Auditing Asset Operational Performance

When auditing the operational performance of assets in asset‑intensive environments, several critical focus areas collectively determine how effectively assets support the organisation’s operational and strategic goals.

These areas provide an integrated, evidence‑based view of performance and directly influence productivity, cost control, risk exposure, and long‑term value realisation.

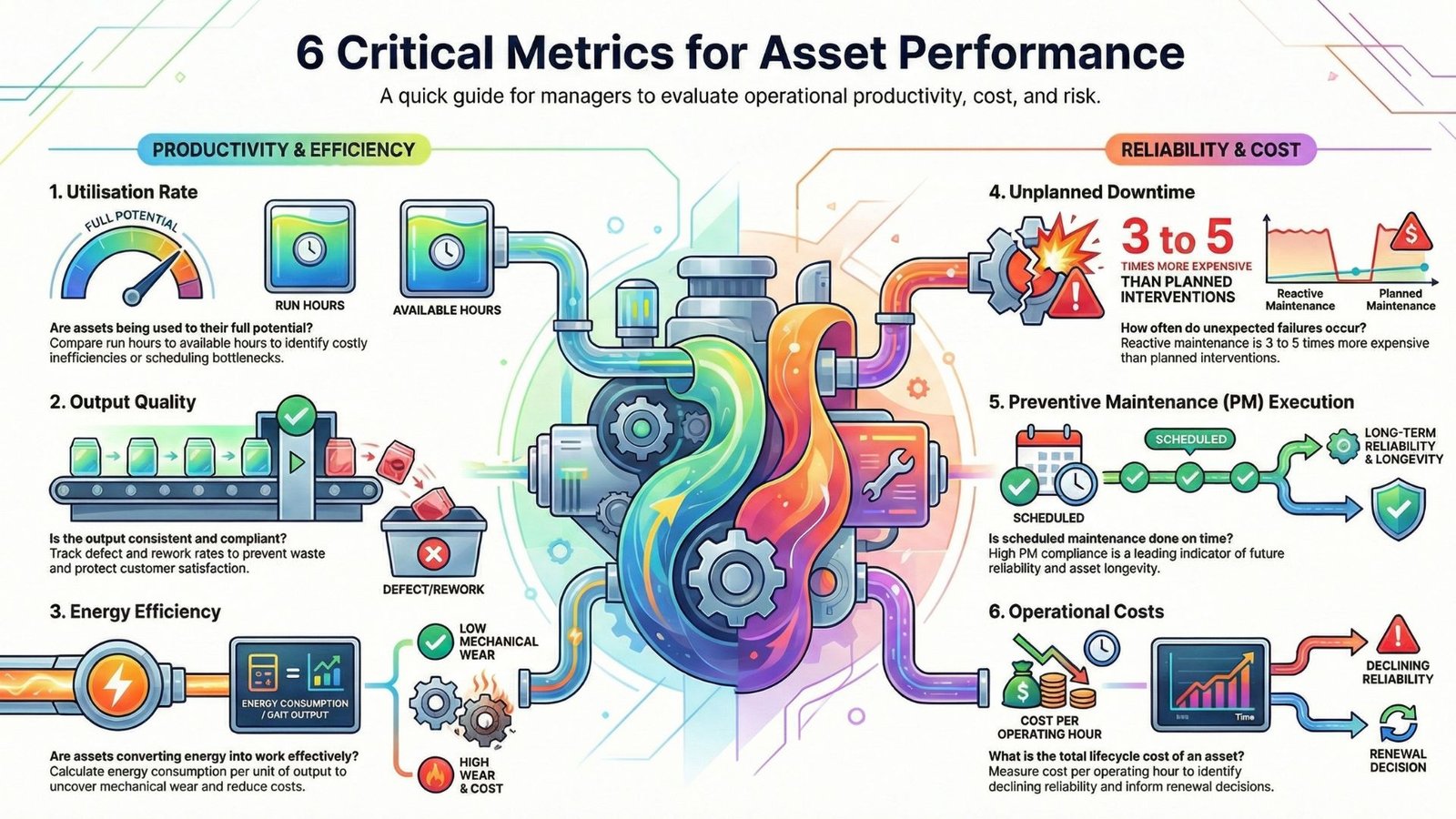

- Utilisation Rate.

