Explaining The Maintenance Planning Skill Set

Disclaimer.

This article is an independent professional analysis based on practical experience and conceptual understanding of maintenance planning principles.

It is not a substitute for certified technical training or organisation‑specific procedures.

Every effort has been made to ensure accuracy and relevance; however, readers should always refer to applicable company standards, OEM documentation and qualified engineering guidance before applying any of the practices described.

All referenced sources were publicly accessible at the time of writing, though availability and URLs may change over time.

The thoughts, interpretations, and opinions expressed are those of the author alone.

Article Summary.

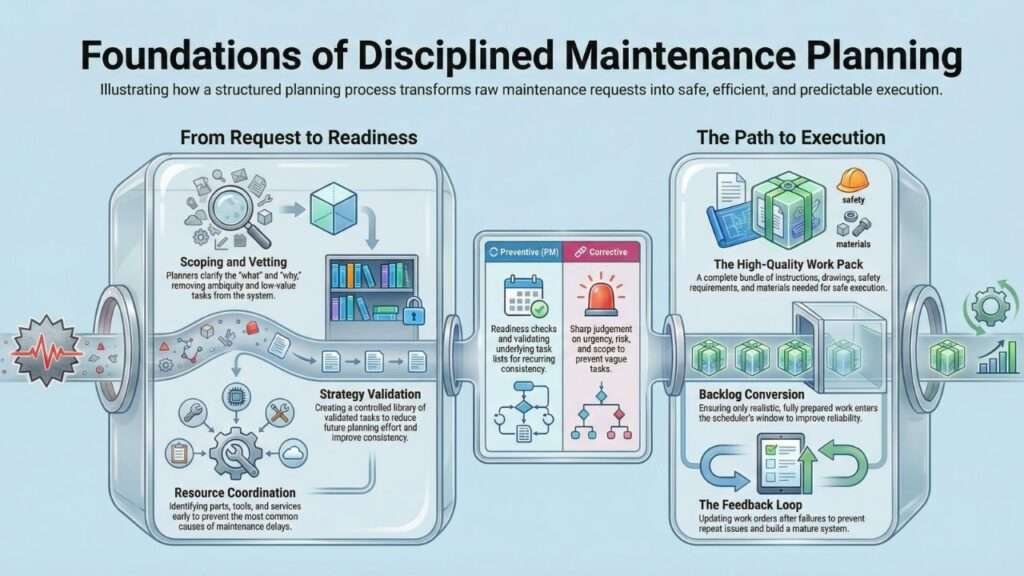

This article defines and explores the skill set of effective maintenance planners, professionals who convert unstructured work requests into executable, risk‑controlled maintenance jobs.

It presents maintenance planning as a disciplined, value‑driven process that underpins asset reliability, operational safety and cost efficiency in industrial operations.

The article examines core activities including validating work requests, developing scopes, preparing work packs, coordinating materials, managing backlogs and sustaining continuous improvement.

Beyond procedural competence, the article highlights the blend of technical literacy, analytical ability, communication, time management and digital capability essential for planners to thrive in modern, data‑driven maintenance environments.

By integrating structured planning into daily operations, organisations can transform reactive maintenance into predictable, reliable performance across the asset lifecycle.

Top 5 Takeaways.

1. Maintenance Planning is proactive control. Effective planning prevents reactive maintenance by embedding foresight into every stage of work preparation.

2. The maintenance planner is the gatekeeper. Every maintenance request must be validated, scoped, and resourced before entering the execution schedule.

3. The work pack is the finished product. A high‑quality work pack ensures technical accuracy, safety compliance, and repeatable outcomes in the field.

4. Quality Maintenance Planning depends on collaboration. Strong interpersonal, analytical, and communication skills connect technical and operational disciplines.

5. Continuous improvement closes the loop. Feedback from execution strengthens future planning, supporting reliability, efficiency, and safety.

Table Of Contents

1.0 Introduction.

2.0 What Is Maintenance Planning?

3.0 The Role and Responsibility of the Planner.

4.0 The Maintenance Planning Process.

5.0 Planning Preventive Maintenance.

6.0 Planning Corrective Maintenance.

7.0 The Work Pack: The Planner’s Key Output.

8.0 Coordination of Materials and Services.

9.0 Managing the Backlog and Schedule Readiness.

10.0 Continuously Improving Maintenance Planning.

11.0 The Planner’s Wider Contribution.

12.0 Maintenance Planning Has Strategic and Operational Value.

13.0 Understanding the Maintenance Planning Skill Set.

13.1 Analytical and Problem‑Solving Ability.

13.2 Communication and Interpersonal Skills.

13.3 Organisational Discipline and Time Management.

13.4 Systems Thinking and Continuous Improvement.

13.5 Digital Capability.

14.0 Conclusion.

15.0 Bibliography.

16.0 Additional Maintenance Planning Resources.

1.0 Introduction.

Maintenance planning forms the backbone of reliable asset management.

It ensures that every task, from preventive inspections to corrective repairs, is defined, justified, resourced and ready before execution begins.

This article explores the complete maintenance planning skill set, detailing how structured preparation improves safety, efficiency, and cost performance.

It positions the planner as the central coordination point bridging engineering intent and hands‑on execution, showing that planning is not merely paperwork but a strategic enabler of organisational reliability.

