Ensuring Operational Safety

Operational safety is one of the most critical components of any business because it protects workers, safeguards property and sustains productivity.

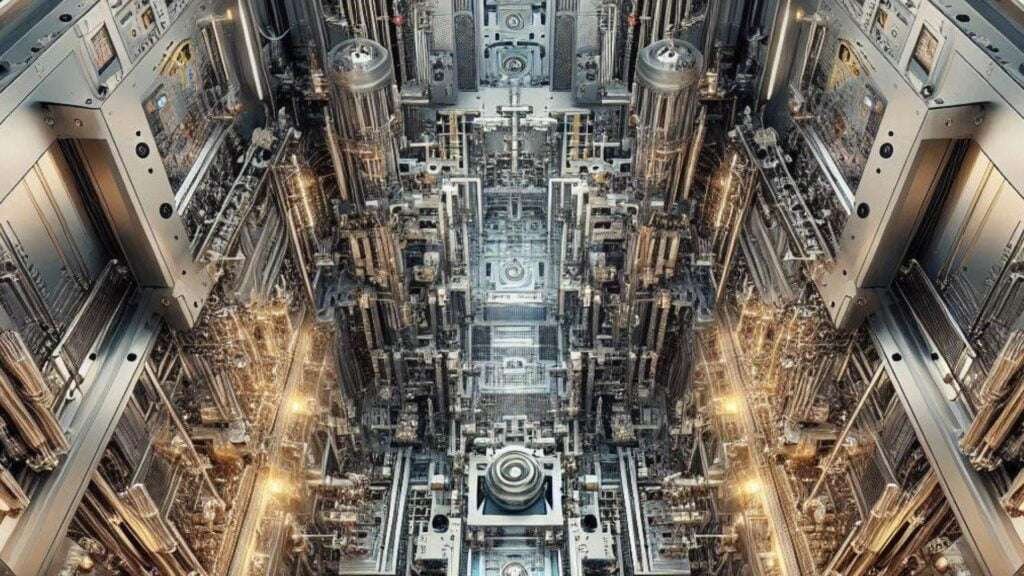

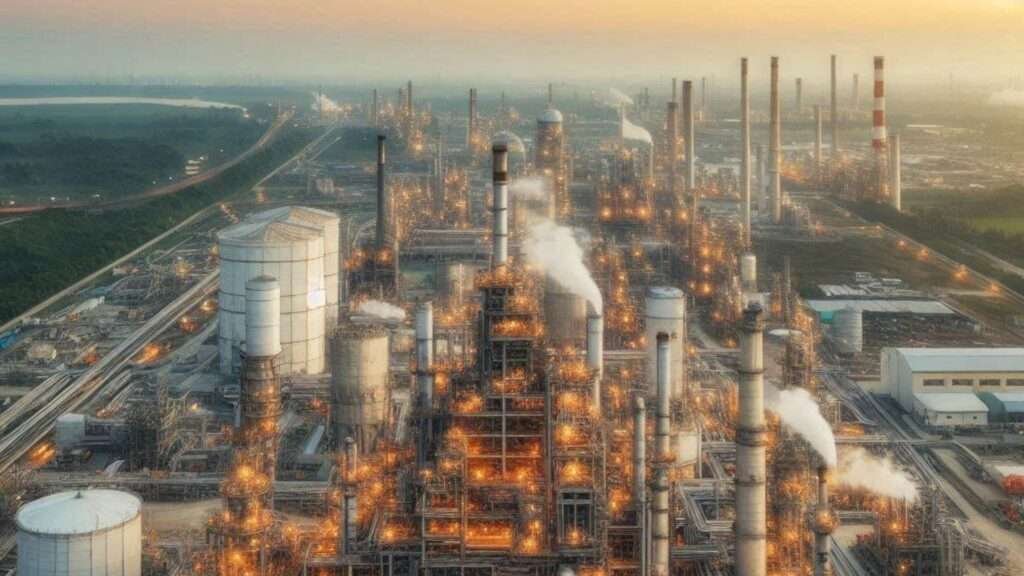

In industries operating various types of mobile and fixed plant, such as mining (coal, gold, iron ore, base metals, nickel, quarries, mineral sands and precious metals), refineries, natural gas processing, power generation, processing, aluminium smelting and steel manufacturing, the stakes are even higher.

