Purchase Asset Management Software Solutions

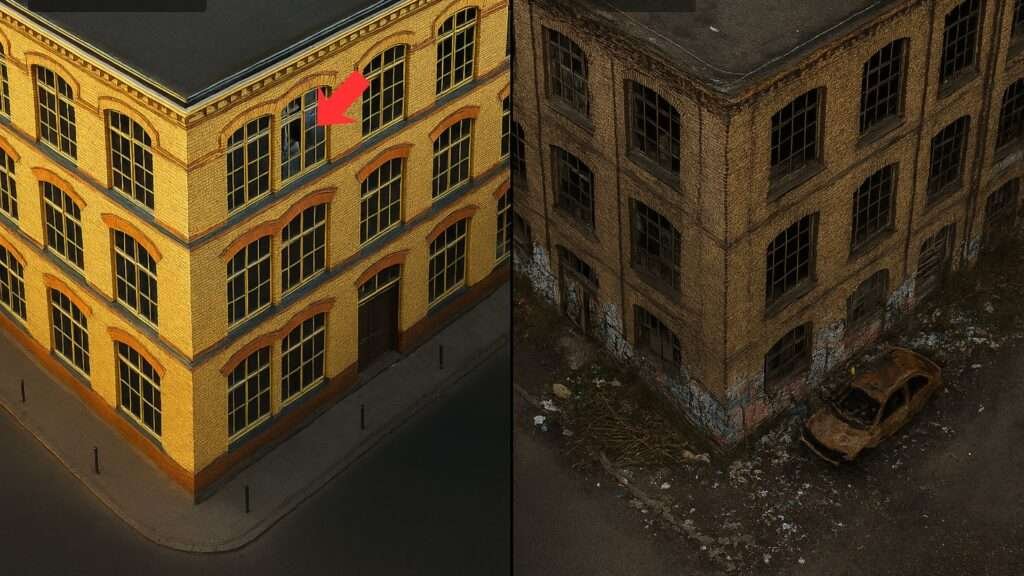

Asset management software is essential for businesses in the manufacturing, commodity extraction, material processing, and refining sectors.

They often make large capital investments and incur significant yearly maintenance costs. The maintenance and operations teams of these companies are under constant scrutiny from shareholders and senior management, as key stakeholders seek to optimize asset performance, streamline maintenance & operations tasks, maximize uptime and minimize waste.

In this article, I will explore the various types of maintenance software available and the modules they include, or ideally should include, to address these challenges.

My goal is to ensure that your company is well-prepared to evaluate and engage with software providers.

Additionally, I will delve into specialized software solutions tailored for automotive workshops.

1.0 Asset Management Software Categories.

The asset/maintenance management software market can be divided into several distinct, yet occasionally overlapping, categories.

Each category have been developed to address a specific range of maintenance and operational needs, ranging from basic maintenance functions to comprehensive asset lifecycle management.

As technology in this field has advanced, the boundaries between these categories have blurred somewhat.

Modern, cost-effective CMMS solutions now sometimes offer integrated features that were once exclusive to high-end ERP systems.

The typical categories are:

1. Computerized Maintenance Management Systems (CMMS)

2. Enterprise Asset Management (EAM)

3. Enterprise Resource Planning (ERP) systems.

2.0 Computerized Maintenance Management Systems (CMMS)

While the term CMMS may feel a bit dated to some people, it remains widely recognized in the maintenance management space.

Compared to the latest ERP systems, CMMS solutions are typically compact, affordable, and well-suited for small to medium-sized businesses.

Typical Features of a CMMS:

1. Work Order Management: Efficient tracking and management of maintenance tasks.

2. Preventive Maintenance:

o Integration of preventive strategies to automatically generate work orders that include technical details, parts requirements, equipment needs, safety considerations.

o Auto generates work should answer the critical questions: What, How, Who, When, and Why if it’s going to reduce the likelihood of breakdowns.

3. Work Planning & Scheduling: Organizes preventive and corrective maintenance into streamlined schedules, maximizing productivity while minimizing waste.

4. Execute & Complete Scheduled & Unplanned Maintenance Work

5. Additional Core Modules:

o Equipment Register: Records essential asset details.

o Materials Module: Manages inventory effectively.

o Work Request System: Ensures all new tasks are reviewed and approved.

What to Look for in a CMMS Solution

Roughly speaking, the more you invest, the more functionality you will have.

Below are some examples of modules/functionality of what a higher end CMMS might include:

1. Purchase Assets & Materials

2. Commission New Assets

3. Initiate & Approve New Work

4. Manage Project Work

5. Materials Management

6. Develop Maintenance Strategies

7. Plan & Approve Work

8. Create & Approve Work Schedules

9. Execute Work (Scheduled and Emergency/Breakdown)

10. Complete/Close Work

11. Analyze Completed Work

12. Manage Maintenance Budget

13. KPIs

14. Manage Health, Safety, Environmental and Community Related Work.

15. Handle Invoices (Pay Bills)

Specialized CMMS Add-ons and Evolving Needs

The booming specialized add-on software market underscores an important consideration: whether your business is likely to experience significant growth in the coming years.

When companies opt for a more affordable CMMS solution early on, it’s often because that’s the only financially viable choice at that stage and is certainly understandable.

However, many may eventually regret that decision when their CMMS no longer meets their needs as the business grows and expands across multiple locations.

If a company has used the same software for several years, its workforce may become highly skilled at fully leveraging that system.

These organizations might naturally be reluctant to risk their established maintenance and operational efficiency by undertaking the time-consuming process of transitioning to a new, more comprehensive solution that they’ll all have to learn and basically start again with.

As a result, they frequently purchase specialized add-on modules (which are often excellent) to fill the gaps in their business requirements.

In doing so, they effectively transform a basic CMMS into a makeshift EAM system. Ironically, this approach can lead to higher overall costs than starting with an EAM from the outset.

I’m not suggesting for one second that there’s anything inherently wrong with that approach. After all, if your company enjoys high user engagement and excellent data quality, you might would rightly be concerned about losing those advantages.

However, you may also be pleasantly surprised at just how much customization and personalization is possible with modern EAMs and ERPs.

It is entirely feasible to retain much of the look and feel of your current CMMS when upgrading to a new EAM or potentially an ERP.

That aside, CMMS solutions are designed to be practical, user-friendly, and affordable, allowing organizations with limited financial resources to maintain robust maintenance processes while meeting their core business objectives.

Popular CMMS Solutions

(Includes Paid, Free & Open Source Offerings)

eMaint by Fluke Corporation.

· Overview: A robust CMMS designed for organizations that need customizable workflows and proactive maintenance solutions.

· Key Features:

o Customizable workflows

o Preventive maintenance scheduling

o Mobile access

· Pricing: Indicative pricing of around ~US $69/user/month for ‘Team’ option (pricing tiers depends on module add-ons and scope etc).

· Target Market: Medium to large organizations

· Website: https://www.emaint.com

MaintainX.

· Overview: A mobile-first maintenance management system emphasizing real-time communication and digital work procedures.

· Key Features:

o Mobile-first interface

o Team messaging

o Digital procedures

· Pricing: Different tiers available—from a free version to Essential & Premium plans starting at approximately US $16/user/month for ‘Essential’ and US $49 per user/month for Premium.

· Target Market: Small to medium businesses

· Website: https://www.getmaintainx.com

UpKeep.

· Overview: A user-friendly, mobile-centric CMMS perfect for asset tracking and parts inventory management.

