Supply Chain Optimization ERP Functionality

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »

Supply chain operations encompass the end‑to‑end processes, systems, and controls that enable an organisation to plan, source, store, move, produce, and deliver materials and products.

These operations form the operational backbone of industrial and asset‑intensive businesses, ensuring that materials flow reliably, inventory is accurate, procurement is controlled, and production and maintenance activities receive the resources they need.

Modern supply chain operations are increasingly data‑driven, system‑integrated, and governed by structured frameworks that link ERP, EAM, CMMS, WMS, and logistics platforms.

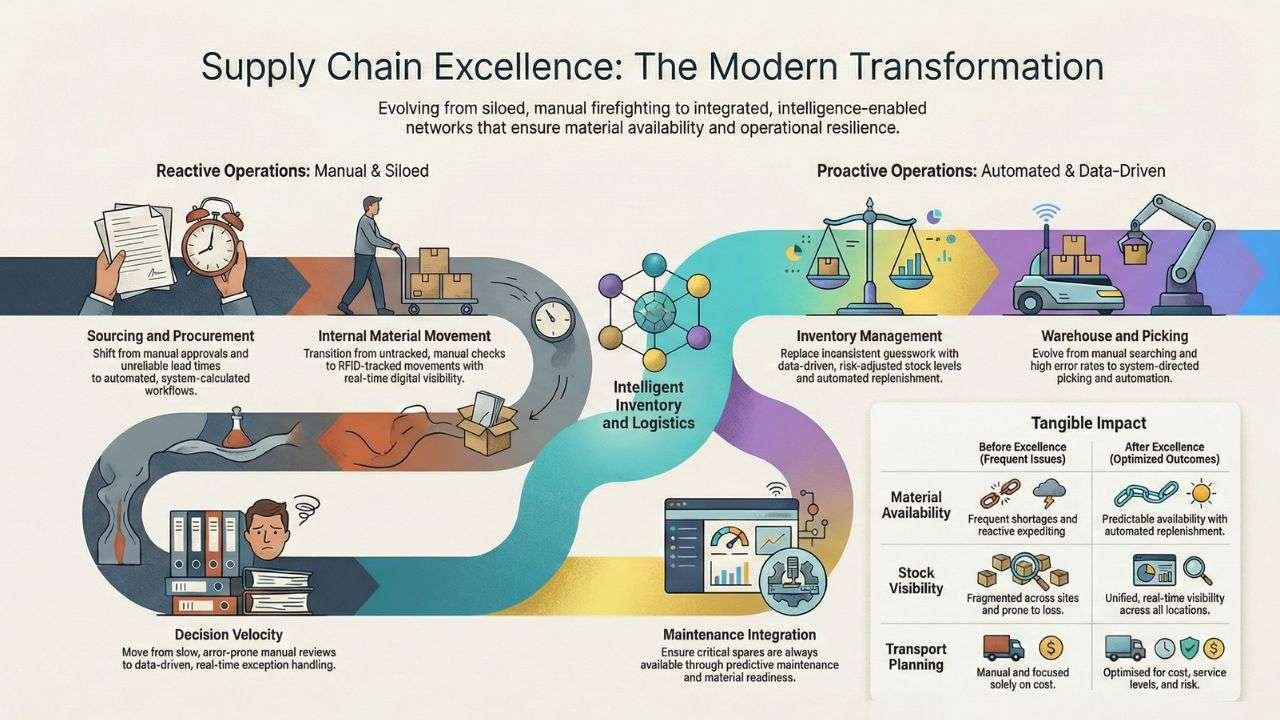

As organisations pursue excellence, supply chain operations evolve from manual, reactive, and siloed processes into coordinated, automated, and intelligence‑enabled networks.

The following sections provide a technical explanation of each component of supply chain operations, along with Before vs After transformation tables that illustrate the operational impact of pursuing excellence.

Supply chain operations ensure that materials, information, and financial transactions move through the organisation in a controlled, predictable, and efficient manner.

They support both revenue‑generating activities (production, distribution) and reliability‑critical activities (maintenance, asset management).

Core objectives include:

| Area | Before Excellence | After Excellence |

| Material Availability | Frequent shortages, reactive expediting | Predictable availability with automated replenishment |

| Working Capital | Excess stock or chronic understocking | Optimised inventory aligned to demand and risk |

| Operational Continuity | High downtime due to missing parts | Maintenance and production supported by reliable supply |

| Decision‑Making | Manual, slow, error‑prone | Data‑driven, real‑time, exception‑based |

Procurement is responsible for sourcing materials, negotiating contracts, and ensuring supplier reliability.

