A Detailed Guide to Holistic CMMS Success

Disclaimer.

This article provides general information about computerized maintenance management systems (CMMS) and maintenance management practices.

It is intended for educational purposes only and should not be considered professional advice specific to your organization.

CMMS implementation requirements, regulatory compliance obligations and best practices vary significantly by industry, location and organizational context.

Readers should conduct their own research, consult with qualified professionals and verify all information before making business decisions or implementing any systems or processes described in this article.

All examples are presented for illustrative purposes. Actual results will vary based on individual circumstances.

Thoughts, views, opinions and ideas expressed are those of the author only.

Article Summary.

Holistic CMMS success represents a fundamental shift from viewing maintenance software as a digital filing system to establishing it as an integrated asset management strategy that connects people, data and processes across entire organizations.

This guide provides Australian professionals in mining, local councils, utilities and manufacturing with a comprehensive roadmap to CMMS implementation and optimization.

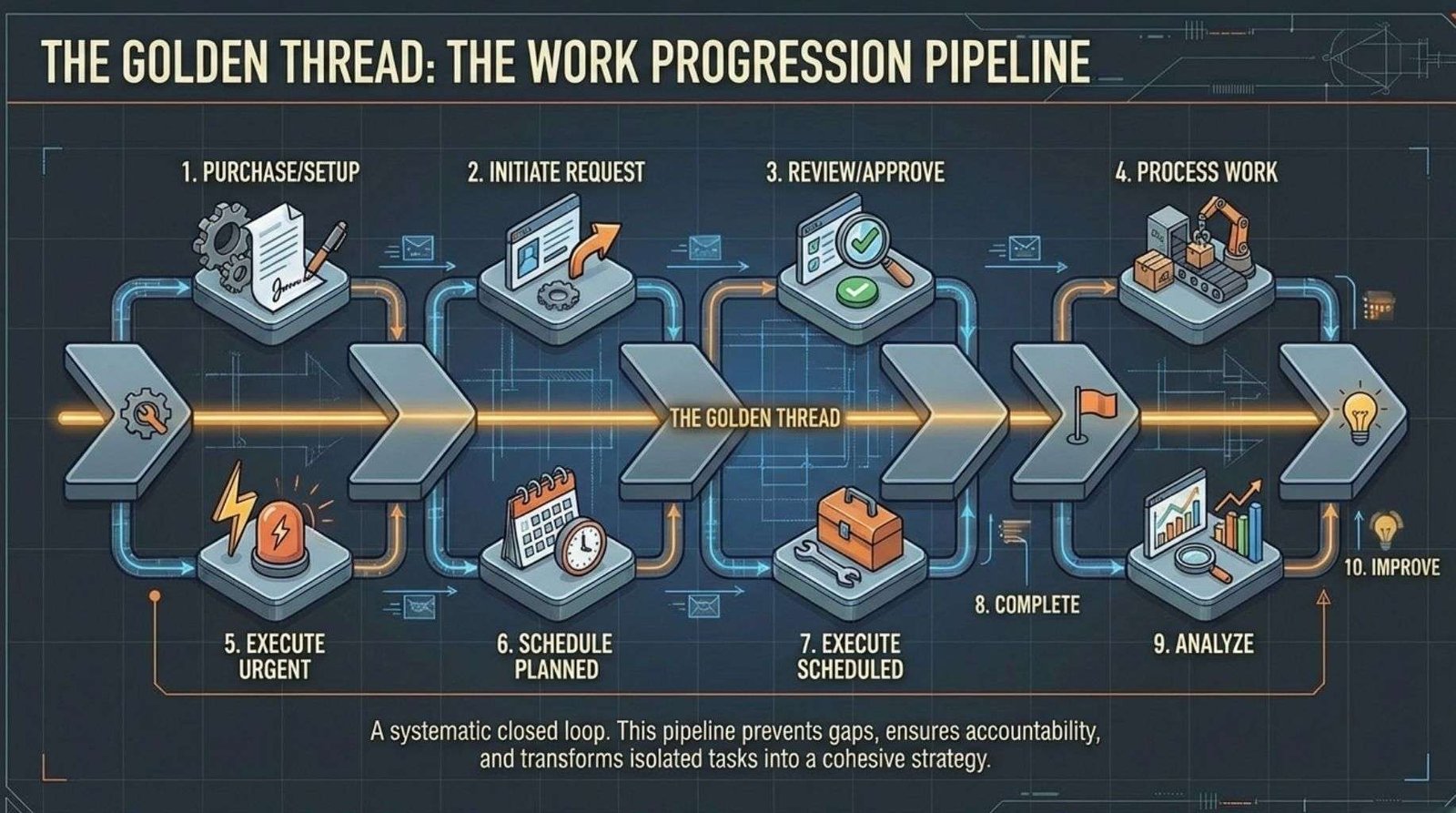

This article uses a reasonably typical work progression pipeline as the central framework for maintenance management, covering ten distinct stages from asset purchase through continuous improvement.

It addresses the critical reality that poor maintenance practices can impose significant financial burdens on organizations, while properly implemented CMMS solutions deliver measurable returns through reduced downtime, improved asset reliability and optimized resource allocation.

Key focus areas include practical implementation guidance, technical configuration requirements, AI integration strategies, industry-specific applications and proven solutions to common challenges.

In a nutshell, this guide emphasizes that CMMS success depends on adoption, data integrity and continuous improvement rather than software installation alone.

Top 5 Takeaways.

1. Holistic CMMS is a strategic initiative, not just software. Success requires integrating people, processes and technology across the entire organization rather than treating the CMMS as a maintenance-only tool.

2. The work progression pipeline provides the framework for success. Managing maintenance through ten distinct stages from asset purchase to continuous improvement creates a systematic approach that prevents gaps and ensures accountability.

3. Process design must precede software selection. Organizations should map their current workflows, identify gaps and design ideal future-state processes before selecting CMMS platforms to avoid forcing operations into inappropriate software constraints.

4. Data quality determines system value. Clean, standardized and complete asset and inventory data is essential before migration. Bad data in equals bad decisions out regardless of software capabilities.

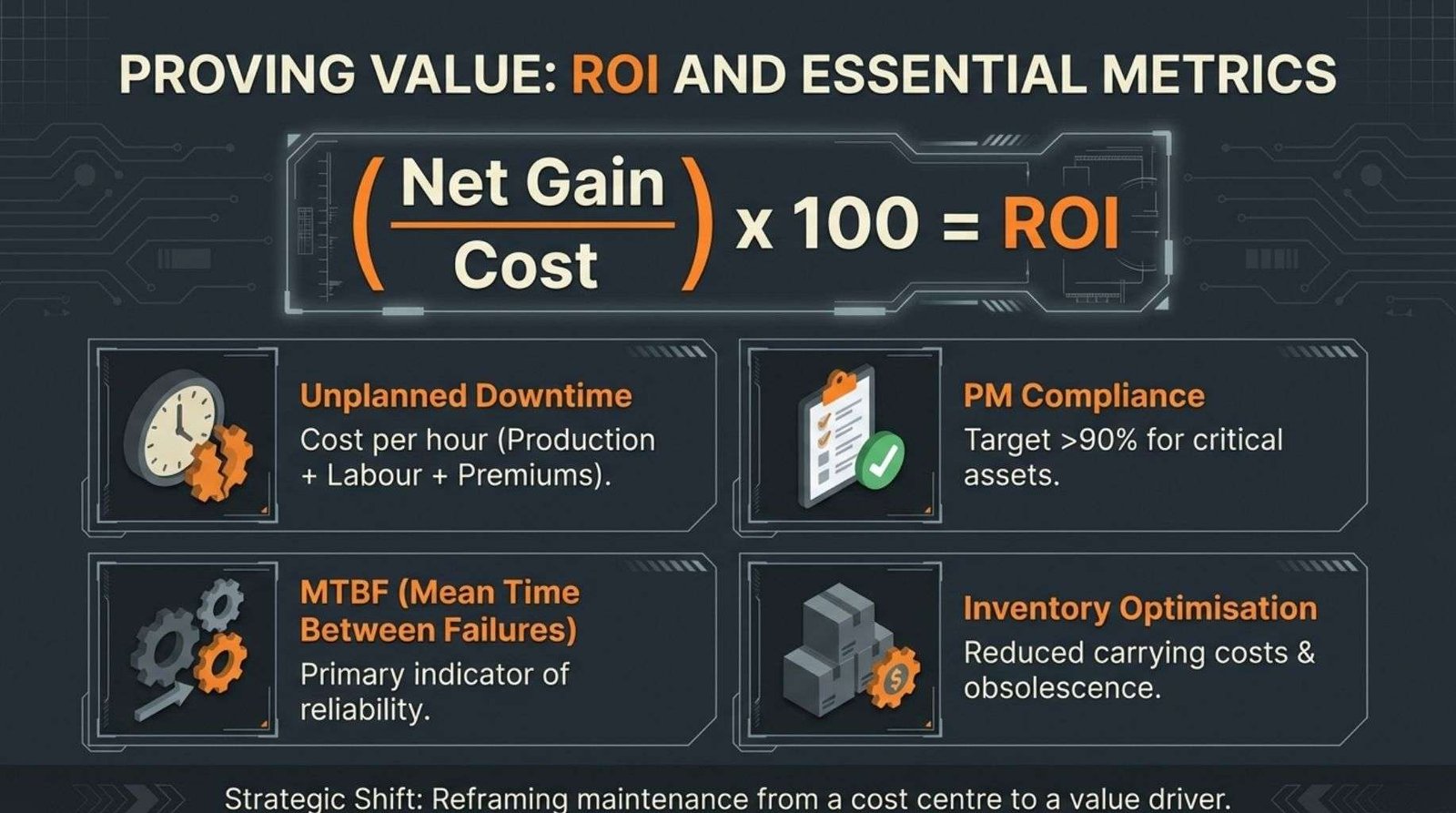

5. Measurable ROI proves value and drives adoption. Tracking essential metrics including unplanned downtime reduction, MTBF improvement and PM compliance provides concrete evidence of CMMS value and justifies continued investment.

Table of Contents.

1.0 What does ‘Holistic CMMS Success’ Really Means?

2.0 The Foundational Principles of Maintenance Management.

3.0 Practical Application: A Step-by-Step Implementation Guide.

4.0 Technical Details: Setting Up Your CMMS for Success.

5.0 Industry-Specific Considerations.

6.0 Common Challenges and Proven Solutions.

7.0 Best Practices and Standards.

8.0 Tools and Technology: Choosing and Using Your CMMS.

9.0 Measurement and Metrics: Proving CMMS Success.

10.0 The Future of Maintenance for Mature Organizations.

11.0 Conclusion: Your Roadmap to Holistic CMMS Success.

1.0 What does ‘Holistic CMMS Success’ Really Means?

1.1. The Cost of Maintenance Failure.

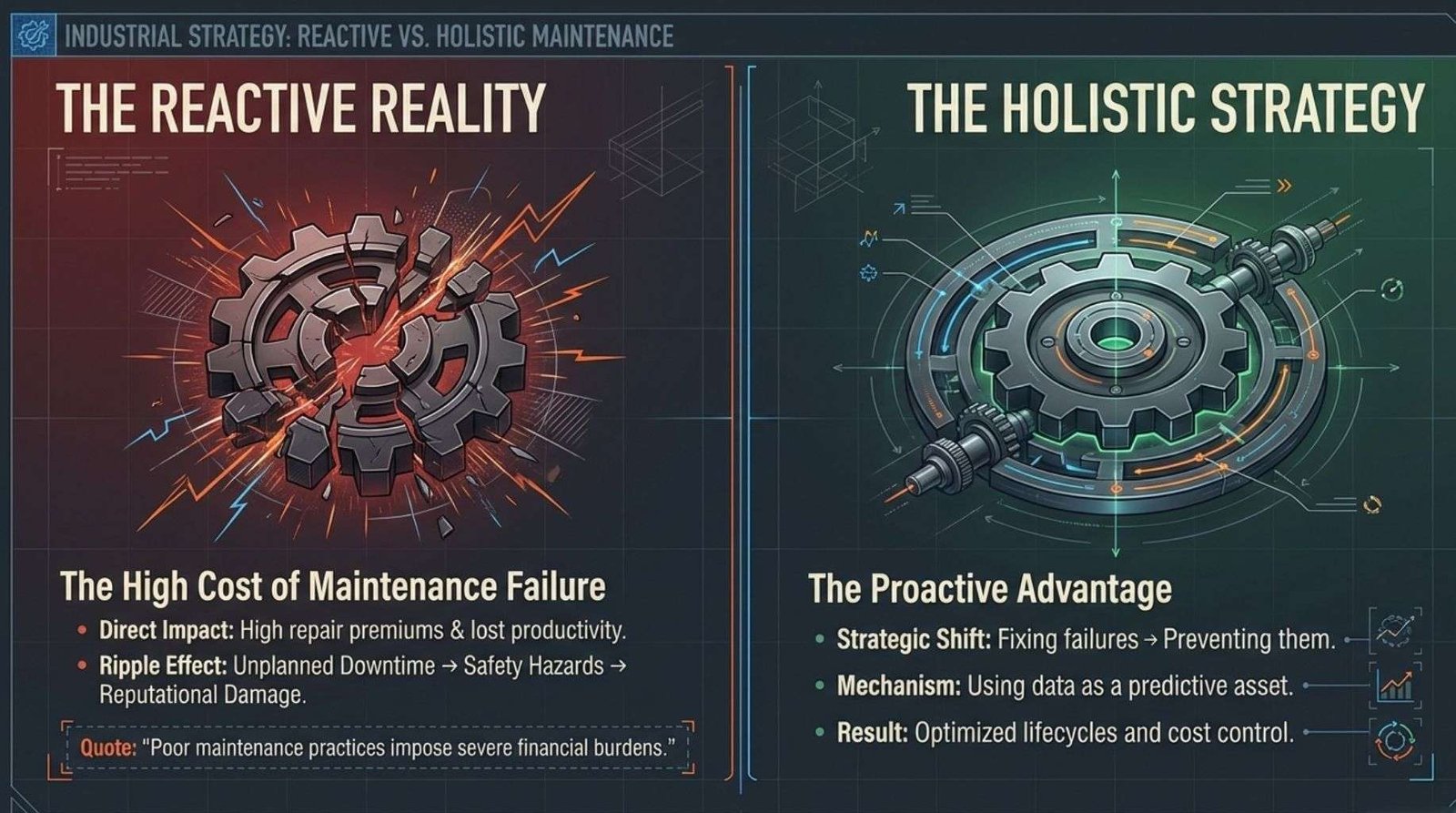

Poor maintenance practices impose severe financial burdens on organizations.

