Maintenance Management Functionality

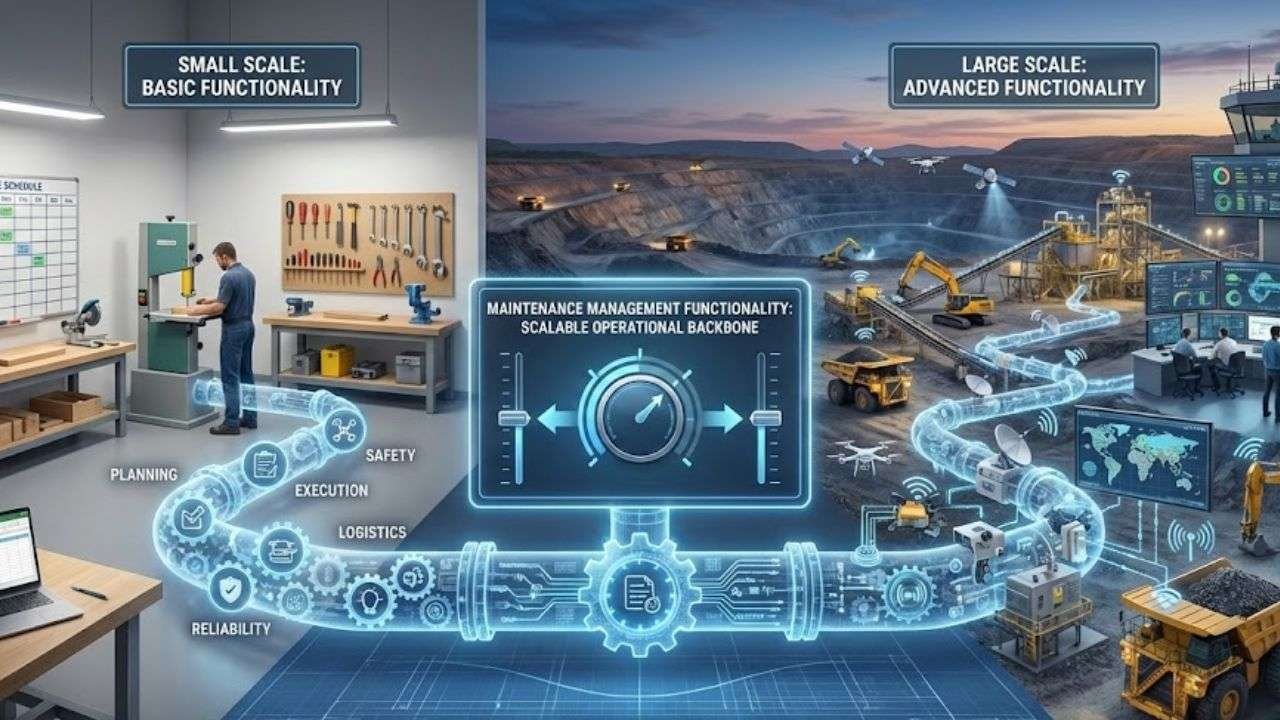

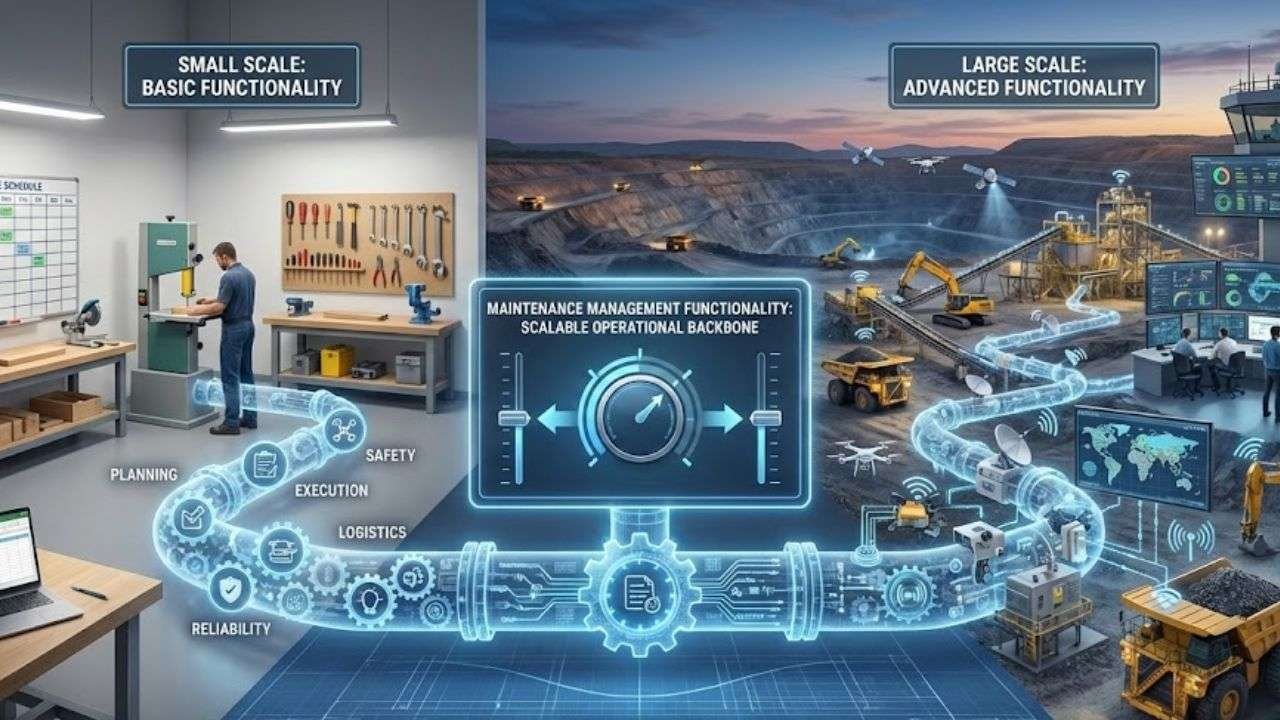

Maintenance Management Functionality refers to the complete set of processes, roles, tools and technologies required to ensure that maintenance activities are delivered in full, on time, at the required quality and in alignment with production, safety and compliance targets.

In other words, it is the operational backbone that enables an organisation to meet its production equation, the balance between output, reliability, safety and cost. At its core, Maintenance Management Functionality is about creating the conditions for equipment and assets to perform as intended.

