How ERP Systems Can Optimise Supply Chain Performance

Disclaimer.

The thoughts, ideas, views, and interpretations expressed in this article are those of the author only.

This material is provided for general informational and educational purposes and should not be relied upon as professional advice, consulting guidance, or vendor endorsement.

It does not constitute technical, financial, operational, or legal advice.

Readers should independently verify all information, assess its relevance to their specific circumstances and consult qualified professionals before making decisions related to technology investments, operational changes, or supply chain strategy.

ERP, supply chain practices, regulations, and vendor capabilities change frequently and with that in mind, this information was current as of Feb-2026 but may change without notice.

Article Summary.

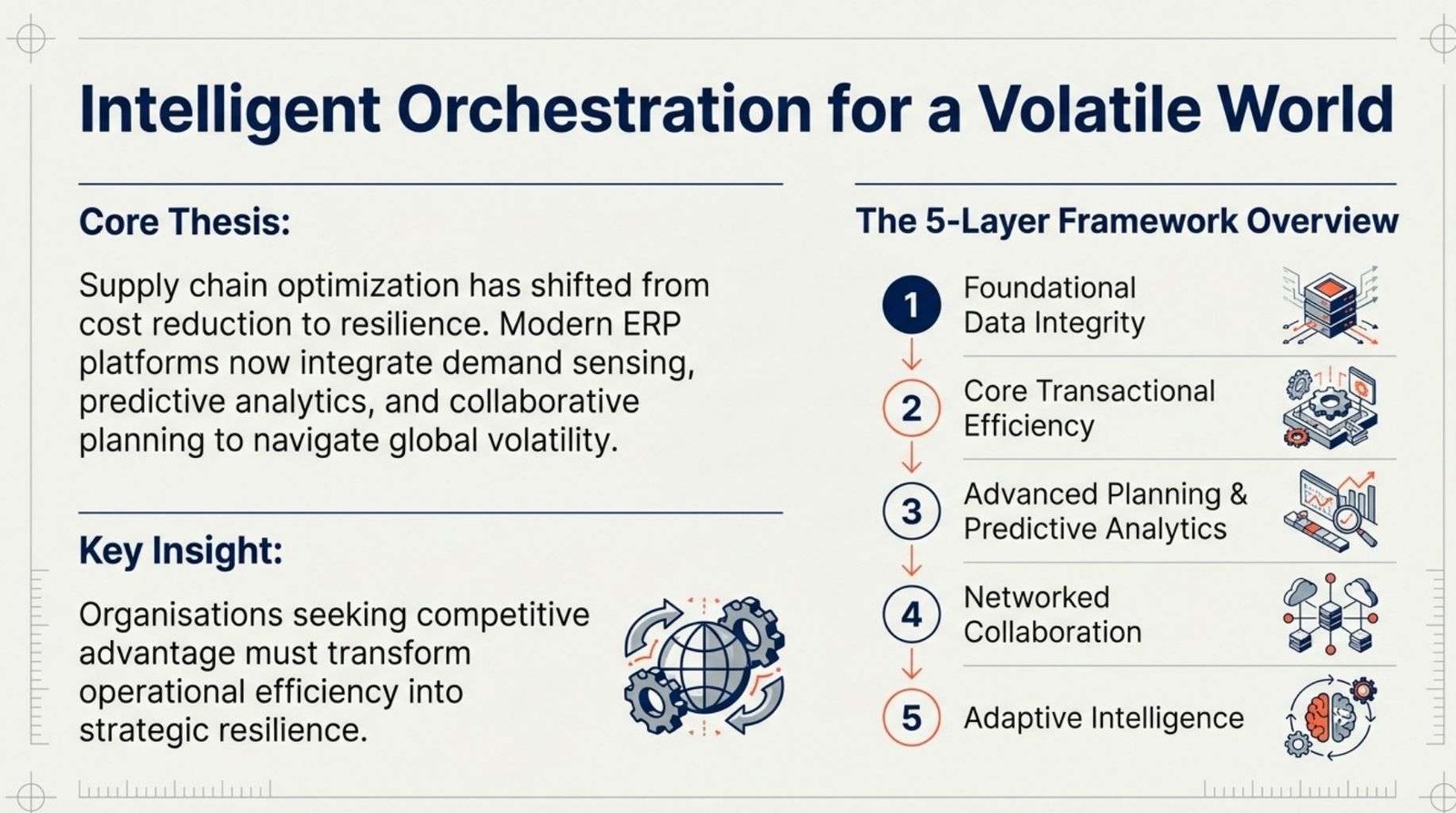

Supply chain optimization ERP functionality has evolved from basic transactional processing into sophisticated decision support systems that enable resilience, visibility and adaptive intelligence across global networks.

Modern ERP supply chain management platforms integrate demand sensing, predictive analytics and collaborative planning to address volatility, regulatory complexity and sustainability expectations.

This article examines the five layer optimization framework, data architecture requirements, implementation realities, vendor capabilities and the convergence of ERP and asset management systems.

Organizations seeking competitive advantage must understand how ERP supply chain capabilities transform operational efficiency into strategic resilience.

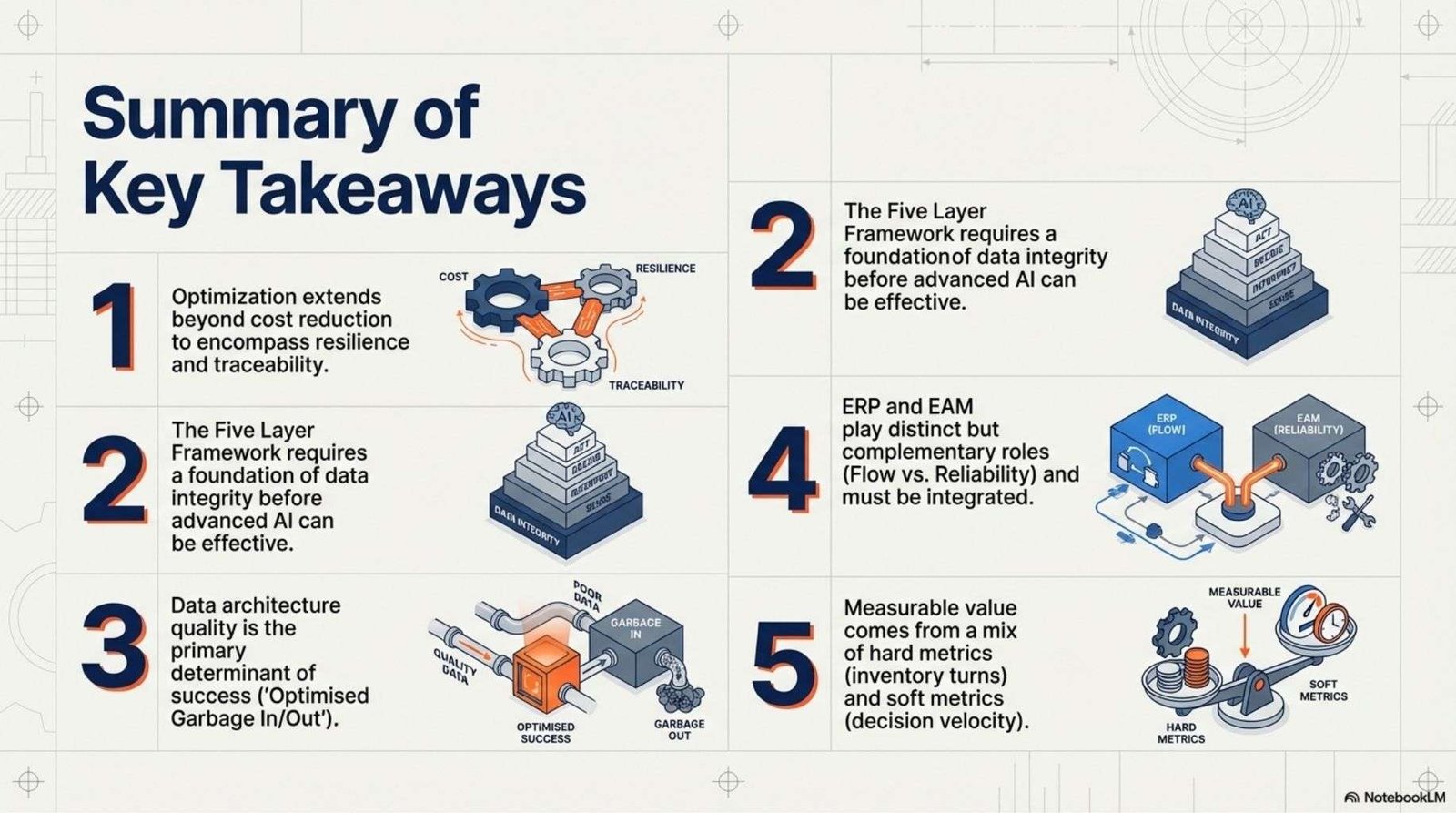

Top 5 Takeaways.

1. Supply chain optimization in ERP extends beyond cost reduction to encompass resilience, traceability and adaptive intelligence in response to global volatility and regulatory pressure.

2. The Five Layer Framework progresses from foundational data integrity through core transactional efficiency, advanced planning, networked collaboration and adaptive intelligence.

3. Data architecture quality directly determines optimization outcomes; unified master data and event driven integration prevent the “optimized garbage in, optimized garbage out” problem.

4. ERP and EAM systems serve distinct but complementary roles; ERP optimizes material and information flows while EAM optimizes asset health and reliability.

5. Measurable value derives from both hard metrics like inventory turns and on time delivery and soft metrics including agility, compliance accuracy and decision velocity.

Table of Contents.

1.0 Overview.

2.0 The Modern Supply Chain Challenge.

3.0 Supply Chain Optimization And Operational & Maintenance Excellence.

4.0 The Five Layer ERP Supply Chain Optimization Framework.

Layer 1: Foundational Data Integrity.

Layer 2: Core Transactional Efficiency.

Layer 3: Planning and Predictive Analytics.

Layer 4: Networked Collaboration.

Layer 5: Adaptive Intelligence.

5.0 Integrative Data Architecture.

Optimized Garbage In, Optimized Garbage Out.

6.0 Implementation Realities and Pitfalls.

ERP Supply Chain Readiness Checklist.

7.0 Measuring the Value of Supply Chain Optimization.

The Total Value Equation.

8.0 ERP Vendor Capability Landscape.

9.0 Scenario Planning Across Industries.

10.0 The Future State: The Autonomous Enterprise Supply Chain.

11.0 How Supply Chain Optimization Differs Between ERPs and EAMs.

12.0 References and Further Reading.

13.0 Terms and Abbreviations Table.

1.0 Overview.

Global supply chains embody a profound coordination challenge, encompassing thousands of interconnected entities, millions of intricate transactions and billions of dollars in essential working capital.

The introduction of supply chain optimization ERP functionality addresses the fundamental need for integrated decision making across procurement, production, distribution and fulfillment operations.

Enterprise Resource Planning systems have transitioned from transactional record keeping platforms to intelligent orchestration engines.

Modern ERP supply chain optimization capabilities incorporate demand sensing algorithms, constraint based scheduling, multi echelon inventory optimization and real time collaboration portals.

This evolution reflects market demands for agility alongside efficiency.

Research from industry analysts indicates that supply chain agility has become a primary driver for ERP investment, surpassing traditional cost reduction objectives.

Organizations face pressure from geopolitical disruption, climate events, regulatory complexity and stakeholder expectations for transparency.

ERP supply chain management provides the integrated data foundation and coordinated planning processes required to navigate this volatility.

The thesis of effective optimization is straightforward. Modern supply chains require intelligence, integration and adaptability.

Intelligence enables predictive rather than reactive decisions. Integration eliminates information silos that create delays and errors. Adaptability allows rapid response to disruption without manual intervention.