· Key Features:

o Intuitive mobile interface

o Asset tracking

o Parts inventory management

· Pricing: Offers a Lite version for US $20 per user/per month and then has a Starter Version of US $45/user/month and then goes up to the Professional and Business+ versions which are custom pricing

· Target Market: Small to mid-market (SMBs to mid-market organizations)

· Website: https://upkeep.com

Fiix by Rockwell Automation.

· Overview: A modern system that leverages AI-driven insights and IoT integration to optimize multi-site maintenance operations.

· Key Features:

o AI-driven insights

o Multi-site management

o IoT integration

· Pricing: There is a free version you can try but with the paid versions, things start at around US $45/user/month for the Basic Plan, then goes up to US $75/month/user for the Professional Option and then with the Enterprise version, pricing is custom.

· Target Market: Manufacturing, facilities, and other industrial sectors. I have written about how using this software could be suitable for a Truck owner/operator.

· Website: www.fiixsoftware.com

Limble.

· Overview: A very versatile, intuitive and flexible CMMS that enhances work order efficacy through features like barcode scanning and customizable PM checklists.

· Key Features:

o Intuitive interface

o Barcode scanning

o Customizable preventive maintenance checklists

· Pricing: Starts at about US $28/user/month for the Standard version, Premium+ is around US $69/user/month and their Enterprise version is custom priced.

· Target Market: SMBs across various industries

· Website: https://limblecmms.com

Hippo CMMS by Eptura

Eptura have done a lot with this software in recent times, Hippo offers a quite a comprehensive suite of intelligent worktech solutions designed to streamline workplace management and operations. Its popularity probably stems from its versatility and ability to cater to businesses of various sizes and industries.

At its core, Eptura provides asset management through its Advanced and Power plans. The Advanced plan includes inventory tracking, barcode scanning, preventive maintenance scheduling, and service request customization. Users can oversee assets across multiple locations, track inventory levels, and gain comprehensive insights into asset performance and costs.

The Power plan expands upon the features offered in the Advanced Plan, offering enterprise asset management with downtime tracking, automated task management, purchase order processing, and developer API access for seamless integration with external tools. It enables businesses to automate maintenance tasks, categorize labor outputs, and generate detailed reports on downtime costs.

Beyond asset management, Eptura also includes visitor management, workplace engagement tools, and solutions for optimising building operations. Users can build an asset registry, categorize equipment, track parts installed on machinery and manage technician workflows (everything you would expect from one of the major players in this space.

I think a good portion of Hippo’s appeal lies in its flexibility, scalability and ability to centralize workplace data for efficient decision-making. Helping businesses benefit from smoother workflows, enhanced security, and greater control over their work environments. With optional add-ons, businesses can customize their experience to meet unique operational needs.

Its widespread adoption is most likely being driven by its ability to simplify complex processes, reduce operational inefficiencies, and provide businesses with the tools needed to thrive in a dynamic work environment.

· Pricing: Custom per client/your needs and wants etc.

· Target Market: Most sectors, it’s well worth a look.

· Website: https://eptura.com/hippocmms

Asset Panda

- Key Features: Cloud-based, customizable, mobile-first

- Pricing: Based on assets tracked

- Target Industries: Small to mid-sized organizations

- Website: assetpanda.com

MPulse by JDM Technology Group.

· Overview: Ideal for detailed maintenance management with configurable dashboards and robust equipment tracking, aimed at critical industries.

· Key Features:

o Configurable dashboards

o Detailed equipment tracking

· Pricing: Typically offered under a perpetual licensing model (priced in the premium range).

· Target Market: Manufacturing, healthcare industries

· Website: https://mpulsesoftware.com

FaciliWorks by CyberMetrics.

· Overview: A specialized platform suited for regulated industries, offering robust calibration management and extensive reporting capabilities.

· Key Features:

o Calibration management

o Extensive reporting

· Pricing: Generally based on a perpetual license model, falling within a higher price bracket (marked as $$$).

· Target Market: Regulated industries (e.g., pharmaceuticals, manufacturing)

· Website: https://faciliworks.com

Maintenance Connection by Accruent.

· Overview: An enterprise-grade CMMS designed to scale with large organizations, featuring advanced reporting and data analytics.

· Key Features:

o Enterprise scalability

o Advanced reporting

· Pricing: Offered mainly via perpetual licenses, with premium to enterprise-level pricing.

· Target Market: Sectors such as healthcare, education, and large organizations

· Website: https://www.accruent.com/products/maintenance-connection

MEX by MEX Pty Ltd.

· Overview: An Australia-based CMMS focusing on asset tracking and preventive maintenance scheduling, especially for the mining and manufacturing sectors.

· Key Features:

o Localized support

o Asset tracking

o PM scheduling

· Pricing: Available under both perpetual licensing and SaaS options, generally classified within mid range price tiers.

· Target Market: Mining and manufacturing industries

· Website: https://www.mex.com.au

Free CMMS.

· Overview: A no-cost option for organizations seeking essential maintenance management functions without the financial commitment.

· Key Features:

o Work orders

o Preventive maintenance scheduling

o Asset tracking with unlimited users

· Limitations: Basic reporting functionality and limited customization options compared to premium offerings

· Website: https://www.freecmms.org

OpenMAINT.

· Overview: An open-source, extensible CMMS focused on asset management, ideal for organizations with technical expertise looking for customizable solutions.

· Key Features:

o Open-source framework

o Extensible platform

o Solid asset management features

· Limitations: Requires technical know-how for setup and configuration; support is community-based

· Website: https://www.openmaint.org/en

Maintenance Care.

· Overview: Suited for small businesses, this tool offers a free tier for core maintenance management needs with a straightforward work order system.

· Key Features:

o Free tier for small businesses

o Efficient work order tracking

· Limitations: The free plan is limited to 3 users, which may necessitate an upgrade as teams grow

· Website: https://www.maintenancecare.com/

My Thoughts:

When considering a CMMS, remember that pricing and features can evolve over time and you can always explore adding additional features, although this would be more expensive.

It all starts off with visiting the vendor websites to confirm the latest details, especially if you’re comparing multiple solutions. Always be sure to ask for demonstrations, whether via Microsoft Teams etc or have them do this on site.

Additionally, weighing factors like scalability, integration with existing systems and the specific needs of your maintenance team will help ensure you choose the tool best suited to your organization.

3. Automotive Workshop Management Software.

Designed specifically for automotive workshops and fleet maintenance operations, workshop management software addresses the unique challenges of servicing and repairing vehicles.

This niche solution streamlines diagnostics, repairs, and overall workflow efficiency in modern workshops.

Some of the key features of this type of software are below.

Real-Time Monitoring & Diagnosis:

Quickly detects and identifies issues using a seamless blend of hardware interfaces, intelligent software algorithms, and robust connectivity solutions.

· Vehicle Communication Interfaces (VCIs)

o OBD-II Scanners & Adapters: Workshops utilize hardware tools—such as OBD-II dongles or Bluetooth/Wi-Fi scanners—that plug into a vehicle’s On-Board Diagnostics (OBD) port to read Diagnostic Trouble Codes (DTCs) and live data.

o Direct ECU Communication: Advanced systems interface directly with a vehicle’s Electronic Control Unit (ECU) to pull real-time sensor data (e.g., engine RPM, fuel pressure, temperature readings).

Quick Note on ECU Communications:

While advanced workshop management software can extract real-time sensor data via the ECU, the depth and breadth of this communication are typically limited by the vehicle’s make and model.

Although the OBD-II standard provides generic diagnostic codes and basic sensor data accessible across many vehicles, many manufacturers employ proprietary protocols and custom diagnostic parameters. These may require specialized tools or software to fully access.

For example, a basic system might retrieve standard metrics without issue on some vehicles, but on others, especially those with more restrictive protocols, the same system might only offer limited access.