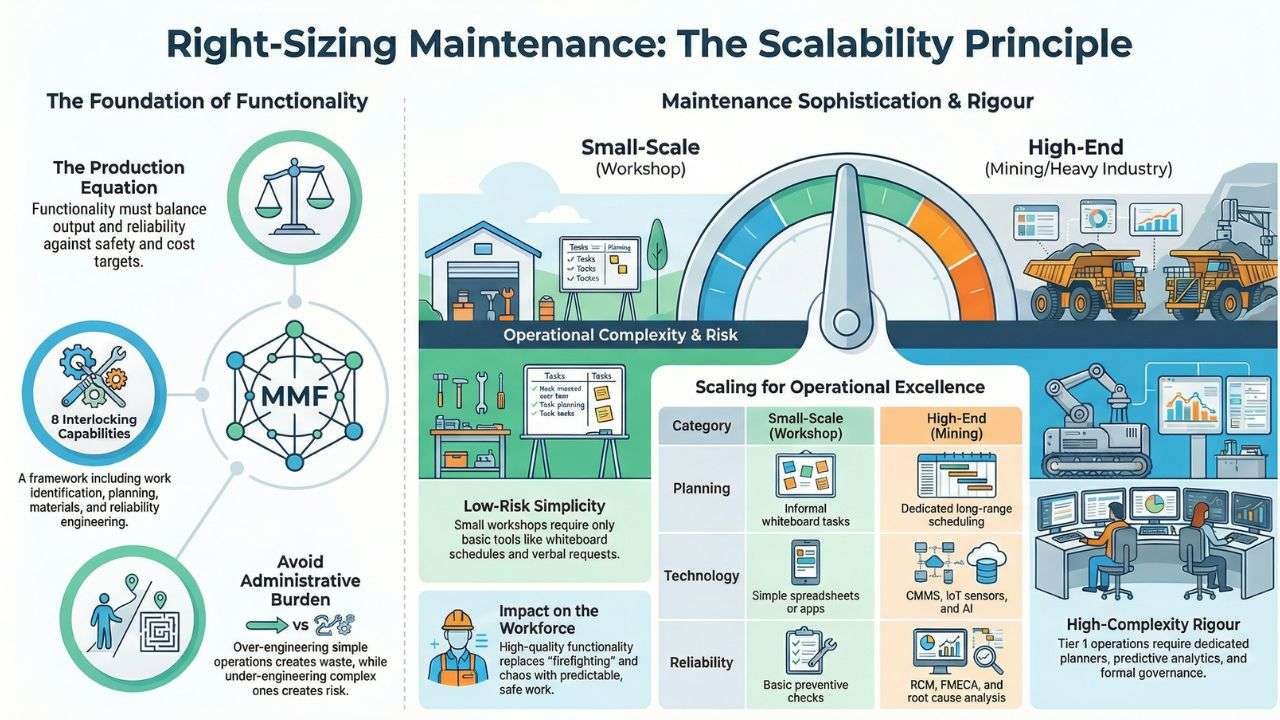

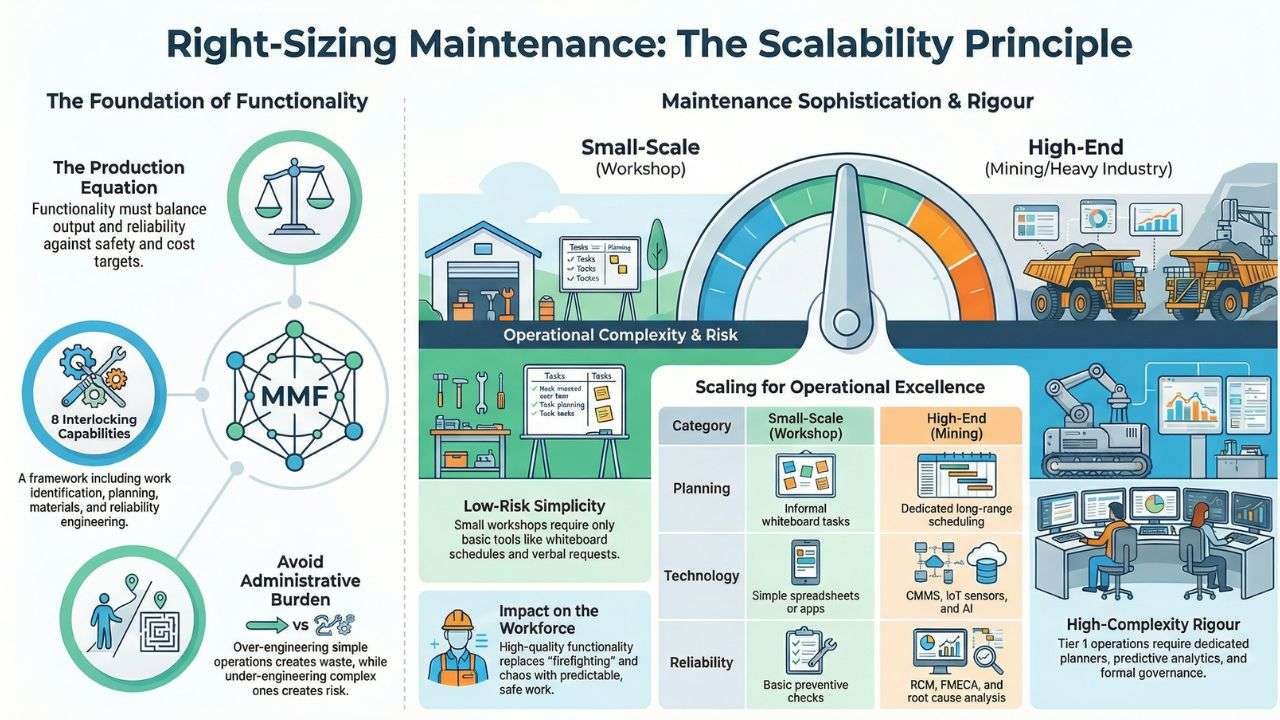

However, the scale and sophistication of that functionality must always match the scale, complexity and risk profile of the operation.

There is no universal template. A small workshop and a tier 1 mining operation both need maintenance management, but the level of functionality required in each environment is vastly different.

This scalability and the discipline to right‑size it, is what determines whether maintenance becomes a strategic enabler or an expensive administrative burden.

What Does Maintenance Management Functionality Actually Encompass?

