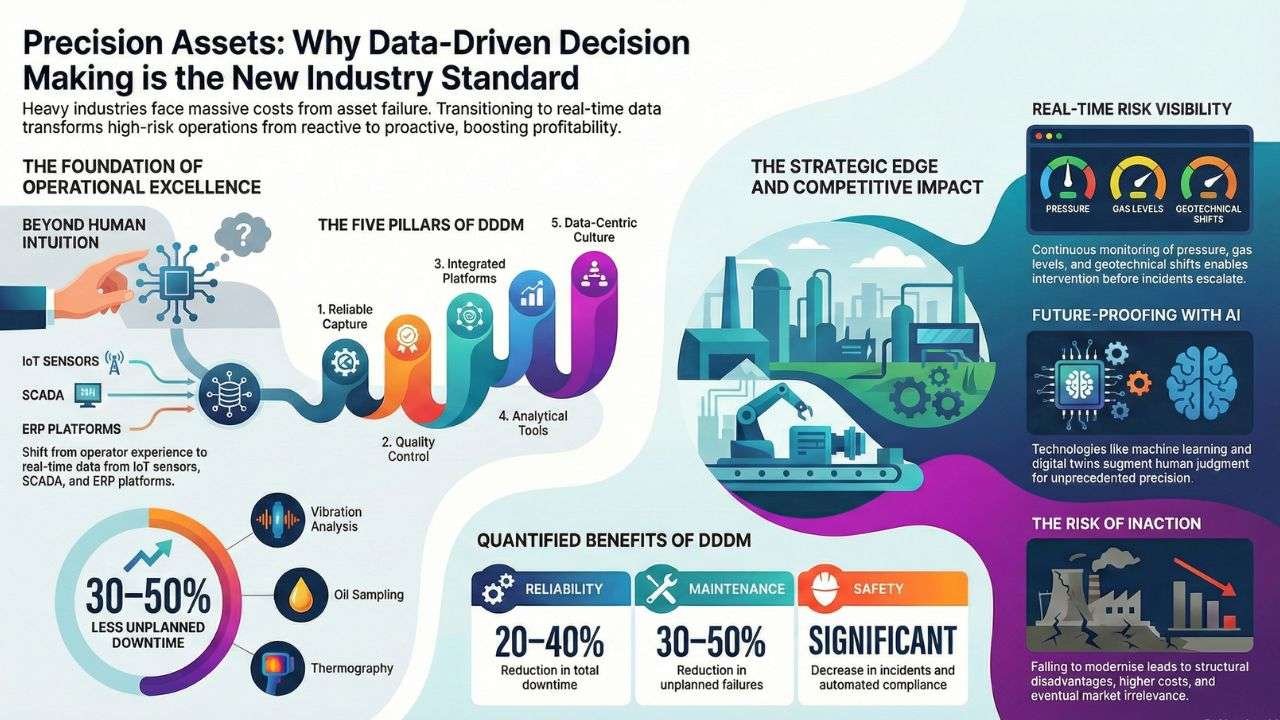

Data-driven decision making (DDDM) marks a fundamental shift in how asset-intensive industries like mining, oil & gas, utilities and manufacturing operate.

It replaces intuition with real-time data from IoT sensors, SCADA systems and ERP platforms to optimize maintenance, reduce risk and drive profitability.

Why DDDM Is Essential in High-Risk Sectors.

Heavy industry faces unique challenges: massive assets, catastrophic failure modes and downtime costing hundreds of thousands per hour.

Data delivers visibility human observation can’t match, detecting early degradation, predicting failures and balancing cost with reliability.

Unlike past reliance on experienced operators’ intuition, modern complexity demands DDDM.

Instrumented assets generate data volumes no team can process manually, making predictive analytics the only path to operational excellence.