Reactive maintenance approaches typically cost organizations substantially more than proactive strategies when accounting for direct repair costs, lost productivity, shortened asset lifecycles and emergency procurement premiums.

The true cost of maintenance failures extends beyond immediate repair expenses. Unplanned downtime disrupts production schedules, creates safety hazards, damages customer relationships and forces organizations into expensive reactive responses rather than cost-effective preventive strategies.

1.2. Defining Holistic CMMS.

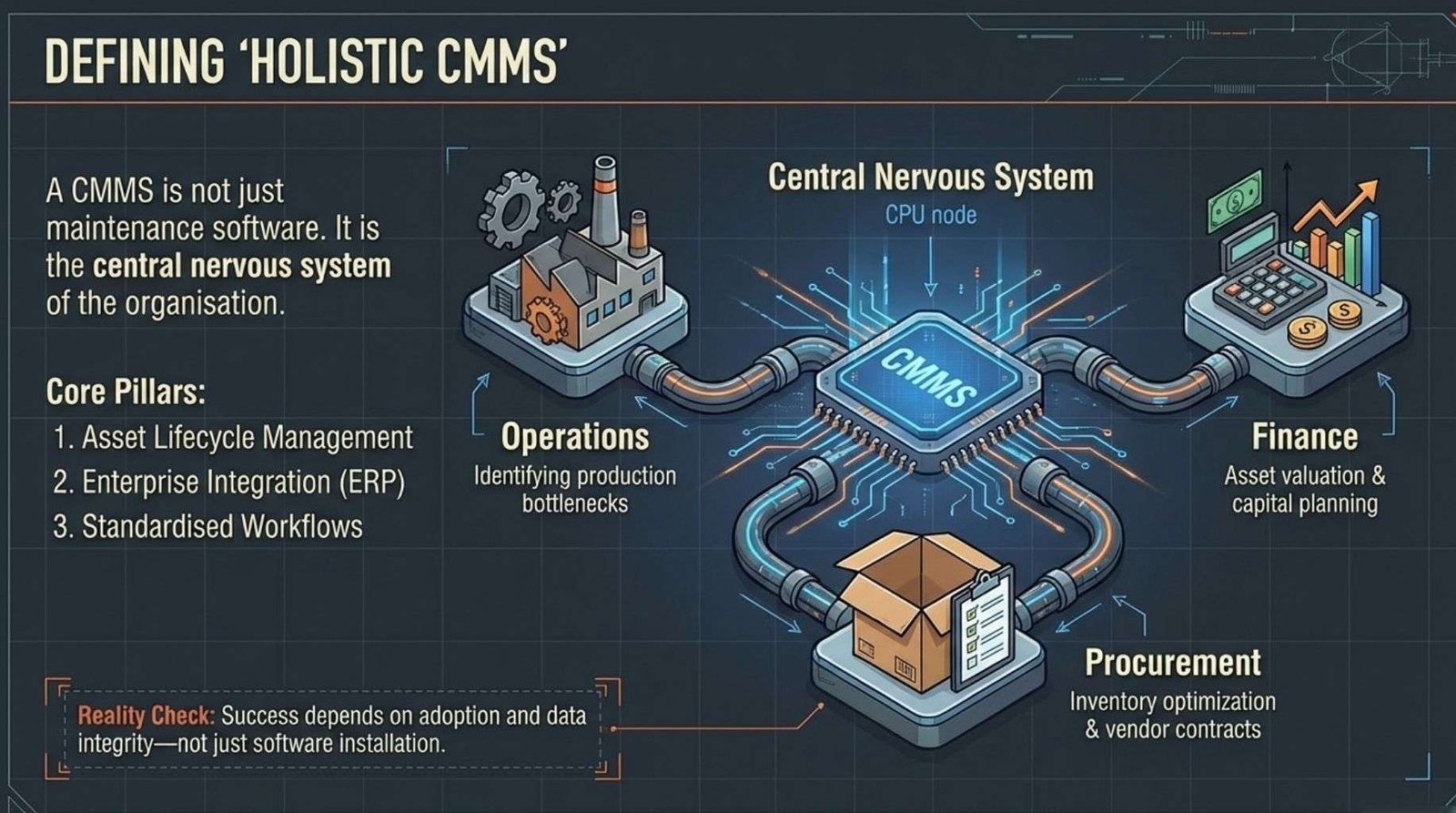

A holistic CMMS functions as an integrated asset management strategy rather than simple work order software.

It serves as the central nervous system for maintenance operations by connecting people, data and processes across entire organizations.

This approach moves beyond treating CMMS as a digital filing cabinet for work orders. Instead, it establishes the system as the foundation for strategic asset management decisions, financial planning, operational efficiency and continuous improvement initiatives.

Holistic CMMS encompasses:

1. Complete asset lifecycle management from acquisition through disposal.

2. Integration with enterprise systems including ERP, procurement and financial platforms.

3. Real-time data flow between operational technology and maintenance execution.

4. Standardized workflows that ensure consistency and accountability.

5. Analytics capabilities that drive strategic decision-making.

1.3. Why This Matters to Australian Professionals.

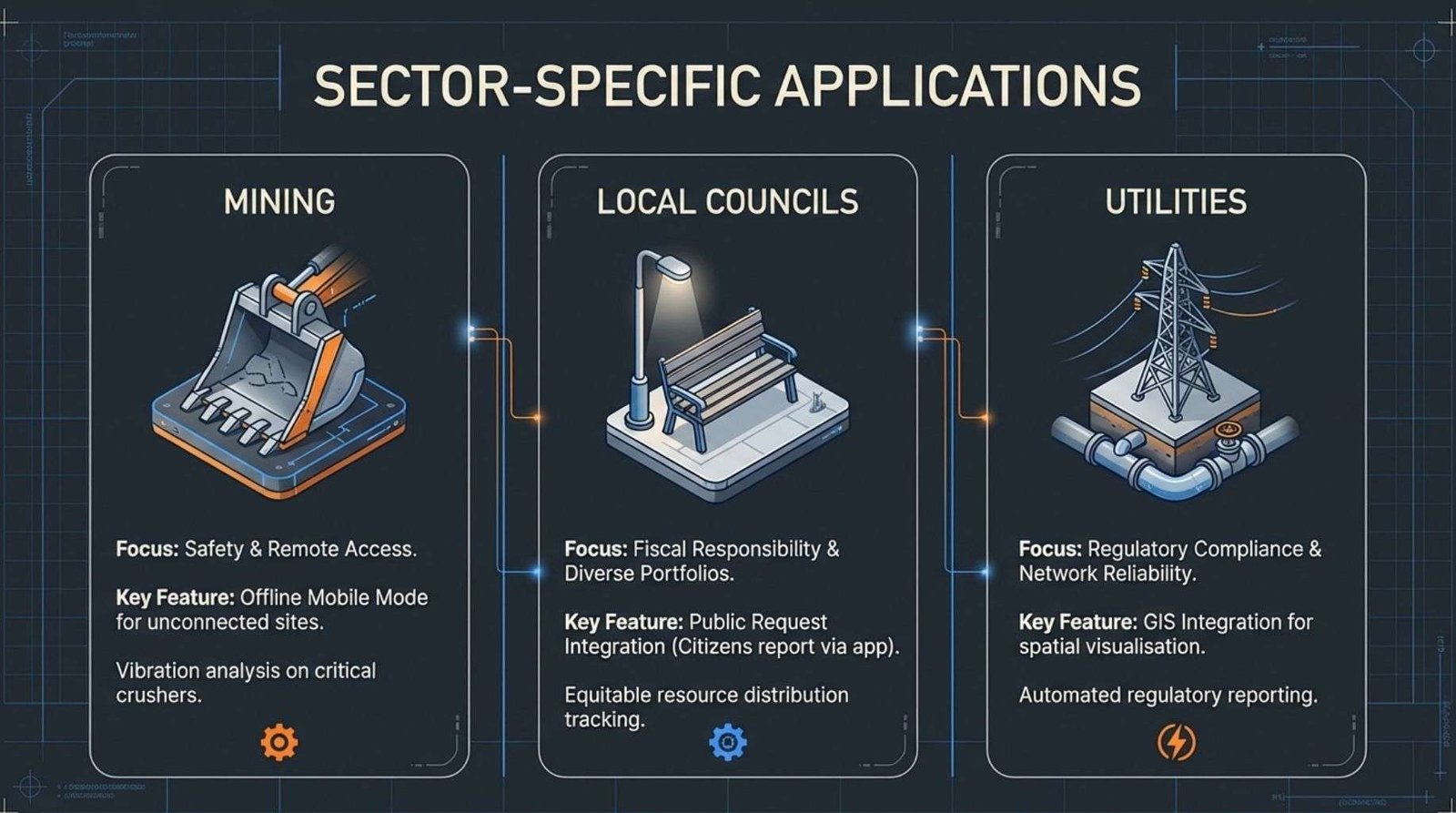

Different industries face unique pressures that make holistic CMMS implementation essential.

Mining Operations.

Mining companies manage substantial capital investments in equipment operating continuously in harsh conditions.

Haul trucks, processing plants and crushing equipment represent significant assets where unplanned failures create immediate safety risks and production losses. Holistic CMMS protects these investments by ensuring systematic maintenance, tracking safety compliance and providing visibility into asset performance across remote sites.

Local Councils.

Municipal organizations manage extraordinarily diverse asset portfolios ranging from libraries and community centers to wastewater treatment plants and road infrastructure. These assets serve public needs while operating under budget constraints and public scrutiny.

Holistic CMMS helps councils demonstrate fiscal responsibility, prioritize limited resources effectively and justify budget requests with concrete data on asset condition and maintenance requirements.

Utilities.

Water, energy and telecommunications utilities operate critical infrastructure where failures create widespread service disruptions and regulatory consequences. These organizations face strict compliance requirements and must maintain vast geographically dispersed networks.

Holistic CMMS ensures regulatory reporting accuracy, prevents catastrophic failures through predictive maintenance and provides the visibility needed to manage complex networked assets.