Definition: The utilisation rate measures how fully an asset’s available capacity is being used. It is a primary indicator of operational effectiveness.

Why this metric matters

- High utilisation indicates that assets are aligned with production demand and delivering optimal throughput.

- Low utilisation often signals bottlenecks, poor scheduling, over‑capacity, or inefficiencies in resource allocation.

- Chronic under‑utilisation suggests capital tied up in assets not generating adequate return.

How to prove it

- Compare actual run hours to available hours.

- Analyse utilisation trends across shifts, seasons, or production cycles.

- Benchmark utilisation against similar assets or industry standards.

Highlighted concept: Asset utilisation analysis

- Output Quality.

Definition: Output quality measures the consistency, accuracy, and compliance of the products or services generated by an asset.

Why this metric matters

- High output quality confirms that assets operate within design parameters and that process controls are effective.

- Poor output quality often indicates mechanical degradation, calibration drift, operator error, or unstable upstream inputs.

- Quality deviations increase rework, waste, warranty claims, and customer dissatisfaction.

How to prove it

- Track defect rates, rework percentages, and quality‑related stoppages.

- Compare output quality before and after maintenance or calibration interventions.

- Audit calibration and process control records.

Highlighted concept: Production quality performance

- Unplanned Downtime.

Definition: Unplanned downtime captures unexpected periods when assets are unavailable due to failure, malfunction, or operational disruption.

Why this metric matters

- Unplanned downtime directly reduces capacity and increases cost per unit of output.

- Reactive maintenance events are typically three to five times more expensive than planned interventions.

- Elevated unplanned downtime often points to underlying reliability or maintenance‑strategy deficiencies.

How to prove it

- Analyse downtime logs by frequency, duration, and root cause.

- Compare ratios of planned versus unplanned maintenance.

- Quantify production and labour impacts resulting from downtime.

Highlighted concept: Reliability‑centred downtime analysis

- Energy Efficiency.

Definition: Energy efficiency evaluates how effectively an asset converts energy into productive work or output.

Why this metric matters

- Energy‑efficient performance reduces operating costs and supports sustainability objectives.

- Inefficient energy use often reflects mechanical wear, poor lubrication, incorrect control parameters, or outdated equipment.

- Energy intensity is one of the most measurable indicators of asset health.

How to prove it

- Calculate energy consumption per unit of output over time.

- Benchmark energy performance against OEM specifications or peer facilities.

- Analyse abnormal energy spikes to identify mechanical or control issues.

Highlighted concept: Energy performance benchmarking

- Preventive Maintenance Execution.

Definition: Preventive maintenance (PM) encompasses scheduled inspections, servicing, and component replacements that prevent unexpected failures.

Why this metric matters

- Effective PM execution reduces unplanned downtime and extends asset life.

- Poor PM compliance leads to accelerated wear, safety incidents, and higher life‑cycle costs.

- PM quality acts as a leading indicator of future reliability performance.

How to prove it

- Review PM compliance rates (on‑time, overdue, and missed tasks).

- Audit task quality and follow‑up work orders, not just completion status.

- Compare failure frequency before and after PM program improvements.

Highlighted concept: Preventive maintenance optimisation

- Operational Costs.

Definition: Operational cost analysis captures all expenditure associated with the operation, maintenance, and support of an asset across its lifecycle.

Why this metric matters

- Rising operational costs often reflect inefficiency, energy waste, or declining reliability.

- Understanding cost drivers supports informed budgeting, forecasting, and asset renewal decisions.

- Lifecycle cost evaluation helps pinpoint assets approaching economic end‑of‑life.

How to prove it

- Measure cost per operating hour or cost per unit of output.

- Analyse maintenance cost trends over time or across asset classes.

- Identify cost spikes linked to specific failure modes or operating conditions.

Highlighted concept: Asset lifecycle cost analysis

Summary.

Focusing on utilisation, output quality, unplanned downtime, energy efficiency, preventive maintenance, and operational costs delivers a comprehensive and verifiable view of asset performance.

Together, these metrics show not only how well assets perform today but also how reliably and economically they will perform in the future.

Addressing these focus areas enables organisations to maximise asset productivity, minimise risk, and reinforce long‑term operational resilience.