More advanced features, such as enhanced diagnostic trouble codes, detailed performance data, or manufacturer-specific sensor readings, may only be accessible when proprietary diagnostic software or hardware from the vehicle maker is integrated with your workshop management software or if you have purchased the additional software as an add-on.

This variability means that while workshop management software is highly capable, its full diagnostic potential is contingent on compatibility with the specific make and model of the vehicle. Be sure to inquire about this when evaluating your software options.

Integration with Diagnostic Software

· APIs – Proprietary or Third-Party:

o The workshop management software should integrate with diagnostic tools (e.g., Bosch KTS, Snap-on MODIS, Autel scanners) via APIs that allow it to fetch and interpret live data.

· AI-Powered Analysis:

o When incorporated, AI compares sensor readings against known failure patterns for various VIN ranges, flagging potential issues before they escalate.

o This functionality can help avoid scenarios where a car, after servicing, breaks down on a busy highway due to an underlying issue that went undetected during the service.

· Cloud-Based Monitoring & Alerts:

o Live Data Streaming: Connected vehicles transmit data in real time to a cloud-based system, enabling technicians or fleet managers to monitor multiple vehicles simultaneously.

o Automated Alerts: The software immediately flags anomalies—such as irregular engine vibrations or low battery voltage—and sends instant notifications to the appropriate personnel.

Workshop Workflow Integration.

Automated Reports & Repair Orders: Diagnostic results are converted into repair orders automatically, while inventory systems update parts availability in real time.

· Technician Guidance:

o Some systems will offer repair procedures or service bulletins based on the detected issues to guide technicians through the necessary steps.

o Telematics & Fleet Connectivity (For Fleet Workshops)

o Remote Diagnostics: Telematics devices continuously capture performance data from fleet vehicles, enabling proactive maintenance before issues escalate to the point of requiring physical inspection.

Key Technologies Enabling Real-Time Diagnostics

· OBD-II Protocols (SAE J1979): Standardized communication for vehicle diagnostics.

· CAN Bus (Controller Area Network): Facilitates robust ECU data exchange.

· IoT & 5G Connectivity: Ensures low-latency, real-time data transfer.

· AI/ML Models: Predict failures by analyzing historical and real-time sensor data.

Example Workflow

1. A car is brought into the workshop and connected to a diagnostic scanner.

2. The workshop management software reads live ECU data and DTCs, cross-referencing this information with trusted databases (e.g., Mitchell1, ALLDATA).

3. The system will leverage all of its functions and quickly work out the most common Causes of a Single-Cylinder Misfire):

a) Faulty or Fouled Spark Plug: The sensor data may show inconsistent or weak spark events from one cylinder, suggesting the spark plug needs inspection or replacement. Given the commonality of this type of repair, it might issue one from the parts department for that particular job reference.

b) Defective Ignition Coil: The system can detect abnormal voltage levels or intermittent coil failures via real-time ECU feedback. If failure is detected, it could be programmed to check stocks and flag if an external purchase would be required.

c) Wiring or Connector Issues: API data might reveal transient losses in signal, directing technicians to check the associated wiring or connectors.

d) Clogged or Malfunctioning Fuel Injector: AI analysis can compare injector performance across cylinders and spot discrepancies, indicating that a particular injector may be clogged or malfunctioning.

e) Localized Fuel Pressure Variations: Even slight imbalances in fuel pressure, reported through the vehicle’s sensors, can cause an unbalanced air–fuel mixture in one cylinder and report on this accordingly.

f) Compression Issues: Integrated diagnostic tools enable compression tests or assess sensor data that indirectly reflect compression anomalies, such as misfires due to worn piston rings or valve issues.

g) Valve or Camshaft Irregularities: Minor irregularities in valve timing may be flagged by data analytics, suggesting the possibility of burnt or misaligned components.

This seamless integration of hardware, intelligent software, and cloud analytics minimizes diagnostic time and significantly enhances auto workshop efficiency.

Workshop Software:

- Key Features: Cloud-based, job tracking, invoicing, reports

- Pricing: Starts at around $60/month

- Shop Size: Small to medium

- Website: workshopsoftware.com.au

GaragePlug:

- Key Features: Digital job cards, customer communication

- Pricing: Only seems to be available via booking a meeting.

- Shop Size: Small independent

- Website: garageplug.com

Autowork Online by MAM Software

- Key Features: Scheduling, invoicing, parts management

- Pricing: Pricing page not currently available, would need to contact them.

- Shop Size: Small to medium

- Website: https://autowork.online/

AutoFluent by MAM Software

- Key Features: Job management, inventory control, accounting

- Pricing: You need to contact them to get a quote

- Shop Size: Medium to large

- Website: https://autorepairsoftware.com/

Auxo Workshop CRM

- Key Features: CRM, invoicing, job tracking

- Pricing: You will need to contact them to get quote.

- Shop Size: Small to medium

- Website: auxosoftware.com

Fleetio

- Key Features: Fleet maintenance, fuel tracking, vehicle inspections

- Pricing: Per 3 tiers, Essential $4, Professional $7, Premium $10 per vehicle, per month, US dollar amounts provided.

- Shop Size: Fleet operators

- Website: fleetio.com

Mitchell1

- Key Features: Labor estimating, repair information, shop management, truck maintenance management

- Pricing: You will need to contact them to discover monthly pricing etc.

- Shop Size: Medium to large

- Website: mitchell1.com

Tekmetric

- Key Features: Digital inspections, workflow management, multi workshop ability

- Pricing: Monthly subscriptions that start from around US $200/month to $439/month and at the upper tier with their Enterprise Package, pricing is custom and via quote.

- Shop Size: Small to medium

- Website: tekmetric.com

ShopMonkey

- Key Features: Digital inspections, customer communication

- Pricing: Monthly subscription, starts with Basic Monkey Tier US $179/month, Clever Monkey US $292/month, Genius Monkey US $427/month and the Multi Workshop Option is custom pricing via quote.

- Shop Size: Small to medium

- Website: www.shopmonkey.io

4. Enterprise Asset Management (EAM).

EAM platforms are engineered for larger or more complex organizations requiring a comprehensive solution for their asset management needs and wants.

These systems cover every stage of an asset’s life, from acquisition and maintenance to eventual disposal/auctioning off etc.

EAM Key Features Include:

EAM platforms are engineered for larger or more complex organizations that require a comprehensive solution for their asset management needs.

These systems cover every stage of an asset’s life, from acquisition and regular maintenance to eventual disposal.

Key Features of EAM Platforms

In essence, an EAM could I guess be thought of as a robust CMMS that comes bundled with almost every conceivable add-on solution.

What sets an EAM apart thought is that it is designed from the ground up to integrate these features, ensuring that all modules work interdependently to add value across the board.

1. Lifecycle Management: An EAM gives you a systematic framework that optimizes an asset’s total cost of ownership (TCO) and performance. Whether managing a standard motor vehicle, a Tier 1 mining machine, an IT system, or a new building, this approach ensures that every financial, operational, and technical decision aligns with the asset’s long-term use and your company’s strategic goals.

2. Advanced Analytics: Delivering in-depth insights, advanced analytics support capital planning, optimize annual maintenance and operations budgeting, and drive performance improvements across the organization.

3. Integration Capabilities: EAM platforms seamlessly integrate all system modules, allowing them to operate as a unified whole and ensuring consistency and efficiency in data management.

While EAM systems may carry a higher price tag compared to CMMS solutions, their broader array of functionalities makes them indispensable for businesses with extensive asset portfolios and complex operational requirements.