1.4. Scope of This Guide.

This guide provides a complete roadmap for CMMS success covering:

1. Core maintenance management principles and the work progression pipeline framework.

2. Practical step-by-step implementation guidance from business case through optimization.

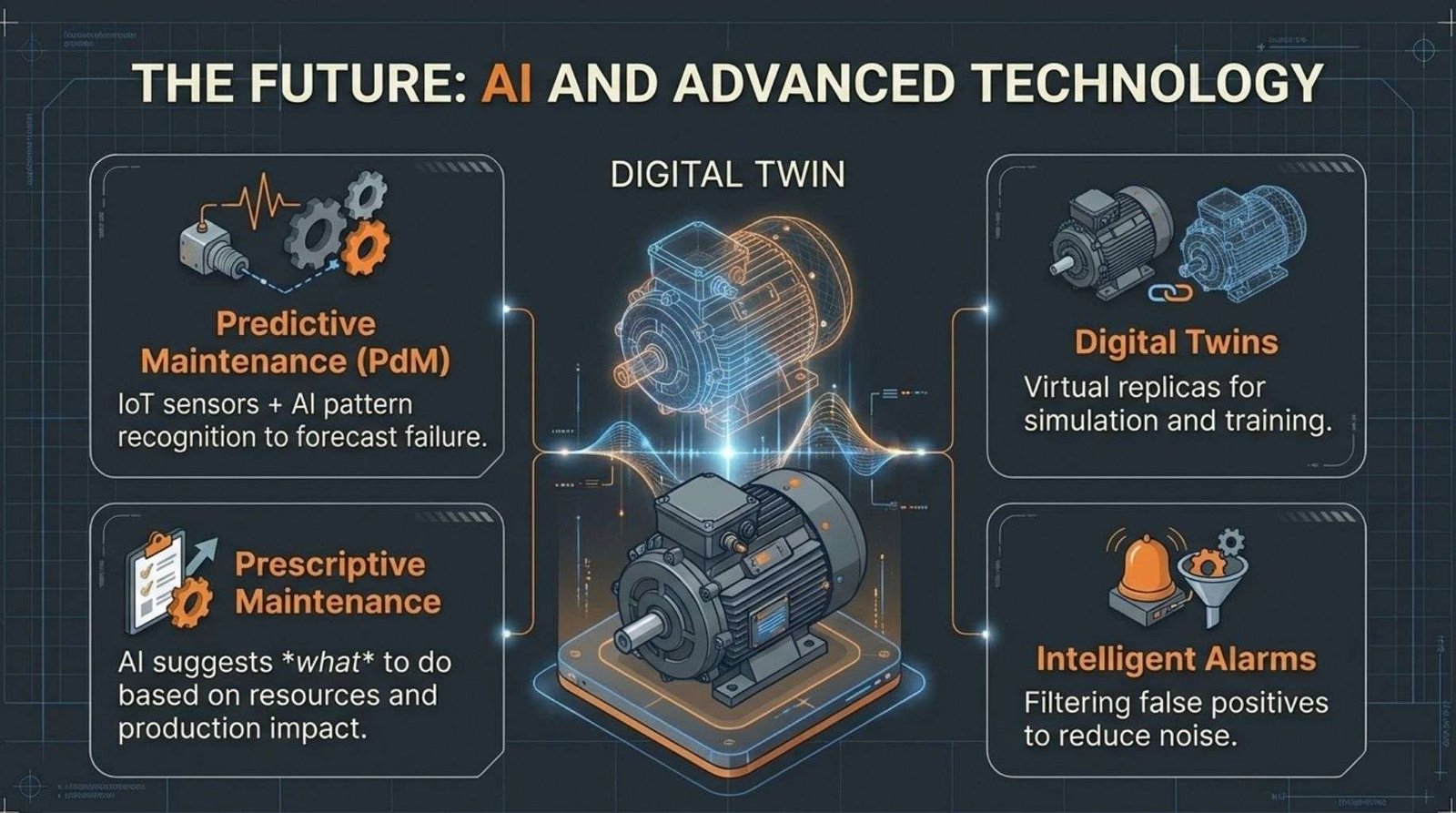

3. Technical configuration details including AI integration and advanced analytics.

4. Industry-specific applications for mining, councils and utilities.

5. Proven solutions to common implementation challenges.

6. Measurement frameworks that demonstrate ROI and justify continued investment.

1.5. Addressing Common Misconceptions.

Misconception: ‘CMMS is just for the maintenance team.’

Reality: A holistic CMMS impacts procurement, finance, operations and executive strategy. Procurement teams use CMMS data to optimize inventory levels and negotiate vendor contracts. Finance departments rely on maintenance cost data for accurate budgeting and asset valuation. Operations managers analyze equipment performance to identify production bottlenecks. Executives use reliability metrics to make capital replacement decisions.

Misconception: ‘Success is just about installing the software.’

Reality: Success depends on adoption, data integrity and continuous improvement. Software installation represents a small fraction of the journey. The majority involves changing work habits, cleaning and standardizing data, training users, refining processes and building a culture that values data-driven decision-making. Organizations that focus solely on technical implementation without addressing these human and organizational factors consistently fail to achieve their CMMS objectives.

2.0 The Foundational Principles of Maintenance Management.

2.1. The Work Progression Pipeline Framework.

The work progression pipeline represents the complete maintenance workflow as a systematic flow from asset purchase through continuous improvement.

This framework provides the ‘golden thread’ connecting all maintenance activities into a cohesive strategy.

Understanding maintenance as a pipeline rather than isolated tasks enables organizations to identify bottlenecks, ensure accountability at each stage and measure performance systematically.

Each stage builds on previous stages and feeds into subsequent stages creating a continuous cycle of improvement.

2.2. Fundamental Principles.

Three core principles underpin effective maintenance management.

1. Asset Lifecycle Thinking: This principle requires managing assets from ‘cradle to grave’ encompassing acquisition, commissioning, operation, maintenance and eventual disposal. Organizations that focus only on operational phases miss opportunities to influence asset performance through better procurement specifications, improved installation procedures and planned end-of-life strategies.

2. Proactive vs. Reactive Balance: The goal is shifting the balance from fixing failures to preventing failures. While some reactive maintenance will always be necessary, organizations should systematically reduce unplanned work through preventive maintenance programs, condition monitoring and predictive analytics. Industry guidance suggests moving toward higher proportions of planned versus reactive maintenance activities.

3. Data as an Asset: Maintenance data must be treated with the same rigor as financial data. This means establishing data governance policies, maintaining data quality standards, protecting data integrity and recognizing that decisions based on poor data create poor outcomes regardless of analytical sophistication.

2.3. The Ten-Stage Work Progression Pipeline.

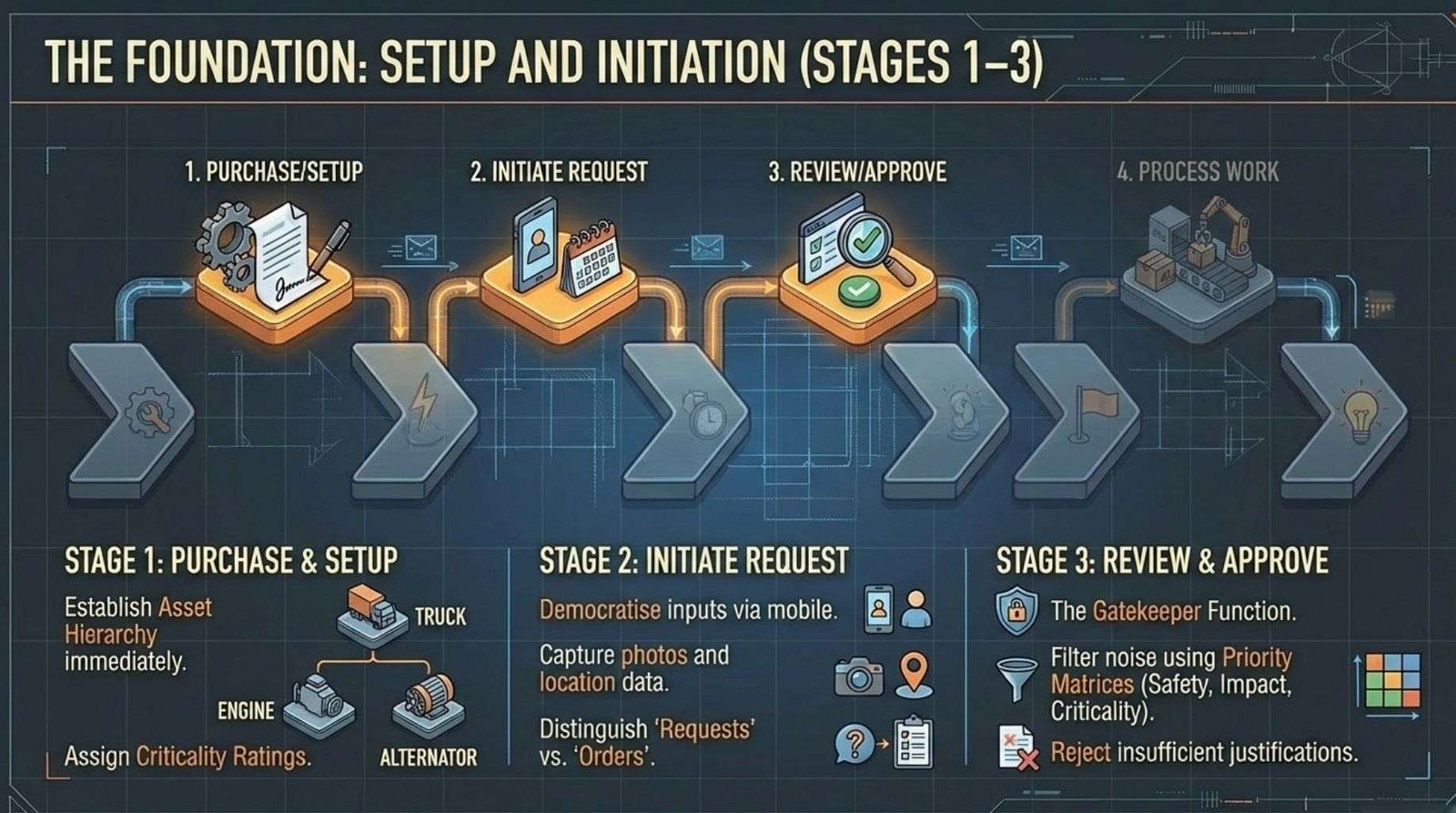

2.3.1. Stage 1: Purchase Assets & Setup Asset Management Strategy.

This stage establishes the foundation for all subsequent maintenance activities. When organizations purchase new equipment, they create hierarchical asset registers showing parent/child relationships.

For example, a haul truck becomes the parent asset with child components including the engine, transmission, hydraulic system and tires. The engine itself has children such as the alternator, fuel injection system and cooling system.

This hierarchical structure enables:

1. Tracking maintenance history at component level while rolling up costs to parent assets.

2. Establishing criticality ratings that inform maintenance priorities.

3. Creating location hierarchies that organize assets by site, area and function.

4. Linking technical documentation and spare parts to specific assets.

Asset management strategy decisions made during acquisition include:

1. Maintenance approach (run-to-failure, preventive, predictive or condition-based).

2. Spare parts stocking levels and locations.

3. Criticality classification that determines maintenance priorities.

4. Expected lifecycle and replacement planning.

2.3.2. Stage 2: Initiate New Work Requests.

Work requests represent the entry point for maintenance needs into the formal system. Workers can use mobile applications to photograph equipment issues and submit work requests with location details, urgency assessment and photographic evidence.

Effective work request systems enable:

1. Anyone in the organization to report potential issues.

2. Mobile submission with photos and location data.

3. Standardized fields that ensure complete information.

4. Immediate notification to appropriate supervisors.

Work requests differ from work orders. Requests represent identified needs that require review and approval. Work orders represent authorized work ready for scheduling and execution.

2.3.3. Stage 3: Review and Approve New Work Requests.

Supervisors evaluate work requests using standardized criteria to determine priority and authorization. Priority matrices typically consider factors including:

1. Safety implications.

2. Service impact and number of affected stakeholders.

3. Regulatory compliance requirements.

4. Asset criticality.

5. Estimated cost and resource requirements.

The approval process converts requests into work orders, rejects requests with insufficient justification or returns requests for additional information.

This stage ensures resources are allocated to highest-priority needs and prevents unnecessary work from entering the system.

