The Maintenance Planning Skill Set

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

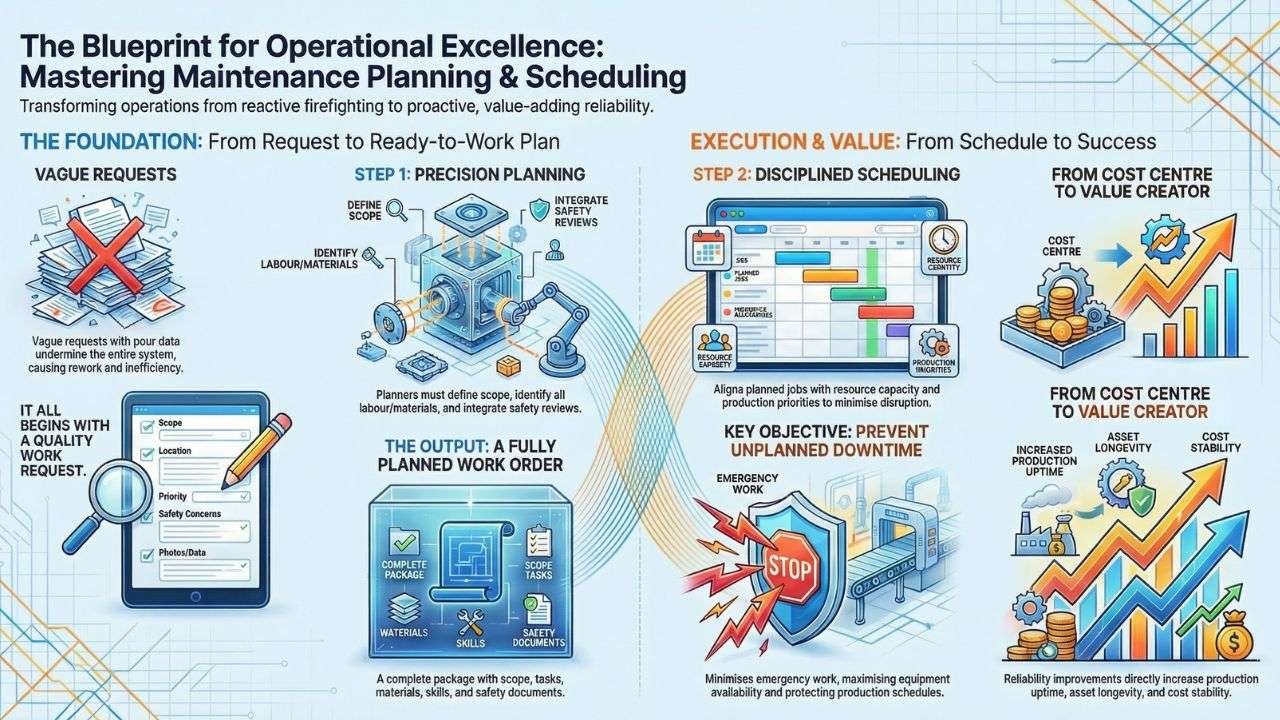

Effective maintenance planning and scheduling goes far beyond creating checklists or assigning technicians to fixed shifts.

It’s a disciplined process built on teamwork, technical knowledge and operational foresight, one that determines whether an organisation achieves reliability, safety and efficiency, or suffers recurring downtime, inflated costs and production disruptions.

In industries that rely heavily on high quality planning and scheduling, such as mining, manufacturing, oil and gas, refining, smelting and energy generation, the ability to execute maintenance work exactly as promised is not merely a technical skill, it’s a business differentiator.

Missed opportunities during approved maintenance windows can interrupt entire production schedules, delay customer deliveries and erode trust between operations and maintenance teams.

Even outside the most intensive production environments, high‑quality planning and scheduling is the heartbeat of reliability and efficiency.

Each fully planned and intelligently scheduled inspection, PM, defect rectification, or condition‑based component replacement acts as a pulse that keeps the production system alive, profitable, dependable and predictable.

When performed with consistency, foresight and data‑driven insight, these functions elevate maintenance from a reactive support function to a cornerstone of operational excellence.

Beyond preventing costly unplanned breakdowns, effective planning and scheduling ensures that people, parts, tools and equipment are available when needed the most, enabling production teams to prepare for maintenance on time and in full.

A mature planning and scheduling process aligns production forecasts with maintenance requirements, supports accurate long‑range planning, maximises uptime and reduces conflict between departments.

At its best, it creates a workplace culture where technicians focus on safe, well‑defined tasks instead of firefighting unexpected problems.

The Foundation: Understanding the Maintenance Business Process.

Every quality maintenance organisation operates along a structured business process, from work identification to execution and performance review.

Planning and scheduling are the ‘Go/No Go’ point of that process. There’s just no value in putting together a list of jobs for execution team to carry out during the next period unless you are highly confident that every job is fully planned and optimally scheduled.

Poor planning and scheduling does little more than ensure uncertainty across the organisation: incorrect parts, scopes of work, missing job packs, underestimated or wrong labour decisions and forgetting to organize specialist contracts are signs that your organization is struggling in more ways than one.

