Asset Optimization

Asset optimization represents the disciplined practice of maximizing the operational and financial contribution of an organization’s critical infrastructure throughout its entire lifecycle.

Rather than treating equipment as static cost centres, modern asset-intensive industries, particularly mining, refining, power generation, gas processing and smelting, now recognize assets as intelligent, interconnected value generators whose performance, reliability and longevity can be systematically enhanced.

At its core, asset optimization aligns every physical and digital resource, processing lines, rotating machinery, control systems, IoT networks and field technologies, with enterprise-wide performance objectives: stable throughput, predictable reliability, zero-harm safety culture, regulatory compliance and long-term competitive advantage.

Industry benchmarks suggest that organizations implementing mature optimization practices achieve 15-25% improvements in equipment availability, 20-30% reductions in maintenance costs and 5-7 year extensions in asset service life, translating directly to higher productive output and substantially reduced capital strain.

The Persistent Challenge.

Despite massive capital investments in specialized asset fleets, most industrial organizations continue to face significant obstacles.

Fragmented data ecosystems leave production systems, maintenance records, condition monitoring and financial data siloed across incompatible platforms.

Reactive maintenance paradigms persist, with 40-50% of maintenance work remaining unplanned and triggered by failures rather than intelligence.

Organizations lack real-time insight into actual asset condition, utilization, degradation trends, or remaining useful life.

Meanwhile, increasing regulatory demands for emissions tracking, safety reporting and predictive risk management compound these challenges, while an aging workforce and difficulty recruiting specialized maintenance technicians strain operational capacity.

The financial impact is substantial. Organizations lacking integrated optimization frameworks lose 10-15% of productive capacity annually through preventable failures, inefficient scheduling, redundant interventions and capital misallocation.

Asset optimization directly counters these issues by ensuring assets are continuously assessed using accurate condition and performance data, serviced proactively based on predictive indicators rather than breakdowns and managed in alignment with safety, production and financial objectives.

The Modern Asset Optimization Framework.

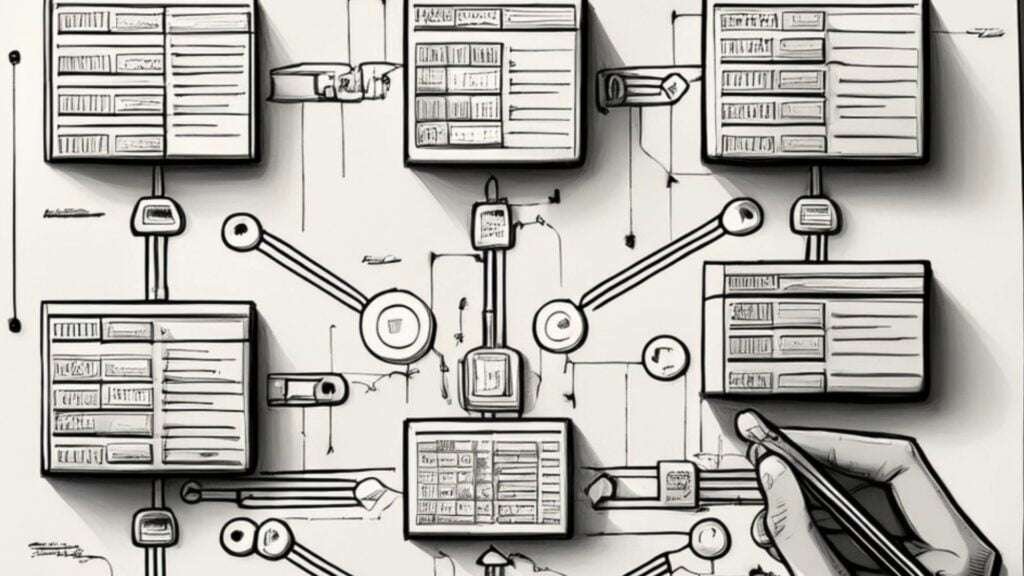

A comprehensive asset optimization program integrates six interconnected capabilities. First, a unified data foundation consolidates real-time condition monitoring through IoT sensors, vibration analysis, thermography and SCADA integration, feeding live asset health data into a centralized system.

This foundation includes historical analytics repositories and complete digital twins of all equipment with standardized naming, criticality classification and lifecycle stage tracking.

