Develop Maintenance Strategies

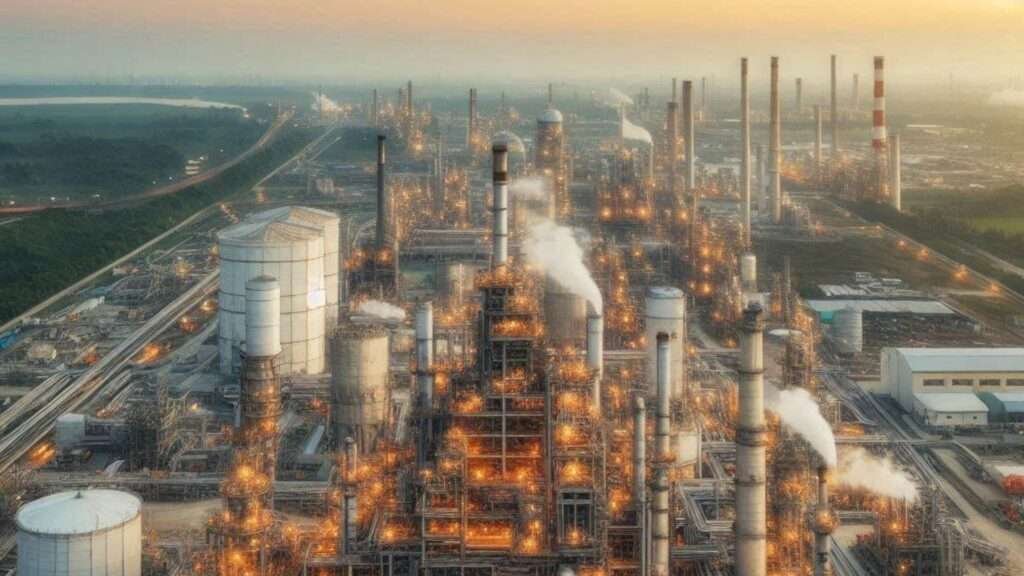

Developing and sustaining quality maintenance strategies is one of the most important activities in any asset‑intensive organisation, especially those operating risk‑laden processes and equipment such as petroleum refineries, natural gas processing plants, acid plants, H₂S‑handling facilities, power stations, minerals processing plants, smelters and steel manufacturing operations.

These environments rely on complex, high‑energy systems where equipment failure can lead to significant safety incidents, environmental harm, production losses, or catastrophic asset damage.

