Asset Integrity

Asset integrity is foundational to asset maintenance management systems because it ensures that physical assets perform reliably, safely, and efficiently throughout their lifecycle.

At its core, it’s about preserving the functionality, performance, and safety of critical equipment so that organizations can operate sustainably and profitably.

In high-risk industries such as mining, manufacturing, oil and gas, and energy production, maintaining asset integrity is not just a technical objective, it is a regulatory, environmental, and operational imperative.

Failing to uphold it can lead to catastrophic incidents, financial losses, and reputational damage that ripple across the business ecosystem.

Why Does Asset Integrity Matter in Maintenance Systems?

- Definition and Scope.

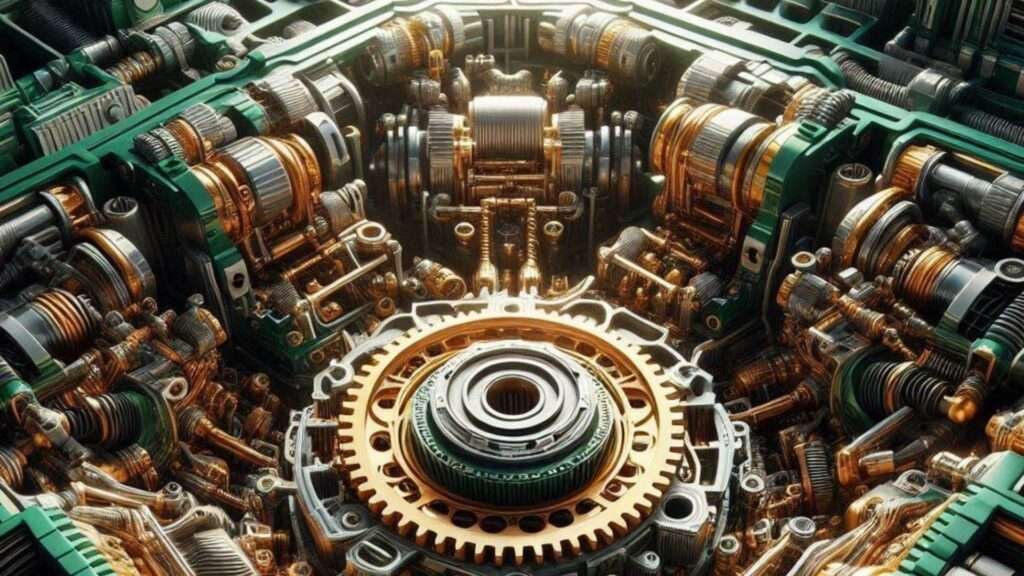

Asset integrity refers to an asset’s sustained ability to perform its intended function without failure, while meeting mandatory health, safety, and environmental (HSE) standards. It weaves together design integrity, operational integrity, and maintenance integrity:

- Design integrity ensures that equipment and infrastructure are engineered to withstand the operational conditions they will face.

- Operational integrity ensures that assets are used and controlled within safe operating limits.

- Maintenance integrity ensures that assets receive systematic care, inspections, and updates throughout their in-service life.

Together, these elements form a lifecycle approach that prevents degradation, extends service longevity, and minimizes risk exposure.

- The Role of CMMS.

A Computerized Maintenance Management System (CMMS) is the central platform for implementing asset integrity in day-to-day maintenance operations.

It manages inspections, automates maintenance workflows, and tracks asset health across distributed facilities.

An effective CMMS ensures that:

- Preventive maintenance actions are strategically planned, scheduled, and executed to minimize unscheduled downtime.

- Corrective maintenance is carried out efficiently, with real-time reporting and traceable records.

- Failure modes are detected early through predictive maintenance tools, often integrated via Industrial IoT (IIoT) sensor networks or third-party analytics software.

- Compliance documentation, certifications, and audit trails are readily accessible for internal reviews or external inspections.

By combining structured maintenance data with risk-based prioritization, CMMS platforms transform reliability management from reactive firefighting to proactive control.

- ERP Asset Maintenance Functionality.

Enterprise Resource Planning (ERP) systems extend asset integrity management beyond the maintenance department by integrating operational data with financial, procurement, and workforce planning modules.

Through ERP-driven asset maintenance functionality, organizations can manage:

- Budgeting and cost control for maintenance and asset life extension projects.

- Procurement and inventory systems that ensure timely availability of critical spares and tools.

- Workforce scheduling and skill alignment based on asset risk profiles and work criticality.

This integration establishes a single source of truth across departments, connecting engineers, operations teams, and finance personnel to the same data environment. The result is a holistic view of asset performance that aligns maintenance integrity with corporate sustainability, safety, and financial goals.

Consequences of Poor Asset Integrity.

Neglecting asset integrity carries severe implications, especially in asset-heavy sectors. The most common outcomes include:

- Unplanned downtime due to unexpected equipment failure.

- Safety incidents from undetected material fatigue, corrosion, or operational overload.

- Regulatory penalties and legal exposure stemming from non-compliance.

- Escalating operational costs as reactive maintenance consumes resources.

These risks compound quickly. In industries such as energy production or chemical processing, a single asset integrity breach can halt operations, endanger personnel, and damage long-term community trust.

Data-Driven Integrity Management.

Modern CMMS and ERP systems now leverage Industry 4.0 technologies to enhance asset integrity management through data-driven decision-making. Features include:

- Predictive analytics that harness real-time sensor data and historical performance to forecast failures.

- Digital twins that replicate equipment behavior under various stresses, enabling engineers to test and refine maintenance strategies virtually.

- Performance indicators such as MTBF (Mean Time Between Failures), MTTR (Mean Time to Repair), and RAMS (Reliability, Availability, Maintainability, Safety) metrics to benchmark performance.