These environments involve high‑energy systems, hazardous materials, heavy machinery and complex processes where even small failures can escalate into serious incidents.

Operational safety begins at the earliest stages of the asset lifecycle, during equipment installation and commissioning.

From that point forward, the operations department holds primary responsibility for ensuring that all activities are carried out safely and in accordance with organisational standards and regulatory requirements.

However, operational safety is never the responsibility of a single group.

It requires coordinated collaboration between maintenance, engineering, health and safety and environmental teams, each contributing essential expertise.

- Why Operational Safety Matters for Mobile and Fixed Plant.

Preventing Harm to People.

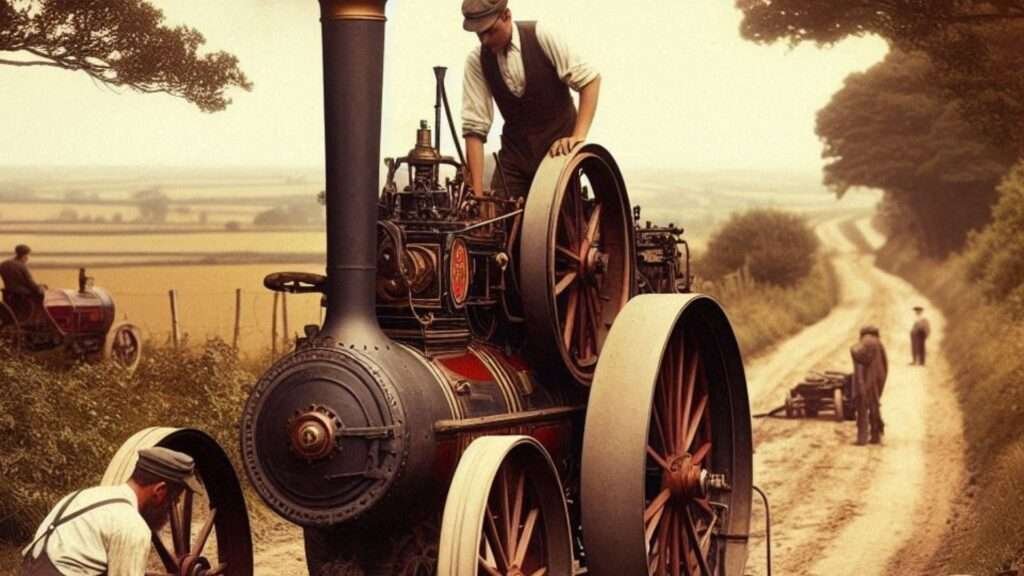

Mobile equipment (e.g., loaders, haul trucks, forklifts) and fixed plant (e.g., crushers, pumps, boilers, conveyors) introduce significant risks such as collisions, entanglement, pressure failures, chemical exposure and stored‑energy releases.

Why this matters:

- These hazards can cause severe injuries or fatalities.

- Many incidents occur due to poor controls, inadequate inspections, or incorrect operation.

- Safety failures damage morale, reputation and regulatory standing.

How to prove it:

- Analyse incident and near‑miss data for patterns linked to equipment condition or operating practices.

- Review regulatory reports and industry case studies showing consequences of poor operational safety.

- Track reductions in injury rates after implementing improved safety controls.

Protecting Assets and Infrastructure.

Equipment failures can cause fires, structural damage, environmental releases, or catastrophic equipment loss.

Why this matters:

- Asset damage leads to costly repairs and extended downtime.

- Insurance premiums and regulatory scrutiny increase after major failures.

- Poorly maintained or incorrectly operated equipment deteriorates faster.

How to prove it:

- Compare asset failure rates before and after implementing structured safety and maintenance controls.

- Track unplanned downtime linked to equipment misuse or inadequate inspections.

- Audit asset condition trends over time.

- c) Sustaining Productivity and Operational Continuity.

Safe operations are reliable operations. When equipment is operated safely and maintained correctly, production becomes more predictable.

Why this matters:

- Unsafe practices often lead to breakdowns, stoppages and bottlenecks.

- Production losses from safety incidents can exceed the cost of prevention many times over.

- Safe operations reduce variability and improve throughput.