Primary keywords integrated throughout this analysis include supply chain optimization ERP functionality, ERP supply chain optimization, ERP supply chain management, supply chain optimization in ERP and ERP supply chain capabilities.

These terms reflect the functional convergence of planning, execution and analytics within unified platforms.

2. The Modern Supply Chain Challenge.

Contemporary supply chain environments operate under unprecedented complexity and uncertainty. Volatility stems from multiple concurrent sources rather than isolated incidents.

Geopolitical tensions disrupt established trade routes and sourcing relationships. Climate events create unpredictable capacity constraints in transportation and production facilities.

Regulatory frameworks impose traceability requirements across multiple jurisdictions with varying standards.

Consumer and investor pressure demands demonstrable progress on environmental, social and governance metrics.

Transparency expectations have escalated beyond simple visibility. Stakeholders require evidence of ethical sourcing, carbon footprint measurement, modern slavery compliance and circular economy practices.

These demands transform supply chain management from operational logistics into strategic risk management.

The optimization paradigm has shifted fundamentally. Traditional approaches emphasized cost minimization through lean inventory, offshore sourcing and economies of scale.

Current approaches prioritize resilience through diversified suppliers, regional capacity and buffer inventory at critical nodes. Cost efficiency remains important but secondary to continuity assurance.

ERP functionality addresses these challenges through integrated coordination. Planning modules incorporate risk factors into demand forecasting and capacity allocation. Procurement systems evaluate suppliers across multiple criteria including reliability, compliance and sustainability performance.

Manufacturing execution integrates with quality management to ensure traceability. Distribution systems optimize for service level achievement rather than minimum cost routing.

The stabilizing role of ERP derives from unified data models and coordinated workflows. When procurement, production, logistics and finance operate from shared information, response times decrease and error rates decline.

Real time visibility enables proactive exception management rather than reactive firefighting.

3. Supply Chain Optimization and Operational & Maintenance Excellence.

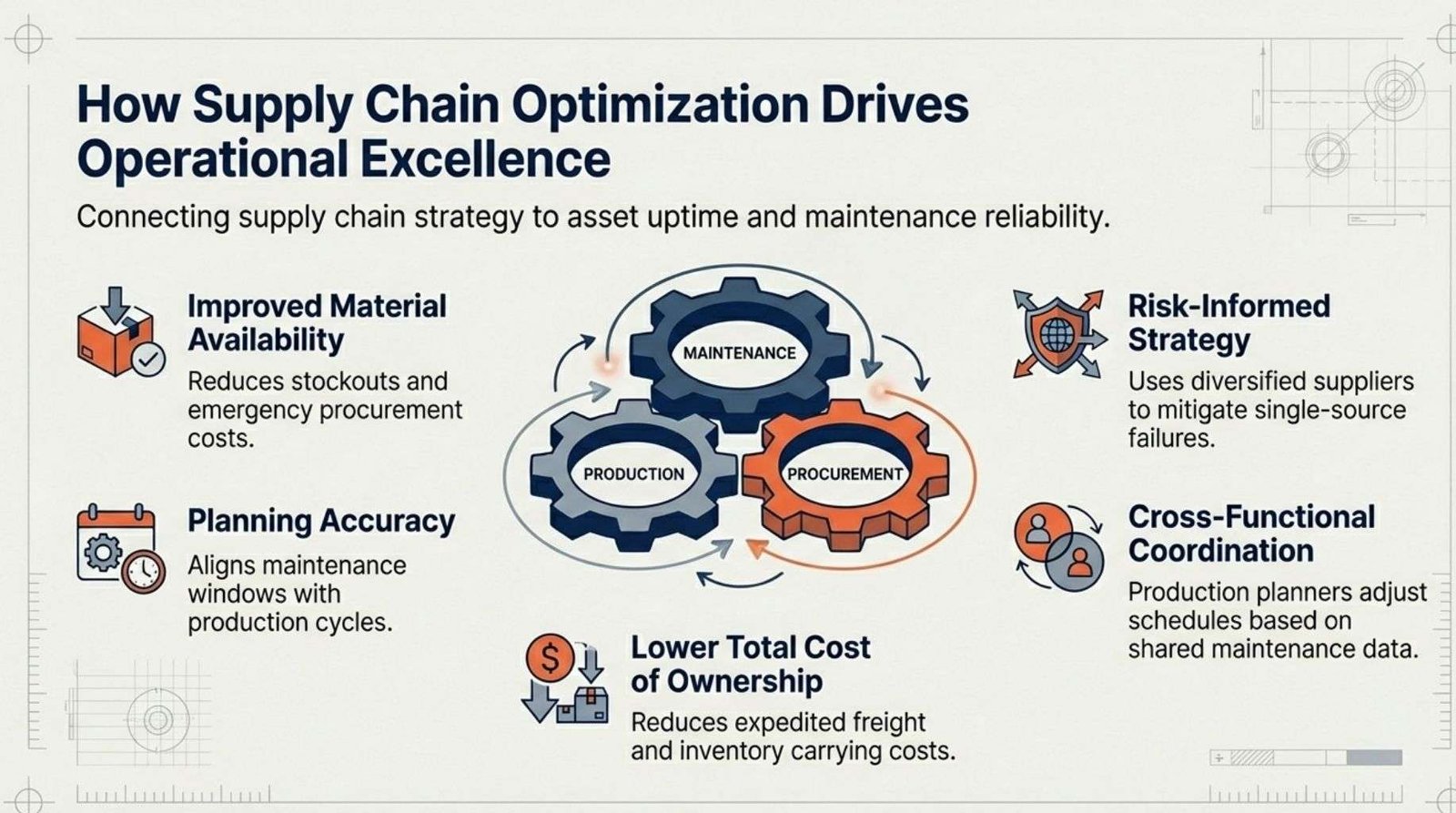

Operations and maintenance performance depend heavily on the availability of the right materials, equipment, information and capacity at the right time.

Supply chain optimization directly influences these factors by improving the reliability, predictability and coordination of supporting processes.

When ERP supply chain capabilities function effectively, operations and maintenance teams experience fewer delays, fewer unplanned disruptions and more stable workflows.

Supply chain optimization excellence contributes to operational and maintenance excellence in several ways.

3.1 Improved Material Availability for Production and Maintenance.

Production and maintenance activities rely on timely access to components, spare parts, consumables and tools.

Supply chain optimization improves material availability through accurate forecasting, coordinated replenishment and real‑time visibility of inventory across sites.

Key benefits include:

1. Reduced stockouts that delay work orders or production runs.

2. Lower emergency procurement requirements, which typically increase cost and lead time.

3. More predictable maintenance scheduling due to reliable spare parts availability.

These improvements support higher equipment uptime and more stable production throughput.

3.2 Enhanced Planning Accuracy Across Operations.

Optimised supply chain planning provides more accurate demand forecasts, capacity plans and material requirements.

Operations and maintenance teams depend on this accuracy to schedule work, allocate resources and coordinate with production.

Benefits include:

1. More reliable production schedules with fewer last‑minute changes.

2. Better alignment between maintenance windows and production cycles.

3. Reduced need for reactive adjustments caused by material or capacity constraints.

Improved planning accuracy reduces operational variability and supports continuous improvement initiatives.

3.3 Reduced Operational Disruptions Through Risk‑Informed Supply Strategies.

Supply chain optimization incorporates risk assessment into sourcing, inventory and logistics decisions.

This reduces the likelihood of disruptions that affect operations and maintenance.

Examples include:

1. Diversified suppliers to mitigate single‑source failures.

2. Buffer inventory at critical nodes to protect against transport delays.

3. Early warning signals from supplier collaboration tools that allow proactive adjustments.

These measures help maintain operational continuity even during external volatility.

3.4 Better Coordination Between Maintenance, Production and Procurement.

ERP‑enabled integration ensures that maintenance, production and procurement operate from shared data.

This alignment reduces miscommunication and improves decision‑making.

Examples include:

1. Maintenance teams receiving real‑time updates on part availability.

2. Procurement teams understanding upcoming maintenance demand from planned work orders.

3. Production planners adjusting schedules based on maintenance requirements and material constraints.

This coordination reduces downtime, improves asset utilisation and supports reliability‑centred maintenance practices.

3.5 Increased Asset Reliability Through Predictive and Preventive Capabilities.

Advanced ERP supply chain functionality supports predictive maintenance by ensuring timely access to condition‑based parts and materials.

When predictive models identify potential failures, supply chain processes must respond quickly to stage required components.

Benefits include:

1. Faster response to emerging equipment issues.

2. Reduced unplanned downtime due to material readiness.

3. More efficient preventive maintenance execution.

Supply chain optimization therefore becomes a foundational enabler of reliability engineering and asset lifecycle management.

3.6 Lower Total Cost of Ownership for Assets and Operations.

Optimised supply chain processes reduce costs associated with inventory, procurement, logistics and downtime.

These savings contribute directly to lower total cost of ownership for equipment and operations and examples include:

1. Reduced expedited freight costs.

2. Lower inventory carrying costs for spare parts.

3. Fewer production losses due to material shortages.

These efficiencies support long‑term operational sustainability and financial performance.