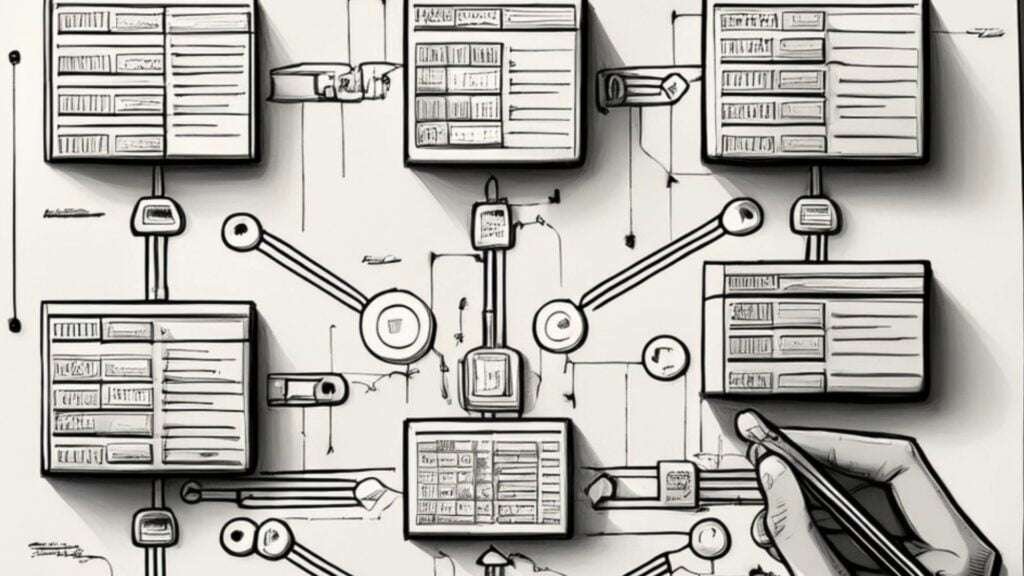

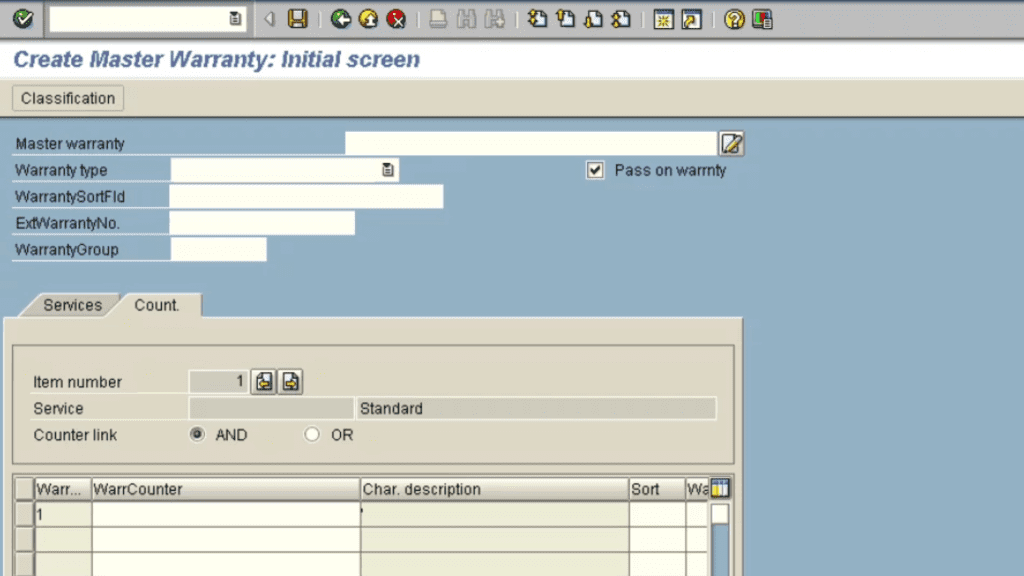

Core Foundations of Effective DDDM.

DDDM requires these interconnected elements:

- Reliable data capture from sensors, work orders and operational systems.

- Quality controls ensuring accuracy, consistency and completeness.

- Integrated platforms linking CMMS, EAM, ERP, SCADA and IoT.

- Analytical tools turning raw data into actionable insights.