2.0 What Is Maintenance Planning?

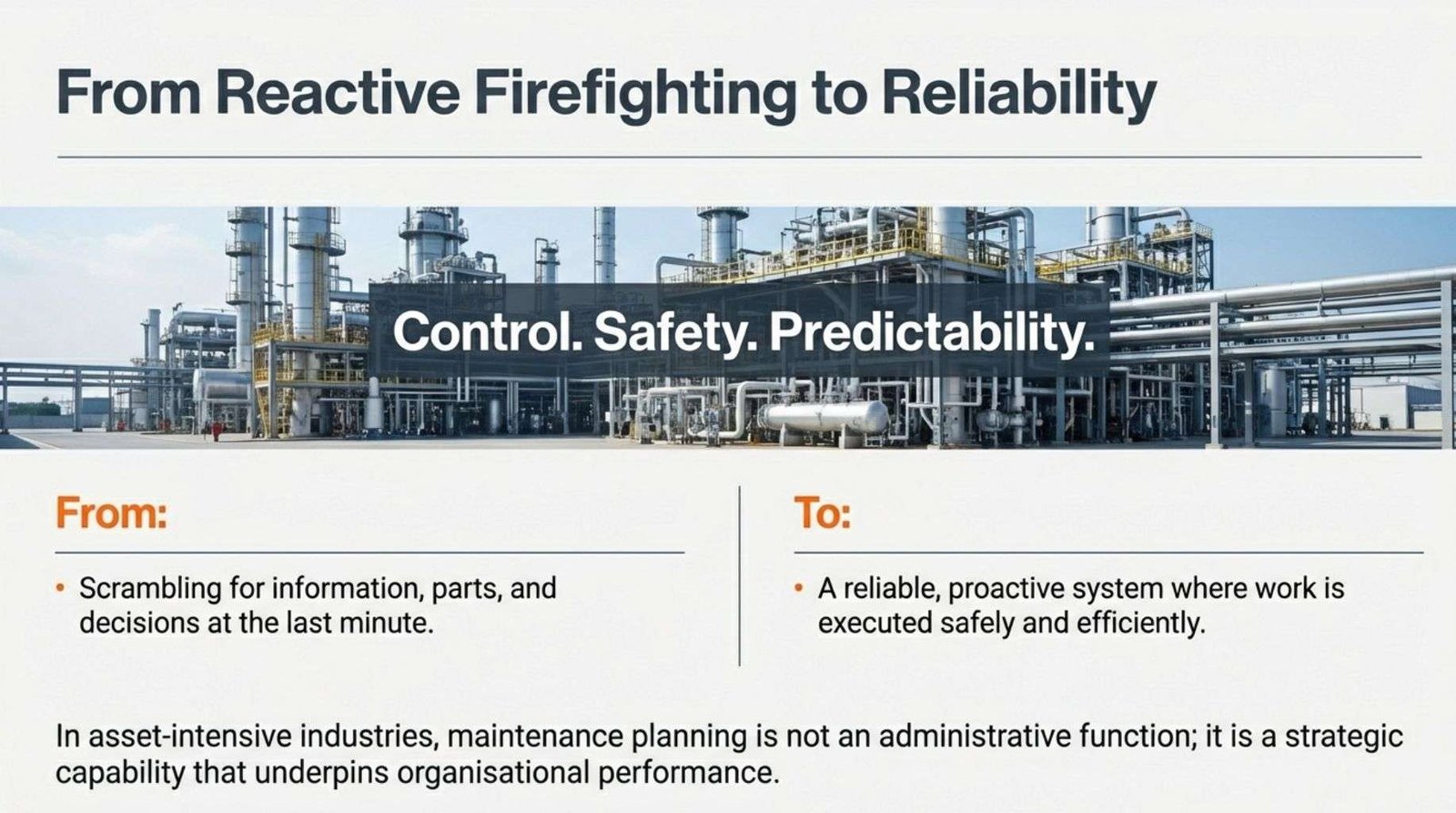

Maintenance planning is the disciplined and structured process of preparing maintenance work so it can be executed safely, efficiently and without unnecessary disruption to operations.

It is not simply an administrative function or the act of scheduling, it is the strategic capability that transforms maintenance from reactive firefighting into a proactive, reliable system.

At its core, maintenance planning ensures that every job, whether preventive, corrective, or improvement-based, is clearly defined, properly resourced and aligned with organisational priorities before technicians begin work.

This disciplined preparation drives operational stability, minimises waste and maintains the integrity, safety and reliability of assets across their life cycle.

3.0 The Role and Responsibility of the Planner.

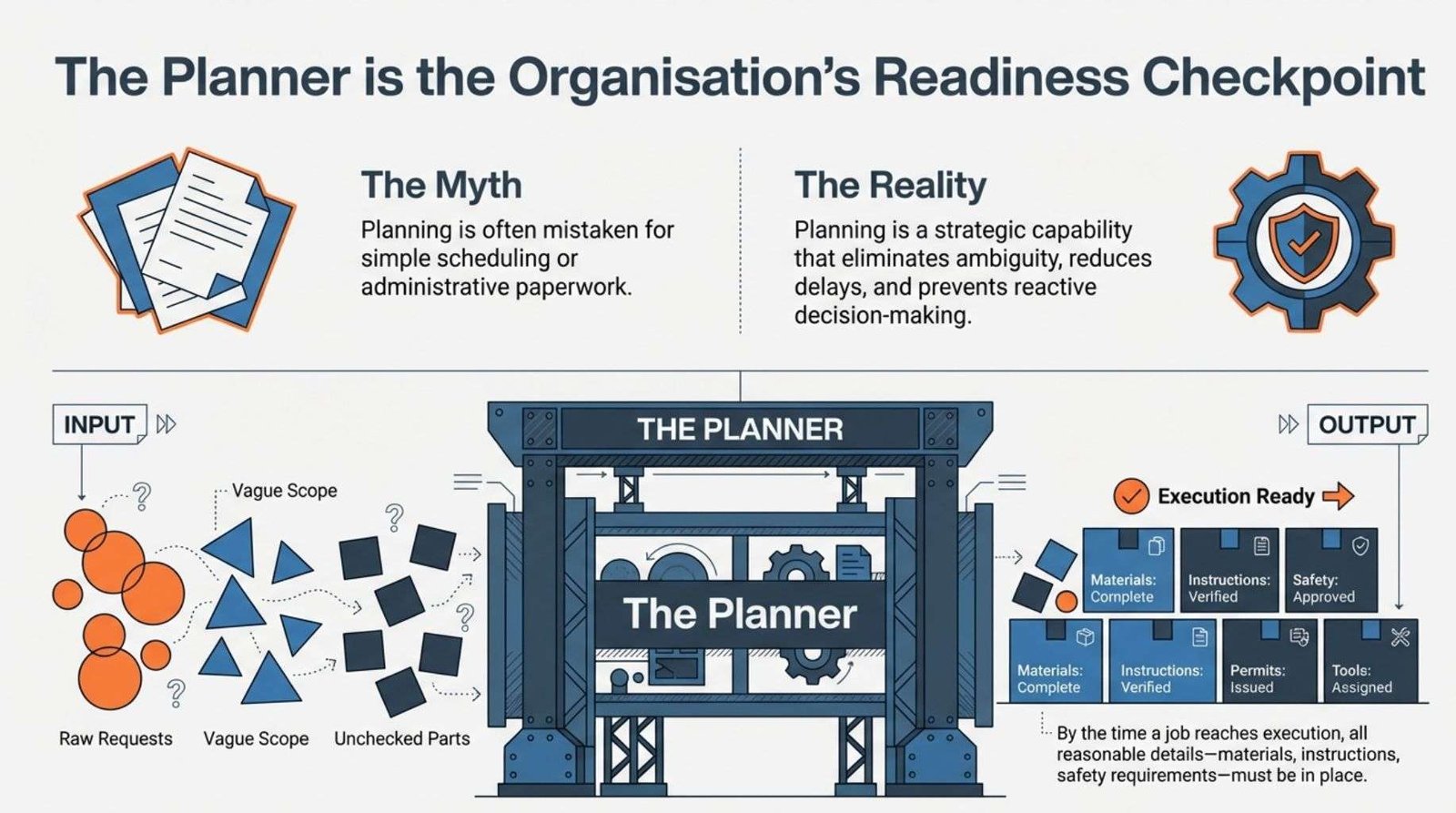

The maintenance planner sits at the centre of the work management process, serving as the organisation’s readiness checkpoint.