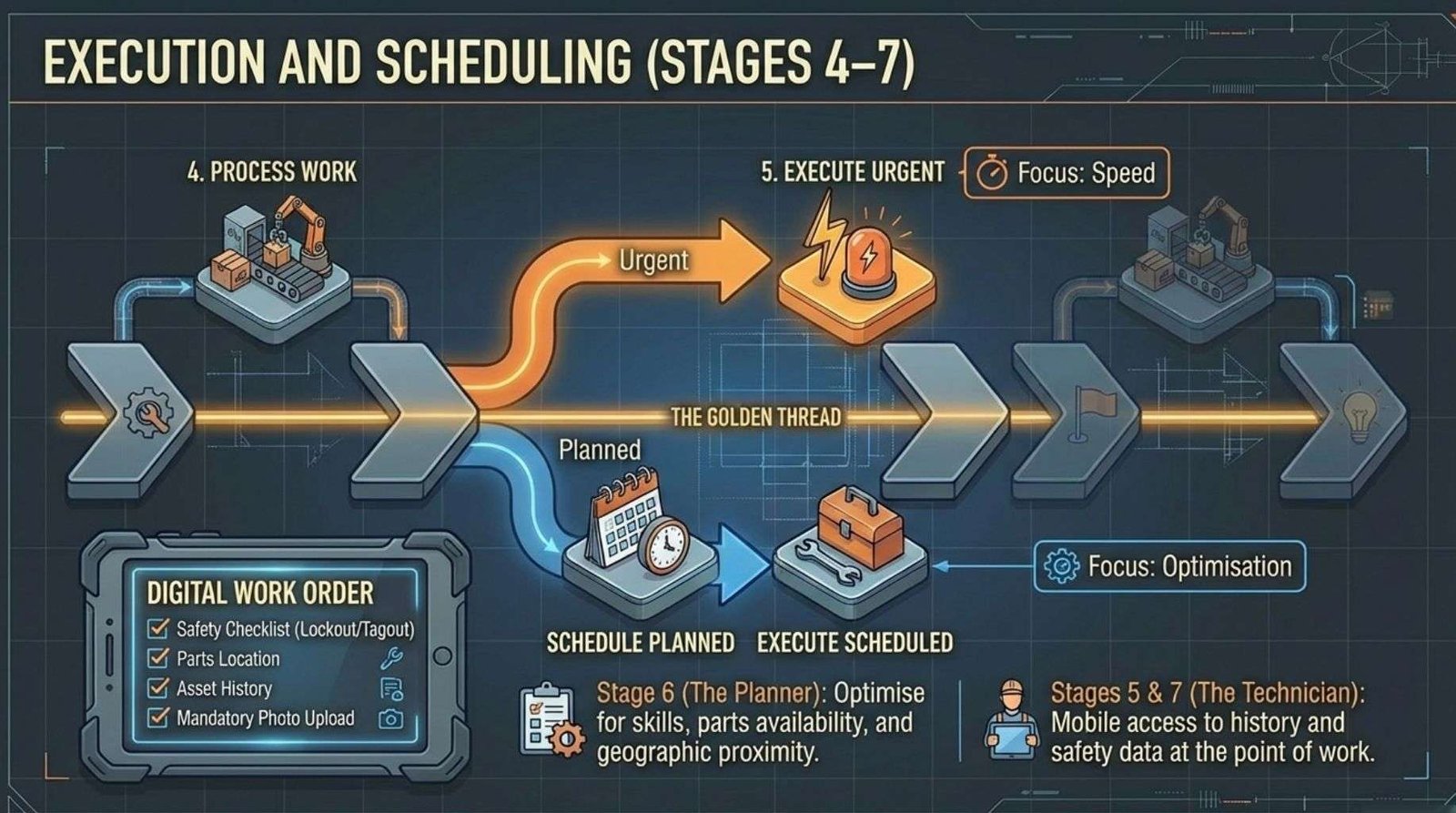

2.3.4. Stage 4: Process New Work – Urgent & Planned.

Approved work orders are categorized as urgent or planned based on required response time. This differentiation drives distinct workflows.

1. Urgent Work. Emergency situations require immediate response. The CMMS can automatically notify on-call technicians, provide asset location and history, identify required parts in inventory and create emergency work orders that bypass normal scheduling processes. Urgent work emphasizes speed and availability over optimization.

2. Planned Work. Scheduled maintenance enters the planning queue where planners develop detailed work plans including task sequences, required skills, necessary parts, estimated duration and safety requirements. Planned work emphasizes optimization and preparation over immediate response.

2.3.5. Stage 5: Execute Urgent Work.

Technicians respond to urgent work orders using mobile devices that provide:

1. Asset location with mapping integration.

2. Equipment history showing previous failures and repairs.

3. Safety procedures and lockout/tagout requirements.

4. Parts location in inventory or nearby vehicles.

5. Ability to update work order status in real-time.

Mobile CMMS access enables technicians to review recent maintenance history, identify likely causes based on previous failures and request specific parts before traveling to equipment locations.

2.3.6. Stage 6: Schedule Planned Work.

Planners use scheduling interfaces to optimize work execution by considering:

1. Technician skills and certifications.

2. Parts availability in inventory.

3. Equipment availability and production schedules.

4. Geographic proximity to minimize travel time.

5. Weather conditions for outdoor work.

Modern CMMS platforms provide visual interfaces where planners can organize technician calendars and work queues. They can move work orders to different days, assign work to specific technicians and group geographically proximate work to improve efficiency.

2.3.7. Stage 7: Execute Scheduled Work.

Technicians follow digital work plans that guide them through standardized procedures. Preventive maintenance checklists typically include:

1. Step-by-step inspection procedures.

2. Required measurements and tolerances.

3. Safety checkpoints requiring confirmation.

4. Parts replacement requirements based on condition or operating hours.

5. Photo documentation of completed work.

Digital checklists ensure consistency, capture data for analysis and provide auditable records of completed maintenance.

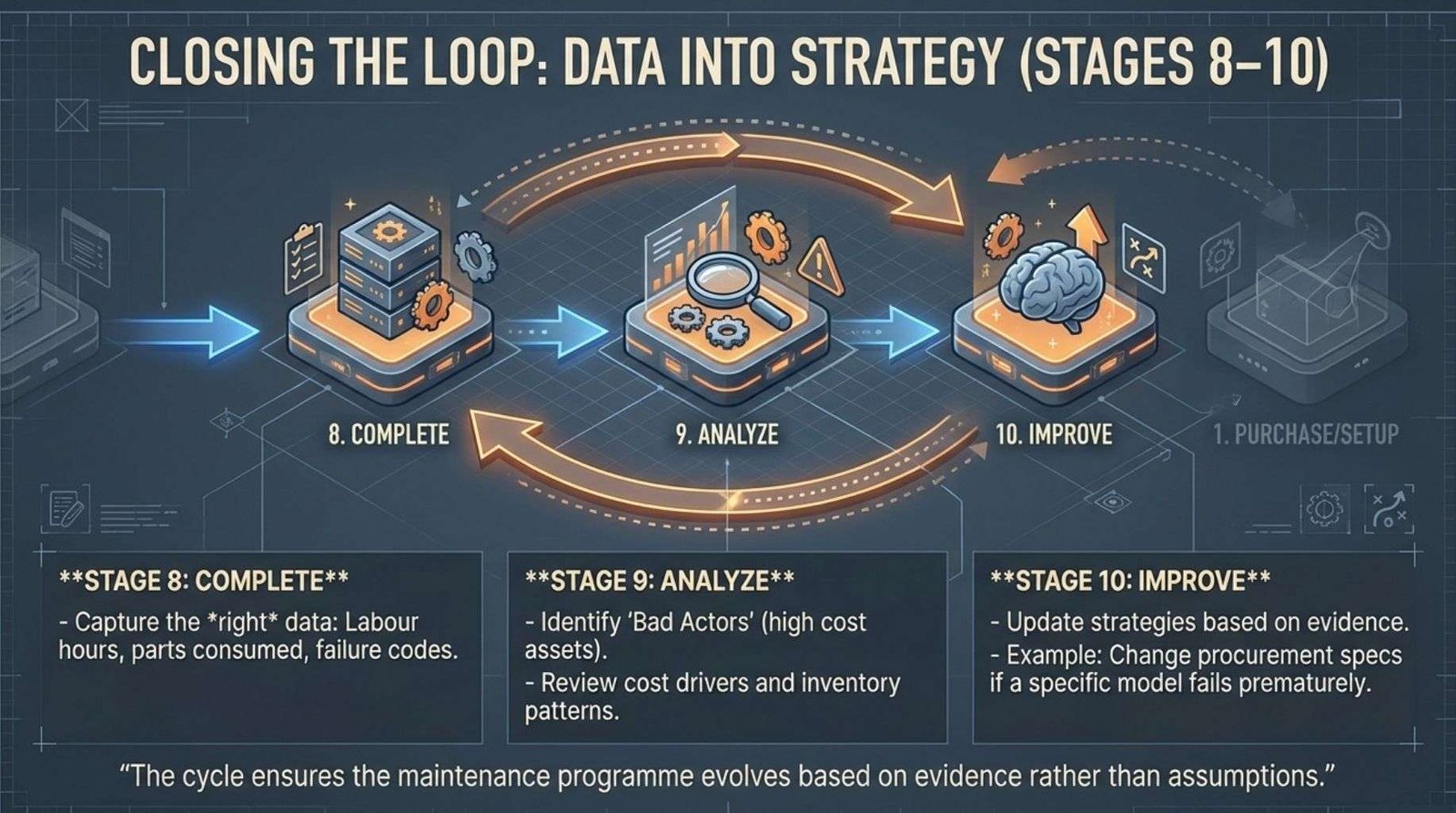

2.3.8. Stage 8: Complete Work.

Work order completion captures essential data for future analysis including:

1. Actual labor hours and costs.

2. Parts consumed from inventory.

3. Failure codes describing problems found.

4. Corrective actions taken.

5. Follow-up work requirements.

6. Asset condition observations.

This completion data becomes the foundation for reliability analysis and continuous improvement. Technician comments become searchable data that may reveal emerging failure patterns.

2.3.9. Stage 9: Analyze Work.

Managers review dashboards and reports that transform raw maintenance data into actionable insights. Analysis reveals:

1. Which assets generate highest maintenance costs.

2. Common failure modes requiring design changes or improved procedures.

3. Technician productivity and skill development needs.

4. Parts usage patterns that inform inventory optimization.

5. Compliance with preventive maintenance schedules.

Analysis of maintenance data can identify patterns such as equipment from particular manufacturers experiencing premature failures.

This insight informs future procurement decisions and triggers proactive replacement programs.

2.3.10. Stage 10: Improve Work Quality and Performance.

The final stage closes the loop by using analysis to drive improvements.

Organizations update maintenance strategies, refine preventive maintenance tasks, adjust parts stocking levels and modify training programs based on performance data.

Analysis may reveal that certain equipment models require repairs more frequently than others.

Organizations can update procurement specifications to avoid problematic models and adjust inspection frequencies for existing units based on failure data. This continuous improvement cycle ensures the maintenance program evolves based on evidence rather than assumptions.

3.0 Practical Application: A Step-by-Step Implementation Guide.

3.1. Phase 0: The Business Case & Governance.

CMMS implementation must begin with outcomes rather than software.

Organizations should define specific measurable objectives such as reducing unplanned downtime, improving preventive maintenance compliance or decreasing maintenance labor costs.

The business case should quantify:

1. Current maintenance costs and inefficiencies.

2. Expected benefits in financial terms.

3. Implementation costs including software, consulting, training and internal resources.

4. Payback period and return on investment.

5. Risk factors and mitigation strategies.

Establish a governance team with representatives from:

1. Maintenance and reliability.

2. Information technology.

3. Operations and production.

4. Procurement and inventory.

5. Finance and accounting.

6. Executive leadership.

This cross-functional team ensures the CMMS meets organizational needs rather than serving only maintenance department interests.

The team establishes decision-making authority, resolves conflicts, allocates resources and maintains executive support throughout implementation.

3.2. Phase 1: Process Mapping (‘As-Is’ and ‘To-Be’).

Maintenance Business Process Mapping reveals how work actually flows through the organization today compared to how it should flow after CMMS implementation.

3.2.1 As-Is Mapping.

Organizations documenting their current work request processes commonly discover:

1. Workers submitting verbal requests to supervisors who record them manually.

2. Supervisors creating work orders in spreadsheets during periodic planning meetings.

3. Technicians receiving printed work orders that often contain incomplete information.

4. Completed work logged in separate spreadsheets using inconsistent formats.

5. No systematic analysis occurring because data is fragmented across multiple files.

These as-is maps reveal significant gaps including lost requests, data duplication, lack of real-time visibility and inability to analyze performance.

3.2.2 To-Be Mapping.

Organizations then design their ideal workflow enabled by CMMS:

1. Workers submit requests through mobile devices with photos and location data.

2. Supervisors receive automatic notifications and approve requests digitally using priority matrices.

3. Approved requests automatically become work orders with standardized data requirements.

4. Planners optimize schedules using interfaces that consider skills and parts.

5. Technicians access work orders on mobile devices with complete information and update status in real-time.

6. Completed work automatically populates analytics dashboards for management review.

The gap between as-is and to-be defines the rules for the work progression pipeline and establishes requirements for CMMS configuration.