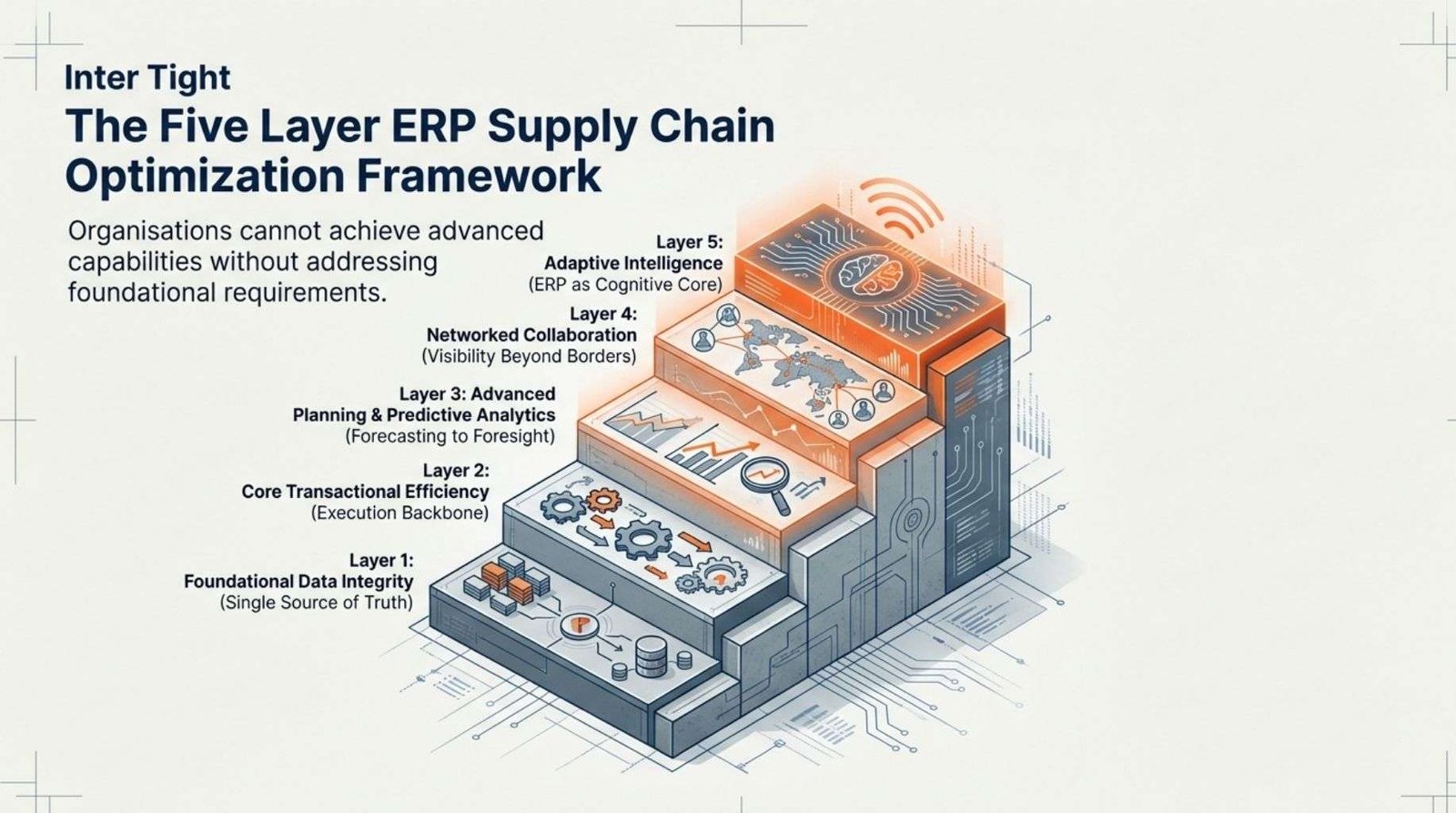

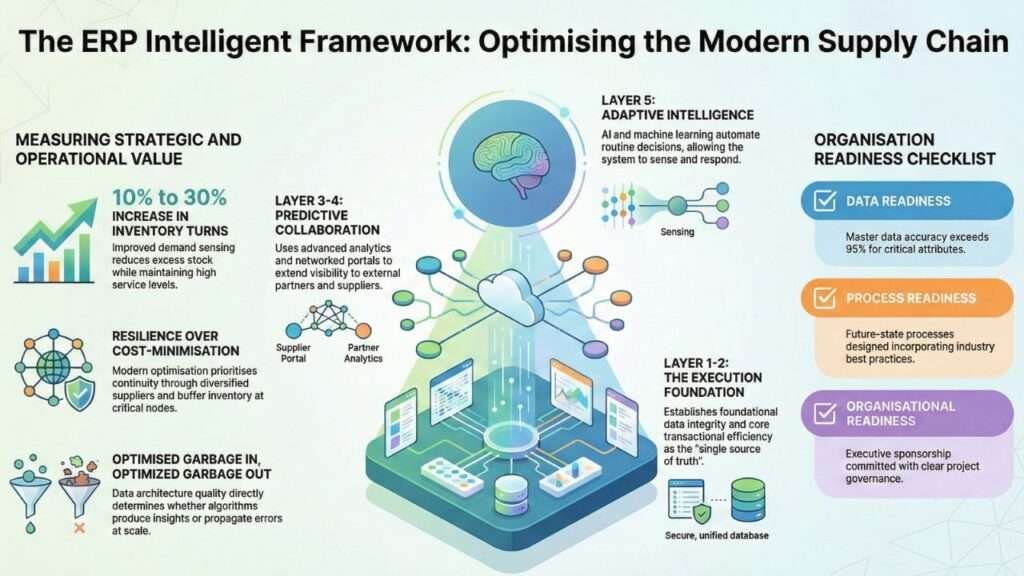

4. The Five Layer ERP Supply Chain Optimization Framework.

Effective supply chain optimization in ERP follows a hierarchical structure where each layer builds upon the foundation established by preceding levels.

Organizations cannot achieve advanced capabilities without addressing foundational requirements.

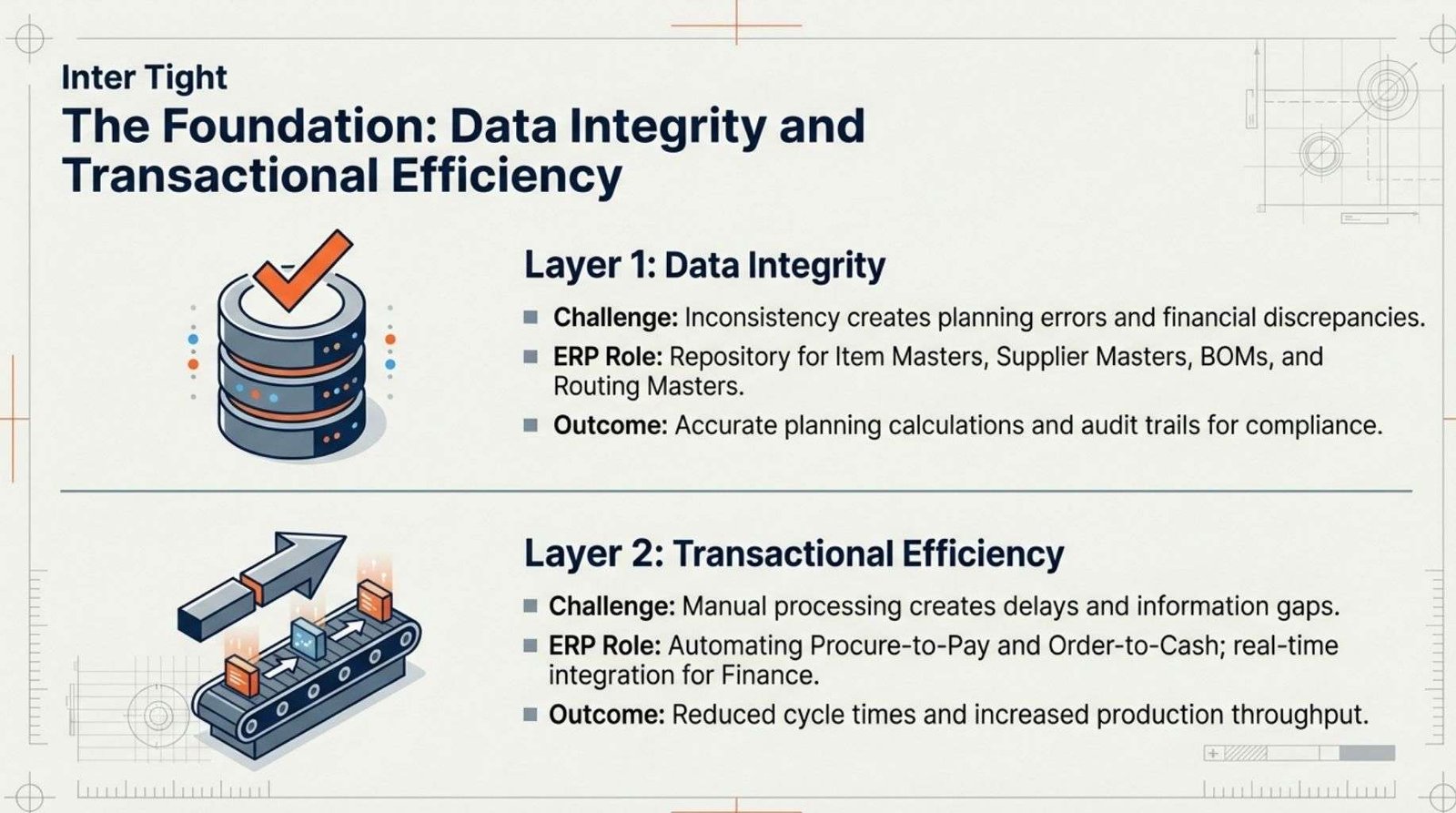

Layer 1: Foundational Data Integrity , The Single Source of Truth.

Site Challenges.

Supply chain decisions depend on accurate information about items, suppliers, customers, locations and relationships.

Data inconsistency creates planning errors, inventory mismatches and financial discrepancies. Organizations operating across multiple sites, systems, or business units face particular difficulty maintaining unified master data.

ERP Functional Role.

ERP systems serve as the master data repository and governance platform. Item masters define material attributes, classifications and planning parameters.

Supplier masters contain qualification status, lead times and contract terms.

Bill of materials structures establish parent child relationships and component quantities. Routing masters specify production sequences, work centers and standard times.

Master data management functionality enforces consistency through validation rules, approval workflows and change tracking.

Data stewardship assigns ownership and accountability for specific domains.

Integration interfaces synchronize master data across connected systems including WMS, MES and PLM platforms.

Key Configuration Levers.

Material type definitions determine planning behavior and transaction rules.

Classification schemes enable segmentation for ABC analysis and inventory policy assignment.

Vendor evaluation criteria establish performance metrics and qualification requirements. BOM effectivity dates control product transitions and engineering changes.

Tangible Outcomes.

Accurate planning calculations reduce excess inventory and stockouts. Fewer manual corrections decrease labor costs and improve data entry efficiency.

Reliable analytics enable fact based decision making. Audit trails support compliance verification and quality investigations.

Layer 2: Core Transactional Efficiency , The Execution Backbone.

Site Challenges.

Supply chain operations generate thousands of daily transactions across procurement, production, warehousing and distribution.

Manual processing creates delays, errors and information gaps. Disconnected systems require duplicate data entry and reconciliation.

ERP Functional Role.

Integrated transaction processing eliminates handoffs and redundant entry. Procure to Pay functionality manages requisitions, purchase orders, goods receipts, invoice verification and payment processing.

Order to Cash functionality handles customer orders, inventory allocation, picking, shipping, invoicing and cash application.

Production Planning coordinates material requirements, capacity scheduling, shop floor execution and completion reporting.

Real time integration ensures transaction visibility across functional areas.

Finance receives cost updates as materials are consumed. Inventory balances update immediately upon goods movements. Customer service views order status without system switching.

Key Configuration Levers.

Approval hierarchies balance control with processing speed. Automated workflows route transactions based on value thresholds and authorization limits.

Exception parameters define tolerance ranges for automatic versus manual processing. Integration timing determines real time versus batch synchronization.

Tangible Outcomes.

Procurement cycle times decrease through automated approval routing and electronic supplier communication.

Order fulfillment accuracy improves through integrated picking and shipping validation. Production throughput increases through coordinated material staging and capacity utilization.

Cash conversion cycles shorten through faster invoicing and payment processing.