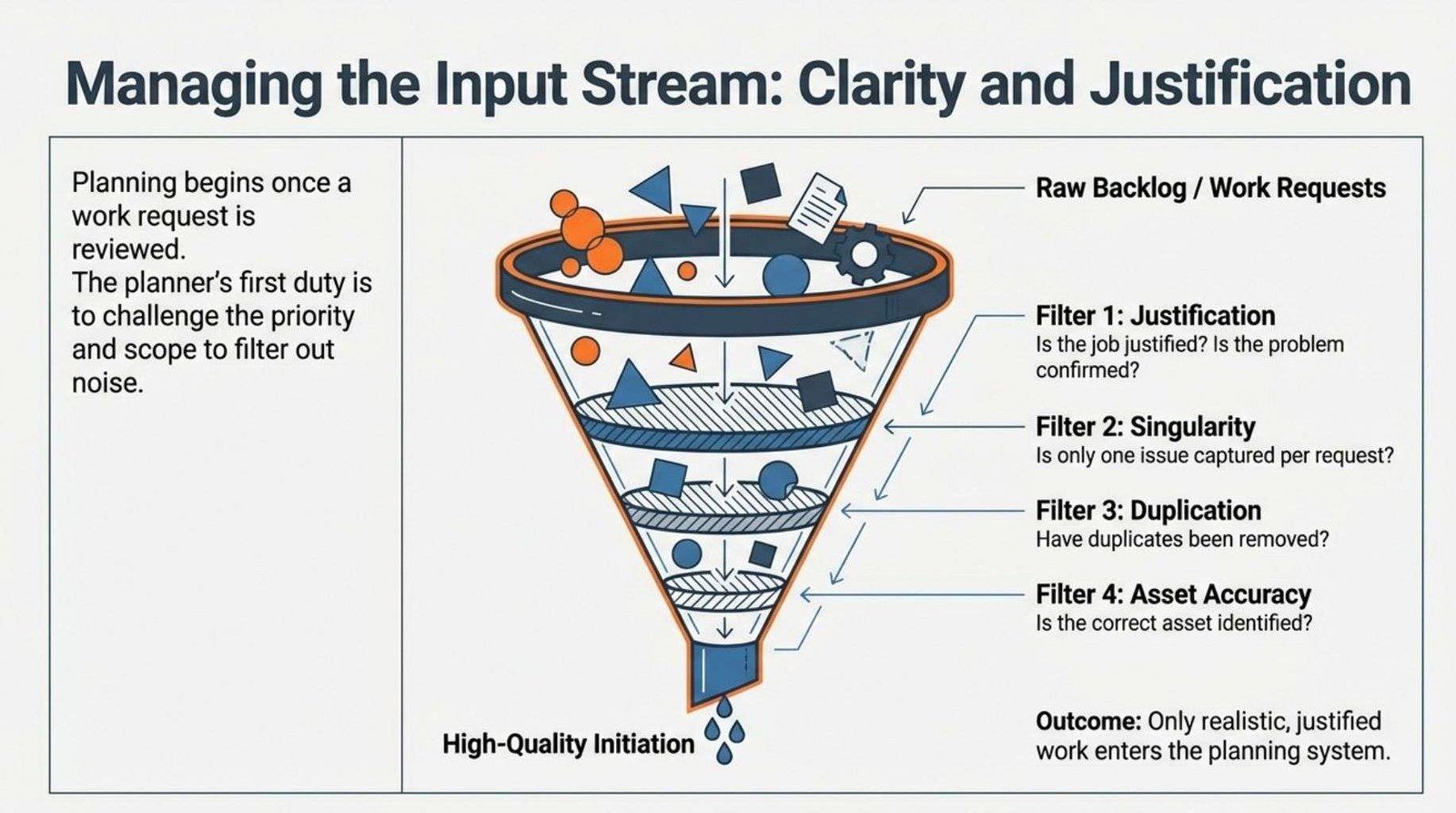

Once a work request is raised, the planner determines its validity, confirms the scope and challenges its priority to ensure that only meaningful, justified jobs enter the planning pipeline.

Each request must be specific, clearly articulated and attached to the correct asset. To maintain efficiency, only one issue should be captured per request, reducing duplication and ambiguity.

Once verified, the planner transforms that request into a ready-to-execute work order. This process involves developing a comprehensive scope of work that technicians can trust, one that defines what needs to be done, why it is needed and exactly how it should be performed.

The planner eliminates uncertainty by ensuring that all instructions, materials and resources are identified and organised before the job moves toward scheduling.