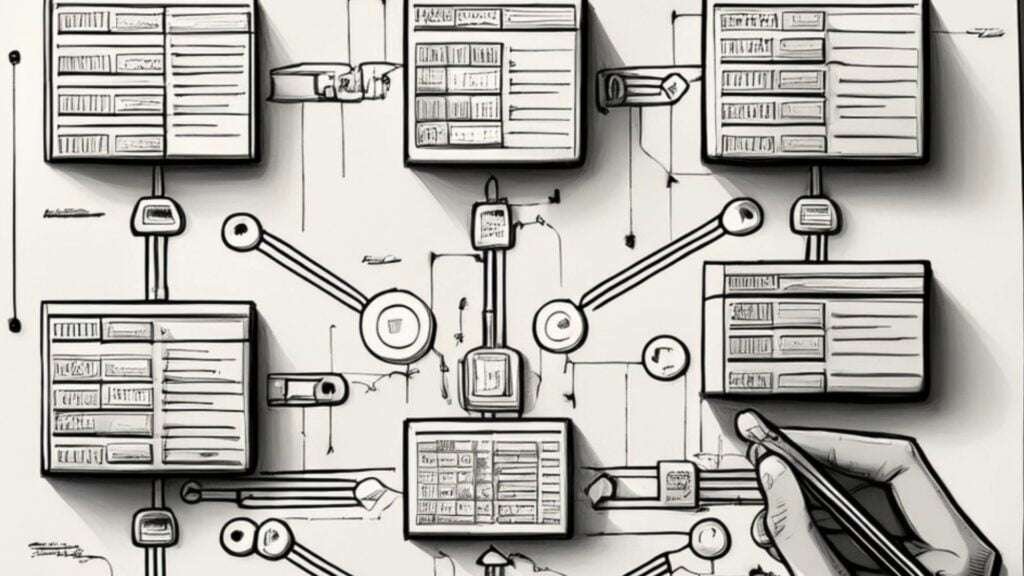

Maintenance Management Functionality is not a single system or department.

It is a framework of interlocking capabilities that together ensure maintenance work is predictable, safe, efficient and aligned with organisational goals.

These capabilities typically include:

- Work identification: spotting defects, capturing work requests and ensuring issues are logged before they escalate.

- Work prioritisation: determining what must be done now, what can wait and what aligns with risk and production priorities.

- Planning and scheduling: defining the scope, materials, labour and sequence of tasks, then locking them into a realistic schedule.

- Execution management: ensuring technicians have the right tools, instructions and access to complete work safely and efficiently.

- Materials and logistics: managing spare parts, procurement, warehousing and lead times.

- Reliability engineering: analysing failures, optimising strategies and improving asset performance.

- Technology and data systems: CMMS platforms, mobile tools, sensors, analytics and reporting dashboards.

- Governance and leadership: supervisors, planners, superintendents and managers who ensure compliance and continuous improvement.

Each of these functions can be simple or sophisticated depending on the organisation’s needs.

The important point is that they must exist in some form and they must work together.

Is Maintenance Management Functionality Scalability The Central Principle?

Yes it is, the amount of Maintenance Management Functionality required is entirely dependent on the production equation.

As production scale, asset complexity and risk increase, so too must the capability of the maintenance function.

A small family‑owned mechanic shop may only need:

- A whiteboard schedule for weekly work.

- A basic toolset.

- One or two technicians who plan and execute work on the fly.

This is appropriate because the risk is low, the asset base is small and the consequences of downtime are manageable.

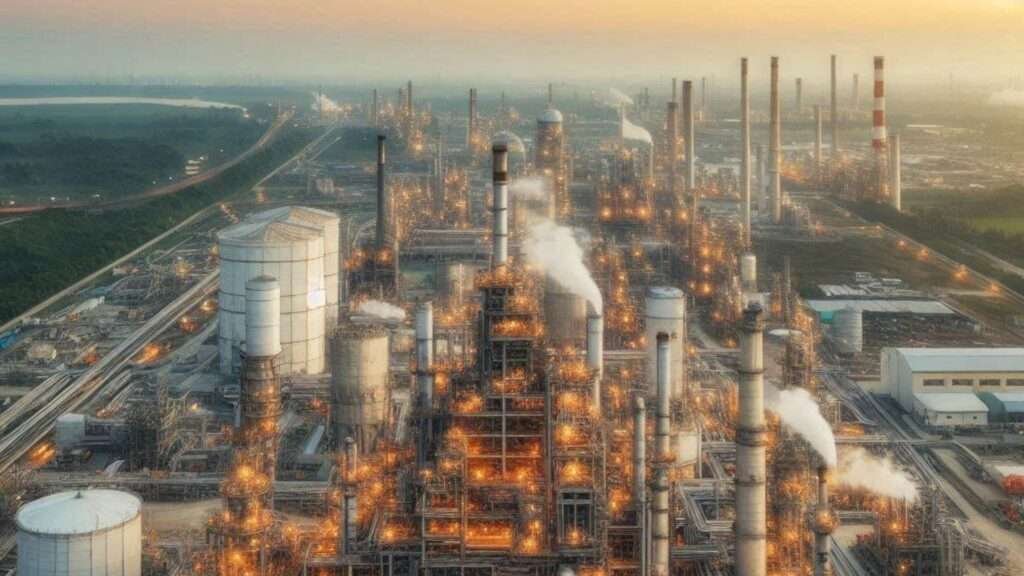

Contrast this with a large mining operation, where the production equation is far more demanding and in this situation, Maintenance Management Functionality may include:

