SAP Cross Application Time Sheet Solution

SAP Cross Application Time Sheet (CATS). The SAP Cross-Application Time Sheet (CATS) is a vital component of the SAP ERP […]

SAP Cross Application Time Sheet Solution Read More »

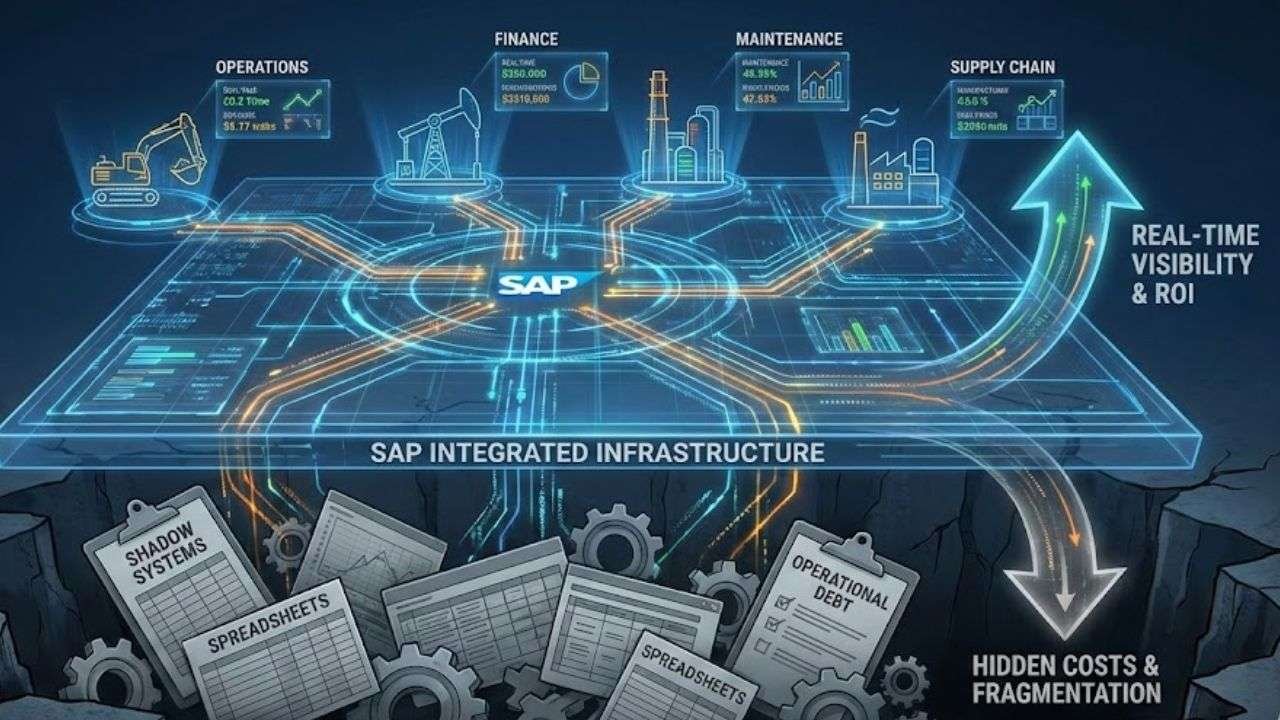

In risk intensive industries that have substantial operating costs such as mining, oil and gas, refining and manufacturing, operational success is defined by precision, reliability and the ability to make informed decisions in real time.

These sectors operate on thin margins, long asset lifecycles and strict regulatory oversight.

In this environment, SAP stands apart not simply as the global leader in enterprise resource planning (ERP) software, but as the only platform capable of unifying the full complexity of industrial operations into a single, coherent system.

What makes SAP indispensable is not any single module, but the integration fabric that binds its components together.

Heavy industry is built on interconnected processes, materials flow into maintenance, maintenance affects production, production drives financials, financials shape planning and planning determines workforce and supply chain readiness.

SAP is designed around this reality. Its modules are not isolated features; they are interdependent parts of a larger operational model that mirrors how industrial businesses actually function.

Integration as the Core Value Proposition.

SAP’s strength lies in its ability to synchronise physical operations with financial accountability.

A maintenance work order is not just a task, it is a cost object, a material movement, a labour allocation and a compliance record.

A production plan is not just a schedule, it is a demand signal for materials, quality checks, logistics and cost forecasting.

A procurement action is not just a purchase, it is a commitment that affects inventory valuation, project budgets and asset lifecycle costs.

When the relevant SAP modules are active, these relationships are automatic. The system becomes a living, real‑time representation of the business.