4.0 The Maintenance Planning Process.

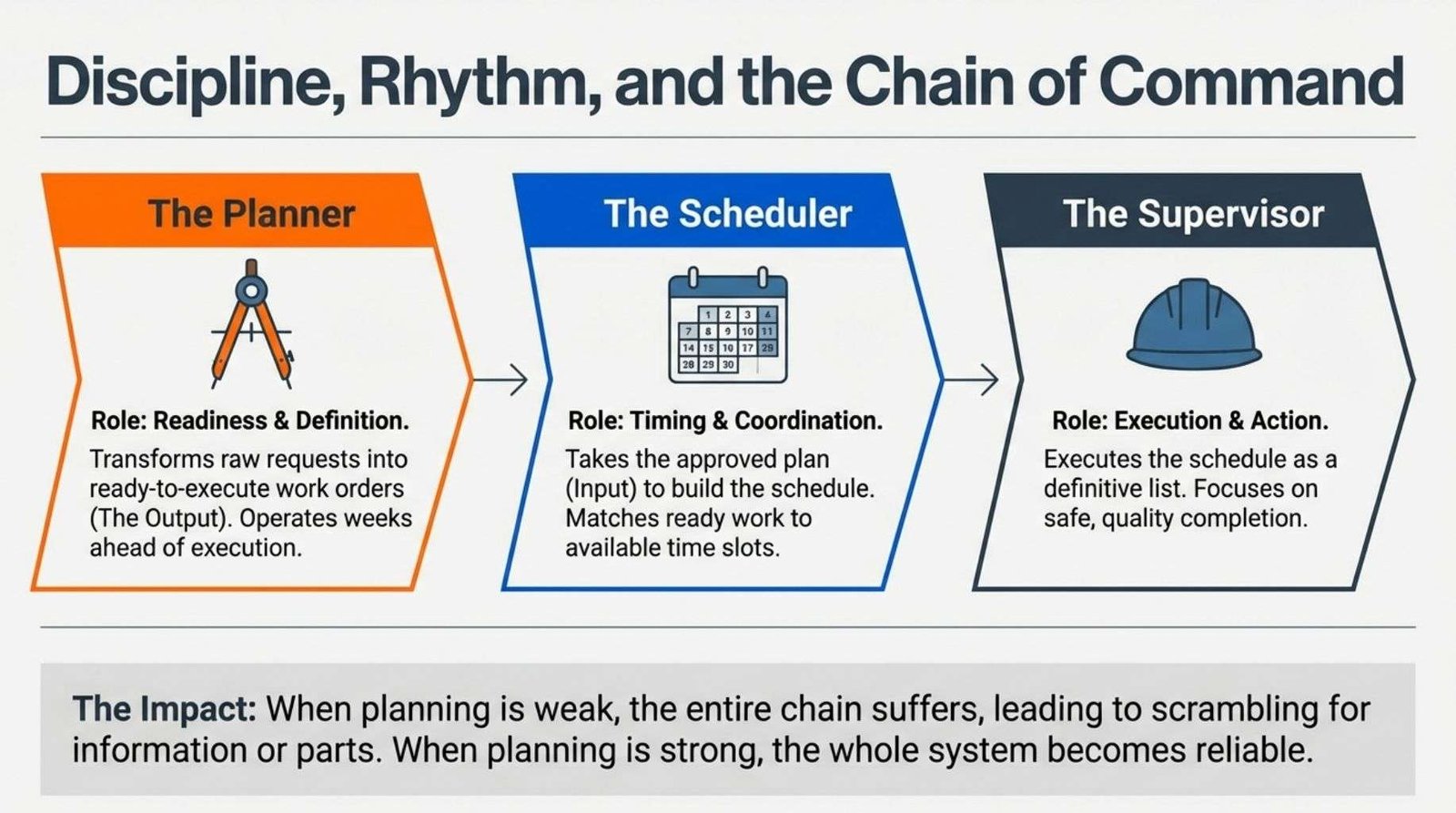

Planning begins with discipline and structure. Planners operate several weeks ahead of the execution schedule, maintaining a steady rhythm that aligns closely with scheduling and supervision.

The planner’s prepared work orders become the scheduler’s input and the scheduler’s approved plan ultimately becomes the supervisor’s execution list.

When planning is weak, the entire chain suffers, from resource shortages to unplanned delays.

When planning is strong, maintenance execution becomes more reliable, predictable and efficient.

Once the work’s purpose and scope are defined, the planner develops the details needed to complete the job safely and effectively.

This includes estimating labour requirements and equipment downtime, identifying all parts, materials, tools and services and confirming technical skills required for each task.

Safety and environmental risks are evaluated and explicitly incorporated into the work instructions so that risk management is embedded into the daily workflow, not treated as an afterthought.

A well-planned job is characterised by clear sequencing, precise documentation and the anticipation of potential execution challenges.

The goal is that technicians should not need to make field decisions about what needs to happen next.

Instead, they should have everything they require before they arrive at the job site, work instructions, safety documentation, materials lists, drawings and quality check criteria.

5.0 Planning Preventive Maintenance.

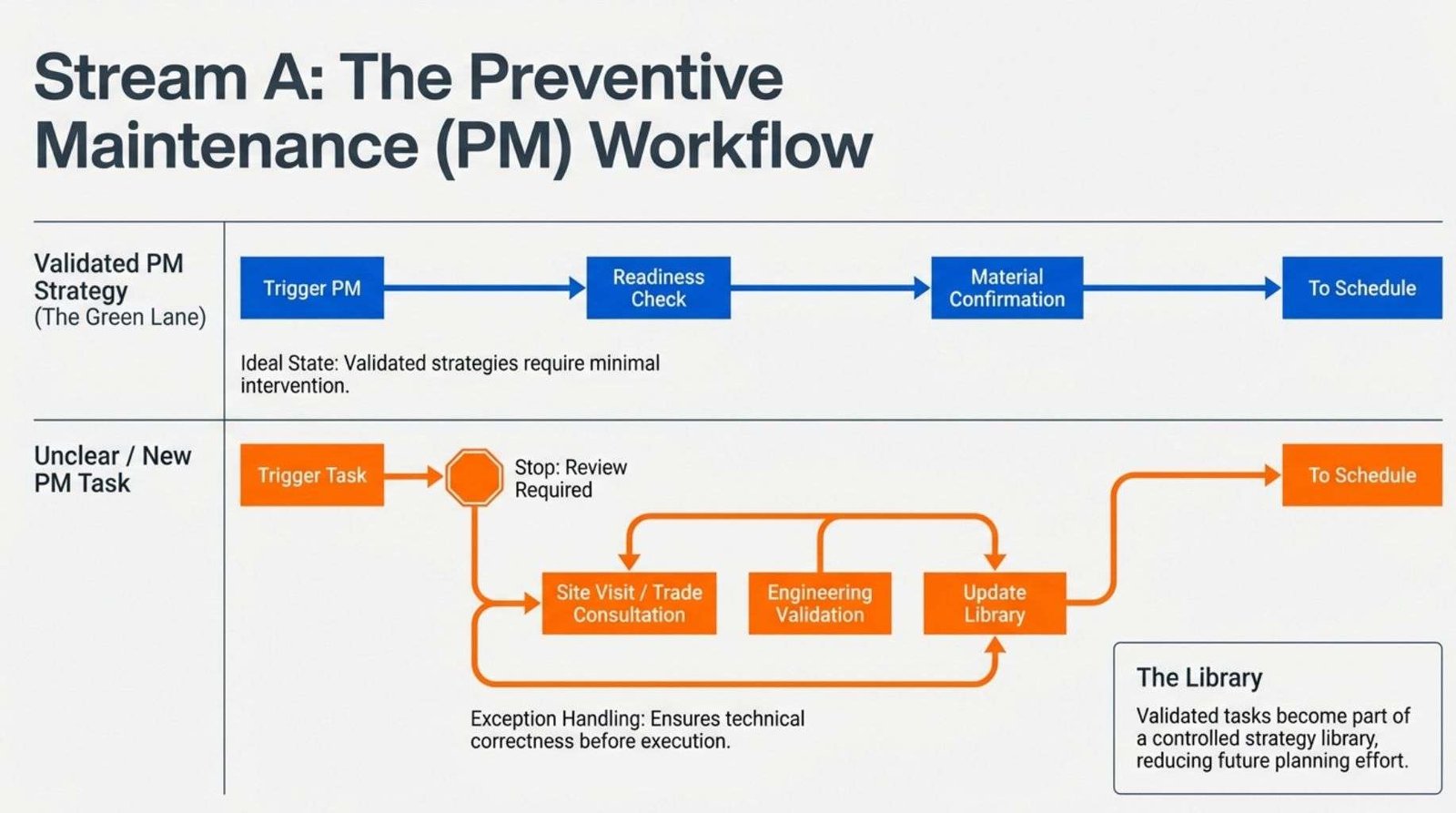

Preventive maintenance (PM) represents a major focus of planning effort because it aims to prevent failure before it occurs.