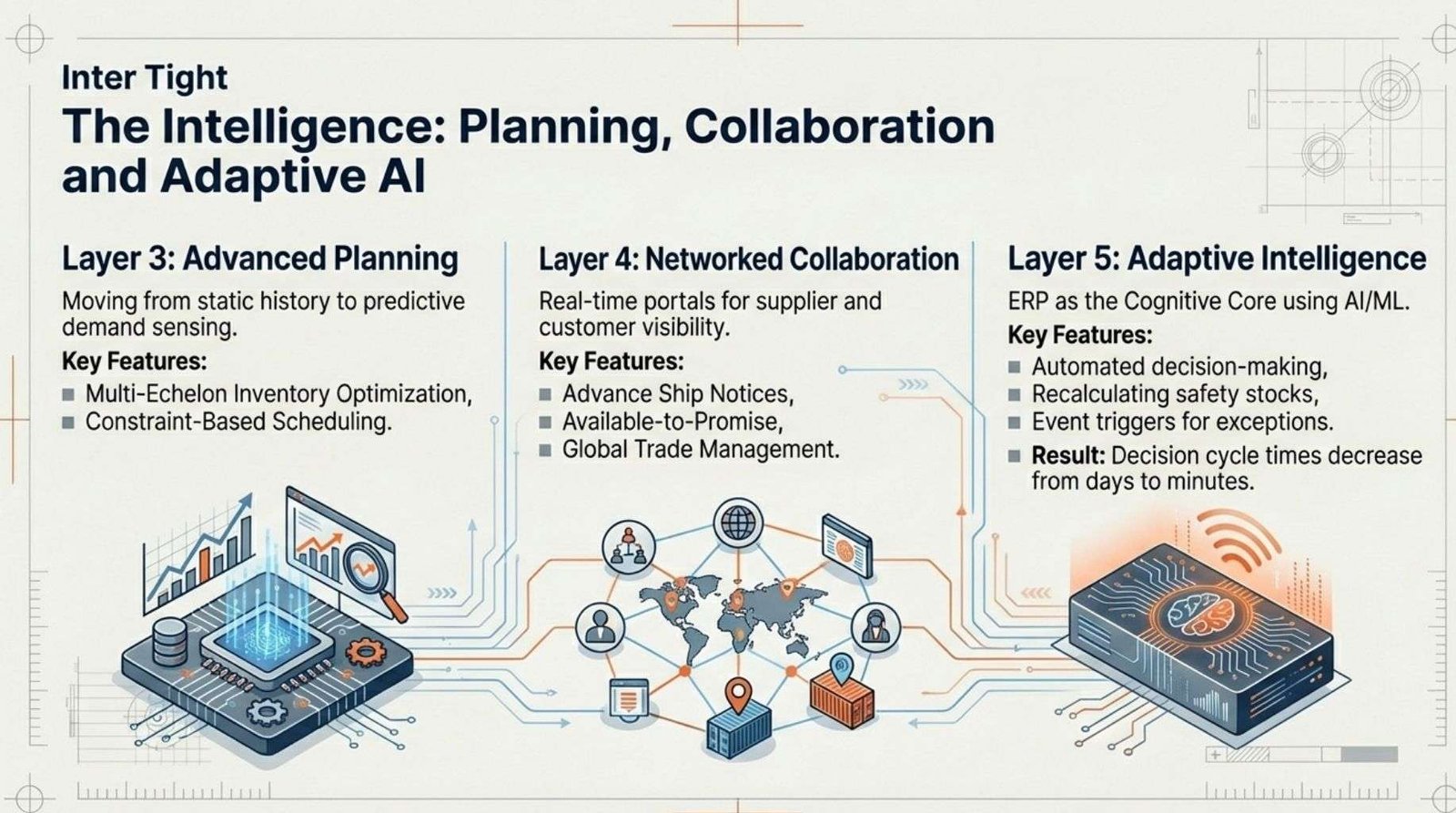

Layer 3: Planning and Predictive Analytics – From Forecasting to Foresight.

Site Challenges.

Static planning processes react to historical patterns and fail to anticipate demand shifts, supply disruptions, or capacity constraints.

Forecast accuracy deteriorates in volatile markets. Inventory policies based on average conditions create either excess stock or service failures.

ERP Functional Role.

Advanced planning functionality incorporates machine learning algorithms for demand sensing.

Statistical models identify patterns, seasonality and trend changes. Causal factors including promotions, pricing and market conditions enhance forecast precision. Collaborative forecasting integrates customer and supplier input.

Multi echelon inventory optimization determines stock positioning across distribution networks.

Safety stock calculations incorporate demand variability and lead time uncertainty. Replenishment policies balance service levels with carrying costs.

Integrated Business Planning synchronizes demand, supply, product and financial plans.

Constraint based scheduling allocates capacity to maximize throughput or margin contribution. Scenario analysis evaluates alternative strategies before commitment.

Key Configuration Levers.

Forecast model selection matches algorithm characteristics to demand patterns. Planning horizons balance visibility requirements with computational complexity.

Safety stock policies differentiate service levels by product classification or customer segment.

Optimization objectives prioritize service, cost, or working capital targets.

Tangible Outcomes.

Forecast error reduction improves production planning stability and reduces expediting costs. Inventory turns increase while service levels improve or remain stable.

Production schedules smooth to reduce changeovers and maximize asset utilization. Working capital requirements decrease through optimized stock positioning.

Layer 4: Networked Collaboration – Extending Visibility Beyond Borders.

Site Challenges.

Supply chain resilience depends on information sharing with external partners. Supplier delays, quality issues, or capacity constraints impact production schedules.

Customer demand signals arrive too late for efficient response. Regulatory compliance requires documentation from multiple parties.

ERP Functional Role.

Supplier portals provide real time visibility to purchase orders, forecasts and inventory levels.

Vendors update delivery schedules, provide advance ship notices and submit invoices electronically.

Quality collaboration workflows enable non conformance reporting and corrective action tracking.

Customer portals allow order placement, configuration and status tracking. Available to promise calculations provide reliable delivery commitments.

Returned goods processing streamlines authorization and credit issuance.

Global Trade Management functionality manages international compliance including restricted party screening, export classification, free trade agreement qualification and customs documentation.

Automated calculations determine duties, taxes and total landed costs.

Key Configuration Levers.

Portal access rights control information visibility by partner and transaction type.

Data sharing agreements define permissible uses and retention requirements. Integration standards determine message formats and communication protocols. Compliance rules configure screening criteria and documentation requirements.

Tangible Outcomes.

Supplier lead times decrease through visibility to actual demand and inventory positions. Quality issues resolve faster through collaborative problem solving and corrective action tracking.

Customer satisfaction improves through accurate delivery promises and proactive exception management.

Compliance violations decrease through automated screening and documentation validation.

Layer 5: Adaptive Intelligence – ERP as the Cognitive Core.

Site Challenges.

Manual decision making cannot match the speed and complexity of modern supply chain operations.

Humans lack capacity to process thousands of simultaneous variables and constraints. Response delays allow small problems to cascade into major disruptions.

ERP Functional Role.

Adaptive intelligence incorporates artificial intelligence and machine learning to automate routine decisions and recommend optimal actions for complex scenarios.

Demand sensing algorithms detect pattern shifts and adjust forecasts automatically. Inventory optimization recalculates safety stocks and reorder points as variability changes.

Production scheduling resolves constraint conflicts and maximizes throughput within capacity limits.

Predictive maintenance integrates asset health data from sensors and equipment monitoring systems.

Failure predictions trigger preventive work orders before breakdowns occur. Maintenance schedules balance reliability requirements with production priorities.

Orchestration agents coordinate workflows across planning, procurement, production and distribution.

Event triggers initiate responses to exceptions including supplier delays, quality holds, or demand spikes. Human oversight maintains governance while automation handles routine execution.

Key Configuration Levers.

Model training data quality and quantity determine prediction accuracy. Confidence thresholds establish automation boundaries requiring human review.

Override permissions balance agility with control. Feedback loops enable continuous model improvement through actual outcome comparison.

Tangible Outcomes.

Decision cycle times decrease from days or hours to minutes or seconds. Forecast accuracy improves through continuous learning from prediction errors.

Asset uptime increases through proactive maintenance before failures. Exception resolution accelerates through automated workflows and recommended actions.

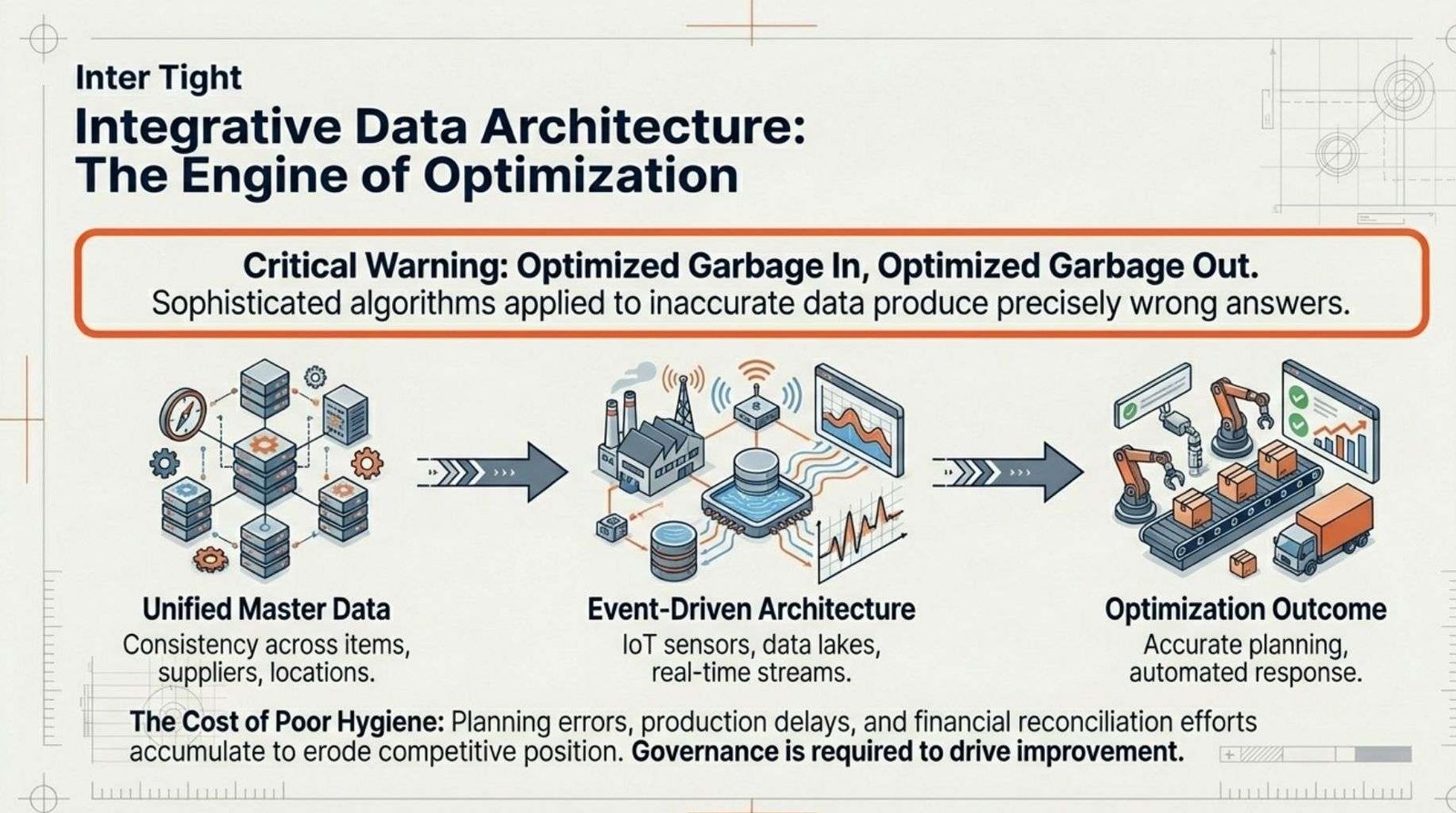

5.0 Integrative Data Architecture – The Hidden Engine of Optimization.

Supply chain optimization capabilities depend fundamentally on data architecture quality.

Advanced algorithms and sophisticated planning logic cannot compensate for fragmented, inconsistent, or inaccurate information.

Unified master data establishes the foundation. Item masters, supplier records, customer accounts and location definitions must maintain consistency across all modules and business units.

Centralized governance prevents duplicate creation and conflicting attributes. Standardized classifications enable meaningful aggregation and analysis.

Taxonomy alignment ensures common language across organizational boundaries. Product hierarchies support planning at appropriate levels of detail.

Location hierarchies enable regional analysis and policy assignment.

Financial dimensions connect operational performance to accounting structures.

Event driven architecture enables real time responsiveness.

Internet of Things sensors monitor equipment status, environmental conditions and material movements.

Data lakes capture high volume event streams for pattern analysis.

ERP systems consume relevant events to trigger planning updates, exception alerts, or automated responses. Analytics platforms generate insights from historical patterns and predictive models.

The hidden cost of poor data hygiene compounds over time. Planning errors create excess inventory or stockouts.

Production delays result from material shortages or quality issues. Customer dissatisfaction stems from missed deliveries or incorrect shipments.

Financial reconciliation requires manual investigation and correction.

These inefficiencies accumulate across thousands of transactions and erode competitive position.