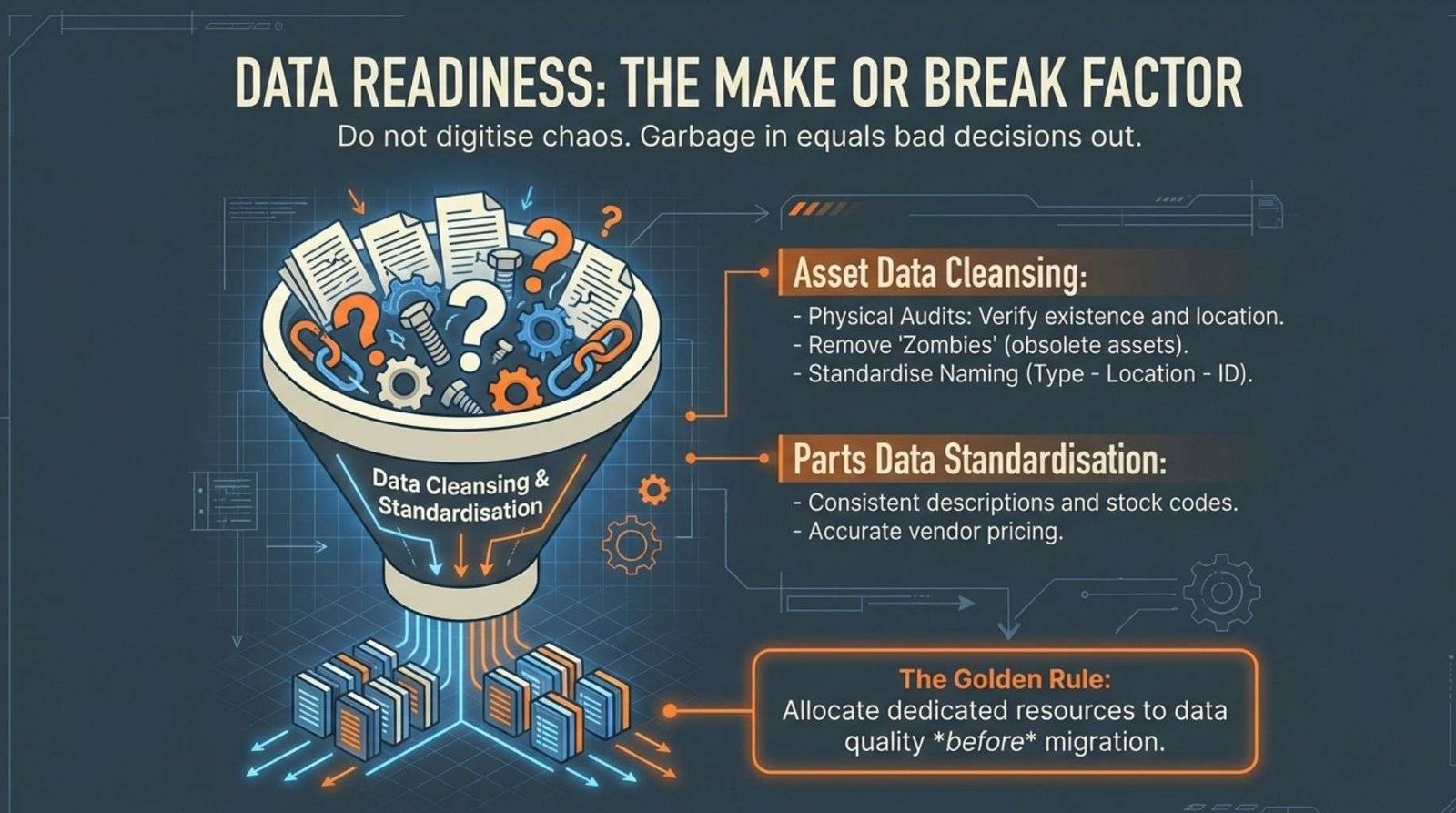

3.3. Phase 2: Data Readiness is Key.

Data quality determines CMMS value. Organizations must audit, clean and standardize data before migration.

3.3.1 Asset Data Cleansing.

Organizations auditing their asset databases commonly discover:

1. Multiple entries for the same physical assets with different naming conventions.

2. Assets listed with incorrect locations.

3. Obsolete assets never removed from the system.

4. Incomplete asset hierarchies missing component relationships.

5. Inconsistent criticality ratings applied by different staff.

Organizations should implement standard naming conventions following structured formats such as: Asset Type – Location – Unique Identifier. Physical audits verify asset existence and location, obsolete entries are removed and criticality criteria are applied consistently across all assets.

3.3.1 Parts Data Standardization.

Organizations must standardize:

1. Part numbers using consistent formats.

2. Descriptions that clearly identify items.

3. Stocking locations using standard codes.

4. Reorder points based on usage analysis.

5. Vendor information with current pricing.

Bad data in equals bad decisions out. Organizations that migrate poor quality data into new CMMS platforms simply digitize their existing problems without gaining analytical capabilities.

3.4. Phase 3: Phased Rollout and Training.

Successful implementations follow phased approaches starting with core workflows before activating advanced features.

Phase 3A: Core Workflows. Begin with foundational capabilities:

1. Asset and location hierarchy.

2. Work order creation and completion.

3. Preventive maintenance scheduling.

4. Basic inventory management.

5. Mobile access for technicians.

Organizations implementing CMMS often start with pilot programs on limited asset groups. They configure core workflows, train staff, resolve issues and refine processes before expanding to other areas.

Phase 3B: Advanced Features. After core workflows function smoothly, add:

1. Condition monitoring integration.

2. Predictive maintenance programs.

3. Advanced analytics and reporting.

4. Integration with ERP and procurement systems.

5. IoT sensor connectivity.

Training Strategy. Implement train-the-trainer programs where:

1. Super-users receive intensive training on all system capabilities.

2. Super-users then train their colleagues in role-specific functions.

3. Training emphasizes how the CMMS makes daily work easier rather than just software features.

4. Ongoing support and refresher training address emerging needs.

Organizations find success by identifying enthusiastic early adopters as super-users who can advocate for the system among skeptical peers. These champions demonstrate practical benefits and provide peer support during the transition.

4.0 Technical Details: Setting Up Your CMMS for Success.

4.1. Making Technology Accessible.

Technical setup enables the work progression pipeline. While configurations may seem complex, they follow logical patterns that reflect organizational structure and operational reality.

4.2. Core Configuration.

4.2.1. Asset Hierarchy.

Asset hierarchy structures the database to reflect physical reality. Organizations might organize assets as:

· Level 1: Region. Geographic or operational regions.

· Level 2: District. Sub-regions or operational areas within each region.

· Level 3: Site. Individual facilities, stations or plants.

· Level 4: Equipment. Major equipment and systems within each site.

· Level 5: Component. Individual components within each equipment.

This hierarchical structure enables:

1. Filtering work orders and reports by any level.

2. Rolling up costs from components to parent equipment.

3. Assigning responsibilities by region or district.

4. Tracking performance at different organizational levels.

4.2.2. Work Order Templates.

Standardized templates ensure data consistency. Preventive maintenance templates typically include:

1. Standard task list with inspection points.

2. Required measurements and tolerances.

3. Estimated duration and skill requirements.

4. Necessary parts and tools.

5. Safety procedures and permits.

6. Customizable fields for site-specific variations.

Templates accelerate work order creation, ensure complete information and enable meaningful comparisons across similar assets.

4.2.3. Approval Workflows.

Digital approval chains route work requests and purchase orders through appropriate authorization levels. Configuration defines:

1. Approval limits by dollar value or work type.

2. Routing rules based on asset criticality or location.

3. Escalation procedures for delayed approvals.

4. Override capabilities for emergency situations.

5. Notification methods for approvers.

Organizations configure approval workflows where routine maintenance below certain thresholds requires only supervisor approval while larger projects route through additional management levels before authorization.

4.3. AI and Advanced Integrations.

4.3.1. Predictive Maintenance Configuration.

AI-enabled predictive maintenance requires robust data integration from multiple sources:

1. IoT Sensors. Configure the CMMS to ingest real-time data feeds from temperature sensors, vibration monitors, pressure gauges and flow meters. This requires establishing secure data connections, defining data formats and setting up storage for high-frequency sensor readings.

2. ERP Systems. Integrate production data, quality metrics and operational parameters that provide context for equipment performance. Organizations can integrate throughput data, operating speeds and environmental conditions to correlate equipment stress with maintenance needs.

3. Historical Data. Migrate maintenance records, failure modes and repair history to train AI models. The quality of historical data directly impacts prediction accuracy.

The CMMS must be configured to trigger automated work orders based on AI predictions. Organizations define thresholds and rules such as creating work orders when sensor readings exceed specified deviations from baseline or when predicted failure probability exceeds defined levels.

4.3.2. Automated Work Order Generation.

AI models require clear rules and parameters defined within the CMMS:

1. Condition thresholds that trigger work orders.

2. Work order templates to use for different prediction types.

3. Priority assignment based on criticality and time-to-failure.

4. Assignment rules directing work to qualified technicians.

5. Review workflows allowing human oversight of AI-generated work.

Establish processes for human review ensuring technicians can override AI suggestions when local knowledge indicates different action is appropriate.

4.3.3. Natural Language Processing Integration.

NLP tools parse technician notes and comments to extract structured data from unstructured text. Configuration involves:

1. Integrating NLP engines with CMMS text input fields.

2. Training models to recognize maintenance-specific terminology.

3. Creating rule sets that flag inconsistencies and incomplete entries.

4. Extracting key failure data and auto-populating structured fields.

Organizations can integrate NLP that reads technician comments and automatically tags work orders with appropriate failure codes while prompting technicians to specify additional details.

4.3.4. AI-Optimized Scheduling.

AI scheduling modules optimize work assignments by considering:

1. Technician Skills. Maintain detailed skill matrices showing certifications, experience levels and equipment familiarity for each technician.

2. Parts Inventory. Real-time inventory visibility ensures schedulers assign work only when necessary parts are available.

3. Travel Times. Geographic data enables grouping proximate work to minimize travel and maximize productive time.

4. Historical Data. AI learns from past schedules identifying which assignments led to efficient completion versus those requiring multiple visits.

The CMMS must maintain comprehensive data in all these areas for AI scheduling to function effectively.

5.0 Industry-Specific Considerations.

5.1. Mining: Safety, 24/7 Operations, Remote Assets.

5.1.1. Critical Focus Areas.

Mining operations prioritize:

1. Safety Compliance. Systematic tracking of safety inspections, lockout/tagout procedures and regulatory requirements.

2. Real-time Visibility. Immediate awareness of equipment status across remote sites operating continuously.

3. Contractor Management. Coordinating maintenance activities across multiple contractor workforces.

5.1.2. Practical Applications.

1. Offline Mobile Access: Mining sites often lack reliable internet connectivity in certain areas. CMMS mobile apps must function offline allowing technicians to access work orders, update status and capture data without connectivity. Changes sync automatically when devices reconnect to the network.

2. Safety System Integration: Integrate CMMS with lockout/tagout systems ensuring all maintenance work follows proper isolation procedures. The system tracks which equipment is locked out, who holds authorization and what work is permitted during isolation periods.

3. Predictive Analytics on Critical Assets: Focus predictive maintenance on conveyor systems, processing plants and mobile equipment where failures create immediate production impacts. Vibration analysis identifies bearing failures in advance allowing planned replacements during scheduled downtime rather than catastrophic failures requiring emergency repairs.

4. Mobile Equipment Management: Configure asset hierarchies that track maintenance by individual equipment unit and by component. This enables analyzing whether certain component models are less reliable or whether specific operating conditions accelerate wear.

5.2. Local Councils: Budget Constraints, Diverse Assets, Public Scrutiny.

5.2.1. Critical Focus Areas.

Although there are many essential tasks for a shire council, they cannot do everything at once and as such they will tend to prioritize:

1. Fiscal Responsibility. Demonstrating efficient use of limited public funds.

2. Diverse Asset Management. Maintaining everything from buildings to roads to parks with limited specialized staff.

3. Public Responsiveness. Addressing community requests and complaints systematically.

5.2.2. Practical Applications.

1. Cost Tracking by Area: Configure CMMS to track maintenance costs by geographic area or organizational unit. This enables understanding how maintenance budgets are allocated across communities and supports equitable resource distribution.

2. Public Request Integration: Integrate public request systems with CMMS so community members can report issues through websites or applications. Requests automatically create work orders routed to appropriate crews with transparent status updates.

3. Asset Class Management: Group diverse assets into logical classes such as Buildings, Parks & Recreation, Roads & Drainage and Fleet. Each asset class uses appropriate maintenance strategies and performance metrics rather than forcing all assets into identical approaches.

4. Budget Justification: Use CMMS data to justify budget requests with concrete evidence. Present asset condition reports showing deferred maintenance backlogs, risk assessments identifying critical assets requiring renewal and cost-benefit analyses demonstrating savings from proactive maintenance programs.

Organizations seeking budget approval for asset renewal can present CMMS data showing maintenance costs increasing over time, recurring safety incidents requiring emergency repairs and risk assessments categorizing assets as requiring intervention. This evidence-based approach supports funding requests more effectively than general appeals.

5.3. Utilities: Compliance, Critical Infrastructure, Networked Assets.

5.3.1. Critical Focus Areas.

Utility organizations prioritize:

1. Regulatory Compliance. Meeting strict reporting requirements for reliability, safety and service quality.

2. Service Continuity. Preventing outages that affect customers and generate regulatory consequences.

3. Network Management. Maintaining visibility across vast geographically dispersed infrastructure.

5.3.2. Practical Applications.

Automated Compliance Reporting.

