The Hidden Costs Of Tyre Maintenance

Getting In Control Of Truck Tyre Maintenance Costs. When it comes to managing the expenses of earthmoving and transport companies, […]

The Hidden Costs Of Tyre Maintenance Read More »

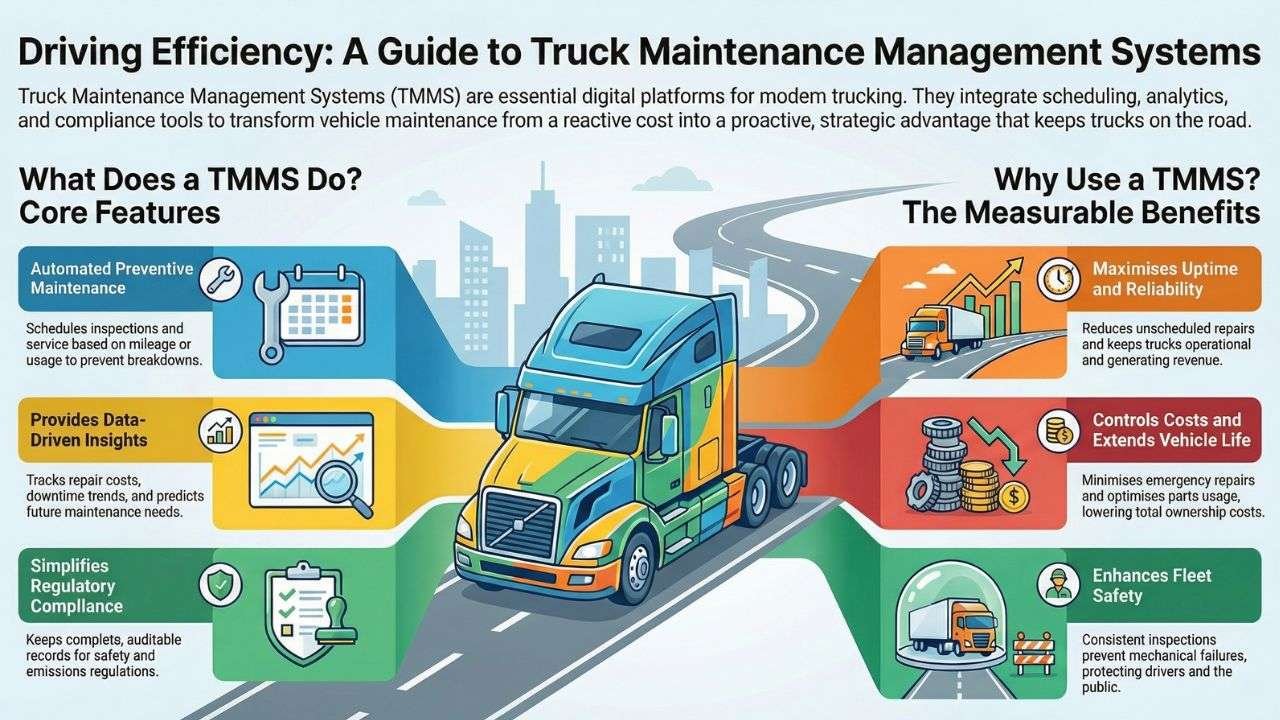

Modern trucking operations, whether large fleets or single owner-operators, depend on reliable, data-driven maintenance management systems to keep vehicles running at peak performance.

Truck Maintenance Management Systems (TMMS) integrate digital tools, analytics and scheduling processes to manage all preventive, corrective and compliance-related maintenance activities across a fleet.

In an industry defined by tight logistics, rising fuel costs and strict regulatory standards, these systems are not just advantageous, they are essential.

Core Components of a Truck Maintenance Management System.

Measurable Benefits of TMMS Implementation.

Steps to Implement an Effective System.

