The Maintenance Planning Skill Set

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

In every heavy industrial environment, from manufacturing plants to power stations, from mining operations to chemical processing facilities, the ability to identify and correct issues early is one of the most powerful forms of protection an organisation can have.

Defects rarely stay small. A minor leak becomes a major rupture, a faint vibration becomes a catastrophic failure and a slight temperature rise becomes a fire risk.

The organisations that excel in safety, reliability and cost control are the ones that treat early defect detection as a shared responsibility, not just a maintenance task, but a whole‑site discipline.

At the heart of this approach is a simple truth: the sooner an issue is identified, the easier, safer and cheaper it is to correct.

Early detection prevents escalation, protects people and preserves assets.

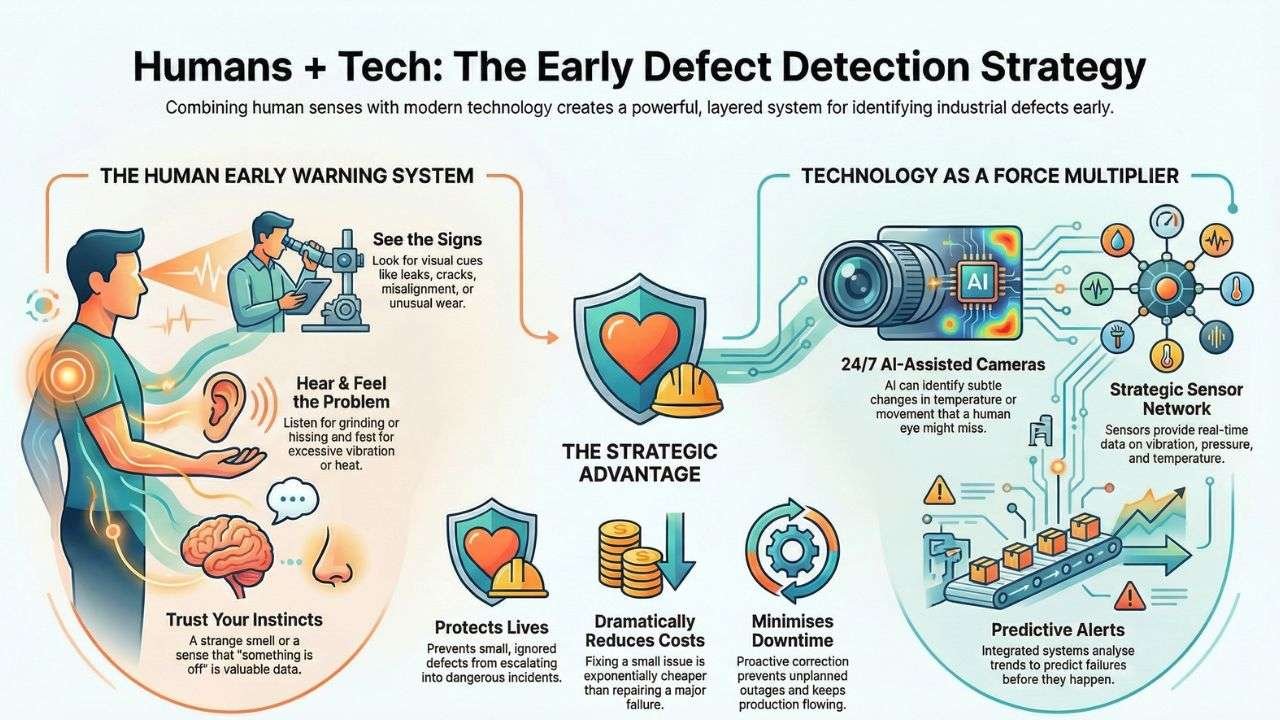

To achieve this, organisations must harness two powerful forces working together, the five human senses and modern monitoring technology and they must also recognise the value of something less tangible but equally vital: operator intuition.

Everyone on Site: Five Senses on High Alert.

Human perception remains one of the most effective defect‑detection tools ever created. When people are trained to stay alert and empowered to speak up, they become a living, breathing early‑warning system.

Even intuition, the sense that something is “off”, matters. Experienced operators develop a deep familiarity with “normal” equipment behaviour.

They integrate multisensory cues, pattern recognition and contextual understanding in ways that instruments cannot. This gut‑level awareness often flags issues long before alarms trigger.

This is not guesswork. It is the rapid connection of environmental clues to stored knowledge, a form of expertise that emerges only through years of exposure.

In drilling operations, for example, operators often detect ambiguous risks that instruments cannot interpret.