5.1 Optimized Garbage In, Optimized Garbage Out.

Sophisticated optimization algorithms applied to inaccurate data produce precisely wrong answers.

Machine learning models trained on historical errors perpetuate those errors at scale. Automated decisions based on faulty information accelerate rather than prevent problems.

Data quality requires sustained attention and investment. Validation rules prevent entry of impossible values or inconsistent combinations.

Duplicate detection algorithms identify redundant records requiring consolidation. Data profiling reveals patterns indicating systematic issues requiring process correction.

Ownership and accountability drive improvement. Data stewards monitor quality metrics and investigate anomalies.

Cross functional review ensures alignment between operational reality and system representation. Continuous improvement cycles address root causes rather than symptoms.

Integration testing validates end to end data flows. Source system changes trigger regression verification.

Performance monitoring detects degradation requiring optimization. Security controls protect sensitive information while enabling appropriate access.

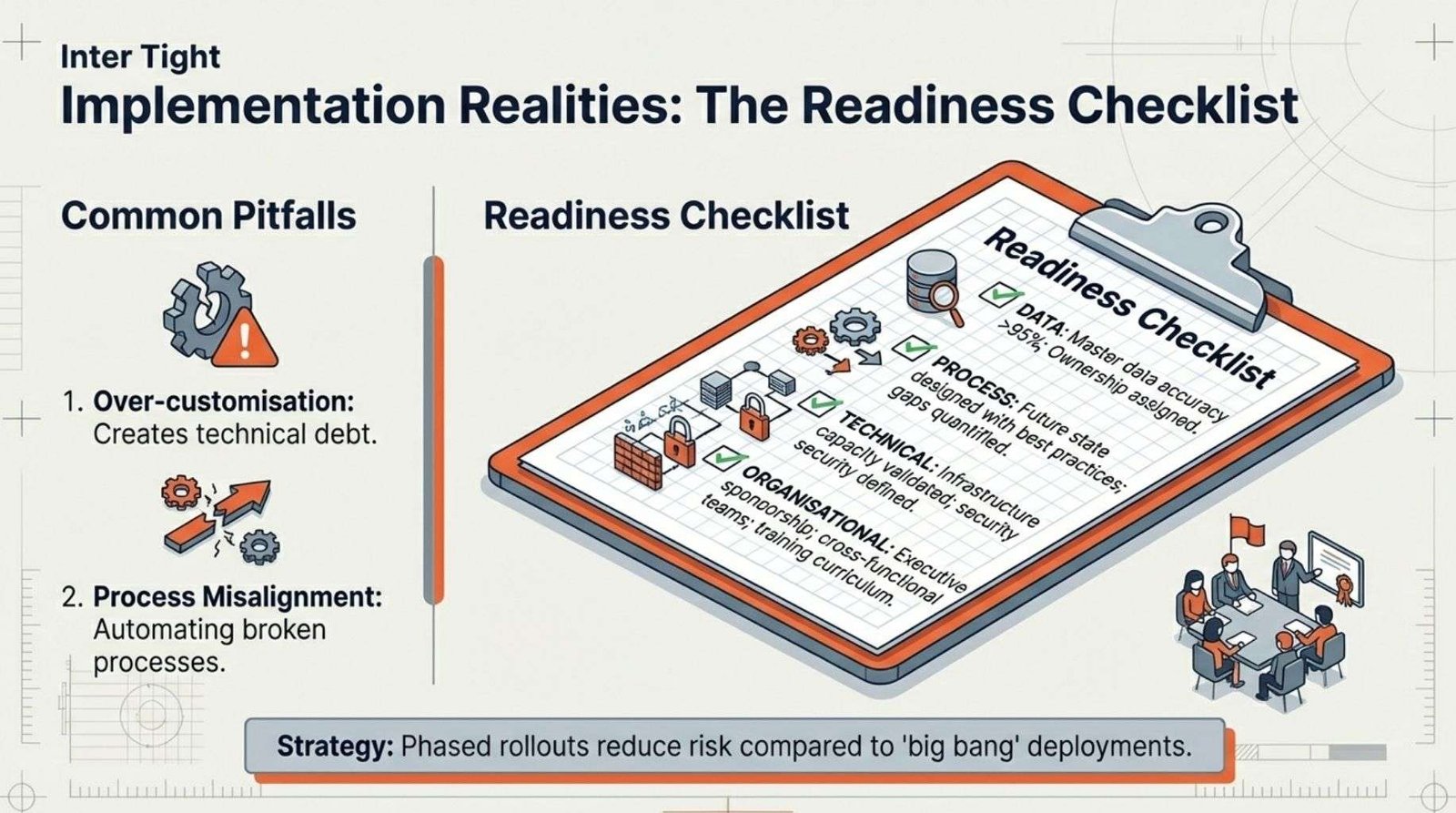

6.0 Implementation Realities and Pitfalls.

Supply chain optimization implementations succeed or fail based on non technical factors more often than technology limitations.

Organizations must address process alignment, change management and governance culture alongside system configuration.

Over customization creates long term technical debt and upgrade obstacles. Organizations justify modifications to match existing processes without challenging whether those processes reflect best practices.

Custom code requires ongoing maintenance, testing and documentation.

Vendor provided functionality evolves with each release while customizations remain static until redevelopment.

Process misalignment occurs when system design contradicts operational reality. Planning horizons may not match actual lead times.

Approval workflows may bypass necessary controls or create bottlenecks. Inventory policies may conflict with storage capacity or handling capabilities.

Successful implementations align processes before configuration rather than forcing systems to accommodate dysfunction.

Change management challenges arise from resistance, capability gaps and competing priorities.

Users accustomed to manual workarounds distrust automated recommendations.

Planners lack skills to interpret optimization results or override when appropriate. Leadership attention shifts to other initiatives before adoption completes.

Data governance culture determines whether master data quality improves or deteriorates. Without clear ownership, nobody takes responsibility for corrections. Without defined standards, inconsistency proliferates. Without consequences, violations continue.

Phased rollouts reduce risk compared to big bang deployments. Pilot implementations validate configuration in controlled environments.

Lessons learned inform subsequent waves. User confidence builds through demonstrated success. However, phased approaches extend timelines and prolong dual system operation.

6.1 ERP Supply Chain Readiness Checklist.

Organizations should assess readiness across multiple dimensions before implementation:

Data Readiness.

1. Master data accuracy exceeds 95 percent for critical attributes.

2. Duplicate records identified and consolidated.

3. Classification schemes defined and applied consistently.

4. Data ownership assigned with accountability metrics.

Process Readiness.

1. Current state processes documented with pain points identified.

2. Future state processes designed incorporating best practices.

3. Gaps between current and future states quantified.

4. Change impacts assessed by role and function.

Technical Readiness.

1. Infrastructure capacity validated for transaction volumes.

2. Integration interfaces specified with source and target systems.

3. Security requirements defined including access controls and audit trails.

4. Disaster recovery and business continuity plans established.

Organizational Readiness.

1. Executive sponsorship committed with visible engagement.

2. Project governance structure defined with decision authority.

3. Cross functional team assembled with appropriate representation.

4. Training approach developed with role based curriculum.

Change Readiness.

1. Communication plan established with stakeholder mapping.

2. Resistance points identified with mitigation strategies.

3. Success metrics defined with baseline measurements.

4. Support model designed for post implementation assistance.

7.0 Measuring the Value of Supply Chain Optimization.

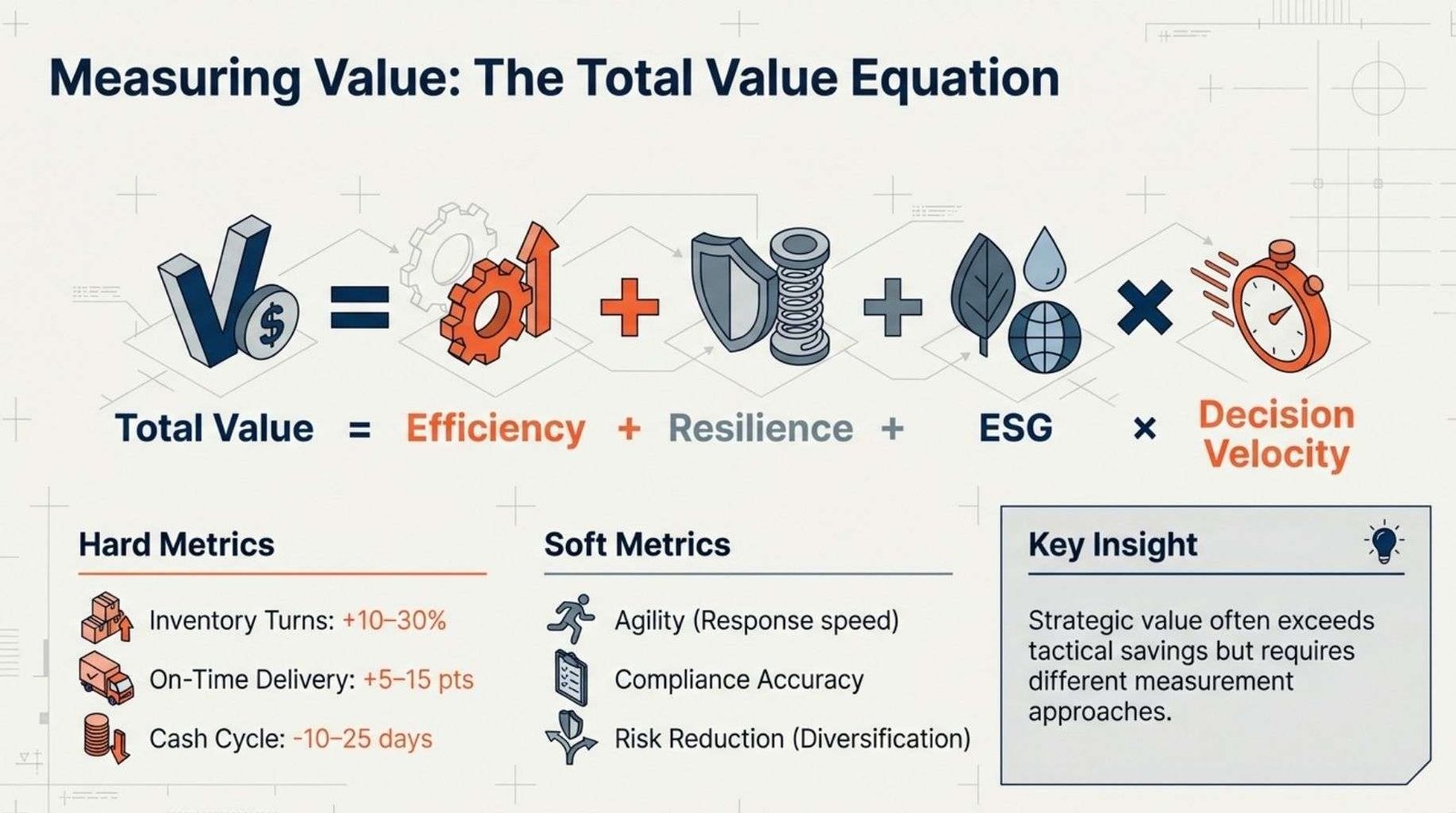

Quantifying return on investment requires balanced assessment of hard and soft metrics.

Financial justification focuses on measurable efficiency gains while strategic value derives from improved agility and risk mitigation.

7.1 Hard Metrics.

Inventory turns measure working capital efficiency. Higher turnover indicates faster conversion of materials into sales revenue.

Optimization improves turns through better demand forecasting, coordinated replenishment and reduced safety stock requirements. Typical improvement ranges from 10 to 30 percent depending on starting maturity.

On time delivery percentage reflects customer service performance. Optimization improves delivery reliability through accurate promising, coordinated execution and proactive exception management.