IBM Maximo by IBM

- Key Features: AI-powered maintenance, digital twin support, IoT integration

- Pricing: Enterprise pricing

- Target Industries: Utilities, oil & gas, manufacturing

- Website: ibm.com/products/maximo

Hexagon – Formerly known as Infor EAM

- Key Features: Industry-specific modules, asset hierarchy, multi-site, 3D visualization, GIS integration, risk assessments

- Pricing: Enterprise pricing

- Target Industries: Manufacturing, healthcare, public sector, mining, oil & gas

- Website: https://hexagon.com/products/enterprise-asset-management

IFS

- Key Features: Mobile workforce management, capital planning

- Pricing: Enterprise pricing

- Target Industries: Aerospace, energy, construction

- Website: ifs.com

AssetWorks by AssetWorks

- Key Features: Fleet management, facility management, space planning

- Pricing: Enterprise pricing

- Target Industries: Government, education, fleet

- Website: https://www.assetworks.com/

TMA Systems by TMA Systems

- Key Features: Facility management, CAFM capabilities

- Pricing: Enterprise pricing

- Target Industries: Education, healthcare

- Website: https://www.tmasystems.com/

6. ERP with Maintenance Modules

ERP solutions such as SAP, Ellipse, and Oracle often include robust maintenance modules within their integrated business management suites.

It’s important to note that not all ERP systems necessarily offer features tailored to asset management needs, which makes understanding their capabilities essential for choosing the right solution.

ERP Key Highlights

1. Integrated Management: Combines maintenance functions with modules for finance, HR, administration, supply chain management, and more, enabling end-to-end business operations on a single platform.

2. Modularity & Scalability: Allows organizations to select and invest only in the functionalities they require, offering flexibility and scalability to meet evolving business needs.

3. Enhanced Operational Synergy: Cross-functional integration promotes data transparency and streamlines processes across departments, improving overall efficiency.

While ERP’s represent the high-end solutions, it’s worth noting that they may not address every conceivable requirement out of the box.

Customizations are often necessary to add specific functionalities tailored to an organization’s unique needs.

ERPs empower businesses to enjoy advanced maintenance capabilities while leveraging the broader benefits of a fully interconnected system, making them indispensable for complex organizational environments.

SAP

- Website: sap.com

Oracle ERP

- Website: https://www.oracle.com/erp/

Microsoft Dynamics 365

- Website: https://www.microsoft.com/en-au/dynamics-365/

Epicor

- Website: https://www.epicor.com/en-au/

OnRamp

Website: https://www.onramp-solutions.com/

Synchro ERP

- Website: synchroerp.com

Ellipse by Hitachi Energy

- Website: hitachienergy.com

6. Global Market Overview

The global maintenance management software market continues to thrive, driven by a confluence of technological innovation and evolving operational needs. Key factors fueling this growth include:

· Asset Optimization: An intensified focus on extending asset lifespans and trimming operational costs has pushed organizations to invest in smarter maintenance strategies.

· Advanced Predictive Capabilities: The integration of predictive maintenance modules enabled by IoT and AI allows organizations to transition to from repairing to anticipating.

· Regulatory Compliance: Stringent statutory and regulatory requirements make it almost impossible for organizations to ignore systems that have the functionality built within the ‘out of the box’ version that will help them ensure compliance.

· Digital Transformation: A marked shift toward cloud-based and mobile-accessible solutions is redefining maintenance workflows, enhancing accessibility and collaboration across geographically dispersed teams.

· Emerging Technologies: The adoption of cutting-edge advancements such as digital twins, combined with rapidly evolving AI, is revolutionizing how maintenance activities are managed.

7. The Main Benefits

It is important to note that software outputs are only as good as their inputs.

I bring this up because when discussing the potential benefits of maintenance management software, I have to assume that your organization will execute a thorough implementation process, provide high-quality training for all staff, and allocate skilled personnel to the right roles.

These steps ensure that the software is fully leveraged and remains effective, preventing issues related to incorrect or poor-quality data inputs.

This principle also applies to data gathered or inferred from disparate systems, whether from operational software like AVEVA Plant SCADA or from Yokogawa’s Distributed Control System (DCS), CENTUM VP R6.12.

Organizations that implement and maintain these systems effectively can typically expect to realize several tangible benefits:

· Enhanced Operational Efficiency: Streamlined processes and automated workflows can often yield a reduction in maintenance labour costs by 15–40%, leading to more efficient resource utilization.

· Maximized Asset Lifespans: Optimized maintenance strategies and predictive insights can potentially offer a 20–25% extension in equipment lifespans without adversely affecting critical business performance.

· Reduced Downtime: By minimizing reliance on reactive maintenance, companies can achieve a 35–50% reduction in unplanned downtime, particularly for urgent repair work.

· Optimized Inventory Management: Intelligent categorization and data-driven inventory controls can reduce maintenance-related inventory costs by 20–30%—eliminating duplications, properly managing shelf life, and safeguarding critical spares from inadvertent destocking.

· Data-Driven Decision Making: Improved visibility into asset performance and broader business metrics empowers organizations to make proactive, informed decisions that align operational strategies with overall business objectives.

Together, these benefits illustrate how investing into a quality maintenance management software product not only drives maintenance and operational excellence but should also provide you with a solid return on investment.

8. Key Modules & Functions.

Equipment/Asset Register.

Below are some of the main reasons why I consider an Equipment/Asset Register essential for any maintenance related software product:

1) Centralized Asset Information:

· This repository acts as the definitive single source of truth, consolidating critical manufacturing specifications, including the original designs and any deviations or modifications made by a company.

· It also integrates operational and performance data captured when the asset was commissioned and this enables informed decision-making during operation of the asset.

· By ensuring data integrity and accessibility, it supports functions like predictive maintenance, compliance monitoring, lifecycle cost analysis, work order management and strategic asset optimization.

2) Facilitates Proactive Maintenance:

· By entering comprehensive asset information into the register, this facilitates preventive maintenance and provides the foundation for optimised equipment performance.

· Asset master data is used to create maintenance strategies, enabling prescriptive tasks to be automatically generated by your CMMS at precisely the right intervals.

· This proactive methodology adapts to operational conditions, mitigates risks and improves cost-efficiency, all while ensuring asset health and operational excellence.

· It prioritizes addressing potential issues before they escalate, significantly reducing downtime and prolonging the lifecycle of equipment.

· Entering all available master data that you have when purchasing a new asset is one of the most important tasks that will be performed.

3) Regulatory Compliance Master Data: The register helps to ensure adherence to safety standards, environmental regulations, and certification requirements, reducing compliance risks.

4) Facilitates Failure Trend Analysis:

· A comprehensive asset/equipment register captures critical master data that enables effective condition monitoring and failure pattern analysis.

· By leveraging this data through the predictive maintenance module of a CMMS, organizations can identify recurring trends, anticipate potential breakdowns, and take proactive measures to prevent equipment failures.

· This approach not only enhances equipment reliability but also reduces unplanned downtime, optimizing operational performance & resource utilization.

5) Enables Optimal Resource Optimisation:

· High-quality asset master data underpins the creation of effective maintenance strategies, such as preventive and predictive maintenance plans.

· These strategies ensure efficient labor allocation, minimize wastage of spare parts, and support compliance with maintenance intervals.

· By aligning maintenance schedules with asset conditions and operational priorities, organizations can achieve on-time and specification-compliant task completion.

· This reduces unplanned downtime, optimizes spare part utilization, and ensures resources are deployed in the most cost-effective and efficient manner.

6) Better Work Order Management: The register links assets to maintenance activities, streamlining planning, execution, and documentation processes.