When modules are missing, the organisation is forced to recreate these connections manually, usually through spreadsheets, bolt‑on tools and departmental workarounds.

This fragmentation erodes the very benefits SAP is designed to deliver.

The Hidden Cost of Partial Implementations.

Many organisations underestimate the long‑term consequences of activating too few SAP modules during initial implementation.

The short‑term savings on licensing and rollout effort often mask the creation of operational debt, a burden of inefficiency that grows over time.

This debt takes many forms:

These issues rarely appear dramatic at first. Instead, they accumulate quietly, creating friction across the organisation.

Over years, the cost of maintaining these workarounds far exceeds the cost of activating the right SAP modules from the start.

The Hidden ROI Trap: When Early SAP Decisions Create Long-Term Constraints.

A recurring pattern across heavy industrial operations is the long‑term impact of early SAP design choices. Many organisations implement SAP with a reduced module footprint, often driven by short‑term cost pressures or the belief that the operation will have a limited lifespan.

Mines expected to run for four years end up operating for twenty. Plants assumed to be temporary become core assets. Yet the ERP foundation remains frozen in the assumptions made on day one.

Technically, this creates a system that is functional but fundamentally incomplete. To compensate for missing modules or disabled functionality, organisations gradually build a patchwork of bolt‑on tools, spreadsheets, custom reports and manual processes.

These workarounds feel inexpensive at first, but they introduce hidden costs:

A common contributing factor is the presence of a “site SAP expert” who has deep knowledge of the local system but limited exposure to SAP’s full capabilities.

When someone has only ever worked with a heavily customised or reduced‑scope SAP environment, they may genuinely believe that certain functions “don’t exist” or “can’t be done in SAP.”

In reality, the functionality has existed for years, but was never activated, configured or understood.

This creates a false narrative:

“We use spreadsheets because SAP can’t do this.”

When the truth is:

“We use spreadsheets because SAP was never implemented to do this.”

From an ROI perspective, the consequences are significant. Organisations eventually reach a point where the limitations of their early SAP decisions begin to constrain growth, compliance, reporting and operational efficiency.

At that stage, the cost of correcting the system, undoing customisations, reconfiguring modules, cleaning data and retraining staff, can approach the cost of a new implementation.

This is the hidden cost of early shortcuts: what looked like savings becomes a long‑term liability.