- Data-centric culture prioritizing evidence over habit.

When aligned, these enable faster, precise decisions grounded in operational reality.

Predictive and Condition-Based Maintenance.

IoT vibration analysis, oil sampling and thermography predict failures, slashing unplanned downtime by 30-50% in leading operations.

Schedule interventions optimally to extend asset life and cut costs.

Optimized Work Management.

Asset histories and failure data streamline planning:

- Sequence tasks efficiently.

- Allocate labor based on demand.

- Eliminate recurring issues via refined job plans.

This boosts wrench time and skilled labor utilization.

Inventory Precision.

Consumption patterns, lead times and criticality analysis optimize spares:

- Right stock levels.

- Automated reorder points.

- Reliable supplier selection.

Result: Fewer stockouts, less tied-up capital.

Embedding Risk Management in Operations.

Real-time SCADA and environmental data provide continuous risk visibility, pressure anomalies, gas levels, geotechnical shifts. Operators intervene before incidents escalate.

Post-failure, data fuels root cause analysis for permanent fixes.

Automated compliance reporting ensures audit-ready proof of standards adherence, easing regulatory pressure.

Strategic Impacts Beyond Daily Operations.

DDDM elevates capital planning:

- Proactive asset replacement or refurbishment.

- Risk-prioritized investments yielding maximum ROI.

Production optimization uncovers bottlenecks and energy waste.

Workforce data reveals skill gaps for targeted training and contractor strategies.

Overcoming Cultural Barriers.

In craftsmanship-driven industries, resistance to data is common, distrust, automation fears, tool unfamiliarity.

Address via:

- Transparent communication of benefits.

- Hands-on training.

- Leadership modeling data use.

Done right, DDDM empowers workers with superior tools, predictable workloads and enhanced safety.

The Next Frontier: AI and Beyond.

Emerging tech accelerates DDDM:

- AI predictive analytics.

- Machine learning for maintenance.

- Digital twins for simulation.

- Autonomous drones for inspections.

These augment, not replace, human judgment, delivering unprecedented precision.

Why DDDM Is A Competitive Imperative.

Adopters could reasonably achieve:

| Benefit |

Impact |

| Reliability |

20-40% less downtime. |

| Safety |

Fewer incidents, stronger compliance. |

| Costs |

Optimized maintenance & inventory. |

| Profitability |

Proactive capital allocation. |

Laggards risk obsolescence.

In heavy industry, that isn’t a dramatic statement, it’s a practical one.

The companies that fail to modernise their maintenance, operations and decision‑making frameworks are not simply “behind”; they are at risk of being structurally disadvantaged.

Their costs could end up being higher, their risks greater, their downtime longer and their ability to compete could erode year after year.

In an environment where margins are tight, assets are complex and regulatory pressure is increasing, falling behind is not a temporary inconvenience. It is a trajectory toward irrelevance.

Data isn’t information and it certainly isn’t noise. It is your strategic edge.

In high‑risk, asset‑intensive sectors, data is the only way to see what the human eye cannot, anticipate what experience alone cannot predict and manage complexity at a scale no manual system can handle.

The organisations that treat data as a core asset, not a by‑product, gain advantages that compound over time.

They make faster decisions, more accurate decisions and safer decisions.

They understand their assets better, deploy their people more effectively and invest capital where it delivers the greatest return.

Data becomes the differentiator between companies that operate with confidence and those that operate with hope.

Between those who prevent failures and those who react to them.

Between those who optimise asset life and those who burn through it.

Between those who can demonstrate compliance instantly and those who scramble to reconstruct records.

Between those who can forecast risk and those who are blindsided by it.

In heavy industry, where the cost of a single bad decision can reach into the millions and where the cost of a systemic pattern of bad decisions can threaten the viability of an entire operation, data is not optional.

It is the foundation of modern reliability, modern safety and modern competitiveness.

The companies that embrace data‑driven decision making are building a future‑proof operating model. The companies that don’t risk falling behind, even if they can’t see it yet.