7) Spare Parts Identification and Availability:

· The inclusion of Bills of Materials (BOMs) and Application Parts Listings (APLs) within the equipment/asset register is crucial.

· These elements establish a seamless connection between the Asset Management (AM) module and the Materials Management (MM) module. This integration enables maintainers to identify spare parts specific to a make/model/serial number range directly from the register or within a work order.

· It allows users to verify parts availability during a maintenance transaction without switching to the MM module.

· Enables companies to assign spare part criticality levels, prioritizing parts essential for maintaining operability of tier 1 assets—those with the highest business priority.

· When properly structured, this functionality reduces tradesperson tool time, minimizes plant downtime, and optimizes a company’s overall maintenance operations.

Preventive Maintenance

ü Creating maintenance strategies that will best address preventive maintenance requirements that will be executed either on a time calendar or certain usage intervals such as distance travelled, core usage performed (tonnes crushed), hours in operation etc.

ü Reduced time and money spent on emergency priority repairs and maximized asset life

Work Order Management

ü Creation, review and approval of corrective work requests; planning and planning status reviews; assignment of fully planned tasks to maintenance schedules; tracking work order progress of scheduled and unscheduled (emergent) work per period and a process for completing maintenance work orders that includes recording any failure data that reliability engineers can analyse.

ü Streamlined workflows, optimized schedules, and enhanced maintenance accountability through key performance measures for work management..

Inventory Management

ü Tracking of spare parts and maintenance supplies

ü Optimized stock levels, reduced stock-outs

Reporting & Analytics

ü Generation of maintenance KPIs and operational insights

ü Data-driven maintenance strategy

Mobile Platform (phones, tablets etc)

- Description: Field access to inspections, work orders and asset information

- Business Impact: Improved technician productivity

9.0 Selection Criteria and Implementation Considerations

Business Size

- Considerations: Scale of operations, number of assets, user count

- Questions to Ask: Does the solution scale to our size?

Industry Requirements

- Considerations: Specialized needs for your sector

- Questions to Ask: Are there industry-specific features?

Deployment Model

- Considerations: Cloud vs. on-premise

- Questions to Ask: Which deployment model suits our IT strategy?

Integration Capabilities

- Considerations: Connecting with existing business systems

- Questions to Ask: Can it integrate with our ERP, IoT devices, etc.?

Mobile Access

- Considerations: Field technician functionality

- Questions to Ask: How robust is the mobile experience?

User Experience

- Considerations: Interface design, ease of use

- Questions to Ask: Will our technicians adopt it readily?

Implementation Support

- Considerations: Vendor assistance with setup

- Questions to Ask: What implementation services are offered?

Training Resources

- Considerations: User training and documentation

- Questions to Ask: What training is provided?

Customization

- Considerations: Ability to adapt to specific workflows

- Questions to Ask: Can workflows be customized?

Total Cost of Ownership

- Considerations: All costs over expected lifespan

- Questions to Ask: What are ongoing costs beyond subscription/license?

Implementation Best Practices

- Define Clear Objectives: Establish specific KPIs and success metrics

- Stakeholder Involvement: Include maintenance technicians and management

- Data Preparation: Clean and validate asset data before migration

- Phased Implementation: Consider a pilot program before full deployment

- Training Program: Comprehensive training for all user roles

- Process Alignment: Update maintenance processes to leverage software capabilities

- Integration Planning: Develop a roadmap for system integrations

- Change Management: Address resistance to adoption proactively

- Support Structure: Establish internal support procedures

- Continuous Improvement: Schedule regular review and optimization

10. Business Process Mapping Before Software Purchase

Before diving into research on the right asset management software solution for your business, it is essential to conduct thorough business process mapping.

This foundational step serves as the blueprint for successful implementation, ensuring that the selected software truly addresses your operational needs rather than forcing existing, misaligned processes into an ill-fitting system.

Why Is Business Process Mapping (BPM) Is So Important?

Part 1: Capturing the “As Is” Process

The current reality—with all its imperfections—must be documented accurately. Failing to capture factual data and relying on assumptions or idealized processes will only delay improvement.

- Establishes Current State Reality:

- Documents how maintenance activities are actually performed, not merely the way we’d like to people to think they are performed.

- Reveals informal workarounds, shadow systems, and undocumented practices that are critical to operations.

- Provides visual representations that aid alignment and understanding across departments at all management levels.

- Identifies Inefficiencies and Improvement Opportunities:

- Highlights redundant steps, bottlenecks, and inefficient handoffs between roles and departments.

- Exposes gaps that may be contributing to maintenance backlogs or asset reliability issues.

- Quantifies time and resource consumption to establish a baseline for future process improvements.

- Aligns Stakeholders on Future Processes:

- Facilitates collaborative redesign of maintenance workflows before any software customization begins.

- Builds consensus for standardizing workflows across locations and business units.

- Ensures shared vision among leadership and end-users for how the new system will operate.

- Drives Software Requirements Definition:

- Transforms documented processes into a clear set of functionality requirements.

- Differentiates between “must-have” features and “nice-to-have” enhancements based on real operational needs.

- Provides realistic scenarios to guide vendor demonstrations and solution testing.

- Mitigates Implementation Risks:

- Minimizes the chance of unexpected process conflicts during deployment.

- Identifies potential change management challenges early in the project.

- Sets clear expectations for how the new software will support your workflows.

Part 2: Design the “To Be” Process

If significant issues are uncovered in the current state, the “To Be” process represents your opportunity for improvement.

This refined process will serve as the reference model for discussions with prospective software vendors.

Process Mapping for Maintenance Departments.

Effective mapping of maintenance processes should follow a structured approach:

- Scope Definition:

- Identify which maintenance processes to map (e.g., work order management, preventive maintenance, inventory control).

- Define clear boundaries for each process.

- Identify all key stakeholders and process owners.

- Data Collection:

- Conduct interviews with frontline technicians, planners, supervisors, and management.

- Observe real-life execution of tasks.

- Review existing documentation, forms, and reports for insights.

- Gather sample data on process timing, frequencies, and volumes.

- Process Documentation:

- Create visual process maps using standardized notations such as BPMN or swimlane diagrams.

- Document inputs, outputs, decision points, and handoffs.

- Note the systems used at each step and define data requirements.

- Identify and mark pain points and inefficiencies.

- Process Analysis:

- Distinguish between value-added and non-value-added activities.

- Identify root causes of inefficiencies.

- Quantify the impact of process issues on key performance metrics such as asset uptime and labor utilization.

- Benchmark against industry best practices using sources like APQC’s benchmarking reports .

- Future State Design:

- Design optimized processes that eliminate identified inefficiencies.

- Incorporate industry best practices and regulatory standards.

- Validate the new design with all stakeholders and adjust as necessary.

Key Maintenance Processes to Map

For asset management initiatives, consider mapping these critical processes:

- Work Order Lifecycle Management:

- From work request submission and approval to execution, documentation, and post-analysis.

- Preventive Maintenance Program:

- Scheduling, work package development, execution, and compliance tracking.

- Inventory and Spare Parts Management:

- Covering parts requisition, procurement, storeroom operations, and issuance to work orders.

- Asset Management:

- Encompassing asset registration, condition assessments, failure analysis, lifecycle planning, and retirement or replacement.

- Contractor Management:

- Managing contractor qualification, scope development, scheduling, invoicing, and performance evaluation.

Process Documentation Standards

For consistency and usability, process maps should include the following elements:

- Process Metadata:

- Process name, ID, owner, last revision date, related processes, and applicable departments or locations.

- The Process Participants Information:

- Detailed roles, responsibilities, systems accessed, and decision-making authorities.