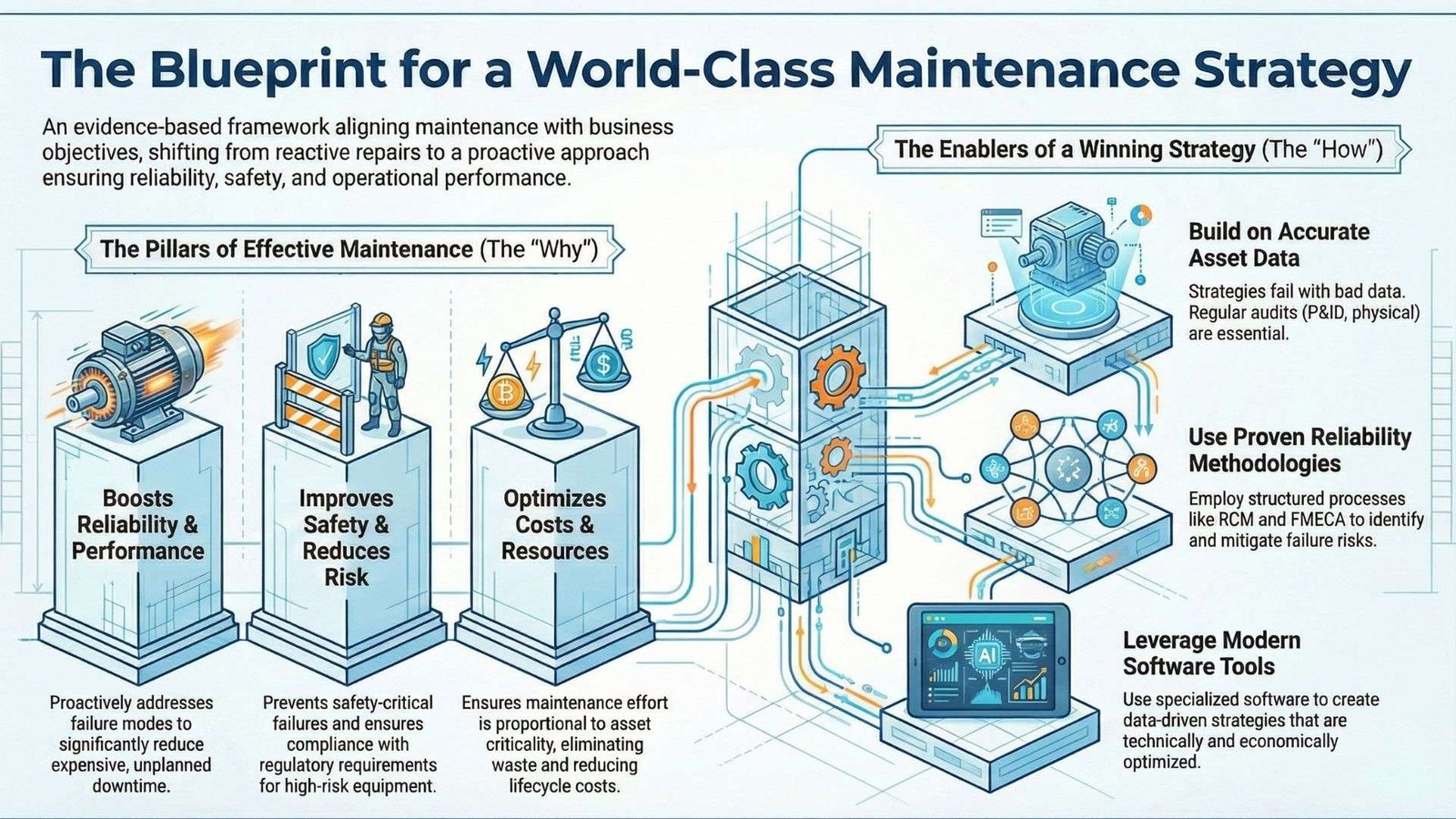

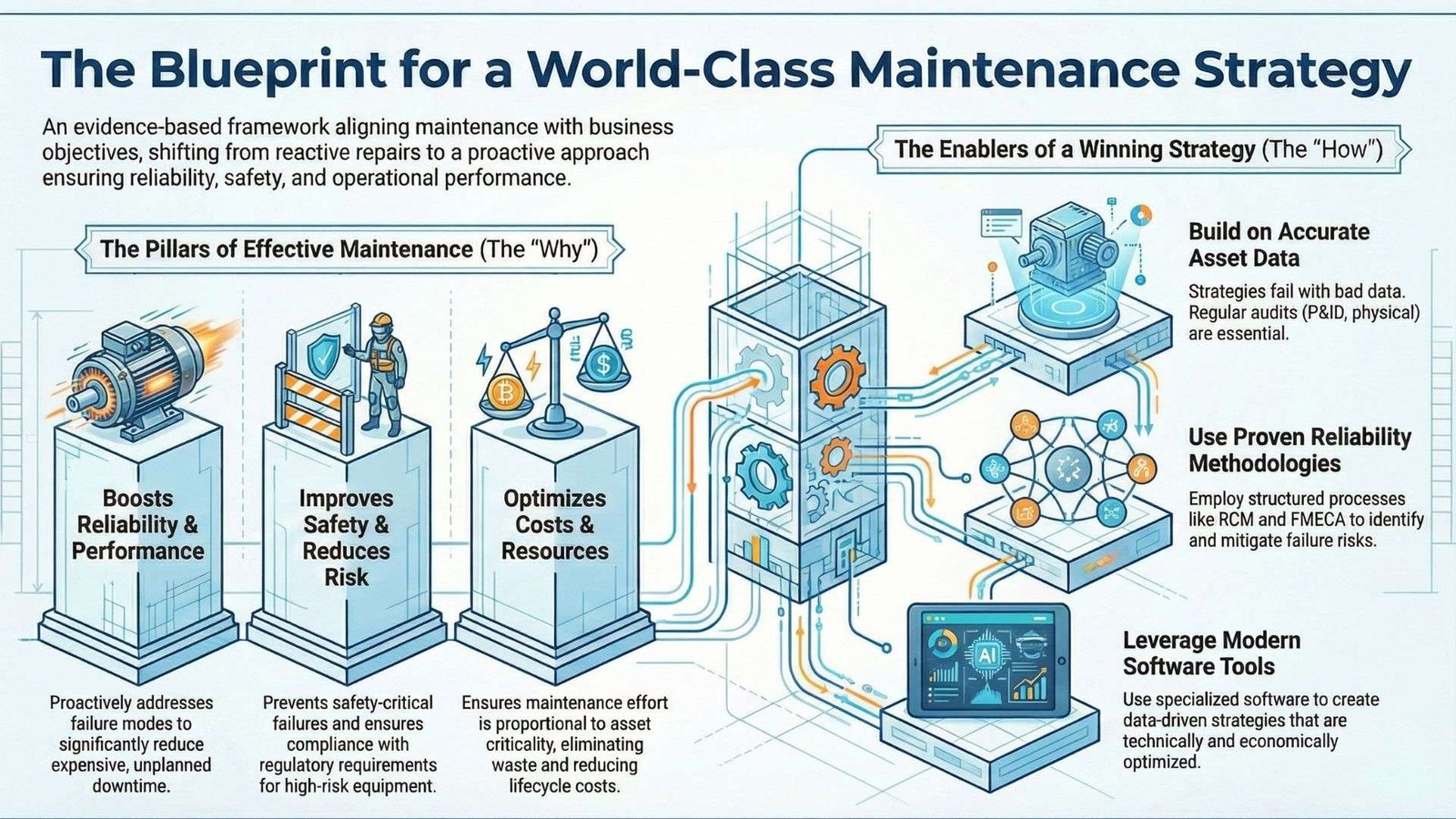

Effective maintenance strategies form the backbone of safe, reliable and cost‑effective operations, ensuring that maintenance effort is targeted, justified and aligned with real‑world asset behaviour.

A maintenance strategy defines the structured approach used to preserve asset reliability, safety and performance throughout the asset lifecycle.

Without a well‑designed strategy, maintenance becomes reactive, inconsistent and vulnerable to failure and the consequences are felt across productivity, cost, safety and operational risk.

A maintenance strategy is not simply a list of tasks. It is a disciplined, evidence‑based framework that aligns maintenance activities with the organisation’s operational, economic and safety objectives.

It ensures that maintenance is performed at the right time, in the right way and for the right reasons, supporting a consistent and defensible approach to asset care.

- Ensuring Reliability, Availability and Performance.

The primary purpose of developing maintenance strategies is to ensure that assets operate reliably and consistently under expected conditions.

Why this is true.

- Every asset has predictable failure modes, wear mechanisms and operational stresses.

- Without a strategy, maintenance teams cannot proactively address these risks.

- Unplanned failures are significantly more expensive and disruptive than planned interventions.

Preventive maintenance is central to this. It is essential for ensuring the dependability, availability and operational quality of any system or piece of equipment.