For mature organisations, validated PM strategies already exist and require only routine readiness checks to confirm materials and documentation.

For unapproved or unclear PM tasks, planners must perform deeper technical reviews, often consulting tradespeople, conducting site visits, or collaborating with engineers, to ensure the maintenance activity is technically sound and aligned with reliability goals.

Once validated, these tasks are added to a controlled preventive maintenance library. This library of standardised tasks significantly reduces future planning effort, improves consistency across work sites and contributes to long-term efficiency.

Whenever recurring preventive maintenance requires additional planning, the underlying PM strategy or task list is updated, ensuring that lessons learned are integrated into standard procedures.

6.0 Planning Corrective Maintenance.

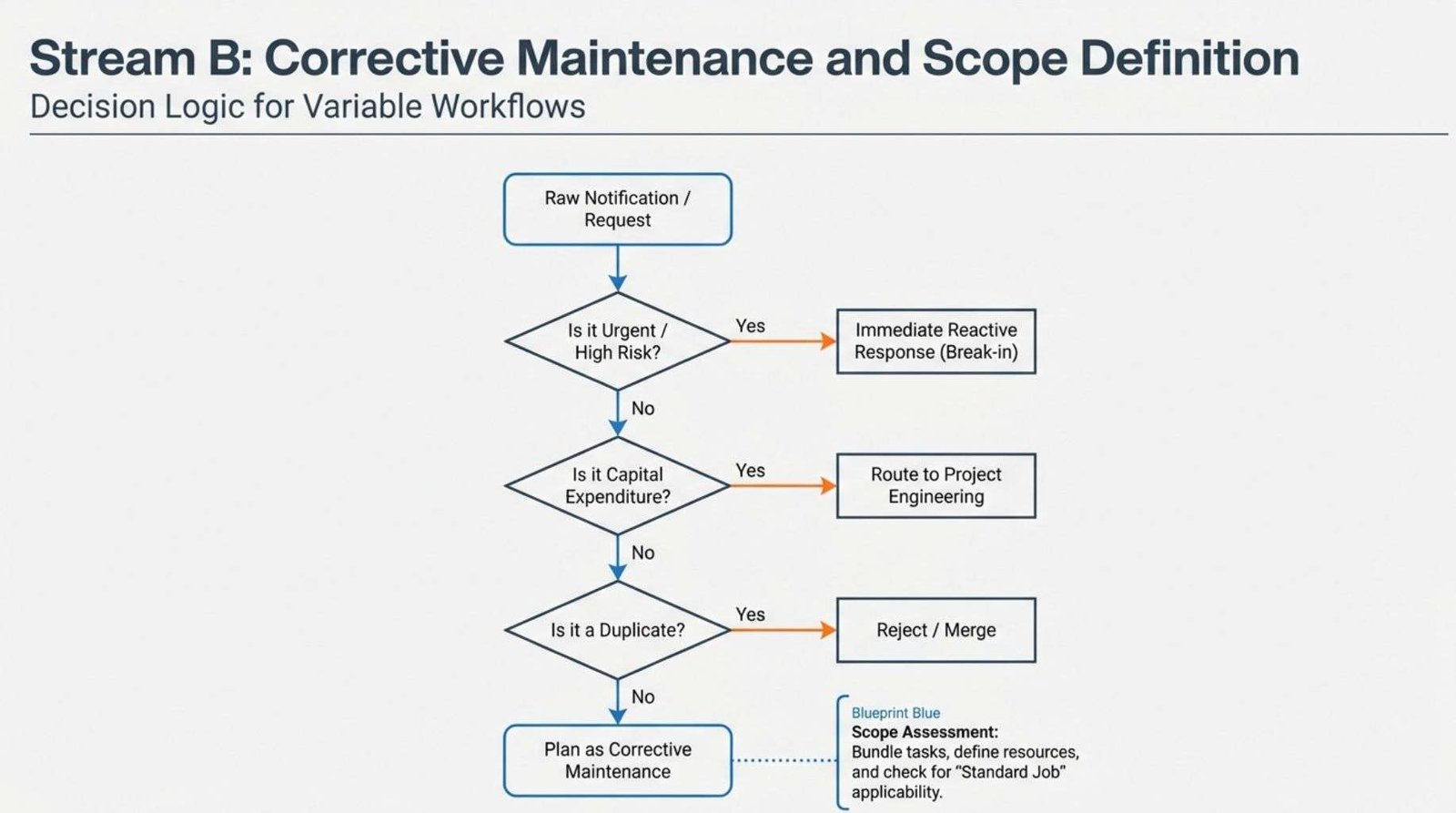

In contrast to preventive maintenance, corrective work typically arises in response to observed defects or failures, making it more variable and demanding sharper judgement.

The planner’s role is to assess urgency and risk, clarify the problem and confirm operational impact. Some corrective tasks can be bundled with other scheduled work, while others may require immediate execution or classification as capital expenditure.

To prevent inefficiency, low-value or vague requests must be screened out during planning. Only well-defined corrective jobs should proceed, with each one carefully scoped to include the required resources and technical details.

If the same corrective tasks arise repeatedly, planners create standard jobs or reusable task lists, allowing similar work to be planned quickly and consistently in the future.

