CMMS Research & Selection Process

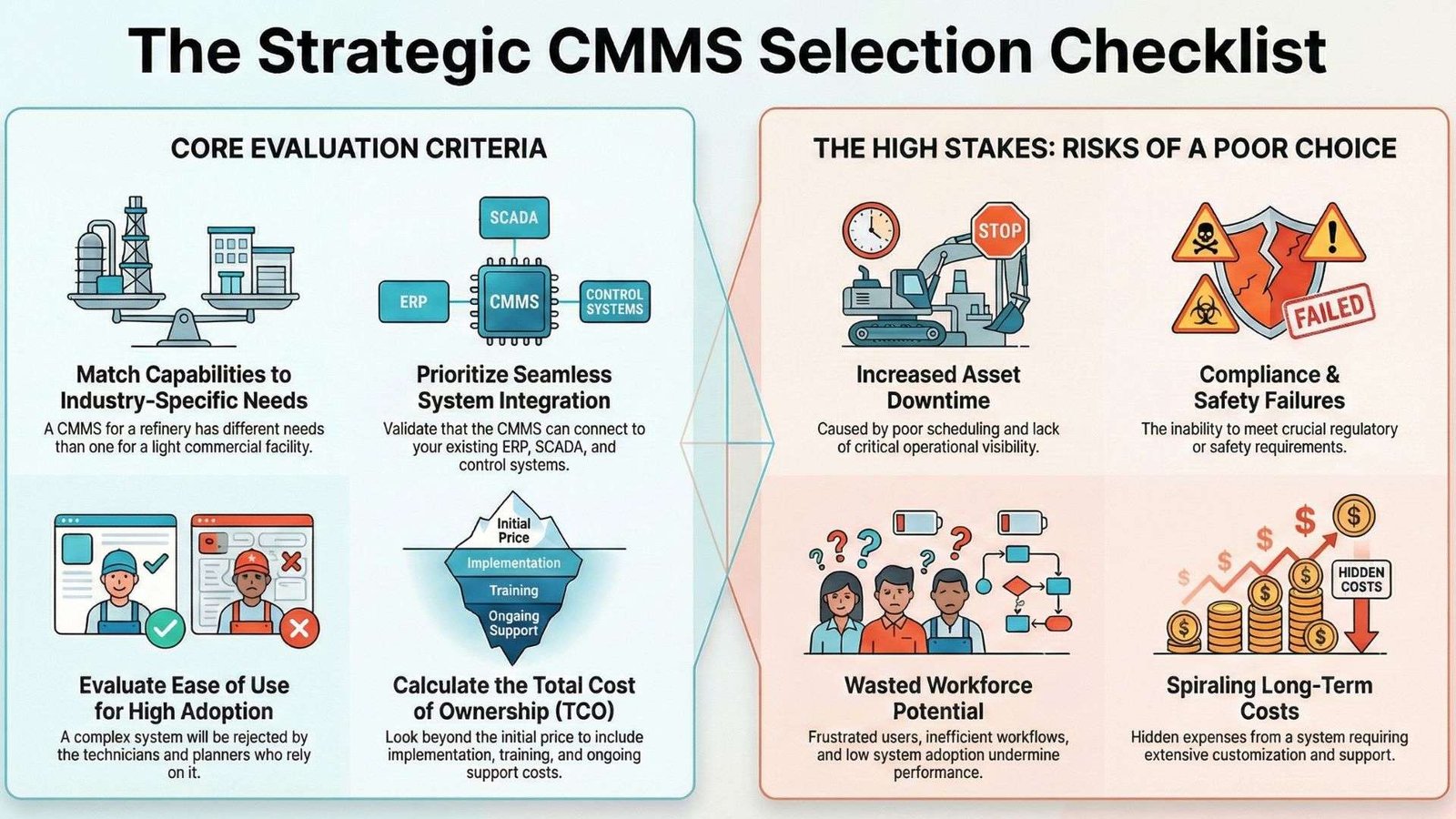

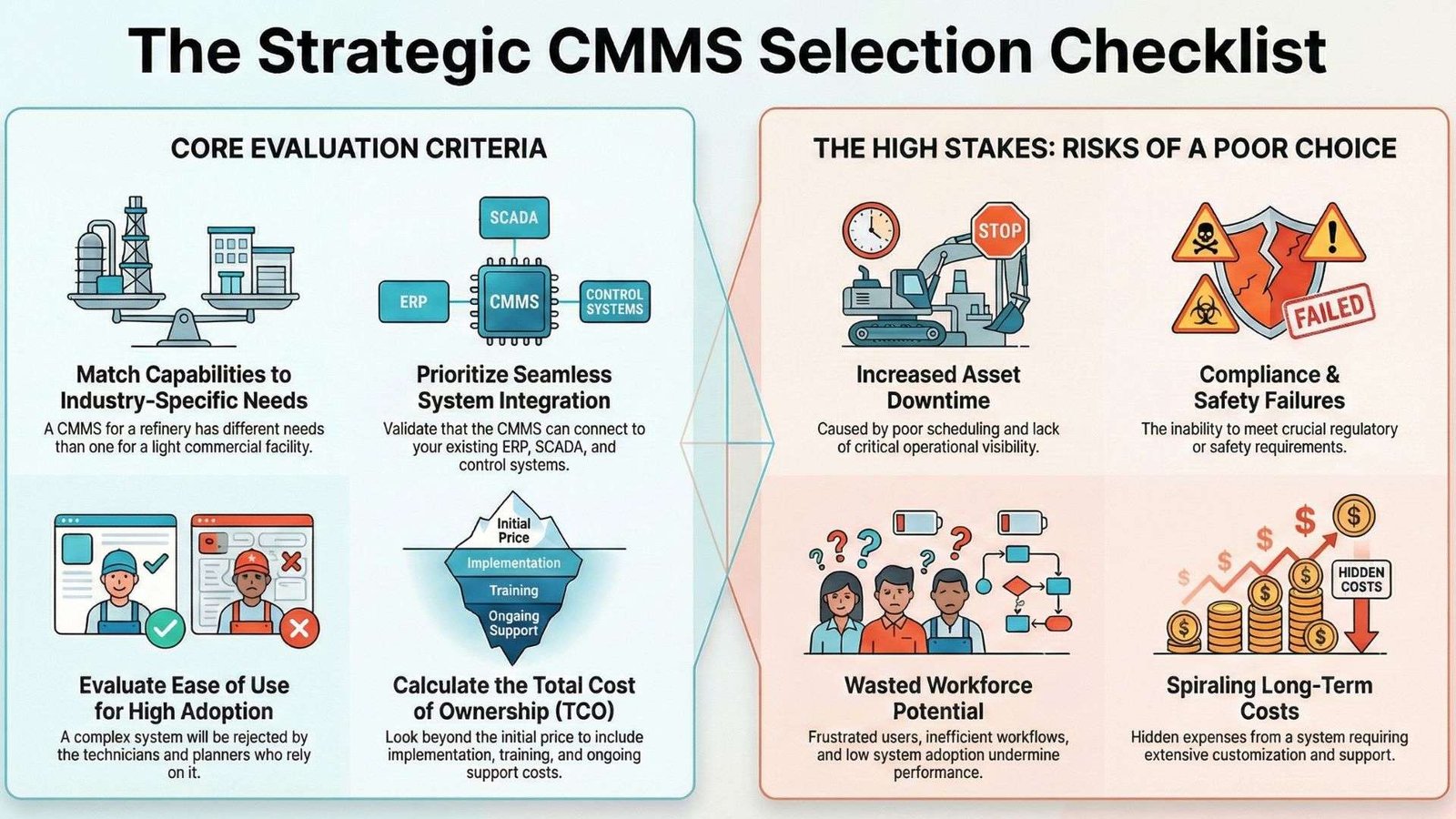

Selecting a Computerised Maintenance Management System (CMMS) is one of the most consequential decisions an asset‑intensive organisation can make.

In industries such as petroleum refining, natural gas processing, power generation, minerals processing, smelting, steel manufacturing and other high‑risk operations, the CMMS becomes the digital backbone that supports maintenance execution, asset reliability, compliance and operational continuity.

Because of this, thorough research and a structured selection process are essential to ensuring the chosen system is not only good value for money but also the right fit for the organisation’s unique operational, regulatory and technical environment.

A CMMS is not a simple software purchase. It is a long‑term operational platform that shapes how maintenance is planned, executed, recorded, analysed and improved.

Choosing the wrong system can create years of inefficiency, unnecessary cost and operational frustration. Choosing the right one can transform maintenance performance, improve asset reliability and support safer, more predictable operations.

Understanding Industry‑Specific Requirements.

The first step in a rigorous CMMS selection process is understanding the unique demands of your industry.

Different sectors have distinct maintenance challenges, regulatory obligations and operational risks. For example:

- Petroleum refineries and gas plants require strong permit‑to‑work integration, isolation management and regulatory traceability.

- Power stations depend on robust preventive and predictive maintenance schedulingto avoid forced outages.

- Minerals processing plants and smelters need advanced condition monitoring integrationand downtime analytics.

- Steel manufacturing operations require high‑volume work order processingand real‑time visibility of critical production assets.

These differences matter. A CMMS designed for light commercial facilities will not meet the needs of a refinery or power station. Understanding these requirements ensures the selection process focuses on systems capable of supporting the organisation’s operational reality.

Aligning CMMS Capabilities With Operational Needs.