These digital tools allow maintenance teams to transition from preventive to predictive and ultimately prescriptive maintenance, where interventions are optimized for timing, impact, and cost efficiency.

Strategic Benefits.

Organizations that treat asset integrity as a strategic discipline, embedded within their CMMS and ERP ecosystems, realize substantial benefits:

- Improved reliability, uptime, and production continuity.

- Lower lifecycle and maintenance costs through early problem detection.

- Enhanced safety culture and regulatory compliance.

- More informed capital investment decisions based on reliable, real-time data.

Ultimately, asset integrity is not a standalone concept but the structural backbone of modern maintenance strategy.

It connects engineering principles, digital systems, and management practices to ensure that every asset performs optimally, safely, and sustainably throughout its life.

Advanced Integration and Digital Transformation.

Modern asset integrity strategies increasingly incorporate artificial intelligence and machine learning algorithms within CMMS platforms, enabling organizations to move beyond reactive maintenance toward true prescriptive maintenance models.

By analyzing historical failure patterns, environmental variables, and sensor telemetry in real-time, AI systems can recommend optimal maintenance windows that minimize production disruption while maximizing equipment lifespan.

Financial Impact and ROI.

Typically, organizations implementing robust asset integrity programs can experience 20-30% reductions in maintenance costs through early failure detection, along with 15-25% improvements in asset availability.

These gains can at times translate directly to competitive advantage, particularly in capital-intensive industries where production uptime directly correlates with revenue generation.

Regulatory Evolution.

Asset integrity compliance frameworks continue evolving globally, with standards like ISO 55001 (Asset Management), API 580 (Risk-Based Inspection), and process safety management regulations becoming increasingly stringent.

Organizations that embed integrity management into their culture and systems position themselves ahead of regulatory requirements rather than reacting to them.

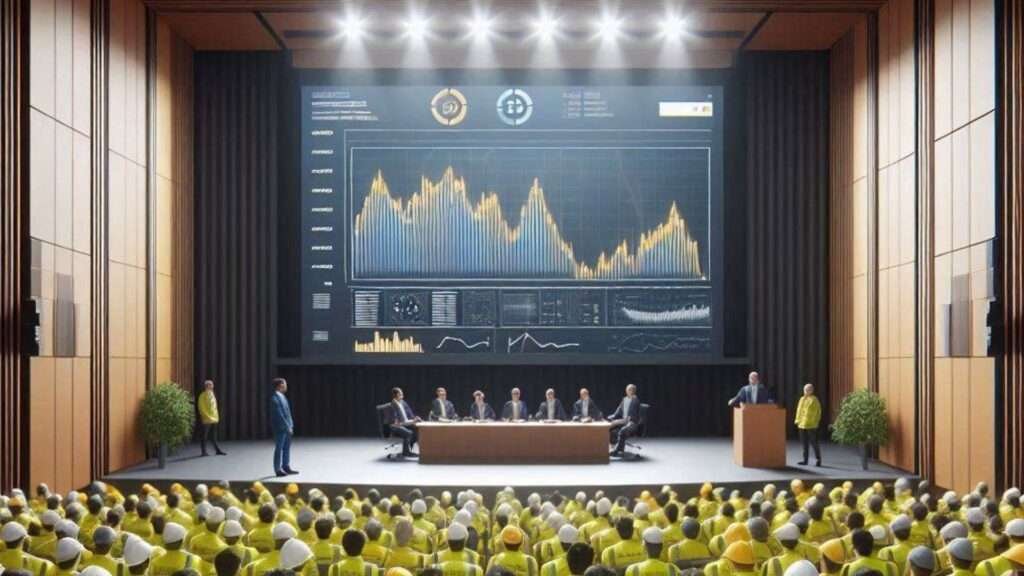

Organizational Maturity.

The transition from siloed maintenance departments to integrated, data-driven asset lifecycle management represents a fundamental shift in organizational maturity, requiring investment in training, technology adoption, and cultural alignment between technical teams and executive leadership.

Conclusion.

In essence, asset integrity is far more than a technical checklist; it is the fundamental philosophy that bridges an organization’s physical infrastructure with its strategic objectives of safety, sustainability, and profitability.

Its successful implementation relies on a holistic lifecycle approach encompassing design, operation and maintenance that is systematically enforced through modern digital tools.

A robust CMMS serves as the operational nerve center, translating integrity principles into disciplined daily workflows, while integrated ERP functionality aligns these efforts with broader financial and organizational goals.

Together, these systems enable a transformative shift from reactive remediation to proactive, data‑driven stewardship.

The consequences of neglect are severe, ranging from catastrophic safety failures to significant financial and reputational damage, underscoring that in high‑risk industries, asset integrity is an indispensable imperative.

Looking forward, the integration of Industry 4.0 technologies is redefining what effective asset integrity management looks like.

These technologies, such as AI‑driven analytics, IoT‑enabled sensors, machine learning, automation, and digital twins represent the fourth industrial revolution, where physical assets and digital systems are tightly interconnected.

They enable real‑time monitoring, predictive insights, autonomous decision support, and continuous optimization across the asset lifecycle.

As these capabilities mature, asset integrity is evolving from a preventive discipline into a prescriptive strategic function.

Organizations that embrace this evolution, investing in the necessary technology, processes, and cultural maturity, secure a formidable competitive advantage.

They achieve not only enhanced reliability and reduced costs but also foster a resilient operational culture that proactively meets regulatory demands and builds enduring trust.

Ultimately, asset integrity is the structural backbone that ensures physical assets remain safe, reliable, and valuable contributors to long‑term organizational success.