- Hundreds of employees across multiple crews.

- 24/7 shift coverage.

- Dedicated planners and schedulers.

- Reliability engineers focused on failure analysis and optimisation.

- A full materials management team.

- Advanced CMMS and predictive analytics.

- Formal governance structures with supervisors, superintendents and a maintenance manager.

In such environments, equipment downtime can cost millions per hour, safety risks are significant and compliance obligations are strict.

The maintenance function must therefore be robust, disciplined and technologically supported.

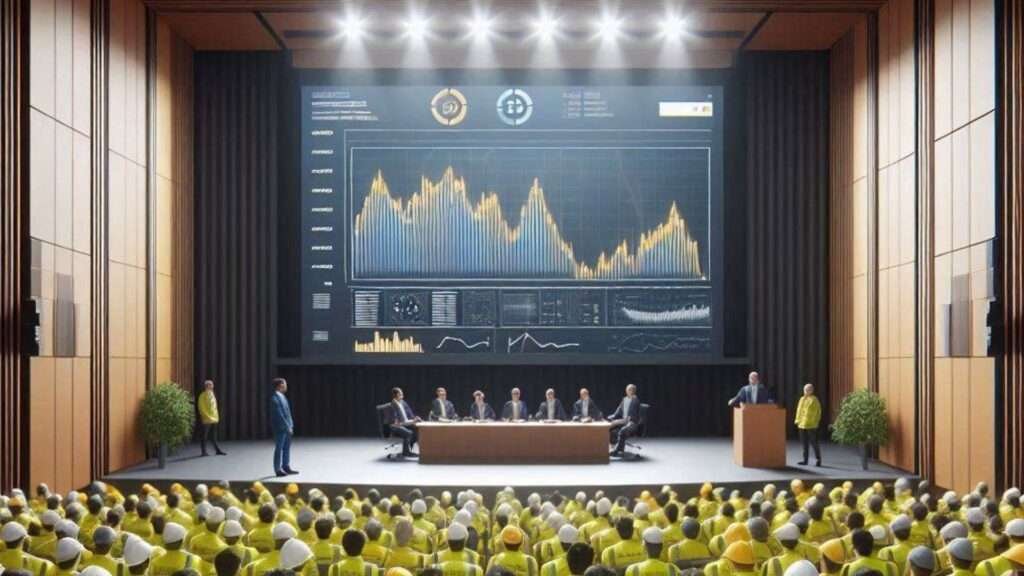

What Does All This Mean to the People in a Maintenance Department?

For the people who work in maintenance, technicians, planners, supervisors, reliability engineers, Maintenance Management Functionality is not an abstract concept. It directly shapes their daily experience.

For technicians – High‑quality functionality means:

- Clear job plans with accurate instructions.

- Parts available when needed.

- Safe access to equipment.

- Less firefighting and more predictable work.

Poor functionality means frustration, delays, rework and unnecessary risk.

For planners and schedulers it provides:

- Reliable data to plan work.

- Stable workflows.

- Clear priorities from operations and leadership.

Without it, planning becomes guesswork.

For supervisors and managers it enables:

- Visibility of performance.

- Control over backlog and risk.

- Confidence in meeting production targets.

Without it, they operate reactively, constantly responding to crises.

For reliability engineers it provides:

- Quality failure data.

- Structured processes for analysis.

- A stable environment where improvements can take hold.

Without it, reliability work becomes theoretical rather than impactful.

In short, Maintenance Management Functionality determines whether people can do their jobs effectively, or whether they spend their days battling avoidable chaos.

How is Maintenance Management Functionality Utilised?

Organisations use Maintenance Management Functionality to:

- Identify and control risk through structured maintenance strategies.

- Plan and execute work efficiently.

- Optimise asset performance through reliability engineering.

- Ensure compliance with safety, environmental and regulatory requirements.