Configure CMMS to automatically generate reports for regulatory agencies. Organizations can export reports showing:

1. Quality tests performed with results.

2. Preventive maintenance completed on critical equipment.

3. Emergency response times to incidents.

4. Asset renewal investments by category.

Automated reporting eliminates manual data compilation, reduces errors and ensures consistent reporting formats meeting regulator specifications.

GIS Integration.

Integrate CMMS with Geographic Information Systems providing spatial visualization of assets. Maintenance planners view maps showing:

1. Asset locations color-coded by condition.

2. Work order concentrations identifying problem areas.

3. Service territories for scheduling optimization.

4. Infrastructure proximity for coordinating work.

Organizations integrating GIS with CMMS can identify clusters of aging equipment in specific areas and proactively schedule replacements before widespread failures occur.

Predictive Maintenance on Critical Infrastructure.

Deploy condition monitoring on substations, pumping stations and major transmission assets where failures create widespread service impacts. Configure the CMMS to prioritize work orders generated from predictive analytics based on customer impact and regulatory requirements.

Outage Management Integration.

Connect CMMS with outage management systems so emergency repairs automatically update communication systems, dispatch crews to highest-priority incidents and track restoration progress in real-time.

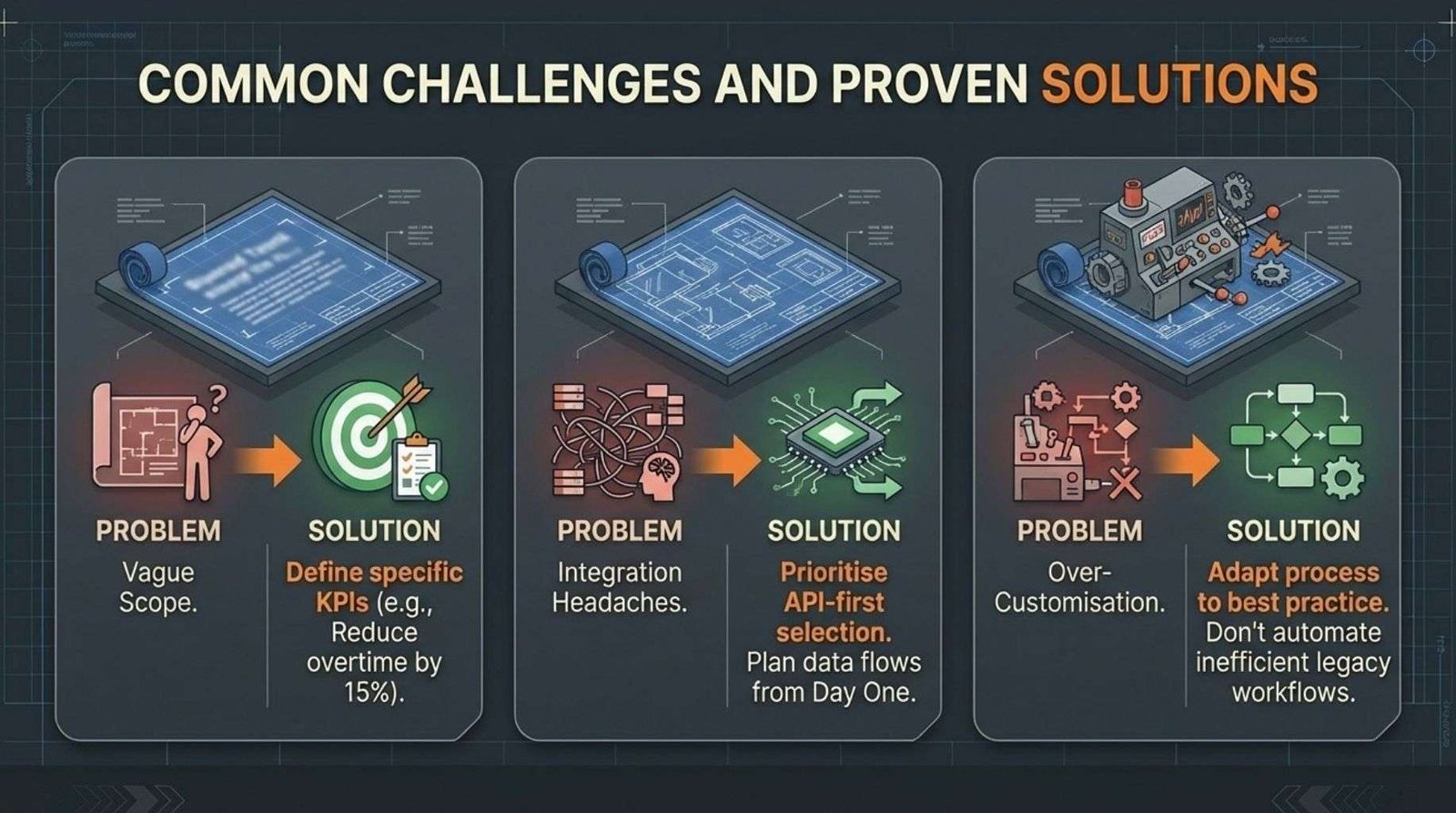

6.0 Common Challenges and Proven Solutions.

6.1. Challenge 1: Resistance to Change from Technicians.

6.1.1. The Problem.

Experienced technicians often resist CMMS implementation viewing it as unnecessary bureaucracy that slows them down.

They prefer familiar paper-based systems or informal work practices developed over years.

Common objections include:

1. ‘I already know what needs to be done.’

2. ‘Entering data takes time away from actual work.’

3. ‘The system is too complicated.’

4. ‘We’ve always done it this way and it works fine.’

6.1.2. The Solution.

Involve Technicians Early.

Include technicians in software selection and workflow design. When technicians help design the system, they develop ownership and ensure workflows reflect field reality. Forming technician advisory groups that review CMMS options and provide input on interface design helps create system advocates.

Demonstrate Personal Benefits.

Show technicians how mobile CMMS apps make their jobs easier:

1. No more searching for paper work orders.

2. Instant access to equipment history at the job site.

3. Parts location information saving trips to storage areas.

4. Photo documentation that protects them from liability.

5. Reduced paperwork at the end of shifts.

Frame the CMMS as a tool that helps technicians rather than a monitoring system checking up on them.

Celebrate Early Wins.

Identify quick wins that demonstrate value. Highlighting instances where technicians used mobile apps to access technical information while repairing equipment and prevented return trips builds momentum. Sharing such stories creates positive momentum.

Champion Super-Users.

Identify enthusiastic early adopters as super-users who receive extra training and provide peer support. These champions answer questions, demonstrate useful features and vouch for the system’s value from a technician perspective.

6.2. Challenge 2: Data Migration Mess.

6.2.1. The Problem.

Organizations migrating from spreadsheets, legacy systems or paper records often have:

1. Duplicate asset records with inconsistent information.

2. Incomplete data missing critical fields.

3. Inconsistent naming conventions and abbreviations.

4. Obsolete information never purged.

5. Relationships between assets and components undefined.

Migrating this problematic data creates a CMMS that replicates existing problems in digital form.

6.2.2. The Solution.

Treat Data Cleansing as a Project Phase.

Allocate dedicated time and resources to data quality before migration.

Organizations should schedule data cleansing phases during which staff:

1. Conduct physical audits verifying asset existence and locations.

2. Standardize naming following new conventions.

3. De-duplicate records merging information from multiple sources.

4. Establish asset hierarchies defining parent/child relationships.

5. Populate missing critical data fields.

6. Remove obsolete assets from the system.

Assign a Dedicated Team.

Form a data quality team with representatives from operations, maintenance and IT. This team establishes standards, conducts audits, resolves discrepancies and validates migrated data.

Implement Progressive Migration.

Migrate high-priority assets first allowing the team to refine processes before tackling complete databases.

Start with critical equipment where data quality matters most then expand to less critical assets using established procedures.

Establish Ongoing Governance.

Create data quality standards that persist after migration:

1. Naming conventions for new assets.

2. Required fields before work order closure.

3. Audit procedures catching errors.

4. Accountability for data accuracy.

6.3. Challenge 3: Vague Scope and Misaligned Expectations.

6.3.1. The Problem.

CMMS implementations fail when organizations lack clear objectives and measurable success criteria.

Vague goals like ‘improve maintenance’ or ‘better data’ provide no basis for decision-making or measuring progress.

Misaligned expectations arise when different stakeholders envision different outcomes without explicit discussion.

6.3.2. The Solution.

Define Specific Business Case with Measurable KPIs.

Establish concrete objectives such as:

1. Reduce unplanned downtime by specified amounts within defined timeframes.

2. Achieve high preventive maintenance compliance for critical assets.

3. Decrease maintenance labor overtime.

4. Reduce spare parts inventory carrying costs.

5. Improve work order completion documentation rates.

These specific targets provide clear success criteria and enable progress tracking.

Focus on Core Workflows First.

Resist the temptation to configure every possible feature during initial implementation. Organizations should focus initial phases exclusively on:

1. Work order management.

2. Preventive maintenance scheduling.

3. Basic inventory tracking.

4. Mobile access for technicians.

After achieving proficiency in these core areas, progressively add condition monitoring, predictive analytics and ERP integration.

Avoid Over-Customization Early.

Excessive customization during implementation increases complexity, extends timelines and creates maintenance burdens.

Use out-of-box functionality when possible and customize only where business processes genuinely require it.

Many organizations discover that adjusting their processes to match CMMS best practices produces better outcomes than forcing software to match existing inefficient workflows.

6.4. Challenge 4: Integration Headaches.

6.4.1. The Problem.

CMMS platforms must integrate with other systems including ERP, procurement, IoT platforms and control systems.

Integration failures prevent data flow between systems creating information silos and manual workarounds.

Common integration problems include:

1. Incompatible data formats requiring manual translation.

2. Real-time synchronization failures causing data discrepancies.

3. Security protocols blocking necessary data exchanges.

4. Undocumented APIs requiring extensive custom development.

5. Version updates breaking existing integrations.

6.4.2. The Solution.

1. Plan Integrations from Day One: Include integration requirements in the initial business case and vendor selection process. Identify all systems requiring integration and define required data flows before selecting CMMS platforms.

2. Prioritize Robust APIs: Select CMMS solutions with well-documented APIs and proven integration frameworks. Evaluate vendors based on their integration portfolio and existing connectors for systems you already use.

3. Use Pre-Built Integrations: Leverage pre-built integration modules when available. Pre-built solutions between SCADA systems and CMMS platforms can eliminate custom development while ensuring reliable data flow from operational sensors to maintenance work orders.

4. Establish Integration Testing Protocols:Test integrations thoroughly before production deployment:

a) Verify data accuracy across systems.

b) Validate real-time synchronization performance.

c) Test error handling and recovery procedures.

d) Confirm security and access controls.

e) Document integration dependencies and maintenance requirements.

7.0 Best Practices and Standards.

7.1. Industry Standards.

7.1.1. ISO 55000 Asset Management.

ISO 55000 provides an internationally recognized framework for asset management published by the International Organization for Standardization.

The standard establishes principles, terminology and requirements for systematic management of physical assets throughout their lifecycle.

The standard emphasizes:

1. Strategic Alignment. Connecting asset management decisions to organizational objectives.

2. Risk-Based Decision Making. Balancing costs, risks and performance.

3. Stakeholder Engagement. Considering needs of employees, customers, regulators and communities.

4. Continuous Improvement. Using performance data to drive ongoing refinement.

Organizations implementing CMMS can align their approach with ISO 55000 by:

1. Defining asset management policies and objectives.

2. Establishing asset hierarchies reflecting organizational structure.

3. Implementing lifecycle cost analysis for major assets.

4. Creating performance metrics linked to strategic goals.

5. Conducting regular management reviews of asset performance.

7.2. Australian Regulatory Requirements.

7.2.1. Mining Regulations.

Mining operations in Australia operate under state-based safety regulations with specific requirements varying by jurisdiction.

New South Wales.

The Work Health and Safety (Mines and Petroleum Sites) Act 2013 is publicly available NSW legislation that requires systematic management of plant and equipment including:

1. Regular inspection and testing schedules.

2. Maintenance records retained for equipment lifetime.

3. Competency verification for personnel maintaining critical equipment.

4. Risk assessments before maintenance activities.

CMMS supports compliance by:

1. Scheduling mandatory inspections with automated reminders.

2. Maintaining auditable records of all maintenance activities.

3. Tracking technician certifications and qualifications.

4. Documenting risk assessments linked to work orders.

7.2.2. Utility Regulations.

Energy Sector.

The Australian Energy Regulator is the national energy market regulator.

Electricity network service providers must meet reliability standards and report performance metrics.

Water Sector.