By anticipating and addressing potential problems before they escalate, organisations reduce downtime and improve performance.

How to prove it.

- Compare unplanned downtime before and after implementing structured strategies.

- Analyse failure recurrence rates after preventive tasks are introduced.

- Track improvements in asset availability and MTBF.

Highlighted concept: reliability‑driven maintenance planning.

- Improving Safety And Reducing Operational Risk.

Maintenance strategies directly influence workplace safety and regulatory compliance.

Why this is true.

- Many safety‑critical failures such as electrical faults, pressure system failures, or mechanical breakdowns are preventable through structured maintenance.

- Regulatory frameworks often require documented maintenance strategies for high‑risk equipment.

- A strategy ensures that inspections, calibrations and safety checks occur at the correct intervals.

How to prove it.

- Review incident logs for failures linked to inadequate maintenance.

- Audit compliance with statutory inspection requirements.

- Track reductions in safety‑related downtime after strategy improvements.

Highlighted concept: risk‑based maintenance controls.

- Using Proven Reliability Methodologies.

Determining maintenance requirements is not guesswork, it is a structured engineering process.

Established methodologies such as Failure Mode, Effects and Criticality Analysis (FMECA) and Reliability‑Centred Maintenance (RCM) have been demonstrated to be highly effective at identifying maintenance needs.