- Process Flow Elements:

- Well-defined activities, decision points with criteria, handoffs, systems involved, and typical durations.

- Supporting Information:

- Templates, data fields, key performance metrics, and known issues or workarounds.

Leveraging Process Maps During Software Company Meetings.

Well-documented process maps serve multiple purposes during the software evaluation phase:

- Vendor Demonstrations:

- Provide vendors with exact representations of your current processes.

- Request them to demonstrate support for your true workflows.

- Gap Analysis:

- Compare vendor capabilities with your documented processes.

- Identify any required process changes or customization needs.

- Implementation Planning:

- Use these maps to inform configuration requirements and test scenarios.

- Develop targeted training materials based on documented workflows.

- Change Management:

- Communicate adjustments with before/after process maps.

- Help users understand and adapt to changes in their daily tasks.

Process Governance and Continuous Improvement

Business process mapping is an ongoing effort. To ensure processes continue to deliver value:

- Process Ownership:

- Assign clear owners for each process and schedule regular reviews of process maps.

- Performance Measurement:

- Establish KPIs for each process.

- Monitor performance across different implementation phases, using data-driven insights to drive improvement.

- Process Excellence Team:

- Form a cross-functional team to oversee process governance and review proposed changes.

Common Pitfalls to Avoid

- Mapping Only the “Official” Process:

- Capture actual work practices including informal, fictional and shadow processes.

- Ignoring Cross-Functional Dependencies:

- Map out inter-departmental handoffs and information flows.

- Focusing Solely on Technology:

- Understand that successful processes integrate people, technology, and policies.

- Insufficient Detail:

- Document processes with enough granularity to derive precise software requirements.

- Overlooking Data Requirements:

- Include specific data needs at each process step and highlight data quality issues.

In Summary

By investing time and money in developing a comprehensive business process map of your “To Be” process before considering new asset management software, you build a solid foundation for a successful, risk-mitigated implementation.

11. Create A User Requirements Statement (URS)

The primary reason for developing a comprehensive User Requirements Statement (URS) before contacting software companies is significant cost and time savings throughout the entire software selection and implementation process.

This upfront investment provides some powerful benefits:

1. Prevents Expensive Misalignment: Without a URS, companies often select software that doesn’t truly meet their needs, resulting in costly customizations, workarounds, or even failed implementations. Studies show organizations with comprehensive requirements documentation experience 25-35% lower customization costs.

2. Drives the Conversation on Your Terms: Rather than being led through generic sales presentations, a URS ensures vendors address your specific business challenges from the first meeting. You control the conversation about how their product meets your actual needs.

3. Reduces Implementation Time: Organizations with well-defined requirements experience 30-40% shorter implementation timelines because configuration decisions are clearer and change requests are minimized.

4. Improves User Adoption: When requirements accurately reflect what users actually need, adoption rates improve by 60-70% as the implemented solution genuinely addresses user pain points.

5. Strengthens Negotiating Position: A detailed URS demonstrates your organization’s seriousness and preparedness, often resulting in more favorable contract terms and pricing.

6. Provides Objective Selection Criteria: The URS creates a structured evaluation framework, preventing decisions based on flashy features rather than business value.

The Business Process Map and URS Is A Powerful Combination

Including your business process maps when first contacting software vendors is extremely important for several reasons:

1. Contextualizes Requirements: Process maps show how requirements fit within your broader operational framework, helping vendors understand not just what you need, but why you need it.

2. Highlights Integration Points: Process maps visually demonstrate how the software needs to connect with other systems and workflows in your organization.

3. Identifies Process Improvements: Good vendors can spot potential process improvements when seeing your workflows, adding value beyond just software functionality.

4. Accelerates Vendor Understanding: Process maps dramatically reduce the time vendors need to understand your business operations, leading to more productive initial conversations.

5. Demonstrates Organizational Maturity: Providing both a URS and process maps signals to vendors that your organization has a mature approach to asset management, often resulting in more serious consideration from top-tier providers.

When making initial contact via email, include a high-level executive summary of your URS in conjunction with your URS with key requirements and attach your business process maps.

This combination signals that you’re a well-prepared buyer who understands their needs, elevating the quality of vendor responses from the start.

Below is my 12 part guide to creating a URS

1. Introduction to User Requirements Statements

2. Strategic Importance of the URS

3. URS Development Methodology

4. Essential Components of an Asset Management URS

5. Prioritization Framework

6. Non-Functional Requirements

7. Using the URS in Vendor Selection

8. Maintaining the URS Throughout Implementation

9. Sample URS Table of Contents

10. Common URS Pitfalls to Avoid

11. Business Benefits of a Quality URS

12. URS Templates and Examples

1. Introduction to User Requirements Statements

A User Requirements Statement (URS) is the definitive document that bridges the gap between business needs and software capabilities.

It translates process requirements into specific, actionable software functionalities that vendors must address. A well-crafted URS is the cornerstone of successful asset management software selection and implementation.

Before contacting software vendors, compiling a comprehensive URS demonstrates that you understand your organization’s needs and requirements. This preparation helps avoid generic sales pitches during initial vendor meetings and ensures that discussions focus on your specific business challenges.

What’s The Purpose of a URS?

- Defines Clear Requirements: Articulates exactly what your organization needs from the software

- Establishes Evaluation Criteria: Provides objective standards for vendor assessment

- Facilitates Implementation Planning: Guides configuration, customization, and deployment

- Supports Change Management: Creates alignment among stakeholders

- Serves as a Reference Document: Provides a baseline for testing and validation

2.Strategic Importance of the URS

2.1 Ensures Alignment with Business Objectives

- Links software capabilities directly to organizational goals and KPIs

- Provides clear traceability between requirements and business value

- Prevents scope creep by establishing boundaries for the implementation

2.2 Creates Vendor Accountability

- Serves as a contractual reference for what the solution must deliver

- Provides objective criteria for acceptance testing

- Establishes a clear baseline for change management during implementation

2.3 Drives Implementation Planning

- Helps determine implementation phasing and priorities

- Informs configuration and customization decisions

- Guides data migration and integration strategies

2.4 Facilitates Accurate Budgeting

- Enables more precise vendor quotations

- Helps identify additional costs beyond software licensing

- Prevents unexpected expenses from missed requirements

2.5 Aligns Stakeholder Expectations

- Creates a shared vision across departments

- Reduces misunderstandings about system capabilities

- Sets realistic expectations for the implementation timeline

3. URS Development Methodology

Developing a comprehensive URS requires a systematic approach:

3.1 Requirements Gathering

- Review completed process maps to identify system touchpoints

- Conduct workshops with key stakeholders from all impacted departments

- Interview end users at different levels (technicians, planners, managers)