State-based water regulators require:

1. Water quality testing at specified frequencies.

2. Treatment plant maintenance ensuring continuous compliance.

3. Emergency response capabilities.

4. Asset management planning demonstrating long-term sustainability.

CMMS enables compliance through:

1. Automated generation of regulatory reports.

2. Tracking of all testing and inspection activities.

3. Work order prioritization based on service impact.

4. Historical records supporting regulatory audits.

7.3. What ‘Good’ Looks Like.

Successful CMMS implementations demonstrate consistent characteristics that differentiate high-performing maintenance organizations from average ones.

1. Complete and Accurate Asset Hierarchy: Every physical asset is recorded in the system with correct locations, parent/child relationships, criticality ratings and complete technical data. Assets can be located immediately and maintenance history is accessible quickly.

2. High Preventive Maintenance Compliance: Critical assets receive preventive maintenance at high compliance rates. This indicates that planned work is actually being executed rather than constantly deferred for reactive emergencies. Industry guidance often suggests targeting compliance rates above 90% for critical assets.

3. Clear Auditable Work Order Trail: Every work order contains complete information including who requested the work, who authorized it, what was done, what parts were used, how long it took and what condition was found. This audit trail supports regulatory compliance, cost analysis and continuous improvement.

4. Strong User Adoption: High percentages of maintenance technicians regularly use the CMMS and mobile apps for work execution. High adoption rates indicate the system is genuinely useful rather than a bureaucratic burden users avoid when possible.

5. Data-Driven Decision Making: Managers regularly review CMMS dashboards and use maintenance data to make strategic decisions about asset replacement, staffing, inventory and process improvements.

8.0 Tools and Technology: Choosing and Using Your CMMS.

8.1. Software Categories.

8.1.1. Core CMMS Platforms.

Numerous CMMS platforms provide comprehensive maintenance management capabilities including work orders, preventive maintenance, inventory management and reporting.

The market includes both cloud-based and on-premise solutions with varying features and pricing models.

When evaluating CMMS platforms, organizations should consider:

1. Deployment model (cloud, on-premise or hybrid).

2. User interface design and ease of use.

3. Mobile capabilities including offline functionality.

4. Integration options with existing systems.

5. Vendor support and training offerings.

6. Total cost of ownership including licensing and implementation.

8.1.2. Specialized Add-ons.

1. IoT Platforms: Industrial IoT platforms connect to sensors, PLCs, SCADA systems and industrial devices enabling real-time condition monitoring. These platforms bridge operational technology with information technology systems.

2. Vibration Analysis: Vibration monitoring systems detect bearing failures, alignment issues and other mechanical problems in advance. These systems can integrate with CMMS platforms to generate work orders automatically.

3. Enterprise Integration: ERP systems integrate with CMMS for procurement, inventory and financial data synchronization. Major ERP platforms provide integration capabilities through APIs or middleware.

8.2. Selection Criteria.

Organizations should define required business processes first, then select software that enables those processes.

8.2.1. Process Before Software.

Organizations should:

1. Map current workflows identifying inefficiencies.

2. Design ideal future-state processes.

3. Document specific requirements for each workflow stage.

4. Use process requirements as vendor evaluation criteria.

This approach prevents the common mistake of selecting attractive software then forcing operations into inappropriate constraints.

8.2.2. Key Evaluation Criteria.

Scalability.

Can the platform grow from limited deployment to enterprise-wide implementation? Consider:

1. User licensing models and costs at scale.

2. Performance with large asset databases.

3. Multi-site and multi-organization capabilities.

4. Hierarchical security and reporting structures.

Integration Capabilities.

Does the platform offer:

1. Well-documented APIs for custom integrations.

2. Pre-built connectors for common systems.

3. Real-time data synchronization.

4. Support for various data formats and protocols.

Mobile Functionality.

Evaluate the mobile experience:

1. Offline capability for remote locations.

2. Interface usability on small screens.

3. Camera integration for photo documentation.

4. Barcode scanning for asset and parts identification.

5. Performance on rugged devices used in industrial settings.

Ease of Use.

Assess whether:

1. Interfaces are intuitive requiring minimal training.

2. Common tasks require few clicks.

3. Search and navigation are efficient.

4. Different user roles have appropriately simplified views.

Vendor Stability and Support.

Consider:

1. Vendor financial stability and market position.

2. Quality of implementation support.

3. Ongoing training and documentation.

4. User community and knowledge base.

5. Roadmap for future enhancements.

8.3. Implementation and Integration.

Structured implementation plans prevent common pitfalls and accelerate time to value.

8.3.1 Implementation Planning.

Develop detailed project plans covering:

1. Phase definitions with clear deliverables.

2. Resource allocation including internal staff and consultants.

3. Timeline with realistic milestones.

4. Risk management and contingency planning.

5. Change management and communication strategies.

8.3.1 Pre-Built Integration Value.

Pre-built integrations between systems can bridge the gap between operational technology and maintenance execution. These integrations:

1. Connect SCADA historian data to CMMS platforms.

2. Enable automated work order creation based on sensor thresholds.

3. Provide technicians with real-time equipment data during work execution.

4. Eliminate custom development and ongoing integration maintenance.

Organizations should actively seek CMMS vendors offering pre-built integrations with their existing technology stack rather than assuming all integrations require custom development.

9.0 Measurement and Metrics: Proving CMMS Success.

9.1. Reframing Maintenance as Value Driver.

Maintenance departments are often viewed as cost centers consuming resources without directly generating revenue.

This perspective misses the reality that effective maintenance protects capital investments, prevents production losses and enables reliable operations.

Reframing maintenance as a value driver requires demonstrating measurable financial impacts through systematic ROI calculation using the standard formula:

(Net Gain from Investment / Cost of Investment) × 100

Where:

· Net Gain represents quantified benefits including downtime reduction, labor savings, inventory optimization and asset life extension.

· Cost of Investment includes CMMS software licenses, implementation services, training and ongoing support.

9.2. Essential Metrics for ROI.

9.2.1. Reduction in Unplanned Downtime.

Unplanned downtime represents costly maintenance failures.

Calculate the cost per hour of downtime by considering:

1. Lost production value.

2. Labor costs for idle workers.

3. Emergency repair premiums.

4. Customer penalties for missed deliveries.

5. Restarting and quality issues.

Organizations should establish their specific downtime costs based on their operations. After CMMS implementation, measure changes in unplanned downtime hours and multiply by the hourly cost to quantify savings.

9.2.2. Mean Time Between Failures (MTBF).

MTBF measures reliability by calculating the average operating time between failures for equipment.

MTBF = Total Operating Time / Number of Failures.

Increasing MTBF proves that maintenance strategies are improving equipment reliability. Organizations track MTBF for critical equipment before and after CMMS implementation to demonstrate improvement.

9.2.3. Preventive Maintenance Compliance.

PM compliance measures the percentage of scheduled preventive maintenance tasks completed on time.

Industry guidance often suggests targeting high compliance rates for critical assets.

PM Compliance.

Completed PM Work Orders / Scheduled PM Work Orders) × 100

Low PM compliance indicates that reactive emergencies constantly disrupt planned work. Organizations can improve PM compliance after CMMS implementation through:

1. Automated scheduling eliminating forgotten tasks.

2. Mobile access making PM execution convenient.

3. Management visibility creating accountability.

High PM compliance drives reliability improvement by ensuring protective maintenance occurs before failures.

9.2.4. Maintenance Labor Cost Savings.

Track labor efficiency improvements through:

1. Reduced Overtime: Better planning reduces emergency callouts. Organizations can measure overtime cost reductions after CMMS implementation through improved scheduling and parts availability.

2. Improved Technician Productivity: Mobile access eliminates trips to obtain work orders and asset information. Technicians spend more time on actual repairs and less time on administrative tasks.

3. Optimized Travel: Geographic scheduling groups proximate work reducing travel time.

Calculate labor savings by comparing labor hours per work order before and after CMMS implementation while controlling for work type and complexity.

9.2.5. Spare Parts Inventory Costs.

CMMS enables inventory optimization through:

1. Reduced Stock Levels: Data-driven min/max calculations prevent overstocking while maintaining availability.

2. Fewer Emergency Purchases: Better planning allows procurement at standard prices rather than emergency premiums.

3. Reduced Obsolescence: Usage tracking identifies slow-moving inventory for liquidation.

Organizations can measure inventory carrying cost reductions while tracking parts availability improvements through CMMS-enabled inventory management.

9.2.6. Asset Lifespan Extension.

Proper maintenance extends asset operating lives deferring major capital expenditures.

Calculate the value by:

1. Determining asset replacement cost.

2. Estimating lifespan extension in years or operating hours.

3. Calculating deferred capital using present value analysis.

Organizations can demonstrate how systematic preventive maintenance and condition monitoring extends asset life and defers capital expenditures.

9.2.7. Reduction in MRO Spend.

MRO (Maintenance, Repair and Operations) encompasses total maintenance spending including:

1. Labor (internal and contractor).

2. Parts and materials.

3. Outside services.

4. Equipment rentals.

Track overall MRO spend as percentage of asset replacement value. Industry benchmarks suggest world-class organizations maintain lower MRO spend percentages than average organizations.

CMMS reduces MRO spend through:

1. Systematic preventive maintenance preventing costly failures.

2. Better planning reducing premium costs.

3. Data-driven inventory management.

4. Contractor management and spend visibility.

9.3. Reporting and Maintenance Analysis Dashboards.

Effective reporting transforms raw data into actionable insights for different organizational levels.

Technician Dashboards Show:

1. Assigned work orders with priorities.

2. Parts reserved for upcoming jobs.

3. Recent work history on assets being maintained.

4. Personal performance metrics.

Supervisor Dashboards Display:

1. Work backlog by priority and age.

2. Team capacity and availability.

3. PM compliance rates.

4. Work order completion trends.

Management Dashboards Present:

1. Cost trends by asset class.

2. Key performance indicators against targets.

3. Asset reliability metrics.

4. Budget variance analysis.

Executive Dashboards Summarize:

1. Overall maintenance effectiveness.

2. Capital deferral opportunities.

3. Risk indicators for critical assets.

4. Strategic initiative progress.

Real-time dashboards enable proactive management by surfacing issues when they emerge rather than discovering problems during periodic reports.

10.0 The Future of Maintenance for Mature Organizations.

10.1. Predictive Maintenance in Depth.

Predictive maintenance uses AI and machine learning algorithms to forecast equipment failures before they occur.

This approach goes beyond traditional preventive maintenance by conditioning maintenance timing on actual equipment condition rather than fixed schedules.

10.1.1 How PdM Works.

Machine learning models analyze patterns in sensor data including vibration, temperature, pressure, oil analysis and electrical signatures.

The models learn normal operating patterns and detect anomalies indicating developing problems.

A typical PdM workflow includes:

1. Data Collection. Continuous sensor monitoring captures operating parameters.

2. Pattern Recognition. AI models compare current data against normal baselines.

3. Anomaly Detection. Algorithms flag deviations exceeding learned thresholds.

4. Failure Prediction. Models estimate time-to-failure based on degradation rates.

5. Work Order Generation. CMMS automatically creates work orders with predicted failure dates and recommended actions.

10.1.2 PdM Integration.

Integrations between vibration monitoring systems and CMMS platforms demonstrate end-to-end PdM:

1. Sensors continuously monitor rotating equipment vibration.

2. Algorithms detect bearing degradation patterns.

3. Systems automatically generate work orders in CMMS.

4. Technicians receive orders with specific maintenance instructions.

5. Parts are automatically reserved from inventory.

6. Work is scheduled before catastrophic failure occurs.

This automation transforms maintenance from reactive response to proactive intervention.

10.2. From Predictive to Prescriptive Maintenance.

Prescriptive maintenance represents the next evolution beyond prediction. While predictive maintenance forecasts when failures will occur, prescriptive maintenance recommends optimal responses considering multiple factors:

1. Failure Consequences. What happens if we defer this repair?

2. Resource Availability. Do we have parts and qualified technicians available?

3. Production Impact. When can we take this asset offline with minimal disruption?

4. Cost Optimization. Should we repair or replace based on lifecycle economics?

Prescriptive AI algorithms evaluate these factors simultaneously and recommend optimal maintenance strategies that human planners can review and approve.

10.3. Digital Twins.

Digital twins create virtual replicas of physical assets enabling simulation and optimization without disrupting operations.

A digital twin includes:

1. Physical Model. 3D representation showing asset configuration and relationships.

2. Behavioral Model. Operating characteristics and performance parameters.

3. Historical Data. Complete maintenance and operating history.

4. Real-Time Data. Current sensor readings and operating conditions.

Organizations typically use digital twins to:

1. Simulate maintenance scenarios and predict outcomes.

2. Optimize operating parameters for efficiency.

3. Train technicians on virtual replicas before touching real assets.

4. Evaluate design modifications virtually.

Organizations can use digital twins of critical equipment to simulate maintenance scenarios and optimize strategies without affecting actual operations.

10.4. AI Applications in Maintenance.

AI technologies are increasingly applied to maintenance operations to improve efficiency and effectiveness.