Leading Software Options for Owner-Operators.

| Software | Key Features | Ideal Use Case |

| Fiix | Cloud-based platform offering preventive scheduling, work order tracking and component history. | Small to mid-sized fleets seeking scalable automation. |

| MaintainX | Mobile-first interface with digital checklists and communication tools. | Solo operators managing maintenance on the go. |

| Fleetio | Comprehensive asset management with maintenance tracking and fuel management. | Fleet operators needing end-to-end tracking. |

| KeepTruckin | Combines ELD compliance with diagnostic reporting and defect tracking. | Operators seeking streamlined compliance and maintenance in one platform. |

| Whip Around | Digital inspections, defect reporting and service scheduling with intuitive UI. | Owner-operators prioritising simplicity. |

| TruckingOffice | Integrated dispatching, accounting and IFTA reporting alongside maintenance management. | Small trucking businesses seeking all-in-one management tools. |

The Strategic Value of Maintenance Management.

Beyond keeping trucks running smoothly, a well-implemented TMMS builds operational resilience.

It transforms maintenance from a reactive cost centre into a strategic capability, improving asset longevity, controlling expenses and ensuring every truck in the fleet contributes to safer, more reliable roads.

By leveraging modern maintenance management technology, truck operators can align engineering discipline with business intelligence, an essential foundation for staying competitive in Australia’s evolving freight and logistics landscape.

Data-Driven Maintenance Economics: Turning Insights into ROI.

Advanced TMMS platforms do more than schedule upkeep, they transform raw operational data into economic intelligence.

By analysing detailed cost-per-kilometre data, maintenance task frequency and parts replacement intervals, fleet managers can quantify the real return on each maintenance decision.

For example, correlating engine performance logs with repair histories may reveal which truck models deliver the lowest total lifecycle cost when maintained under specific intervals.

This enables evidence-based procurement and maintenance interval planning, aligning engineering outcomes with financial results.

Sophisticated fleets increasingly benchmark these metrics using rolling averages and predictive modelling to establish their Maintenance Cost Index (MCI), a proprietary indicator comparing preventive maintenance expense against downtime and lost revenue risk.

By integrating TMMS data with accounting and telematics platforms, maintenance becomes a measurable investment rather than an overhead cost.

Beyond Compliance: Building a Predictive Safety Culture.

Most fleets focus on compliance-driven inspections, but leading operators use TMMS analytics to create a predictive safety culture instead of a reactive one.

By integrating telematics and driver behaviour data, such as harsh braking, over‑revving, or extended idling, maintenance managers can identify patterns that precede mechanical stress or component wear.

This predictive model goes beyond fault codes and looks at behavioural precursors to failure.

For instance, frequent abrupt braking events may accelerate brake fade, while long idling periods can indicate engine inefficiency.

Addressing these root causes through preventative coaching and targeted service intervals keeps trucks safer and longer-lasting.

Over time, this transforms safety into a quantifiable performance domain where incident rates, defect recurrence and near-miss thresholds are tracked and reduced through maintenance discipline and driver engagement, not just compliance paperwork.

The Future of TMMS: AI, IoT and Autonomous Maintenance Ecosystems.

The next frontier of highway truck maintenance lies in connected and autonomous maintenance ecosystems powered by artificial intelligence and Internet of Things (IoT) technologies.

These advancements will reshape TMMS into dynamic, self-learning frameworks capable of continuous optimisation, cutting both costs and emissions across vehicle fleets.

Operators who invest early in data integration architectures and API‑ready platforms will find themselves far ahead when this ecosystem becomes mainstream.

Getting In Control Of Truck Tyre Maintenance Costs. When it comes to managing the expenses of earthmoving and transport companies, […]

The Hidden Costs Of Tyre Maintenance Read More »

Highway Dump Truck Maintenance Manual / CMMS Guide Disclaimer. This content is for informational and educational purposes only. It reflects

Truck Maintenance Management Read More »

Framework for Developing Truck Asset Management Plans Disclaimer This article is provided for general informational and educational purposes only. The

Highway Truck Asset Management Plan Read More »