In advanced supply chain operations, procurement is tightly integrated with planning, inventory, and financial systems.

| Area | Before Excellence | After Excellence |

| Supplier Data | Inconsistent, duplicated, outdated | Governed, validated, synchronised across systems |

| Lead Times | Unreliable, manually tracked | System‑calculated, monitored, and continuously updated |

| Purchasing | Manual approvals, paper‑based | Automated workflows with audit trails |

| Supplier Risk | Reactive issue management | Proactive risk scoring and diversification |

Materials management governs the physical and transactional movement of materials within the organisation.

It ensures that materials are received, stored, moved, and issued accurately.

| Area | Before Excellence | After Excellence |

| Receiving | Manual checks, inconsistent documentation | System‑guided receiving with quality gates |

| Internal Movements | Untracked, prone to loss | Barcode/RFID‑tracked with real‑time updates |

| Shelf‑Life Items | Expiry discovered during use | Automated expiry alerts and FEFO enforcement |

| Stock Visibility | Fragmented across sites | Unified, real‑time visibility across all locations |

Inventory management determines how much stock to hold, where to hold it, and when to replenish it.

It directly affects working capital, service levels, and operational continuity.

| Area | Before Excellence | After Excellence |

| Stock Levels | Guesswork, inconsistent | Data‑driven, risk‑adjusted, optimised |

| Accuracy | Frequent discrepancies | High accuracy through cycle counting and automation |

| Replenishment | Manual, reactive | Automated, forecast‑driven |

| Spare Parts | Missing during breakdowns | Critical spares always available with risk‑based stocking |

Warehouse operations manage the physical storage, handling, and retrieval of materials. Excellence in this area requires both process discipline and system integration.

| Area | Before Excellence | After Excellence |

| Picking | Manual searching, high error rate | System‑directed picking with verification |

| Storage | Inefficient use of space | Optimised layouts and automated systems |

| Traceability | Limited or manual | Full traceability with digital records |

| Labour Efficiency | High walking time | Reduced movement through automation |

Production planning aligns demand, capacity, and material availability to create executable schedules.

| Area | Before Excellence | After Excellence |

| Forecasting | Based on historical averages | Predictive, demand‑sensing models |

| Scheduling | Manual spreadsheets | Automated, constraint‑based scheduling |

| Material Readiness | Frequent shortages | Full alignment between MRP and inventory |

| Changeovers | Unplanned, disruptive | Optimised sequencing to reduce downtime |

Bills of materials and SKU data form the structural foundation of supply chain operations. Errors in these areas propagate across planning, costing, and execution.

| Area | Before Excellence | After Excellence |

| BOM Accuracy | Frequent errors, outdated | Controlled, validated, engineering‑aligned |

| SKU Data | Inconsistent attributes | Standardised, governed, and system‑validated |

| Change Control | Informal, undocumented | Workflow‑driven with audit trails |

| Planning Parameters | Arbitrary values | Data‑driven, reviewed, and optimised |

Logistics ensures that materials and products move efficiently between suppliers, internal sites, and customers.

| Area | Before Excellence | After Excellence |

| Transport Planning | Manual, cost‑only | Optimised for cost, service, and risk |

| Tracking | Limited visibility | Real‑time tracking and exception alerts |

| Compliance | Manual documentation | Automated GTM workflows |

| Freight Costs | Unpredictable | Controlled through analytics and optimisation |

In asset‑intensive industries, supply chain operations directly influence maintenance performance.

Integration with CMMS/EAM systems ensures that maintenance plans are supported by material readiness.

| Area | Before Excellence | After Excellence |

| Spare Parts Availability | Frequent delays | Predictable availability aligned to work orders |

| Maintenance Planning | Reactive | Fully supported by material readiness |

| Breakdown Response | Delayed by missing parts | Rapid response with pre‑staged materials |

| Cost Control | High expediting costs | Controlled through proactive planning |

Pursuing excellence in supply chain operations delivers measurable improvements across:

When supply chain operations mature, organisations move from firefighting to foresight, from manual effort to automation, and from siloed processes to integrated, intelligence‑enabled workflows.

How ERP Systems Can Optimise Supply Chain Performance Disclaimer. The thoughts, ideas, views, and interpretations expressed in this article are […]

Supply Chain Optimization ERP Functionality Read More »