7.0 The Work Pack: The Planner’s Key Output.

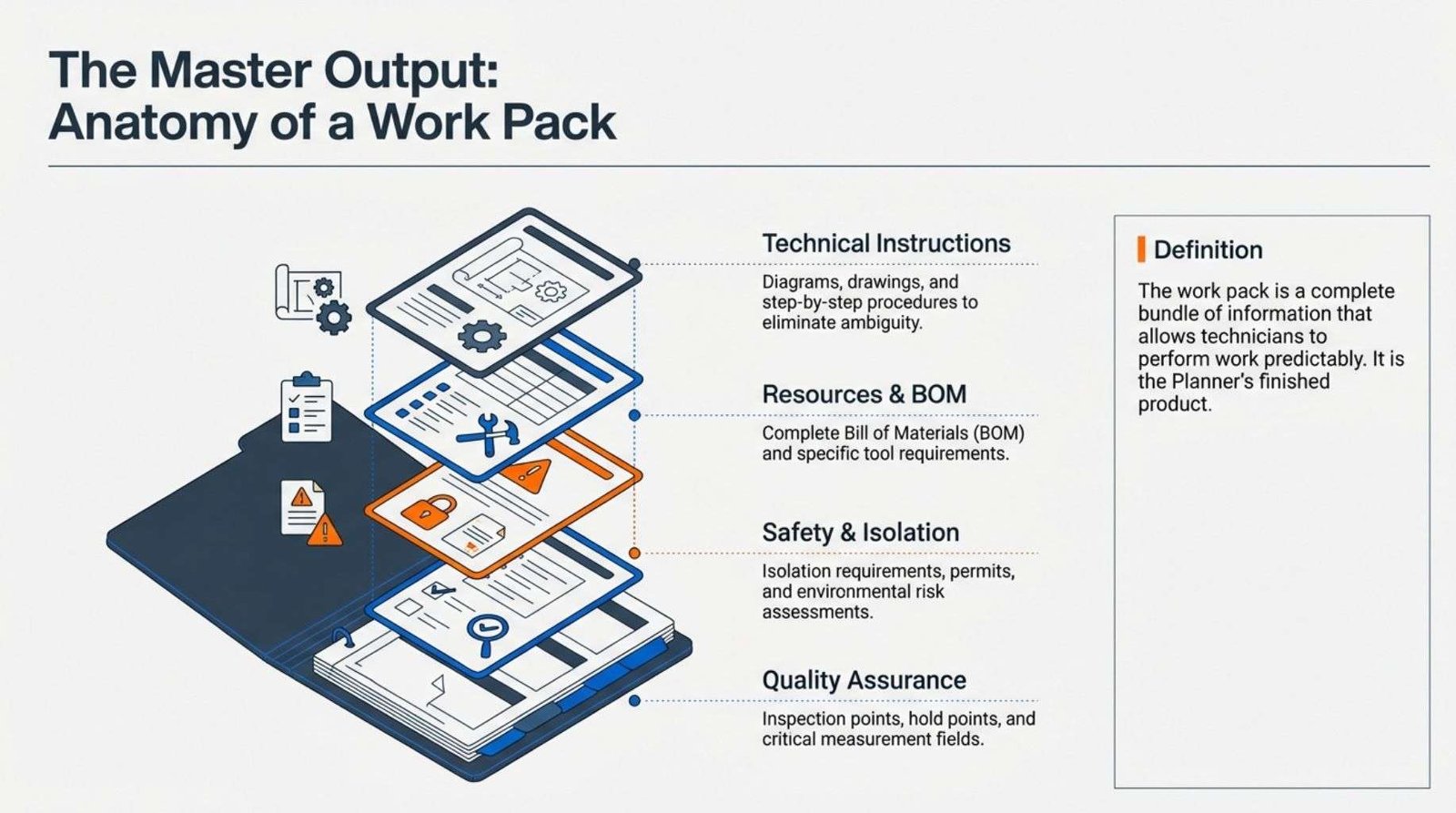

The most tangible product of the planning process is the work pack, a comprehensive, ready-to-use guide that transforms planning into execution.

A high-quality work pack serves as the technician’s roadmap, providing precise instructions that eliminate guesswork and ensure repeatable, safe maintenance.

A typical work pack includes:

1. Sequenced task instructions, arranged across three phases:

a. Pre-work (site preparation, isolation and readiness),

b. Execution (technical steps and inspection requirements) and

c. Post-work (testing, restoration and documentation).

2. Safety documentation, detailing isolation requirements, hazards and environmental controls.

3. Technical content, such as diagrams, drawings and specifications.

4. Materials and parts lists, ensuring all components are pre-validated and available.

5. Quality and inspection points, including hold points, measurements and final checks.

Well-prepared work packs directly translate to improved technician efficiency, reduced rework and safer, more predictable maintenance outcomes.

8.0 Coordination of Materials and Services.

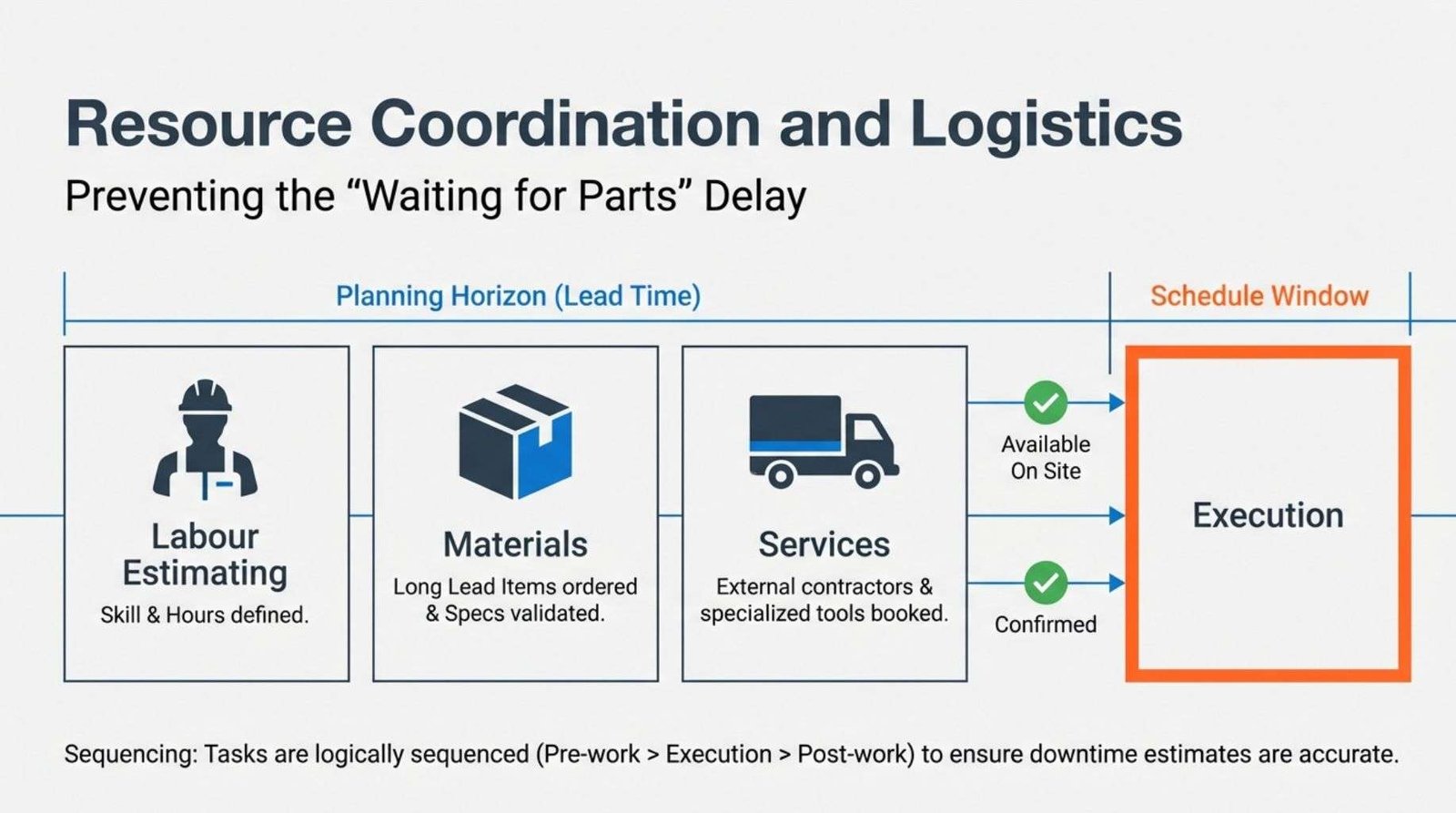

Materials and services coordination is another foundation of strong maintenance planning. Failure to secure parts and materials in advance is one of the most common causes of maintenance delays.