- Support production targets by reducing downtime and increasing predictability.

- Manage cost by balancing labour, materials and asset life.

The functionality becomes the operating system of the maintenance department. It defines how work flows, how decisions are made and how performance is measured.

What Difference Could High‑Quality Functionality Make?

When Maintenance Management Functionality is well‑designed and right‑sized, the impact is profound and organisations experience:

- Higher equipment availability because failures are prevented or resolved quickly.

- Improved safety outcomes due to structured processes and reduced reactive work.

- Lower maintenance costs through efficient planning and reduced waste.

- Better workforce morale because people have the tools and clarity they need.

- Greater production stability, enabling predictable output and reduced variability.

- Stronger compliance with regulatory and internal standards.

Conversely, poor functionality leads to:

- Chronic breakdowns.

- High overtime and contractor spend.

- Safety incidents.

- Unplanned downtime.

- Low morale and high turnover.

- A culture of firefighting.

The difference between these two states is rarely the skill of the workforce. It is the quality of the system they operate within.

How Do You Determine The Right Level Of Functionality?

Right‑sizing Maintenance Management Functionality requires structured analysis and common methodologies include:

- Reliability‑Centered Maintenance (RCM) to define what maintenance is required for each asset.

- Total Productive Maintenance (TPM) to build operator ownership and reduce losses.

- Failure Modes, Effects & Criticality Analysis (FMECA) to understand risk and prioritise effort.

- Resource allocation analysis to determine staffing and skill requirements.

- Technology assessments to identify the right digital tools.

These methods ensure that functionality is built deliberately, not through guesswork or legacy habits.

What Is The Bottom Line?

Maintenance Management Functionality is the engine room of asset‑intensive operations.

When it is scaled correctly, it enables safe, reliable and cost‑effective production.

When it is under‑developed or over‑engineered, it becomes a source of risk, waste and frustration.

The goal is simple: build only the functionality required to meet the production equation, no more, no less. The organisations that master this principle are the ones that would likely achieve operational excellence, year after year.

Comparative Tables for Maintenance Management Functionality.

- 1. High‑End Operational & Maintenance Excellence (Large Mining Operation)

The below table illustrates the breadth and depth of functionality required when an organisation is pursuing world‑class reliability, safety, and production performance.

| Category |

Description |

| Work Identification |

Formal defect elimination programs, operator inspections, condition monitoring, automated alerts |

| Work Prioritisation |

Risk‑based frameworks, criticality models, structured approval workflows |

| Planning & Scheduling |

Dedicated planners, long‑range scheduling, shutdown planning, digital work packs |

| Execution Resources |

Large multi‑trade crews, 24/7 coverage, specialised tooling, mobile technology |

| Materials Management |

Warehouse teams, procurement systems, vendor contracts, critical spares strategy |

| Reliability Engineering |

RCM, FMECA, root cause analysis, predictive analytics, asset strategy optimisation |

| Technology Stack |

CMMS/EAM, IoT sensors, dashboards, mobile apps, integrated planning systems |

| Governance & Leadership |

Supervisors, superintendents, maintenance manager, KPIs, compliance audits |

| Safety & Compliance |

Permits, isolations, risk assessments, regulatory reporting, training systems |

| Continuous Improvement |

Lean programs, defect elimination, performance reviews, cross‑functional teams |

- Small‑Scale Maintenance Functionality (6‑Person Woodworking Business)

This table shows the minimal, right‑sized functionality needed for a small workshop where risk, asset complexity, and production pressure are low.

| Category |

Description |

| Work Identification |

Verbal requests, simple visual checks, basic defect notes |

| Work Prioritisation |

Common‑sense urgency decisions, owner oversight |

| Planning & Scheduling |

Whiteboard schedule, weekly task list, informal planning |

| Execution Resources |

General‑purpose tools, shared responsibilities, basic PPE |

| Materials Management |

Small parts cabinet, local suppliers, simple reorder habits |

| Reliability Engineering |

None required beyond basic preventative checks |

| Technology Stack |

Spreadsheets or a simple CMMS app if desired |

| Governance & Leadership |

Owner/manager oversight, toolbox chats |

| Safety & Compliance |

Basic safety procedures, equipment manuals, PPE compliance |

| Continuous Improvement |

Occasional process tweaks, informal discussions |

These tables make the contrast unmistakable: one environment requires a full ecosystem of roles, systems, and governance; the other needs only the essentials to stay safe, productive and organised.