When organisations encourage people to trust their instincts, they gain a powerful safety advantage.

Technology As A Force Multiplier: Sensors, AI & Continuous Monitoring.

While human senses and intuition are powerful, they cannot be everywhere at once. Modern technology fills that gap, providing continuous, precise and data‑driven monitoring that enhances early detection.

The combination of human awareness and technological intelligence is where true excellence emerges.

People catch what machines miss; machines catch what people cannot see. Together, they create a layered, resilient detection system that dramatically reduces risk.

Why This Applies Across All Heavy Industries.

Whether the environment is a refinery, a mine, a power station, or a manufacturing line, the fundamentals are the same: complex machinery, high‑risk processes and the need for both human oversight and technological support.

Operators in these environments develop an intimate familiarity with equipment behaviour. They know how a pump should sound, how a turbine should feel, how a gearbox should smell when running normally.

This deep, embodied knowledge allows them to detect deviations that instruments may not register until the problem worsens.

This universal applicability is why early detection is not just a maintenance principle, it is a cross‑industry safety philosophy.

The Organisational Advantage: Culture, Cost and Resilience.

Empowering people to act on their instincts and report abnormalities fosters a proactive safety culture. It reduces reliance on reactive measures and strengthens organisational resilience.

The benefits are significant:

Training programs that build this “storehouse of knowledge” and encourage people to trust it, turn individual intuition into collective safety strength.

Conclusion.

Identifying and correcting issues early is the foundation of safe, reliable and cost‑effective operations.

When every person on site keeps their senses alert, when intuition is respected and when technology provides continuous monitoring and predictive insight, defects are caught before they grow, risks are controlled before they escalate and assets are protected before they fail.

This is the future of maintenance: a partnership between human awareness, human intuition and intelligent technology, working together to create safer workplaces, stronger assets and more resilient organisations.

Explaining The Maintenance Planning Skill Set Disclaimer. This article is an independent professional analysis based on practical experience and conceptual […]

The Maintenance Planning Skill Set Read More »

Examining What Good Maintenance Planning Looks Like. Disclaimer. This article provides general information about maintenance planning principles and practices. It

Develop A Full Understanding Of Maintenance Planning Read More »

Maintenance Business Process For A Gold Mine. Disclaimer. This article draws on general gold mining industry knowledge, common CMMS principles

Setting Up A Maintenance Business Process For A New Gold Mine Read More »

Build Audit Systems That Reveal Truth and Improve Performance Disclaimer. This article provides general guidance, frameworks, and examples to support

Building Your Maintenance Audit Framework Read More »

The Essential Basics of Equipment Maintenance: Clean, Inspect, Measure & Adjust. Equipment maintenance is a critical aspect of ensuring the

Essential Basics Of Equipment Maintenance Read More »

The Interconnection of The Six Big Losses, OEE, TPM, RCM & Pareto Analysis. With this article I’ll be explaining the

The Six Big Losses-OEE-TPM-RCM Read More »

Understanding Asset Management Metrics for Business Success. Asset management metrics are critical tools that help businesses measure, quantify, and optimize

Understanding Asset Management Metrics Read More »

Get In Control Of Your Assets Using BADA, Taproot & Software. Getting in control of your Assets allows you to

Get In Control Of Your Assets Read More »

Defect Elimination Management And Bad Actor Analysis. Effective Defect Elimination Management is critical for maintaining asset integrity, optimising performance, and

Defect Elimination Management Read More »

What Is A Maintenance Shutdown Event? Maintenance shutdown events are critical events when industrial facilities plan to temporarily halt operations

What Is A Maintenance Shutdown Read More »

Key Aspects Of Asset Operational Performance Audits. In asset-intensive industrial companies, efficient, safe, and cost-effective asset utilisation is critical to

Asset Operational Performance Audits Read More »

What Exactly Is The Role Of A Maintenance Planner? A maintenance planner is essential to the seamless operation of any

What is a Maintenance Planner Read More »

Planning Maintenance Work with SAP Regardless of what CMMS you might have in front of you, the trick to being

Planning Maintenance Using SAP Read More »

Your Boss needs practical solutions not emotional problems. Identify the problem objectively, describe the impact, and propose a solution. No

Your Boss Needs Solutions Not Problems Read More »

Understanding the true value of early defect detection It is difficult to prevent your assets from becoming defective due to

Early detection & Correction of asset defects Read More »

Broken Window Theory And CMMS Master Data Disclaimer. This article is provided for educational and professional development purposes. It draws

Improving Your CMMS Using the Broken Window Theory Read More »