How to improve HME Safety

Heavy Mobile Equipment (HME) operations carry inherent risks and the complexity of modern fleets means that safety can never rely on memory, habit, or isolated processes.

The most reliable way to strengthen safety performance is to build a system that makes safe behaviour unavoidable, a system that embeds compliance, visibility and accountability into every maintenance and operational decision.

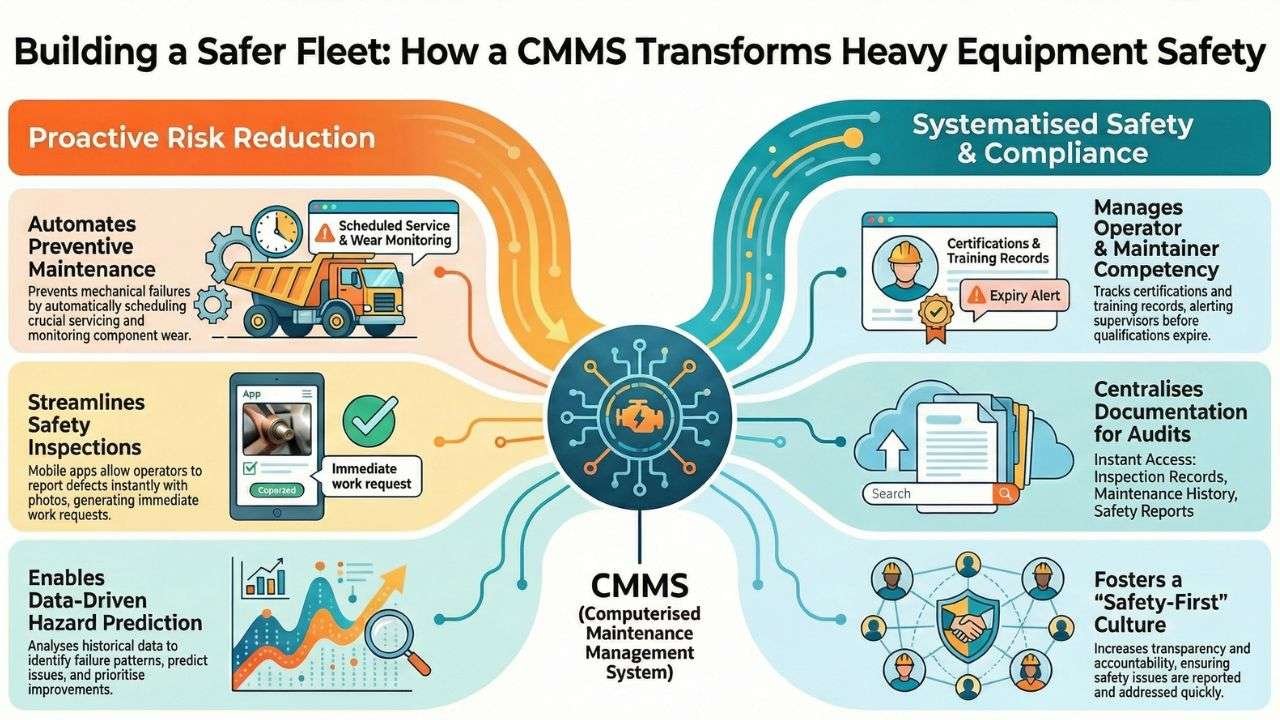

A well‑implemented Computerised Maintenance Management System (CMMS) is one of the most powerful tools for achieving this.

A CMMS enhances HME safety by transforming scattered information into a unified safety ecosystem.

It ensures that inspections, maintenance, training and operational controls are not only completed, but also recorded, monitored and continuously improved. When managed well, a CMMS becomes the backbone of a safety‑first culture.

- Strengthening Preventive Maintenance and Hazard Control.

Many HME incidents stem from preventable mechanical failures. A CMMS directly reduces this risk by automating and enforcing preventive maintenance.

Prearranged reminders ensure that critical tasks are never missed, while real‑time tracking of equipment hours and usage helps maintenance teams service machines at the right intervals.

Monitoring wear and tear on essential components allows teams to identify hazards before they escalate into failures.

Telematics integration takes this even further by providing continuous, real‑time insight into equipment health.

Abnormal temperatures, pressures, vibrations, or fluid levels can trigger immediate alerts, enabling rapid intervention. Monitoring fuel and fluid usage also helps detect leaks or inefficiencies that may indicate deeper safety issues.

- Improving Inspection Quality and Compliance.

Safety inspections are only as effective as the system that supports them. A CMMS ensures inspections are completed consistently, documented thoroughly and reviewed systematically.

Customisable inspection forms allow teams to tailor checklists to specific HME types, ensuring that no critical component is overlooked.

Mobile Pre‑Start Inspections streamline the process even further. Operators can complete inspections on a mobile app, attach photos or videos of defects and automatically generate work requests for any issues found.

This eliminates delays, reduces paperwork and ensures defects are addressed promptly.

The CMMS also records the full history of inspections, enabling supervisors to identify recurring issues, track compliance and verify that corrective actions have been completed.

- Enhancing Operator and Maintainer Competency.

Human performance is a major factor in HME safety. A CMMS helps manage this by tracking operator certifications, training records and competency requirements.

It can alert supervisors when licences or safety‑critical skills are approaching expiry, ensuring no one operates or maintains equipment without the proper qualifications.

For maintainers, the CMMS can track HME‑specific skills, safety training and refresher requirements. Some systems even allow booking of training courses directly through the platform, reducing administrative burden and improving compliance.

- Ensuring Documentation, Traceability and Regulatory Readiness.

Safety depends on accurate, accessible information. A CMMS centralises all safety‑related documentation, including:

- Manufacturer safety bulletins.

- Recall notices.

- Equipment‑specific safety procedures.

- Maintenance histories.

- Incident and near‑miss reports.

- Upgrade and modification records.

This ensures that everyone, operators, maintainers, supervisors and auditors, has access to the information they need.

The system also provides alerts for upcoming regulatory audits and stores the evidence required to demonstrate compliance.

During an audit, a CMMS can instantly produce records of safety inspections, maintenance of critical components, operator training status and incident investigations.

This not only improves audit outcomes but also builds trust in the organisation’s safety culture.

- Supporting Data‑Driven Decision Making.

One of the greatest strengths of a CMMS is its ability to turn raw data into actionable insight.

Analysing historical maintenance and inspection data helps predict future failures, identify systemic weaknesses and prioritise improvements.

Safety performance reports highlight trends, recurring hazards and areas where additional controls may be needed.

Integrating weather data adds another layer of risk management, helping teams plan operations around environmental conditions that may affect visibility, traction, or equipment stability.

- Creating a Culture of Safety‑First Operations.

Ultimately, improving HME safety is not just about technology, it’s about behaviour. A CMMS reinforces safe behaviour by making it easier to do the right thing and harder to overlook critical steps.

It provides transparency, accountability and structure. Operators can record comments and issues directly into the system, giving them a voice in the safety process. Supervisors can track response times to safety‑critical repairs, ensuring that hazards are addressed quickly.

When used effectively, a CMMS provides an unbiased, data‑driven picture of safety performance.

It highlights strengths, exposes gaps and supports continuous improvement. Most importantly, it helps build a culture where safety is not an aspiration but a daily operational reality.