Effective planners identify parts early, validate technical specifications, manage long-lead items and coordinate with procurement and stores teams so that everything is ready before the scheduled start date.

This level of foresight prevents last-minute scrambling and ensures that maintenance teams can focus entirely on the technical execution of their work.

The planner’s proactive engagement with procurement, vendors and service contractors further strengthens reliability across the maintenance lifecycle.

9.0 Managing the Backlog and Schedule Readiness.

Maintenance planning also plays a critical role in managing the maintenance backlog, which often contains more work than can be completed immediately.

The planner reviews all open work orders, confirms which jobs are fully ready and defers those that lack information, materials, or approval into future planning cycles. This disciplined backlog management ensures that only realistic, executable work enters the schedule, preventing overloaded maintenance windows and improving execution success rates.

This stage links planning, scheduling and execution in a continuous workflow:

1. Planner: Prepares and validates work for readiness.

2. Scheduler: Builds the schedule from the planner’s output.

3. Supervisor: Executes the approved schedule with technicians.

Each role depends on the previous one. The planner’s diligence sets the foundation on which scheduling and supervision rely.

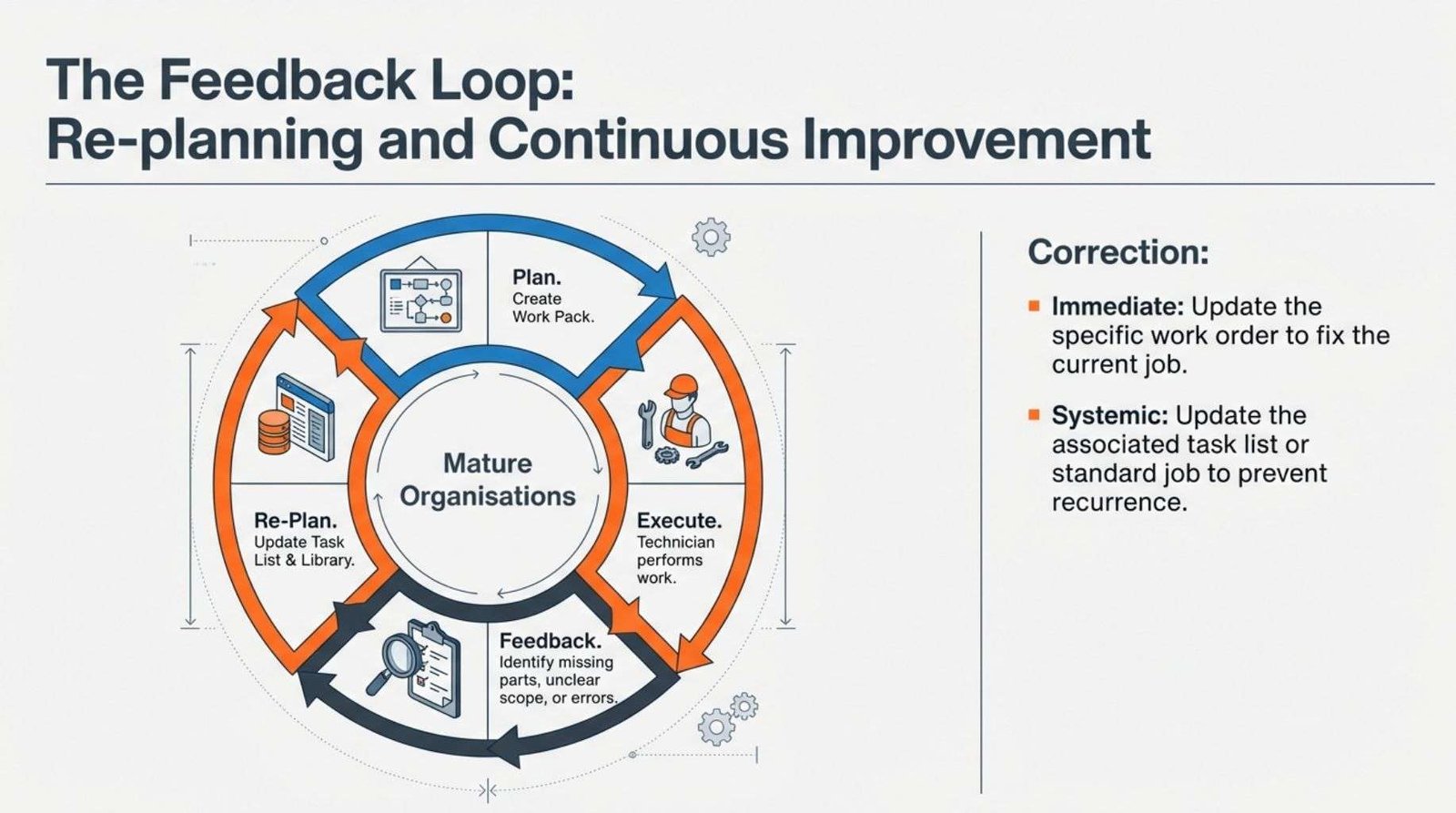

10.0 Continuously Improving Maintenance Planning.

Maintenance planning is not static, it depends on continuous improvement driven by feedback from the field.

When a planned job cannot be completed due to missing information, unavailable parts, or inadequate instructions, the event triggers a “re‑planning” activity.

In these cases, the planner updates both the work order and any associated task list or strategy library entry to ensure that the same problem does not recur.

This feedback loop strengthens the overall quality and maturity of the maintenance system. Over time, patterns in failed or delayed work reveal weaknesses in planning, documentation, or supply chain processes, which planners can systematically address.

This iterative cycle of preparation, execution and refinement builds organisational resilience and efficiency.