- Review industry standards and regulatory requirements

- Analyze current system limitations and pain points

3.2 Requirements Classification

- Categorize requirements by module/function

- Distinguish between “must-have” vs. “nice-to-have” requirements

- Identify functional vs. non-functional requirements

- Note current vs. future-state requirements

3.3 Requirements Documentation

- Write clear, specific, measurable requirements

- Assign unique identifiers to each requirement

- Include rationale and business impact for key requirements

- Document relationships between requirements

- Provide example scenarios or use cases for complex requirements

3.4 Validation and Review

- Conduct structured reviews with stakeholder groups

- Validate technical feasibility with IT

- Check for conflicts between requirements

- Ensure completeness across all functional areas

3.5 Approval and Baseline

- Obtain formal sign-off from key stakeholders

- Establish change control process for requirements

- Create a baseline version for vendor distribution

4. Essential Components of an Asset Management URS

4.1 Introduction and Purpose

- Project background and objectives

- Scope of the software implementation

- Expected business benefits and ROI drivers

- Assumptions and constraints

4.2 Current System Analysis

- Overview of existing systems and processes

- Current pain points and limitations

- Integration requirements with retained systems

- Data migration requirements and sources

4.3 General System Requirements

- User interface and usability requirements

- Performance and scalability needs

- Security and access control requirements

- Availability and reliability expectations

- Compliance and regulatory requirements

- Language and localization needs

- Mobile functionality requirements

4.4 Functional Requirements by Module

Asset Management

- Asset hierarchy and classification

- Asset lifecycle management

- Asset performance tracking

- Asset health monitoring

- Risk and criticality assessment

Work Order Management

- Work order creation and workflow

- Planning and scheduling

- Resource allocation

- Work execution and completion

- Work history tracking

Preventive Maintenance

- Maintenance strategy management

- Task list and job plan management

- Schedule generation and optimization

- Compliance tracking

- Performance metrics

Inventory Management

- Parts and materials management

- Inventory optimization

- Procurement integration

- Warehouse management

- Spare parts analysis

Resource Management

- Labor tracking and management

- Skill matrix and certification tracking

- Contractor management

- Resource scheduling and optimization

- Time reporting and analysis

Documentation Management

- Document storage and retrieval

- Version control

- Document linking to assets/work

- Document workflow and approvals

- Technical documentation management

4.5 Data Requirements

- Master data structure and hierarchies

- Data fields and attributes required

- Data quality and validation rules

- Historical data retention requirements

- Data archiving and purging policies

4.6 Reporting and Analytics Requirements

- Standard reports required

- Dashboard and KPI requirements

- Ad-hoc reporting capabilities

- Data export and sharing needs

- Analytics and business intelligence requirements

4.7 Integration Requirements

- Systems requiring integration

- Data exchange methods and frequencies

- Master data synchronization approach

- Real-time vs. batch integration needs

- API and interface requirements

4.8 Implementation Requirements

- Phasing and rollout approach

- Training and change management needs

- Testing and validation requirements

- Go-live support expectations

- Post-implementation support needs

5. Prioritization Framework

To facilitate decision-making during vendor selection and implementation planning, establish clear prioritization criteria:

5.1 Must Have

- Requirements critical to core business processes

- Legal or regulatory compliance requirements

- Requirements that address major pain points

- Capabilities needed for go-live

5.2 High Priority

- Important business process enhancements

- Requirements with significant efficiency impact

- Capabilities needed within 3 months of go-live

5.3 Medium Priority

- Process improvements with moderate impact

- Enhanced functionality for core processes

- Capabilities needed within 6 months of go-live

5.4 Nice to Have

- Future state requirements

- Incremental improvements

- Advanced functionality that could be implemented later

6. Non-Functional Requirements

Beyond specific features, the URS must address these critical non-functional aspects:

6.1 Performance Requirements

- Response time expectations

- Concurrent user capacity

- Transaction volume handling

- Data processing windows

- Batch processing requirements

6.2 Security Requirements

- Authentication methods

- Authorization and access controls

- Audit trail requirements

- Data protection standards

- Compliance with industry regulations

6.3 Usability Requirements

- Interface design standards

- Accessibility needs

- Training requirements

- Documentation expectations

- Language support

6.4 Reliability Requirements

- Uptime expectations

- Backup and recovery requirements

- Business continuity provisions

- Disaster recovery capabilities

- Failover mechanisms

6.5 Scalability Requirements

- Future growth projections

- Geographic expansion plans

- Potential future integrations

- Data volume growth expectations

- User base expansion plans

7. Using the URS in Vendor Selection

The completed URS becomes a powerful tool during vendor selection:

7.1 RFP Development

- Use URS as the foundation for RFP requirements

- Request specific responses to each requirement

- Ask vendors to indicate native capability vs. customization

- Require vendors to explain their approach to meeting requirements

7.2 Evaluation Scoring

- Create a weighted scoring matrix based on requirement priorities

- Evaluate vendors against specific URS requirements

- Compare vendors on percentage of requirements met out-of-box

- Assess customization complexity for unmet requirements

7.3 Vendor Demonstrations

- Require vendors to demonstrate how they meet key requirements

- Develop demo scripts based on critical user scenarios

- Evaluate usability and workflow alignment during demos

- Validate technical claims in the vendor’s RFP response

7.4 Contract Negotiations

- Reference the URS in contractual agreements

- Include key requirements in statements of work

- Tie payment milestones to requirements validation

- Define acceptance criteria based on URS fulfillment

8. Maintaining the URS Throughout Implementation.

The URS should be a living document throughout the implementation process:

8.1 Requirements Traceability

- Map requirements to configuration items

- Track requirement fulfillment during implementation

- Document where requirements are addressed in the system

- Validate implementation against original requirements

8.2 Change Control

- Establish a formal process for requirement changes

- Assess impact of change requests on scope, budget, and timeline

- Document approvals for requirement modifications

- Maintain version history of requirements changes

8.3 Testing Reference

- Develop test cases directly from URS requirements

- Validate system against original requirements

- Document requirement verification during user acceptance testing

- Address any gaps between requirements and implementation

9. Sample URS Table of Contents

For organizations developing a URS, this outline provides a comprehensive structure:

- Executive Summary 1.1 Project Background 1.2 Business Objectives 1.3 Expected Benefits 1.4 Implementation Approach

- Project Scope and Vision 2.1 In-Scope Processes and Functions 2.2 Out-of-Scope Elements 2.3 Future Considerations 2.4 Constraints and Assumptions

- Current State Analysis 3.1 Existing Systems Overview 3.2 Process Pain Points 3.3 Integration Landscape 3.4 Data Sources and Quality

- General System Requirements 4.1 User Interface and Experience 4.2 Performance Requirements 4.3 Security and Access Control 4.4 Availability and Reliability 4.5 Compliance Requirements 4.6 Mobile Functionality

- Functional Requirements 5.1 Asset Management 5.2 Work Order Management 5.3 Preventive Maintenance 5.4 Inventory Management 5.5 Resource Management 5.6 Contractor Management 5.7 Documentation Management 5.8 Safety Management

- Reporting and Analytics Requirements 6.1 Standard Reports 6.2 Dashboards and KPIs 6.3 Ad-hoc Reporting Capabilities 6.4 Analytics and Business Intelligence

- Integration Requirements 7.1 Enterprise Systems Integration 7.2 Operational Technology Integration 7.3 Mobile Device Integration 7.4 Third-Party Systems Integration

- Data Requirements 8.1 Master Data Structure 8.2 Data Migration Requirements 8.3 Data Quality and Validation 8.4 Data Retention and Archiving

- Implementation Requirements 9.1 Deployment Approach 9.2 Training Requirements 9.3 Testing and Validation 9.4 Go-Live Support 9.5 Post-Implementation Support

- Appendices 10.1 Glossary of Terms 10.2 Current Process Maps 10.3 Sample Forms and Reports 10.4 Volume Metrics

10. Common URS Pitfalls to Avoid

10.1 Focusing on Features Instead of Outcomes

- Define what business outcomes the system needs to achieve

- Avoid specifying exact implementation details that limit vendor approaches

- Focus on the “what” rather than the “how”

10.2 Excessive Customization Requirements

- Challenge requirements that force customization of standard functionality

- Consider process changes that could leverage out-of-box capabilities

- Evaluate the true business value of customization requests

10.3 Unrealistic Expectations

- Validate requirements against market reality

- Research what’s standard vs. cutting-edge in current solutions

- Benchmark against industry norms and best practices

10.4 Incomplete Stakeholder Input

- Ensure all departments and user roles contribute requirements

- Consider requirements from the perspective of all user types

- Include both strategic and operational perspectives

10.5 Overlooking Non-Functional Requirements

- Define performance, security, and usability needs explicitly

- Consider infrastructure and technology constraints

- Address compliance and regulatory requirements

10.6 Ignoring Future Needs

- Consider organizational growth and evolving business needs

- Include requirements for adaptability and scalability

- Anticipate future integration requirements

10.7 Insufficient Detail

- Vague requirements lead to misunderstandings and gaps

- Ensure requirements are specific, measurable, and testable

- Provide context and rationale for requirements

11. Business Benefits of a Quality URS

Organizations that invest in developing comprehensive URS documents report significant benefits:

- 30-40% reduction in implementation time

- 25-35% decrease in customization costs

- 40-50% fewer change requests during implementation

- 60-70% higher user adoption rates

- 35-45% reduction in post-implementation support issues

By developing a thorough URS before engaging vendors, organizations create clarity around their needs, establish objective selection criteria, and lay the groundwork for successful implementation.