Service level improvements of 5 to 15 percentage points are common.

Cash conversion cycle measures days between cash outflow for materials and cash inflow from customers.

Optimization shortens cycles through faster order processing, reduced inventory holding periods and accelerated invoicing. Cycle reductions of 10 to 25 days create significant working capital release.

Perfect order rate combines on time, complete, damage free and correctly documented delivery. Optimization improves perfect order rates through integrated execution and quality controls.

Improvements of 10 to 20 percentage points reduce costs of returns, credits and customer dissatisfaction.

7.2 Soft Metrics.

Agility measures speed of response to demand changes or supply disruptions. Optimization improves agility through real time visibility, scenario planning and automated workflows.

Quantification requires tracking response times for specific event types.

Compliance accuracy reflects adherence to regulatory requirements, contract terms and quality standards.

Optimization improves compliance through automated validation and documentation. Violations and penalties provide measurable baselines for improvement.

Risk reduction encompasses supplier diversification, inventory buffering and alternative sourcing.

Optimization enables risk assessment and mitigation without excessive cost. Quantification requires modeling potential disruption impacts and their probabilities.

Decision velocity measures time from information availability to action execution. Optimization accelerates decisions through automated recommendations and streamlined approvals.

Tracking decision cycle times by type provides improvement metrics.

7.3 The Total Value Equation.

Comprehensive value assessment incorporates four dimensions that interact rather than simply add.

Efficiency improvements reduce operational costs through labor productivity, inventory reduction and process automation.

Resilience improvements reduce risk exposure through diversification, visibility and faster response.

ESG performance improvements enhance reputation and reduce regulatory risk through transparency and accountability. Decision velocity improvements accelerate time to value across all other dimensions.

Total value equals efficiency gains plus resilience value plus ESG value multiplied by decision velocity improvement factor.

Organizations should quantify improvements across all dimensions rather than focusing exclusively on cost reduction.

Strategic value often exceeds tactical savings but requires different measurement approaches.

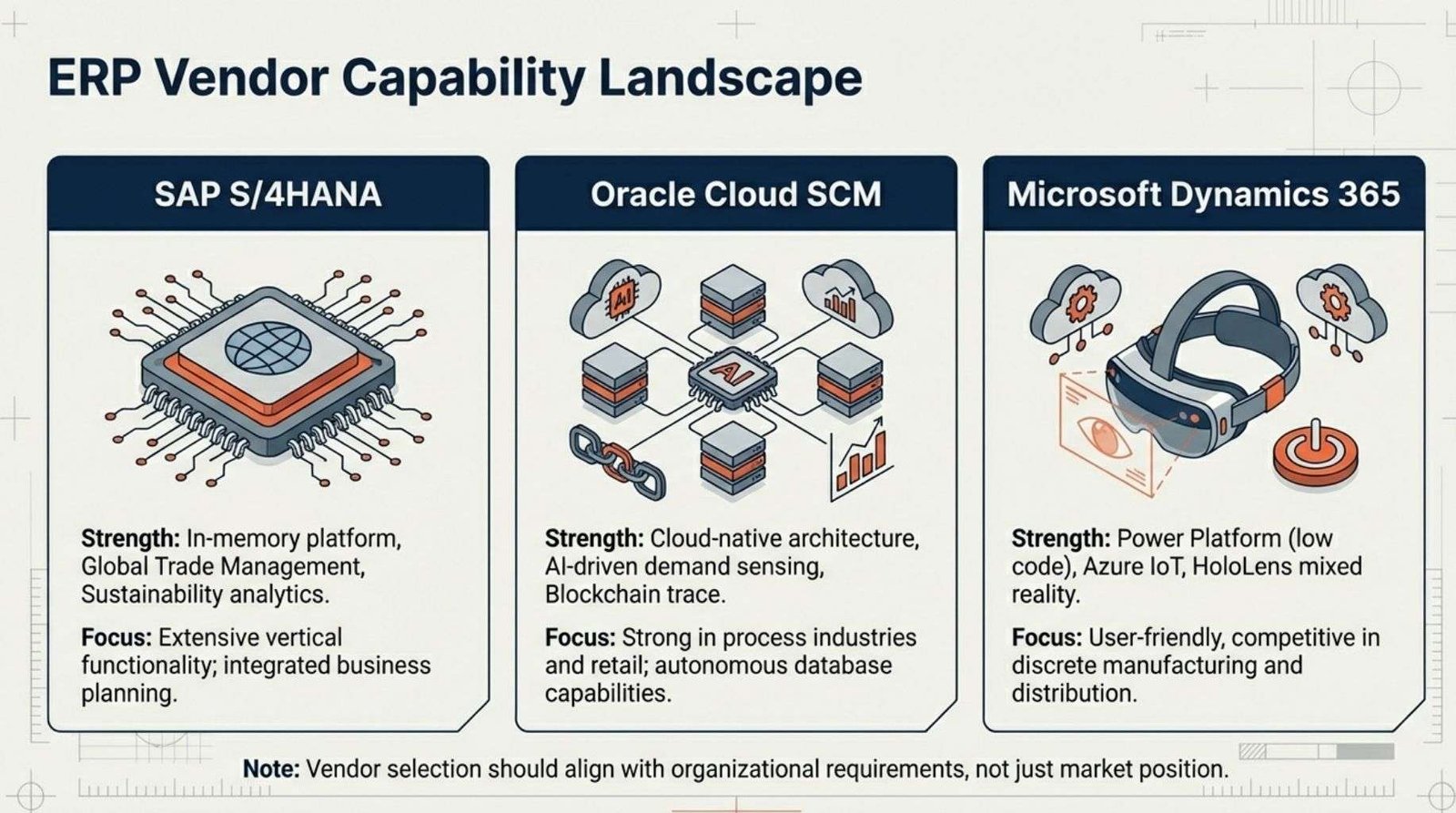

8.0 ERP Vendor Capability Landscape.

Major ERP platforms provide supply chain optimization functionality with variations in architecture, deployment models and advanced capabilities.

Vendor selection should align with organizational requirements, industry characteristics and future direction rather than current market position.

8.1 SAP S/4HANA.

SAP S/4HANA represents the in memory platform evolution of SAP’s ERP system. Supply chain functionality includes embedded advanced planning, integrated business planning modules and real time analytics.

Demand sensing incorporates machine learning algorithms. Multi echelon inventory optimization determines stock positioning across networks.

Global trade management provides comprehensive compliance capabilities.

Integration with SAP Ariba enables supplier collaboration and procurement automation. Connection to SAP Logistics Business Network facilitates multi party visibility and coordination.

Sustainability analytics track carbon footprint and circular economy metrics. AI readiness includes pre built business AI scenarios and integration with generative AI capabilities.

Industry specific functionality addresses requirements in discrete manufacturing, process industries, retail and other sectors.

Implementation complexity reflects broad functional scope and configuration flexibility. Cloud deployment options coexist with on premise installations.

8.2 Oracle Cloud SCM.

Oracle Cloud Supply Chain Management provides comprehensive planning, procurement, manufacturing and logistics capabilities within a cloud native architecture.

Demand management incorporates AI driven forecasting and demand sensing. Supply planning includes constraint based optimization and scenario comparison. Manufacturing execution connects planning to shop floor operations.

Procurement functionality includes sourcing, contracting and supplier portal capabilities. Logistics encompasses order management, warehouse management and transportation management.

Global trade management addresses compliance and documentation requirements.

Integration with Oracle’s broader cloud application portfolio enables unified data models across finance, human resources and customer experience.

Machine learning capabilities provide embedded intelligence for forecasting, quality prediction and supplier risk assessment. Blockchain based track and trace functionality supports traceability requirements.

8.3 Microsoft Dynamics 365 Supply Chain Management.

Dynamics 365 Supply Chain Management provides planning, procurement, manufacturing and warehouse capabilities within Microsoft’s business application platform.

Master planning incorporates optimization algorithms for demand forecasting and inventory positioning. Manufacturing execution integrates with shop floor systems and quality management.

Procurement includes vendor collaboration and automated workflows. Warehouse management provides directed putaway, picking and cycle counting.

Transportation management coordinates carrier selection and freight optimization.

Integration with Power Platform enables low code customization and workflow automation. Connection to Azure IoT provides equipment monitoring and predictive maintenance capabilities. Copilot integration brings generative AI assistance for planning and analysis tasks.

Mixed reality capabilities through HoloLens support warehouse and manufacturing operations.

8.4 Comparative Assessment.

Demand sensing maturity varies across platforms with SAP and Oracle providing longer established machine learning integration.

Microsoft is advancing rapidly through Azure AI integration. IBP maturity reflects SAP’s acquisition and development of specialized planning tools with Oracle and Microsoft building integrated capabilities.

GTM capabilities are most comprehensive in SAP with Oracle providing strong functionality and Microsoft addressing core requirements.

Sustainability analytics are most developed in SAP through dedicated modules with Oracle and Microsoft building capabilities.

AI readiness reflects underlying platform characteristics with Oracle leveraging autonomous database capabilities, SAP embedding business AI scenarios and Microsoft providing deep Azure AI integration.

Industry depth varies with SAP providing most extensive vertical functionality, Oracle strong in process industries and retail and Microsoft competitive in discrete manufacturing and distribution.

Total cost of ownership depends on deployment model, customization requirements and existing technology ecosystems.

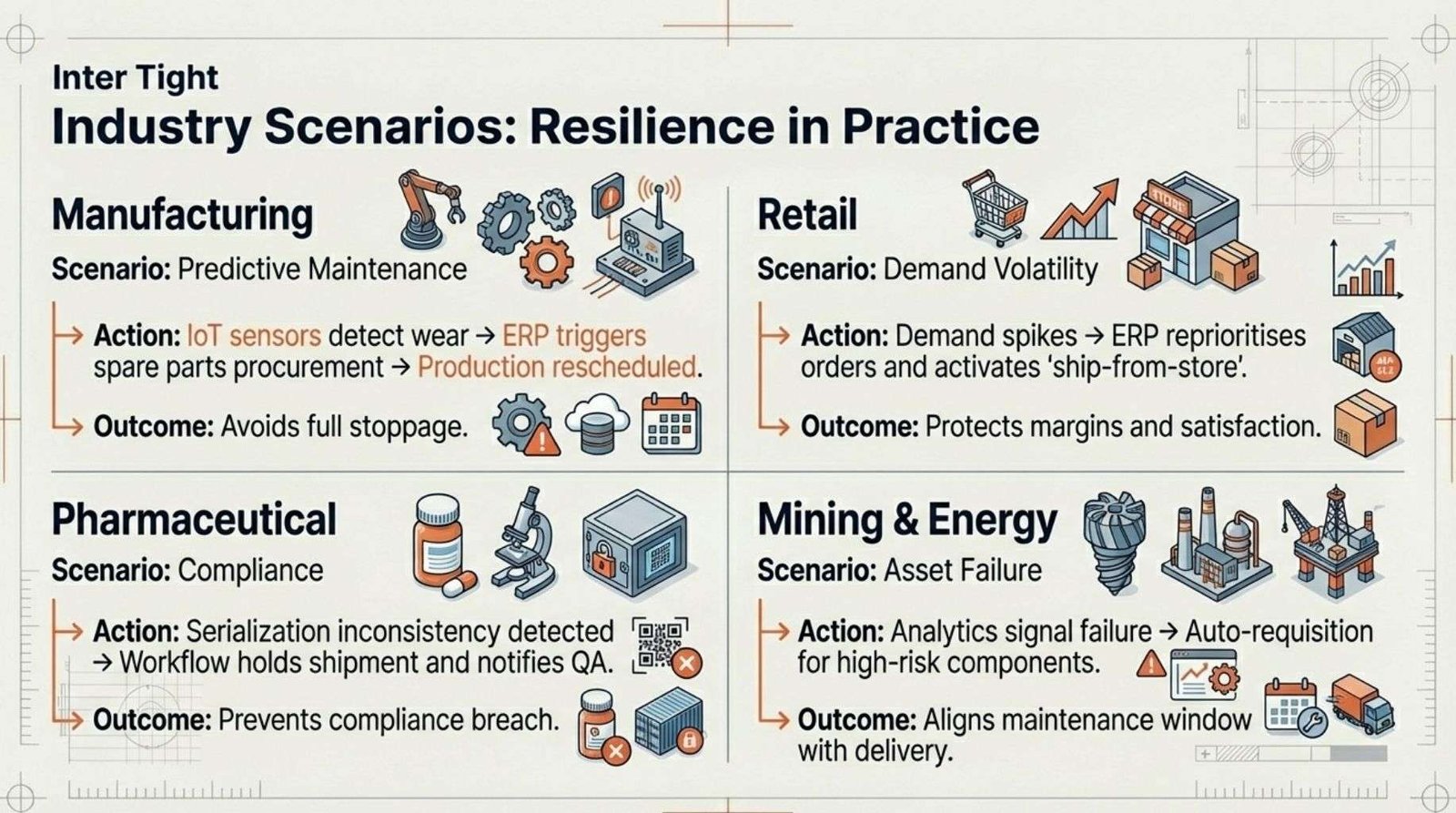

9.0 Scenario Planning Across Industries.

Effective ERP-driven supply chain optimization is not only about improving performance , it’s also about anticipating disruptions and preparing structured responses.