Poor scheduling to me is a show stopper, the operational conflicts it creates and the unplanned production losses it brings about, are just too hard for a senior production manager to accept.

The importance of Maintenance Management Functionality across the board can not be underestimated and a big part of that is your choice in Enterprise Resource Planning System (ERP) or CMMS.

High-quality organisations therefore treat these steps as formal systems with clear governance, skills and accountability.

Success begins with quality control at the start of every process and sub-process. Each new work request/notification must be reviewed for clarity, safety concerns and operational importance before being accepted it and converting it into a fully planned work order, the planner needs to be fed quality information.

High-quality fully planned work orders include everything the maintenance execution team need to do the job and this is why experienced tradespeople that become planners typically tend to do so well.

Step One: Precision in Maintenance Planning.

Planning gives structure to maintenance work before a wrench ever turns. The planner’s role combines technical knowledge, logistical foresight and communication skills.

A well-planned work order results in a complete maintenance package: scope, tasks, materials, skills, safety documentation and time estimates, all ready for scheduling.

Step Two: The Discipline of Maintenance Scheduling.

Scheduling is where planned work becomes operational reality. It aligns resource capacity with maintenance need while balancing production priorities. Effective scheduling seeks one outcome: right work, right time, right resources, minimal disruption.

The scheduling process begins with a quality review of planned jobs to ensure completeness. Work that lacks essential planning data should never be scheduled prematurely.

Once verified, schedulers assess each job against real-world constraints, from production availability and weather conditions to contractor schedules and material delivery timelines.

Commonly, scheduling is optimised within a defined “window” such as weekly or bi-weekly cycles.

Tasks are ranked using risk-based prioritisation, ensuring that safety-critical and production-impacting work is addressed first.

Key factors influencing scheduling decisions include:

By aligning with these parameters, the scheduler ensures that maintenance is executed strategically rather than reactively, supporting corporate goals for reliability, safety and cost performance.

Objectives of Quality Planning and Scheduling

In short, the discipline of planning and scheduling translates strategic intent into operational stability.

The Hidden Human Factor.

In my experience, many maintenance systems fail not because of technology or process, but because of culture.

The principles of Reliability Engineering reminds us that maintenance decisions are influenced by behavioural bias, fatigue, communication gaps and inconsistent work practices.

Skilled planners counter these risks through clarity and standardisation.

Checklists and job plans are not administrative clutter, they are expressions of empathy for the technician performing the work.

Realistic time allowances, clear task sequences and well‑defined scopes reduce cognitive load and improve safety.

When organisations encourage field feedback loops, through post‑job reviews, digital check‑ins, or structured debriefs, continuous improvement becomes a natural outcome rather than an aspiration.

High‑performing teams embed learning cycles into their maintenance programs. Technicians record real‑world durations, access issues and complications after job completion, enabling planners to refine future estimates.

Over time, this forms an evolving tribal knowledge database that improves planning accuracy and strengthens accountability.

The Often‑Ignored Foundation: Work Identification.

Before planning and scheduling can succeed, the quality of work requests must be high. Poorly scoped, vague, or reactive requests undermine even the best systems. In classy organisations, work identification is treated as a critical control point, not an administrative formality.

Typically, high‑quality work requests will always include:

This level of detail ensures planners receive actionable inputs, not guesswork and prevents them from wasting their time having to track down the originators.

It reduces rework, prevents misdiagnosis and eliminates the costly cycle of “go‑look‑go‑get‑go‑back.”

High‑performing organisations train operators and maintainers to recognise defects early, document them clearly and provide the contextual evidence needed to make informed decisions.

When work identification is done well, planning becomes faster, scheduling becomes smoother and maintenance execution becomes predictable.

When it is done poorly, the entire system becomes reactive, inefficient and vulnerable to failure.