How to prove it:

- Measure OEE (Overall Equipment Effectiveness) before and after safety improvements.

- Track production losses attributed to equipment failures or unsafe conditions.

- Compare planned vs. unplanned downtime ratios.

- How Operational Safety Is Ensured.

Health, Safety, Integrity, Performance & Environmental Checks.

These checks must be completed on time, in full and to specification. They are essential for detecting hazards early.

Why this matters:

- Missed or incomplete checks allow deterioration to go unnoticed.

- Early detection prevents escalation into major failures.

- Regulatory compliance depends on documented, timely inspections.

How to prove it:

- Audit compliance rates for safety and integrity checks.

- Track defect detection trends and corrective action closure rates.

- Compare incident frequency before and after improving check compliance.

- b) Ensuring Assets Are Fit for Purpose

Operations must ensure that only equipment suitable for its intended use is deployed, and that it is maintained according to governing standards.

Why this matters:

- Using incorrect or unfit equipment increases risk of failure.

- Mobile plant requires strict controls around load limits, braking systems and operator competency.

- Fixed plant requires correct configuration, guarding and process alignment.

How to prove it:

- Review asset certification, compliance records and maintenance history.

- Conduct field audits to verify equipment condition and suitability.

- Track defects linked to incorrect equipment selection or configuration.

Routine Maintenance and Inspections.

Routine inspections and maintenance are essential for identifying wear, damage, or abnormal conditions that could compromise safety.

Why this matters:

- Mobile plant experiences high mechanical stress and requires frequent checks.

- Fixed plant failures can propagate through interconnected systems.

- Early intervention reduces risk and cost.

How to prove it:

- Compare failure modes before and after implementing structured inspection regimes.

- Track maintenance backlog and overdue safety tasks.

- Audit the quality of completed inspections.

Building an Interdependent Safety Culture.

The ultimate goal of operational safety, whether for mobile plant, fixed plant, or complex processing systems, is to create an interdependent safety culture.

This is the highest level of safety maturity, where individuals and teams take responsibility not only for their own safety but also for the safety of those around them.

In an interdependent culture, people actively look out for one another, intervene when they see unsafe conditions or behaviours, and work collaboratively to maintain a safe operating environment.

Why this matters

- Interdependent cultures reduce incidents because safety becomes a shared value, not a set of rules imposed from above.

- Workers feel empowered to speak up, challenge unsafe practices, and stop work when necessary.

- Teams become more cohesive, communication improves, and operational discipline strengthens.

- Interdependent cultures outperform compliant cultures because they address the human and behavioural factors that most incidents stem from.

In industries operating risk‑laden mobile and fixed plant, this cultural maturity is essential. Equipment alone cannot prevent incidents, people must consistently make safe decisions, follow procedures, and support each other.

How to prove it.

- Conduct safety culture assessments and track movement from dependent → independent → interdependent behaviours.

- Measure increases in proactive reporting (hazards, near misses, improvement ideas).

- Track reductions in at‑risk behaviours observed during field leadership interactions.

- Review intervention rates, how often workers step in to prevent unsafe actions.

- Analyse improvements in safety performance that correlate with cultural initiatives.

An interdependent safety culture is not created through rules alone. It emerges when leadership models the right behaviours, when teams trust each other and when operational, maintenance, and safety groups work together with a shared purpose: everyone goes home safe, every day.

Summary.

Operational safety is fundamental to protecting people, assets, and productivity, especially in industries operating mobile and fixed plant where risks are amplified by high energy, heavy machinery, and hazardous processes.

By ensuring rigorous collaboration across departments, maintaining strict compliance with Health, Safety, Integrity, Performance & Environmental checks, verifying that all equipment is fit for purpose and performing routine inspections and maintenance, organisations create a safe, reliable and efficient operating environment.

Critically, the goal is not just procedural compliance but the development of an interdependent safety culture, where individuals and teams take shared responsibility for safety and actively support one another.

This cultural maturity strengthens operational discipline, reduces incidents, and enhances overall performance.

When organisations prioritise operational safety at both the procedural and cultural levels, they protect their people, preserve their assets and build the foundation for long‑term operational success.

This disciplined approach not only prevents incidents but also improves asset performance, reduces downtime and supports long‑term operational success.