Once industry requirements are understood, the next step is evaluating how well each CMMS aligns with the organisation’s operational needs.

This involves assessing features such as:

- Asset hierarchy and master data structure.

- Maintenance Strategy Development.

- Preventive and predictive maintenance scheduling.

- Work order management.

- Integration with SCADA, DCS, Drawing Software and Condition Monitoring systems.

- Warehousing, Inventory and procurement management.

- Mobile workforce enablement.

- Regulatory compliance tracking.

A structured checklist helps ensure that no critical capability is overlooked.

This checklist should reflect not only current needs but also future growth, digital transformation plans and emerging technologies such as IoT sensors and advanced analytics.

Evaluating Ease of Use and User Adoption.

Even the most powerful CMMS will fail if it is difficult for technicians, planners and supervisors to use.

Poor usability leads to incomplete data, workarounds and low adoptionall of which undermine maintenance performance.

A rigorous selection process evaluates:

- Interface simplicity.

- Mobile usability.

- Workflow clarity.

- Training requirements.

- User feedback from similar industries.

Organisations that skip this step often end up with a system that looks impressive on paper but is rejected by the people who rely on it daily.

Assessing Integration and Data Compatibility.

A CMMS does not operate in isolation. It must integrate with existing systems such as:

- Condition monitoring systems such as Augury.

- Inventory Optimization such as EazyStock (by Syncron).

- Specialized Procurement and advanced inventory management platforms such as SIGMA (by SDI).

- Industrial control and operations technology systems such as SCADA, DCS and Aveva Edge (formerly Citec).

- Document management systems such as Hexagon SDx (formerly Intergraph SDx).

- Electronic Parts Catalogues such as LinkOne.

- Vertical Carousel/VLM solutions such as Modula and related software such as Modula WMS Lite or Modula Cube Manager.

Poor integration leads to duplicated data, manual workarounds and inconsistent information, all of which increase cost and risk.

Thorough research ensures the chosen CMMS can support seamless data flow across the organisation.

Understanding Total Cost of Ownership.

A CMMS’s purchase price is only one part of its cost. A rigorous selection process evaluates the total cost of ownership, including:

- Licensing or subscription fees.

- Implementation and configuration.

- Data migration.

- Integration costs.

- Ongoing support.

- Future scalability.

A system that appears inexpensive upfront may become far more costly over time if it requires extensive customisation or lacks essential features.

Avoiding the Consequences of a Poor CMMS Choice.

The risks of selecting an inadequate CMMS are significant:

- Increased downtime due to poor scheduling or visibility.

- Inability to meet regulatory or safety compliance requirements.

- Frustrated users and low adoption.

- Inefficient maintenance workflows.

- Poor asset master data quality.

- Higher long‑term costs.

- Disruption during implementation and transition.

These consequences can persist for years, making CMMS selection one of the most important decisions in the maintenance and reliability domain.

Ensuring External System Integration Before CMMS Purchase.

A critical but often overlooked component of CMMS research is determining whether the system can integrate or interface with external site systems.

In asset‑intensive industries, maintenance does not operate in isolation; it relies on data flowing seamlessly between multiple platforms such as ERP systems, SCADA/DCS, condition monitoring tools, historian databases, procurement systems and safety or permit‑to‑work platforms.

If these integrations are not understood and validated before purchasing a CMMS, organisations risk selecting a system that cannot support essential workflows.

Why this matters.

- Many CMMS platforms have limited or proprietary integration capabilities.

- Some require costly custom development or middleware to connect with existing systems.

- Others may not support the data formats, communication protocols, or security requirements used on site.

- In high‑risk industries, integration failures can compromise compliance, delay maintenance, or distort asset performance data.

How to prove it

- Conduct a detailed integration assessment during the selection phase.

- Validate API capabilities, data structures and vendor‑supported connectors.

- Confirm that real‑time data (e.g., vibration, temperature, run hours) can flow into the CMMS without manual intervention.

- Ensure the CMMS can push data back to ERP or procurement systems for cost tracking and inventory control.

By resolving integration requirements upfront, organisations avoid costly surprises, rework and operational disruption and ensure the CMMS can fully support their maintenance ecosystem.

Summary.

Thorough CMMS research and a structured selection process are essential for ensuring the chosen system is not only cost‑effective but also aligned with the organisation’s operational, regulatory and technical needs.

In asset‑intensive, high‑risk industries, the CMMS becomes the foundation of maintenance performance, asset reliability and operational safety.

Evaluating industry‑specific requirements, usability, integration capability, total cost of ownership and long‑term scalability ensures the system can support real‑world maintenance demands.

Critically, confirming external system integration before purchase prevents costly implementation failures and ensures seamless data flow across the organisation.

By investing time and effort into a rigorous selection process, organisations position themselves to choose a CMMS that delivers long‑term efficiency, reliability and operational value.