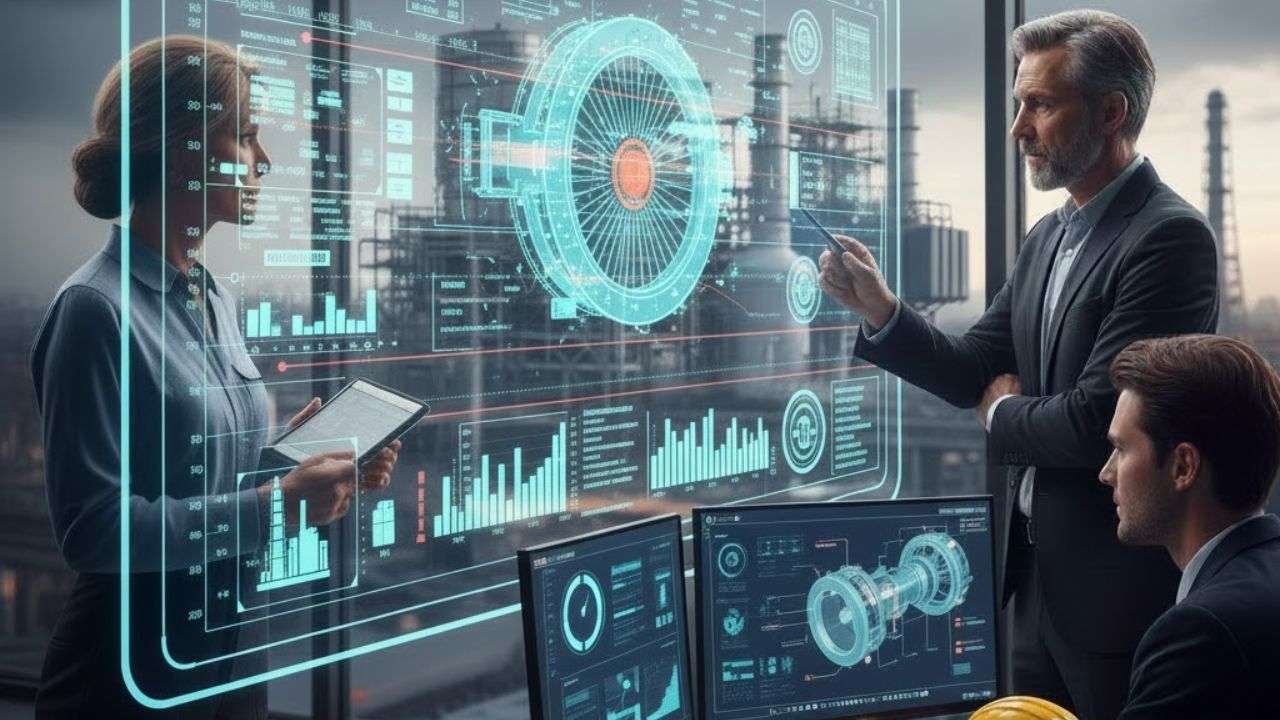

Integrating Technology: From Reactive History to Predictive Insight.

Modern maintenance planning is merging with digital asset management. Advanced CMMS and EAM platforms integrate work order data with predictive analytics, creating a knowledge‑driven ecosystem rather than a calendar‑driven one.

This shift transforms maintenance from reactive firefighting into proactive asset stewardship.

The Planner–Scheduler–Supervisor Triangle.

Planning and scheduling excellence depends on a clear operational handshake between roles.

A mature system uses a frozen weekly schedule, protects planned work from disruption and maintains a healthy backlog aligned with asset criticality.

The Strategic Perspective: Maintenance as a Value Creator.

Many organisations still view maintenance as a cost centre. In reality, effective planning and scheduling turn it into a strategic value generator.

Reliability improvements directly influence:

Downtime avoided through good planning converts immediately into revenue. Optimised scheduling reduces overtime, improves contractor utilisation and stabilises operational rhythms.

When aligned with frameworks such as ISO 55000, maintenance becomes a core pillar of organisational excellence.

Advanced Insight: Dynamic Scheduling Under Real‑World Constraints.

Static schedules rarely survive first contact with reality. Weather, breakdowns and shifting production priorities demand dynamic scheduling.

Leading organisations often use:

These tools highlight conflicts early, enabling supervisors to reshuffle tasks without compromising overall workflow.

Integrating scheduling with production forecasting also reveals opportunities for opportunity maintenance, performing additional work while equipment is already offline.

Beyond Process: Building a Reliability Culture.

True maintenance excellence is cultural, not procedural. It reflects a shift from fixing failures to preventing them.

A reliability‑focused culture:

When reliability becomes a shared mindset, planning and scheduling deliver not just efficiency, they deliver resilience.

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

Securing An Advertised Role As A Maintenance Planner The overall effectiveness and efficiency of a company’s machinery and equipment is

Securing A Maintenance Planner Role Read More »

What Exactly Is The Role Of A Maintenance Planner? A maintenance planner is essential to the seamless operation of any

What is a Maintenance Planner Read More »

Effective Work Scheduling Process & Your CMMS. When it comes to managing a high-risk heavy industrial business, one of the

Maintenance Work Scheduling Read More »

Collaboration is the key for Effective Risk Management at Workplaces. Heavy Industrial workplaces, by their very nature, pose inherent risks

Effective Risk Management at Work Read More »

The Importance of a Safety and Maintenance Interconnection. The interconnection of safety and maintenance is critical in heavy industrial workplaces

Safety and Maintenance Interconnection Read More »

Planning Maintenance Work with SAP Regardless of what CMMS you might have in front of you, the trick to being

Planning Maintenance Using SAP Read More »

Asset Management Training for Maintenance Planners The Woodhouse Academy Online. The Woodhouse Asset Management Academy is a well-regarded provider of

Asset Management Training for Planners Read More »

Steps for Ensuring CMMS Quality Work Orders Work Order Quality Requirements Once any new work requests have been reviewed and

Ensuring CMMS quality Work Orders Read More »

Important tips for those people thinking about planning a Shutdown Note: This article should be read in conjunction with Maintenance

Thinking About Planning A Shutdown? Read More »

Understanding the true value of early defect detection It is difficult to prevent your assets from becoming defective due to

Early detection & Correction of asset defects Read More »