10.4.1 Intelligent Alarm Filtering.

Traditional systems generate numerous alarms with high percentages being false positives or minor issues requiring no immediate action. AI-powered filtering engines can:

1. Analyze historical alarm patterns to identify false positives.

2. Use machine learning to distinguish critical alerts from routine variations.

3. Suppress nuisance alarms while escalating genuine equipment problems.

4. Prioritize work orders based on business impact and failure probability.

Organizations implementing intelligent alarm filtering have reported substantial reductions in alarm noise, allowing technicians to focus on genuine maintenance needs rather than investigating non-actionable alerts.

11.0 Conclusion: Your Roadmap to Holistic CMMS Success.

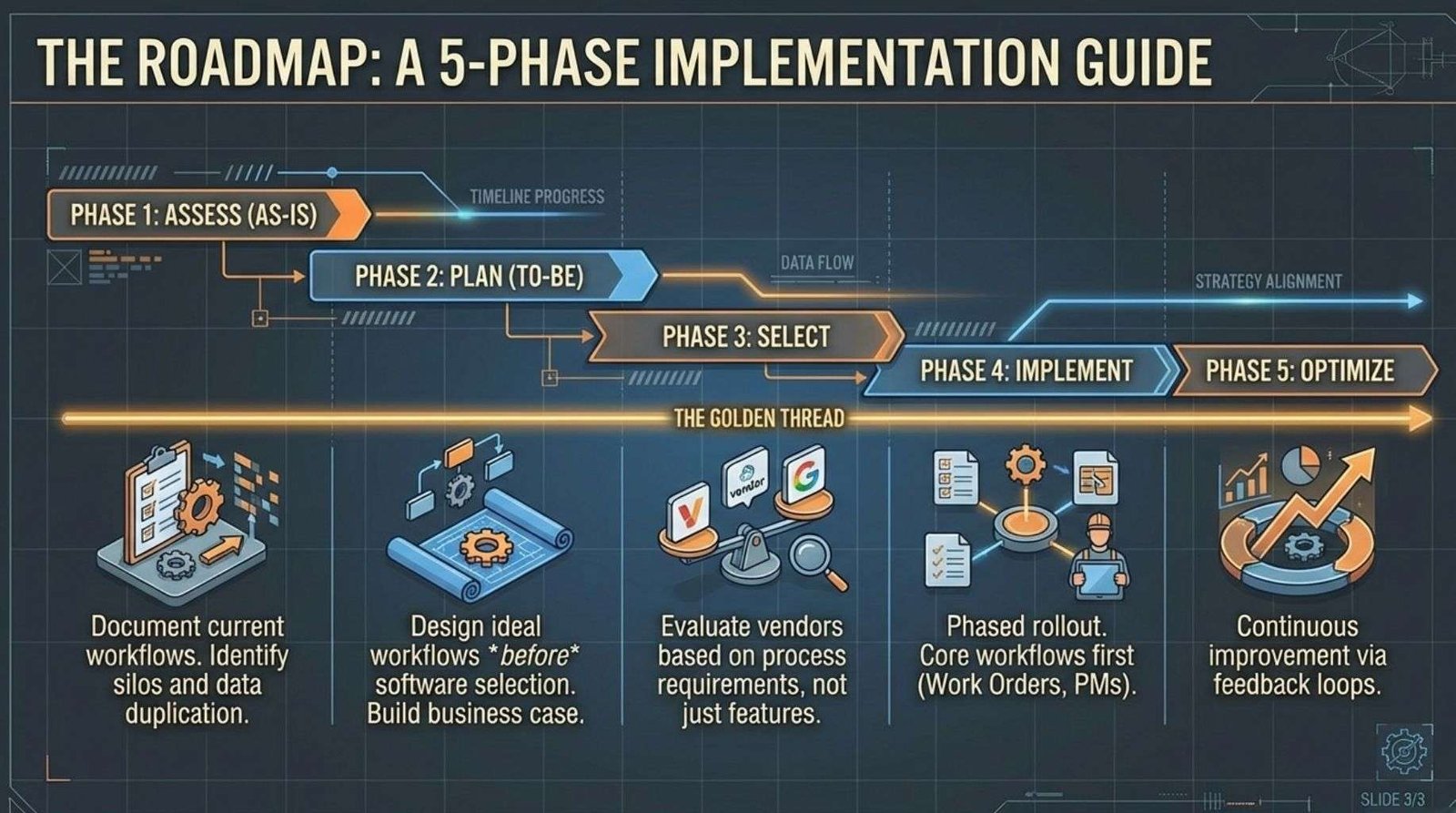

Holistic CMMS success represents a journey of organizational transformation rather than a software purchase.

Success emerges from systematically integrating the work progression pipeline with appropriate technology, high-quality data and engaged people committed to continuous improvement.

11.1. The Five-Phase Framework.

Phase 1: Assess.

Audit your current ‘as-is’ processes and data quality. Conduct honest assessments of:

1. Current workflow effectiveness and bottlenecks.

2. Data quality in existing systems.

3. User skill levels and technology readiness.

4. Integration requirements with other systems.

5. Regulatory compliance gaps.

Phase 2: Plan.

Define your ‘to-be’ workflows and build a business case with clear KPIs. Establish:

1. Specific measurable objectives for CMMS implementation.

2. Detailed process maps showing ideal workflows.

3. Governance structure with cross-functional representation.

4. Resource allocation including budget and internal staff.

5. Timeline with realistic milestones.

Phase 3: Select.

Choose a CMMS that fits your processes rather than forcing your processes into software constraints. Evaluate platforms against:

1. Business process requirements documented during planning.

2. Integration capabilities with existing systems.

3. Scalability for future growth.

4. Mobile functionality for field users.

5. Vendor stability and support quality.

Phase 4: Implement.

Follow a phased approach with intense focus on data quality and training. Execute:

1. Data cleansing and standardization before migration.

2. Phased rollout starting with core workflows.

3. Comprehensive role-based training programs.

4. Change management addressing user concerns.

5. Pilot programs proving value before full deployment.

Phase 5: Optimize.

Use data and emerging technologies including AI and IoT to drive continuous improvement. Establish:

1. Regular performance review against KPIs.

2. Feedback mechanisms capturing user improvement ideas.

3. Process refinement based on operational experience.

4. Advanced feature adoption as maturity increases.

5. Integration of new technologies as they prove valuable.

11.2. Immediately Usable Resources.

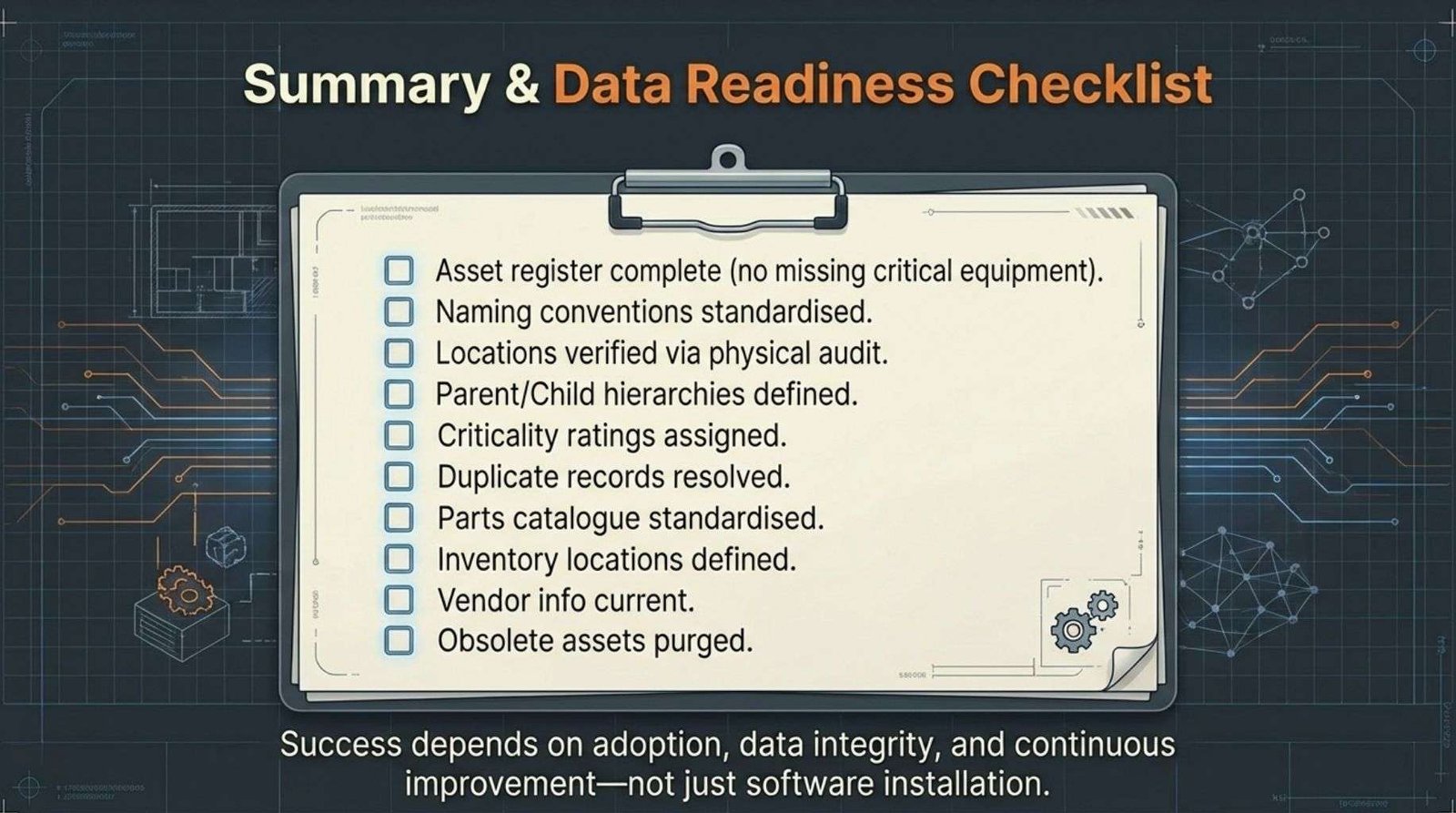

10-Point CMMS Data Readiness Checklist:

1. Asset register is complete with no missing critical equipment.

2. Asset naming follows consistent standardized conventions.

3. Asset locations are accurate and verified through physical audit.

4. Asset hierarchies show parent/child relationships correctly.

5. Criticality ratings are assigned using documented criteria.

6. Duplicate asset records have been identified and resolved.

7. Parts catalog uses standard descriptions and part numbers.

8. Inventory locations are clearly defined and consistent.

9. Vendor information is current with accurate contact details.

10. Obsolete assets and parts have been purged from databases.

Maintenance Work Progression Pipeline Template:

Ø Stage 1: Purchase Assets & Setup Asset Management Strategy.

Ø Stage 2: Initiate New Work Requests.

Ø Stage 3: Review and Approve New Work Requests.

Ø Stage 4: Process New Work – Urgent & Planned.

Ø Stage 5: Execute Urgent Work.

Ø Stage 6: Schedule Planned Work.

Ø Stage 7: Execute Scheduled Work.

Ø Stage 8: Complete Work.

Ø Stage 9: Analyze Work.

Ø Stage 10: Improve Work Quality and Performance.

CMMS Vendor Scorecard Framework:

Ø Process Alignment (35 points). How well does the platform support your documented business processes?

Ø Integration Capability (20 points). What integration options exist for your current technology stack?

Ø Usability (20 points). How intuitive is the interface for different user roles?

Ø Scalability (15 points). Can the platform grow with your organization?

Ø Vendor Support (10 points). What quality of implementation and ongoing support is available?

11.3. The Path Forward.

Organizations embracing holistic CMMS approaches position themselves to:

1. Protect capital investments through systematic asset management.

2. Reduce operating costs via optimized maintenance strategies.

3. Improve safety through better equipment reliability and compliance tracking.

4. Enhance decision-making with data-driven insights.

5. Build resilience through predictive capabilities and proactive maintenance.

Organizations across diverse industries and scales can achieve measurable value through systematic implementation of holistic CMMS principles.

Mining operations managing substantial assets, local councils serving communities with limited budgets and utilities maintaining critical infrastructure all demonstrate that CMMS success is achievable.

The journey begins with commitment to viewing maintenance as a strategic capability rather than a necessary cost.

Organizations that treat CMMS implementation as a technology project typically achieve modest improvements in administrative efficiency.

Organizations that embrace holistic approaches transforming people, processes and technology achieve breakthrough improvements in reliability, cost and strategic value.

Start your holistic CMMS journey today by conducting an honest assessment of your current state, defining clear objectives for where you want to go and systematically executing the five-phase framework.

The investment in thoughtful implementation will deliver returns measured in substantial cost savings, risks mitigated and organizational capabilities enhanced for years to come.