The following scenarios illustrate how organizations across key sectors can identify risks, respond decisively and leverage ERP intelligence to maintain continuity and efficiency.

9.1 Manufacturing: Predictive Maintenance and Production Continuity.

If unplanned equipment downtime disrupts output or delivery schedules, production targets and customer commitments can quickly fall behind.

ERP systems integrated with maintenance management and IoT sensors allow early detection of component wear, hydraulic degradation, or temperature anomalies.

When such warnings appear, teams can automatically reschedule production, trigger spare parts procurement and coordinate technician availability to avoid a full stoppage.

The key is connecting asset health data directly to planning functions, ensuring the system itself helps balance responsiveness and cost control.

9.2 Retail: Demand Volatility and Fulfillment Agility.

Retailers face unpredictable shifts in demand, especially during promotions, product launches and supply interruptions.

If demand spikes beyond forecasts, ERP systems can respond by reprioritizing orders, redistributing inventory between stores, or activating alternate fulfillment channels such as ‘ship-from-store.’

Likewise, if sales underperform, automated inventory reallocation and markdown optimization prevent stock obsolescence.

Real-time visibility across warehouses and storefronts allows agile decisions that protect margins and customer satisfaction when conditions change overnight.

9.3 Pharmaceutical: Compliance Breaches and Traceability Risks.

A missed serialization code or incomplete batch record can escalate into a major compliance breach.

When ERP systems detect inconsistencies in lot tracking or serialization data, automated workflows should trigger a containment protocol, holding shipments, notifying quality assurance leads and generating full trace histories for audit support.

Proactive monitoring within ERP ensures traceability from raw materials to patient delivery, minimizing recall scope and protecting regulatory standing.

9.4 Mining and Energy: Critical Asset Failure and Supply Risk.

For mining or energy operations, unexpected equipment failures or delays in spare part procurement can halt production.

ERP systems help model what-if scenarios, simulate equipment downtime and calculate impacts on output. If predictive analytics signal possible failure, automatic purchase requisitions for high-risk components can be issued, while maintenance windows are aligned with material deliveries.

By linking reliability engineering to procurement and inventory workflows, the operation maintains availability and reduces exposure to costly idle time.

These scenarios underscore the value of ERP not just as an optimization tool, but as a predictive and corrective backbone for supply chain resilience.

Organizations that treat their ERP environment as an early-warning and response system transform challenges into opportunities for smarter, data-driven action.

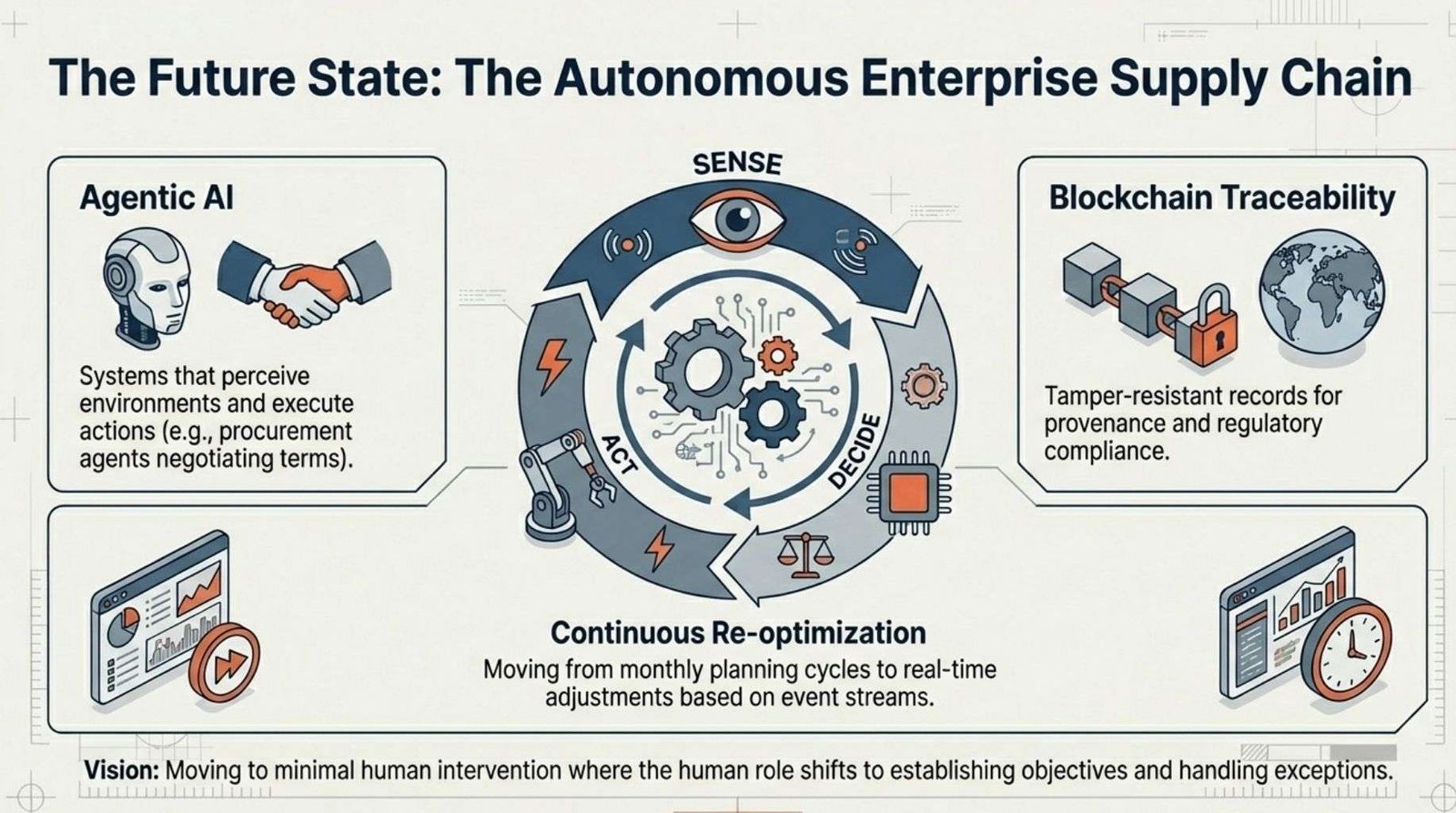

10.0 The Future State: The Autonomous Enterprise Supply Chain.

Supply chain evolution trends toward systems that sense, decide and act with minimal human intervention while maintaining appropriate governance and oversight. This vision represents gradual capability enhancement rather than revolutionary transformation.

10.1 ERP as Coordinated Optimization Platform.

Future ERP systems will function as orchestration engines coordinating specialized applications rather than monolithic suites attempting universal functionality. Planning optimization will consume data from execution systems, external sources and partner networks.

Execution systems will receive plans and adapt to real time conditions. Analytics platforms will provide insights feeding back into planning models.

Integration architectures will shift from point to point connections to event driven publish subscribe models.

Changes in one domain will trigger automatic updates across dependent systems. Latency will decrease from hours or days to seconds or minutes.

Data consistency will improve through unified event streams and common data models.

10.2 Agentic AI Coordination.

Agentic artificial intelligence refers to systems capable of perceiving environments, making decisions and taking actions to achieve objectives.

In supply chain contexts, agents might monitor inventory levels, detect exception conditions, evaluate alternative responses and execute optimal actions within defined parameters.

Procurement agents could identify supplier risks, evaluate alternative sources, negotiate terms and issue purchase orders.

Planning agents could detect demand shifts, adjust forecasts, reoptimize inventory positions and update production schedules. Logistics agents could monitor shipment status, reroute for delays and communicate updates to customers.

Human oversight would establish objectives, define constraints, approve high value decisions and intervene for exceptions.

Transparency requirements would ensure explainability of agent decisions and actions. Governance frameworks would balance automation benefits with accountability and control.

10.3 Blockchain Based Traceability.

Blockchain technology provides distributed ledger capabilities enabling tamper resistant record keeping across multiple parties without centralized authority. Supply chain applications include product provenance tracking, authenticity verification and regulatory compliance documentation.

Pharmaceutical traceability could record every custody transfer from manufacturing through patient administration. Food safety could track ingredients from farm through processing to consumer.

Conflict mineral sourcing could verify ethical origin and chain of custody. Carbon footprint could accumulate emissions across transportation, production and distribution.

ERP systems would integrate with blockchain networks to write transaction records and verify authenticity.

Planning and execution would leverage verified data for compliance reporting and risk assessment. Implementation challenges include standardization, scalability and governance across competing organizations.

10.4 Continuous Reoptimization as Operating Model.

Static planning cycles with monthly or weekly updates will give way to continuous reoptimization responding to real time conditions.

Demand signals will trigger forecast updates and inventory adjustments immediately rather than waiting for planning cycle closure.

Supply disruptions will initiate scenario evaluation and alternative sourcing within minutes of detection. Production schedules will adapt to material availability and equipment status without manual intervention.

This shift requires robust data architecture, sophisticated algorithms and organizational change management.

Systems must handle high frequency updates without performance degradation. Algorithms must balance responsiveness with stability to prevent excessive volatility. Organizations must trust automated decisions while maintaining appropriate oversight.