This upfront investment pays dividends throughout the software lifecycle, reducing costs, accelerating time-to-value, and ensuring the selected solution genuinely addresses business requirements.

12. URS Templates and Examples

12.1 Standard Analysis Requirements Example

When developing a URS for asset management software, consider including standard analysis requirements that will help measure maintenance strategy performance:

Work Order Analysis Requirements

- Average days from work order creation to completion

- Planned versus actual work order costs (monthly and yearly)

- Analysis of work orders with zero actual costs but had planned costs

- Identification of work orders without time confirmations

Maintenance Strategy Performance Metrics

- Corrective maintenance costs over time

- Breakdown work order costs over time

- Parts usage on preventive maintenance work orders (Planned Vs Actual)

- Follow up work requests created from preventive maintenance orders

- Change request notifications (process improvement requests)

Report and Dashboard Requirements

- Ability to create and save custom reports

- Standard reports for maintenance strategy analysis

- KPI dashboards for maintenance performance

- Trend analysis capabilities with multiple trendline options

- Drill-down capabilities from summary to detailed information

12.2 Sample Requirement Format

Each requirement should be documented in a consistent format:

Requirement ID: AM-WO-001

Requirement Type: Functional

Module: Work Order Management

Title: Work Order Creation

Description: The system shall allow users to create work orders with detailed information including asset, location, priority, required completion date, work type, and description.

Rationale: To ensure all maintenance work is properly documented and tracked through completion.

Priority: Must Have

Source: Maintenance Planning Workshop

Business Impact: High – Core operational requirement

Acceptance Criteria:

- Work orders can be created for any asset in the system

- All required fields are validated before submission

- Work orders automatically route to appropriate approvers

- Newly created corrective work orders that have been approved and new system generated work orders will appear in planner work queues.

Notes: Integration with mobile solution required

12. Are Looking To Purchase Asset Management Software?

Selecting and implementing the right maintenance management software represents a strategic investment that can fundamentally transform an organization’s operational efficiency, asset reliability, and bottom-line performance.

This document has navigated quite a bit of the asset/maintenance management solution market from focused CMMS platforms, Automotive Workshop Management Software to enterprise-grade EAM systems and ERP solutions.

Hopefully I’ve provided you with some good insights that will help your decision-making process.

The Proven Path to Selection Success.

Organizations that achieve exceptional ROI (sometimes even exceeding 200% within 18-24 months) would follow a structured approach that begins with understanding their own processes and requirements:

1. Process Process Mapping Is Always First: Before evaluating any software options, document your current maintenance processes in detail. Understand workflow inefficiencies, identify improvement opportunities, and design optimized future-state processes that the software will need to support. This foundation ensures your selection addresses real operational needs rather than forcing processes to fit ill-suited technology. Organizations that skip this step report nearly 40% higher implementation costs due to late-stage adjustments and reconfiguration.

2. Develop a Comprehensive URS: Create a detailed User Requirements Statement that translates process needs into specific software capabilities. Categorize requirements by priority, distinguishing between “must-have” functionality and “nice-to-have” features. This document becomes your objective benchmark for evaluating vendor solutions and ensuring implementation success. Companies utilizing comprehensive URS documentation experience 30-40% shorter implementation timelines and 25-35% lower customization costs.

3. Assess Organizational Readiness: Evaluate your team’s capacity for change, technical capabilities, and resource availability. Consider factors like data quality, integration requirements, and infrastructure constraints that may impact implementation. A readiness assessment can identify potential bottlenecks and risks months before they become costly implementation problems.

4. Research and Shortlist Vendors: Use the information in this guide as a starting point to identify vendors whose solutions align with your industry, size, and specific requirements. Request detailed information about their capabilities, implementation methodology, and support services. Begin with your requirements rather than vendor capabilities to avoid being influenced by impressive but unnecessary features.

5. Conduct Structured Evaluations: Develop a weighted scoring system based on your URS priorities. Request demonstrations that showcase how vendors meet your specific requirements using real-world scenarios from your operations. Involve key stakeholders in the evaluation process to build buy-in. Have vendors demonstrate YOUR scenarios rather than their polished demo scripts.

6. Check References Thoroughly: Speak with multiple references from organizations similar to yours in size, industry, and complexity. Ask about implementation challenges, unexpected costs, support quality, and realized benefits. The most revealing insights often come from asking: “What do you wish you had known before selecting this company?”

7. Understand The Total Cost of Ownership: Look beyond initial licensing fees to understand the full financial impact, including implementation services, training, customization, integration, infrastructure, and ongoing support costs. Hidden costs typically add 40-70% to the advertised price over the first three years.

8. Develop a Detailed Implementation Plan: Create a comprehensive roadmap that addresses data migration, configuration, testing, training, and change management. Establish clear milestones, responsibilities, and success criteria. Organizations with detailed implementation plans are 3.5 times more likely to complete projects on time and within budget.

9. Invest in Change Management: Allocate sufficient resources to user training, process adjustment, and ongoing support. The most sophisticated software will fail without effective user adoption. Organizations that invest at least 15% of project budget in change management achieve 30% higher adoption rates.

10. Measure and Optimize: Establish baseline metrics before implementation and track performance improvements after deployment. Use this data to continuously refine your maintenance processes and software configuration. Continuous measurement enables organizations to realize 20-30% additional value post-implementation.

Be Careful Of These Things!

Even well-intentioned businesses can derail their software selection process and end up with something that they regret.

So please be vigilant against these frequently made 5 mistakes:

1. Feature Infatuation: Becoming overly captivated with impressive features that don’t address your core business requirements

2. Skipping the Foundation Work: Rushing to evaluate software before mapping processes and documenting requirements

3. Underestimating Implementation Complexity: Failing to allocate sufficient time and resources for data migration, integration, and training

4. Neglecting User Perspectives: Not involving frontline maintenance staff in the requirements gathering and selection process

5. Accepting Generic Demonstrations: Allowing vendors to control the narrative rather than insisting they demonstrate your specific scenarios

The Transformative Impact

Remember that maintenance management software is not merely a technology solution but a business transformation tool.

The most successful implementations occur when organizations view software selection as part of a broader initiative to enhance maintenance strategy, optimize workflows, and build a culture of reliability.

Your Next Step

This particular journey requires commitment and it’s the organizations that invest the necessary time and resources in the process that will achieve the outcomes you hoped for.

Start things off by assembling a cross-functional team to begin mapping your current maintenance processes and developing your URS and Business Process Maps.

This foundational work will best position your organization for making the selection that will best serve your needs for many years to come.