Second, predictive and preventive intelligence deploys advanced diagnostics using machine learning algorithms to identify emerging degradation patterns weeks or months ahead of failure.

These systems provide failure mode prediction with probability-based forecasting and confidence intervals, optimize maintenance schedules balancing preventive interventions with production demands and dynamically prioritize work orders based on failure likelihood, business impact and safety criticality.

Third, integrated work management provides a unified platform serving as the single source of truth for all maintenance activities.

Mobile-first execution enables technicians to access real-time work instructions, historical context and parts availability while capturing work evidence directly from the field.

The system orchestrates complex maintenance campaigns involving multiple teams, coordinates shutdowns to minimize production disruption and matches technician skills and certifications to work demands through intelligent scheduling.

Fourth, lifecycle and capital planning capabilities forecast remaining useful life to inform retirement decisions and capital budget planning.

The system drives spare parts optimization strategies, provides visual clarity on fleet composition and equipment age distribution and tracks total cost of ownership across acquisition, maintenance, energy and disposal phases to enable accurate equipment replacement ROI analysis.

Fifth, safety, compliance and sustainability features maintain complete auditable maintenance records for regulatory bodies, embed lockout-tagout workflows and confined space protocols in work processes, track environmental impact including carbon footprint and emissions and link safety events to maintenance data for root cause analysis and systemic improvement.

Sixth, cross-functional visibility and decision support provide executive dashboards with real-time KPIs including overall equipment effectiveness, mean time between failures, maintenance cost percentage and safety incidents.

Integration between maintenance systems and enterprise resource planning ensures maintenance schedules align with production planning and demand forecasting, while financial accountability through variance tracking drives cost discipline.

The Critical Role of Modern CMMS Platforms.

A high-quality Computerized Maintenance Management System (CMMS) is no longer a static work order system, it is the operational intelligence hub that makes asset optimization possible.

Modern CMMS platforms serve as the single source of truth, consolidating all maintenance work history, asset specifications, sensor data feeds, spare parts management, labour allocation, compliance records and financial tracking.

This unified data eliminates blind spots and enables accurate predictive modelling.

The CMMS enables predictive analytics by training machine learning models on accumulated historical data, comparing live sensor streams against learned baselines to flag deviations before failure and continuously refining predictive accuracy with each maintenance event.

For work orchestration and risk management, CMMS algorithms balance competing demands, provide prescriptive guidance preventing common errors, ensure high-impact work receives resources first and manage complex shutdown campaigns.

For regulatory and compliance assurance, the CMMS maintains audit-ready documentation, automates alerts for expiring certifications and inspection intervals, correlates safety events with maintenance history and updates work processes to reflect new regulatory standards.

In capital and financial optimization, the system provides data-driven replacement decisions, reduces inventory carrying costs through predictive insights, measures technician utilization and productivity and enables real-time budget variance management.

The CMMS empowers the workforce by equipping technicians with historical context and best practices, standardizing work procedures, identifying training needs through performance analytics and preserving institutional knowledge.

Strategic Outcomes and Competitive Imperative.

When asset optimization is executed with a robust CMMS platform, organizations place themselves in a good position to achieve improvements:

- 15-25% increases in equipment availability through fewer unplanned outages.

- 20-30% reductions in maintenance costs via optimized scheduling.

- 5-7 year extensions in asset service life through proactive condition management.

- 40-60% reductions in maintenance-related safety incidents.

- 95%+ first-pass compliance rates.

- 15-20% decreases in capital expenditure through deferred replacement.

- 5-15% improvements in energy efficiency.

- 25-40% gains in technician productivity.

In today’s industrial landscape, asset optimization powered by an advanced CMMS is not optional, it is the foundation of operational resilience and profitability.

Organizations that combine disciplined asset governance with intelligent CMMS platforms unlock hidden productive capacity, reduce uncertainty, strengthen safety outcomes and build competitive advantages that are difficult for rivals to replicate.

The organizations winning in capital-intensive industries have transformed their maintenance functions from cost centres into intelligence-driven value centres, where every maintenance decision is informed by data, every asset’s potential is systematically realized and every dollar of maintenance spending is optimized for enterprise benefit.

Your CMMS is not just a maintenance scheduling tool, it is your operating system for asset excellence.