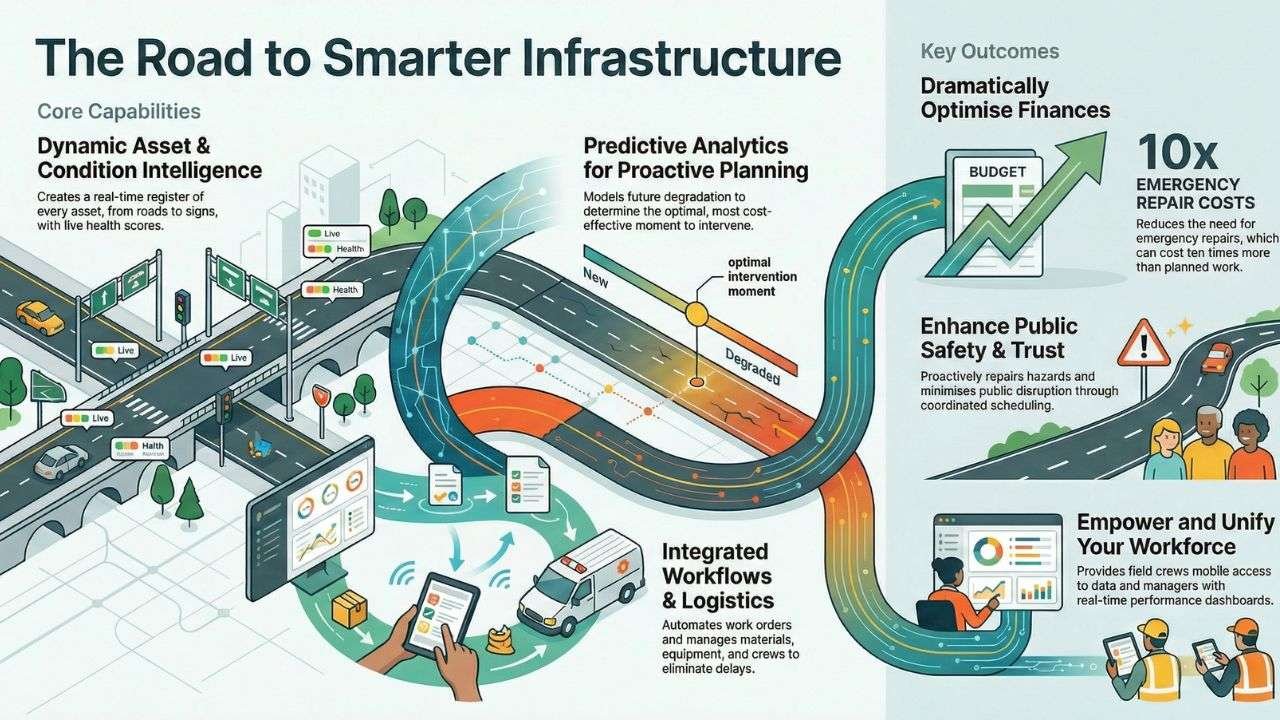

Why a Complete SAP Footprint Pays Dividends.

A broader SAP footprint unlocks capabilities that compound over time. Heavy industrial businesses benefit from:

In industries where downtime costs millions per hour and regulatory breaches carry severe consequences, these advantages translate directly into operational resilience and financial performance.

Training and Rollout Effort: Not a Cost, but Capability Building.

It is true that activating more SAP modules requires more training, more change management and more people using the system to its full potential. It may also require more contractors or internal specialists to support the environment.

But this is not overhead, it is capability development.

In heavy industry, where safety, compliance and asset reliability are non‑negotiable, having a workforce that understands and uses SAP deeply is a competitive advantage.

It creates a culture of discipline, data integrity and cross‑functional alignment. These cultural foundations are just as important as the technology itself.

A Foundation for Growth and Expansion.

Companies that plan to grow, new sites, new assets, new product lines, new regions, benefit enormously from having a complete SAP foundation already in place. With a fully integrated ERP:

Growth becomes a matter of replication, not reinvention.

SAP as Infrastructure, Not Software.

The organisations that extract the most value from SAP share a common mindset: SAP is not a tool, it is infrastructure.

Just like power, water or network connectivity, SAP becomes the backbone that everything else depends on.

When implemented comprehensively from the start, it reduces long‑term integration costs, eliminates patchwork systems, ensures every department operates from the same source of truth and enables the business to scale without losing control.

In heavy industry, where operational excellence is inseparable from financial performance, this philosophy is not just beneficial, it is essential.

SAP Cross Application Time Sheet (CATS). The SAP Cross-Application Time Sheet (CATS) is a vital component of the SAP ERP […]

SAP Cross Application Time Sheet Solution Read More »

Understanding Enterprise Resource Planning Systems. ERP systems are critical for businesses with complex operations, high-value assets, and stringent regulatory requirements.

Enterprise Resource Planning Systems Read More »

Effective Work Scheduling Process & Your CMMS. When it comes to managing a high-risk heavy industrial business, one of the

Maintenance Work Scheduling Read More »

Materials Management Quality Is A Common Concern. Materials management is a critical component of the supply chain that contributes significantly

Materials Management Quality Read More »

Why you need Maintenance Analysis Dashboards. There is no limit to how many measures we can create to look at

Maintenance Analysis Dashboards Read More »

The Power of Quality Master Data Management. I’m sorry for stating the obvious but Asset management is a critical function

Quality Master Data Management Read More »

The Early Years of Computerized Maintenance Management Systems Today, I thought I’d give you some background on Computerised Maintenance Management

Computerized Maintenance Management Systems Read More »

Planning Maintenance Work with SAP Regardless of what CMMS you might have in front of you, the trick to being

Planning Maintenance Using SAP Read More »

Asset Lifecycle techniques to get the most out of your assets. Getting the most from your assets in terms of

Get the most out of your Assets Read More »

Steps for Ensuring CMMS Quality Work Orders Work Order Quality Requirements Once any new work requests have been reviewed and

Ensuring CMMS quality Work Orders Read More »

List of SAP r3 Transactions for Beginners SAP r3 – Useful Adhoc Transactions Transaction Description OIOB Create & Edit PM

List of SAP r3 Transactions Read More »

Important tips for those people thinking about planning a Shutdown Note: This article should be read in conjunction with Maintenance

Thinking About Planning A Shutdown? Read More »

Understanding the true value of early defect detection It is difficult to prevent your assets from becoming defective due to

Early detection & Correction of asset defects Read More »

Scheduled Work Percentage & Other Maintenance Performance Measures. Measure and review your maintenance process’s performance on a regular basis. Use

Analysing Maintenance Performance Read More »

Execute And Complete Maintenance Work Orders. Effective maintenance management is crucial for the smooth operation of any facility. This article outlines

Exectute Maintenance Work Orders Read More »