Why this is true.

- FMECA identifies how assets fail, why they fail and the consequences of those failures.

- RCM determines the most appropriate maintenance tasks to prevent or mitigate those failures.

- These methodologies ensure that maintenance effort is targeted, justified and aligned with risk.

How to prove it.

- Compare maintenance task lists before and after RCM/FMECA analysis.

- Track reductions in failure modes addressed by new tasks.

- Audit the alignment between maintenance tasks and asset criticality.

Highlighted concept: reliability engineering methodologies.

- Leveraging Modern Maintenance Strategy Software.

Purpose‑built software tools such as OnPlan, OnePM and Strategy Optimizer provide structured, data‑driven environments for developing maintenance strategies.

Why this is true.

These tools allow organisations to incorporate:

- Equipment ageing.

- Repair timeframes.

- Spare‑part costs.

- Maintenance crew expenses.

- Redundancy and system configuration.

- Safety and environmental considerations.

This ensures that maintenance strategies are not only technically sound but also economically and operationally optimised.

How to prove it.

- Compare strategy development time with and without software support.

- Track improvements in cost forecasting accuracy.

- Audit the completeness and consistency of maintenance plans produced using these tools.

Highlighted concept: maintenance strategy optimisation software.

- Ensuring Asset Master Data Accuracy Through P&ID Audits and Physical Equipment Identification Audits.

Even the best maintenance strategy methodologies and software tools cannot produce accurate results if the underlying asset master data is wrong.

This is why regular P&ID audits, as‑built drawing reviews and physical equipment identification audits are essential.

Why this is true.

Engineering project teams often replace, relocate, or retire equipment and despite project completion checklists, updates to drawings and asset registers are sometimes missed.

Over time, this creates a dangerous gap between the digital plant and the physical plant.

How this affects maintenance strategies.

- Strategies may be developed for equipment that no longer exists.

- Newly installed equipment may be missing from the strategy entirely.

- Incorrect equipment models lead to incorrect BOMs, spare parts and maintenance procedures.

- Reliability analysis becomes distorted when failure history is linked to the wrong assets.

How audits protect data quality.

- P&ID audits verify that process connections, instrumentation and equipment configurations match reality.

- Physical equipment identification audits confirm that asset tags, models and metadata are correct.

- These audits close the loop between engineering changes and asset master data.

How to prove it.

- Compare CMMS asset lists with field‑verified equipment.

- Track the number of maintenance tasks corrected or eliminated after audits.

- Measure reductions in “no work required” PMs caused by non‑existent assets.

Highlighted concept: master data integrity assurance.

- Optimising Costs and Resource Allocation.

A well‑designed maintenance strategy ensures that maintenance effort is proportional to asset criticality.

Why this is true.

- Over‑maintaining low‑risk assets wastes labour and materials.

- Under‑maintaining critical assets increases failure risk and lifecycle cost.

- Strategies ensure that maintenance resources are used where they deliver the greatest value.

How to prove it.

- Analyse maintenance cost per asset before and after strategy optimisation.

- Track reductions in unnecessary preventive tasks.

- Compare planned vs. reactive maintenance ratios.

Highlighted concept: cost‑efficient maintenance planning.

- Supporting Production and Operational Continuity.

Maintenance strategies protect the organisation’s ability to meet production targets and customer commitments.

Why this is true.

- Production relies on asset availability.

- Without a strategy, maintenance becomes reactive, causing unpredictable downtime.

- Planned maintenance windows allow production teams to schedule around known interruptions.

How to prove it.

- Track improvements in OEE.

- Measure reductions in production losses caused by equipment failures.

- Compare planned vs. unplanned downtime ratios.

Highlighted concept: production‑aligned maintenance.

Summary.

Developing maintenance strategies is essential for ensuring reliability, safety, cost control and operational continuity. But these strategies can only be as accurate as the asset master data they rely on.

Regular P&ID audits, physical equipment identification audits and master data verification ensure that maintenance strategies are built on a correct understanding of the physical plant.

Combined with proven methodologies like FMECA and RCM and supported by modern tools such as OnPlan, OnePM and Strategy Optimizer, organisations can create maintenance strategies that are technically justified, economically optimised and aligned with real‑world operating conditions.