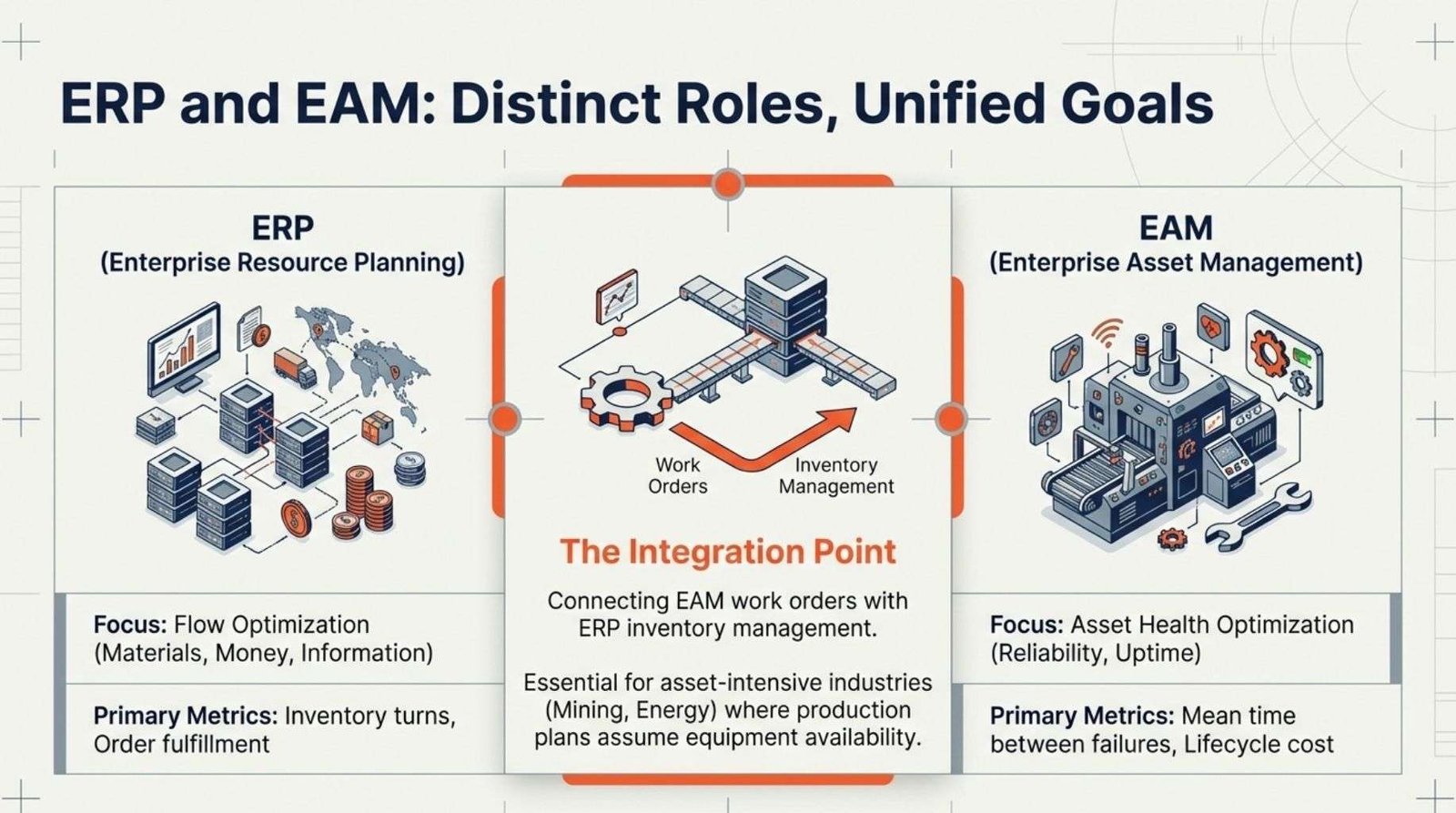

11.0 How Supply Chain Optimization Differs Between ERPs and EAMs.

Enterprise Resource Planning and Enterprise Asset Management systems serve distinct but complementary purposes within organizations.

Understanding their different optimization objectives enables appropriate application and integration.

11.1 ERP: Flow Optimization.

ERP systems optimize the flow of materials, information and financial value across supply chain processes. Planning modules determine what to produce, purchase, or distribute based on demand forecasts and capacity constraints. Execution modules coordinate procurement, manufacturing, warehousing and distribution activities. Financial modules capture costs, recognize revenue and manage working capital.

Optimization objectives include inventory minimization while maintaining service levels, throughput maximization within capacity limits and working capital efficiency.

Metrics emphasize order fulfillment performance, inventory turns and cash conversion cycles. Success derives from coordinated planning and execution across organizational boundaries.

11.2 EAM: Asset Health Optimization.

EAM systems optimize the health, reliability and lifecycle performance of physical assets including equipment, facilities and infrastructure.

Maintenance planning determines when to perform preventive, predictive, or corrective work. Work execution manages labor, materials and contractor resources. Asset performance monitoring tracks condition, reliability and total cost of ownership.

Optimization objectives include uptime maximization, lifecycle cost minimization and regulatory compliance.

Metrics emphasize asset availability, mean time between failures and maintenance cost ratios. Success derives from proactive intervention before failures and optimized maintenance strategies.

11.3 Complementary Relationship.

Supply chain performance depends fundamentally on asset reliability in asset intensive industries including manufacturing, mining, energy and utilities. Production plans assume equipment availability.

Procurement timing depends on production schedules. Inventory positioning reflects manufacturing lead times.

Asset management performance depends on supply chain coordination. Maintenance work requires parts availability.

Preventive maintenance schedules must align with production priorities. Equipment replacements require procurement planning and logistics coordination.

11.4 Integration Requirements.

Effective integration connects EAM work orders with ERP inventory management to ensure parts availability for maintenance activities.

Maintenance schedules inform production planning about equipment downtime. Asset performance data feeds into capacity planning and constraint management.

Procurement coordinates spare parts purchasing with maintenance forecasts rather than only production requirements.

Organizations operating both systems should establish clear data ownership, avoid duplicate entry and maintain single sources of truth for shared entities. Equipment masters may reside in EAM with financial and inventory attributes synchronized to ERP.

Maintenance materials may exist in both systems with inventory transactions flowing to ERP for financial recording.

11.5 When Integration Matters Most.

Asset intensive industries benefit most from ERP EAM integration. Manufacturing requires coordination between production schedules and equipment maintenance.

Mining depends on mobile equipment availability and processing plant reliability. Energy generation cannot tolerate unplanned outages. Transportation depends on vehicle and infrastructure availability.

Organizations with modest asset bases may handle integration through manual coordination or periodic synchronization.

Asset intensive operations require real time integration to optimize both supply chain flow and asset health simultaneously.

Investment in integration delivers returns through improved production reliability and reduced operating costs.

12.0 References And Further Reading.

Industry Research and Analysis.

- Gartner, Inc. Supply chain planning solutions market analysis and vendor evaluation. Stamford, Connecticut. 2024.

- Gartner, Inc. ERP cloud adoption trends and implementation best practices. Stamford, Connecticut. 2025.

- IDC Research. Digital transformation in supply chain management: technology investment priorities. Framingham, Massachusetts. 2024.

- IDC Research. Enterprise resource planning: market forecast and competitive landscape. Framingham, Massachusetts. 2025.

- MIT Center for Transportation and Logistics. Supply chain resilience: building adaptive capabilities. Cambridge, Massachusetts. 2024.

- MIT Sloan Management Review. Data quality and supply chain performance: an empirical study. Cambridge, Massachusetts. 2024.

Professional Standards and Frameworks.

- APICS Supply Chain Council. Supply Chain Operations Reference Model version 12. Chicago, Illinois. 2023.

- APICS. Certified Supply Chain Professional body of knowledge. Chicago, Illinois. 2024.

- Institute for Supply Management. Professional standards and competency framework. Tempe, Arizona. 2024.

- Council of Supply Chain Management Professionals. Supply chain management definitions and glossary. Lombard, Illinois. 2023.

Vendor Technical Documentation.

- SAP SE. SAP S/4HANA supply chain management technical reference guide. Walldorf, Germany. 2025.

- SAP SE. SAP Integrated Business Planning implementation methodology. Walldorf, Germany. 2024.

- Oracle Corporation. Oracle Cloud Supply Chain Management implementation guide. Redwood City, California. 2025.

- Oracle Corporation. Oracle Advanced Supply Chain Planning technical documentation. Redwood City, California. 2024.

- Microsoft Corporation. Dynamics 365 Supply Chain Management feature overview. Redmond, Washington. 2025.

- Microsoft Corporation. Supply chain optimization with Copilot: implementation guide. Redmond, Washington. 2025.

Industry Whitepapers and Case Studies.

- McKinsey and Company. Supply chain 4.0: achieving digital transformation at scale. New York, New York. 2024.

- Boston Consulting Group. Building resilient supply chains in an uncertain world. Boston, Massachusetts. 2024.

- Deloitte Consulting. ERP transformation: lessons from global implementations. New York, New York. 2024.

- PricewaterhouseCoopers. Supply chain risk management in the digital age. London, United Kingdom. 2024.

Academic Research.

- Harvard Business Review. The new science of supply chain resilience. Boston, Massachusetts. 2024.

- Stanford Graduate School of Business. Predictive analytics in supply chain management. Stanford, California. 2023.

- Wharton School of Business. Working capital optimization through integrated planning. Philadelphia, Pennsylvania. 2024.

- Journal of Operations Management. ERP implementation success factors: a meta analysis. Volume 68, Issue 3. 2024.

Sustainability and Compliance.

- Carbon Disclosure Project. Supply chain emissions reporting standards and guidance. London, United Kingdom. 2024.

- Global Reporting Initiative. Sustainability reporting in supply chain management. Amsterdam, Netherlands. 2024.

- International Organization for Standardization. ISO 28000 supply chain security management. Geneva, Switzerland. 2023.

- European Commission. Digital Product Passport implementation guidelines for supply chain traceability. Brussels, Belgium. 2025.

Technology and Innovation.

- IEEE Transactions on Engineering Management. Artificial intelligence applications in supply chain optimization. Volume 71, Issue 2. 2024.

- Association for Computing Machinery. Blockchain applications in supply chain traceability and transparency. Communications of the ACM. Volume 67, Issue 5. 2024.

13.0 Terms and Abbreviations Table.

Term / Abbreviation | Description | Definition |

AI | Artificial Intelligence | Computer systems capable of performing tasks requiring human intelligence, including learning, reasoning and pattern recognition. |

ATP | Available to Promise | Inventory quantity available for customer order commitment based on current stock and planned production. |

BOM | Bill of Materials | Structured list of components, quantities and relationships required to manufacture a finished product. |

CMMS | Computerized Maintenance Management System | Software managing maintenance activities, work orders and asset performance tracking. |

EAM | Enterprise Asset Management | System optimizing physical asset health, reliability and lifecycle performance. |

ERP | Enterprise Resource Planning | Integrated software managing business processes across finance, operations, human resources and supply chain. |

ESG | Environmental, Social, Governance | Framework measuring organizational performance on sustainability, social responsibility and governance practices. |

GTM | Global Trade Management | ERP functionality managing international trade compliance, documentation, duties and regulatory requirements. |

IBP | Integrated Business Planning | Cross-functional planning process aligning demand, supply, product and financial plans. |

IoT | Internet of Things | Network of physical devices embedded with sensors, software and connectivity enabling data collection and exchange. |

MES | Manufacturing Execution System | Software managing production activities from order release through finished goods. |

ML | Machine Learning | Subset of artificial intelligence enabling systems to learn and improve from experience without explicit programming. |

MRP | Material Requirements Planning | Planning method calculating material quantities and timing based on production schedules and inventory levels. |

MRP II | Manufacturing Resource Planning | Extension of Material Requirements Planning incorporating capacity planning and financial integration. |

OTD | On-Time Delivery | Performance metric measuring percentage of customer orders delivered by promised date. |

PLM | Product Lifecycle Management | System managing product data from concept through design, production, service and disposal. |

RCCP | Rough-Cut Capacity Planning | High-level capacity validation confirming feasibility of production plans before detailed scheduling. |

ROI | Return on Investment | Financial metric measuring profitability of investment relative to cost. |

S&OP | Sales and Operations Planning | Monthly process balancing demand forecasts with supply capabilities to establish executable plans. |

SKU | Stock Keeping Unit | Distinct item identifier for inventory tracking and management purposes. |

TMS | Transportation Management System | Software optimizing freight planning, execution, settlement and carrier management. |

WMS | Warehouse Management System | Software managing inventory storage, movement, picking, packing and shipping operations. |