Asset Lifecycle Management

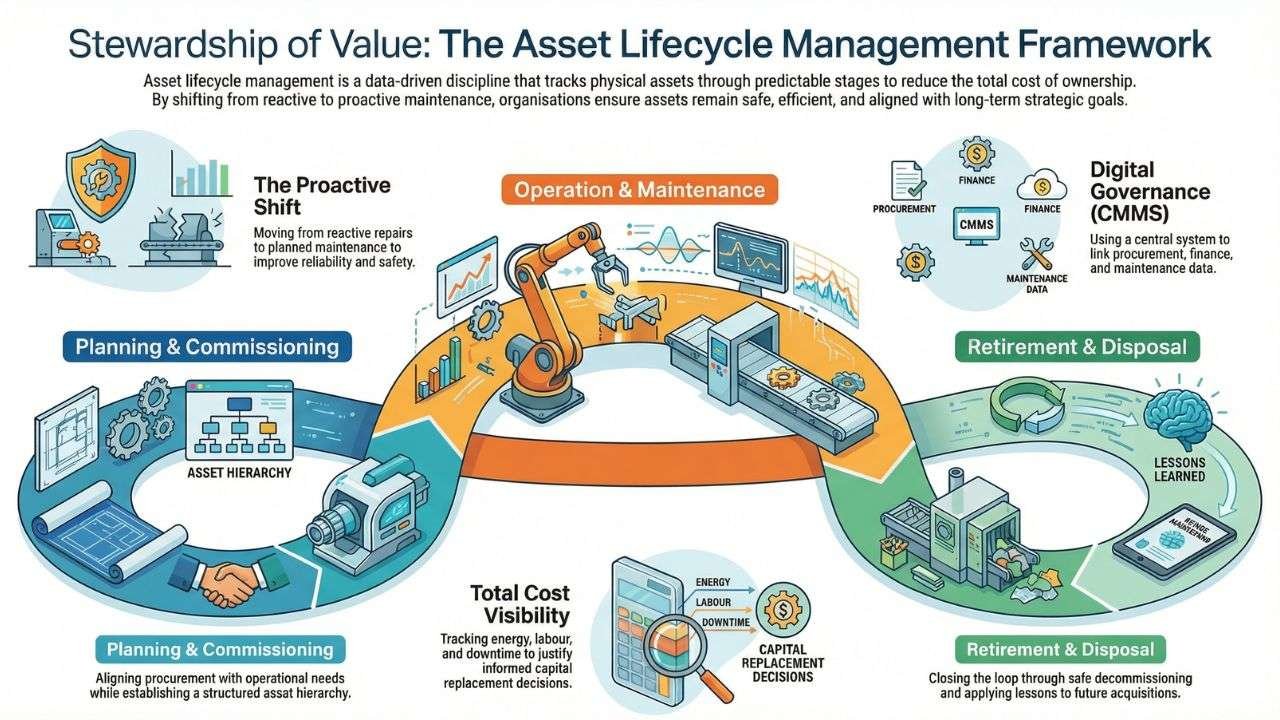

Asset lifecycle management is the discipline of managing physical assets from the moment an organisation decides to acquire them until the point they are retired, disposed of or replaced.

It is a structured, evidence‑based approach that ensures assets deliver maximum value, operate safely and support organisational objectives throughout their entire lifespan.

In modern maintenance and operations environments, asset lifecycle management is not a theoretical concept but a practical framework that guides procurement, maintenance, budgeting, risk management and long‑term planning.

At its core, asset lifecycle management recognises that every asset passes through predictable stages: planning, acquisition, commissioning, operation, maintenance, optimisation and end‑of‑life.

Each stage presents opportunities to influence cost, reliability and performance. Organisations that manage these stages deliberately and consistently achieve lower total cost of ownership, fewer failures and more predictable operational outcomes.

Those that do not often experience the opposite: reactive maintenance, unplanned downtime, premature asset failure and escalating costs.

The lifecycle begins long before an asset arrives on site. During the planning and acquisition stage, organisations define functional requirements, evaluate vendors and determine whether the asset aligns with long‑term operational needs. Decisions made here have lasting consequences.

For example, specifying the wrong pump capacity or selecting equipment without considering environmental conditions can lock an organisation into years of inefficiency.

Effective lifecycle management ensures procurement teams collaborate with maintenance, operations and engineering to select assets that are fit for purpose, maintainable and compatible with existing systems.

Once an asset is purchased, the commissioning stage establishes the foundation for its future performance. Proper installation, configuration and testing ensure the asset begins its life in optimal condition.

This stage also includes building the asset hierarchy, linking documentation, loading preventive maintenance tasks and establishing criticality ratings.

A well‑structured hierarchy allows organisations to track costs, failures and performance at both component and system levels. Without this structure, maintenance teams struggle to analyse trends or make informed decisions.

The operational and maintenance stage is the longest and most resource‑intensive part of the lifecycle.

This is where the principles of proactive maintenance, data governance and continuous improvement become essential.

Preventive maintenance tasks must be designed based on manufacturer recommendations, operational context and historical performance.

Condition monitoring and predictive analytics provide early warning of emerging issues, allowing organisations to intervene before failures occur. Data captured through work orders, inspections and sensor readings becomes the evidence base for refining maintenance strategies.

A key principle of asset lifecycle management is the shift from reactive to proactive maintenance.

Reactive work will always exist, but organisations that rely heavily on it experience higher costs, more downtime and greater safety risks.

Proactive maintenance, whether preventive, condition‑based or predictive, extends asset life, improves reliability and reduces operational disruptions.

Lifecycle management provides the structure to make this shift by ensuring maintenance activities are planned, prioritised and aligned with asset criticality.

Another critical element is cost visibility. Asset lifecycle management enables organisations to track the true cost of ownership, including labour, parts, energy consumption, downtime and replacement expenses.

This information supports budgeting, capital planning and investment decisions. When organisations understand which assets consume the most resources or fail most frequently, they can justify replacements, redesigns or process improvements with confidence.

As assets age, lifecycle management becomes even more important. Performance may decline, maintenance costs may rise and failure risks may increase.

Data‑driven analysis helps determine whether to continue maintaining an asset, refurbish it or replace it entirely.

This decision is not based on intuition but on measurable indicators such as mean time between failures, maintenance cost trends, operational impact and safety considerations.

Mature organisations use lifecycle data to build long‑term capital replacement plans that prevent unexpected failures and budget shocks.

The final stage, retirement and disposal, closes the loop.

Proper decommissioning ensures safety, environmental compliance and responsible handling of hazardous or recyclable materials.

Lessons learned from the asset’s performance feed back into procurement and planning for future assets. This continuous improvement cycle is a defining characteristic of effective lifecycle management.

In modern organisations, asset lifecycle management is inseparable from digital systems. A CMMS provides the structure for capturing data, managing work, analysing performance and supporting decision‑making.

When configured correctly, the CMMS becomes the central nervous system of lifecycle management, linking procurement, maintenance, operations and finance. It ensures that every stage of the lifecycle is visible, measurable and aligned with organisational goals.

Ultimately, asset lifecycle management is about maximising value while minimising risk. It ensures assets operate safely, reliably and efficiently throughout their life. It supports compliance, reduces waste and enables organisations to plan with confidence.

Whether in mining, utilities, manufacturing or local government, the organisations that excel at lifecycle management are those that treat assets not as isolated pieces of equipment but as strategic investments that require deliberate, disciplined stewardship from beginning to end.