11.0 The Planner’s Wider Contribution.

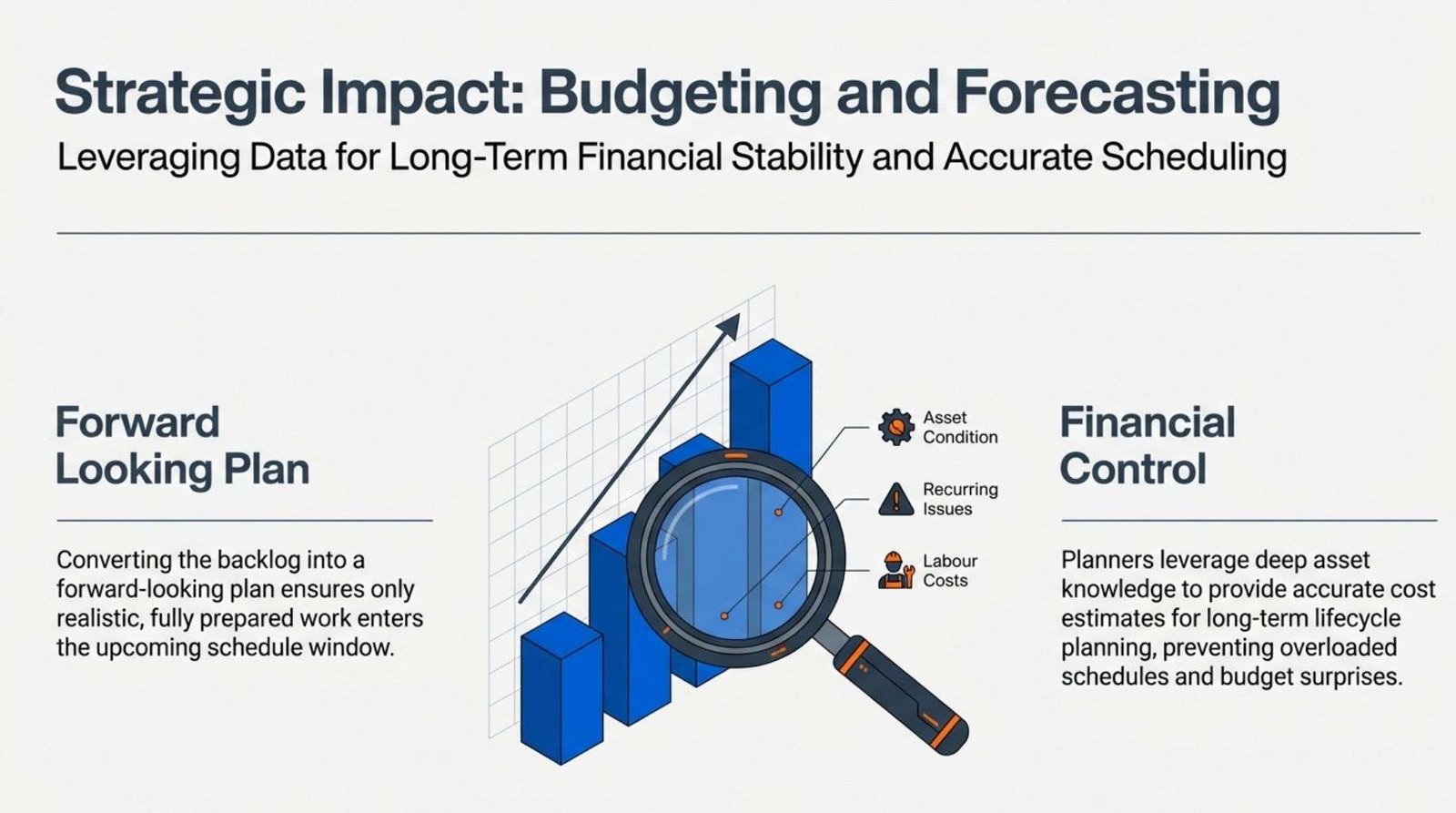

Beyond the day-to-day preparation of work, planners contribute significantly to broader organisational goals.

Their intimate understanding of asset conditions, recurring issues and maintenance costs allows them to provide valuable input into budgeting, forecasting and long-term asset planning.

Planners help to identify trends such as frequent failures, excessive resource usage, or chronic bottlenecks, information that supports capital planning and continuous reliability improvement.

12.0 Maintenance Planning Has Strategic And Operational Value.

Ultimately, disciplined maintenance planning transforms how an organisation manages its physical assets.

It balances risk, effort and operational impact to ensure that maintenance activities support long-term asset integrity, cost control and safe operations.

Strong planning delivers several measurable outcomes:

1. Improved tool time: Technicians spend more of their shift performing productive work instead of waiting for materials or clarifying instructions.

2. Reduced waste: Better preparation limits unnecessary labour and inventory costs.

3. Predictable execution: Jobs proceed smoothly and safely according to plan, minimising disruption to operations.

4. Enhanced reliability: Assets perform more consistently because maintenance is targeted, timely and well-controlled.

13.0 Understanding The Maintenance Planning Skill Set.

At the foundation of the role is strong technical literacy. Planners benefit enormously from understanding how assets operate, how they fail and what is required to restore them to optimal condition.

They do not need to be master tradespeople or reliability engineers, but they must possess enough mechanical or electrical discipline to interpret work requests, identify missing information and define accurate, high‑quality scopes of work.

Technical competence enables planners to challenge vague descriptions, spot unrealistic expectations and translate engineering intent into clear, actionable tasks that technicians can execute confidently in the field.

13.1 Analytical and Problem‑Solving Ability.

Planning is inherently analytical. Planners review equipment histories, breakdown reports, condition monitoring data and PM inspection results to identify trends, recurring issues and early indicators of failure.

This insight allows them to anticipate upcoming work, initiate proactive tasks and prioritise activities based on risk, urgency and consequence.

Site visits are an essential part of this learning cycle. The most effective planners seek feedback directly from technicians, using real‑world execution challenges to refine future work orders, strengthen PM strategies and build standard jobs.

This continuous improvement mindset distinguishes mature planners from those who simply process paperwork.

13.2 Communication and Interpersonal Skills.

Maintenance planning is a collaborative discipline. Planners work closely with operations, trades, engineering, procurement and supervision.

They must extract accurate information from technical experts while guiding conversations toward clarity and practicality.

Their written communication, especially in work packs, must be precise, unambiguous and easy to follow.

Clear communication reduces misunderstandings, prevents delays and strengthens safety outcomes.

13.3 Organisational Discipline and Time Management.

Because planning must stay several weeks ahead of scheduling, planners require strong personal discipline.

They convert a constantly shifting backlog into a realistic forward plan, balancing competing priorities while meeting readiness targets.

Attention to detail is critical; overlooked materials or unclear instructions can cascade into costly downtime once execution begins.

13.4 Systems Thinking and Continuous Improvement.

Skilled planners understand that maintenance is a connected system: initiation, planning, scheduling, execution and feedback.

Their role is not only to prepare today’s job but to strengthen tomorrow’s process. They document standard jobs, maintain preventive maintenance libraries and ensure lessons learned are captured and reused.

Their mindset aligns daily actions with organisational goals such as safety, reliability and cost optimisation.

13.5 Digital Capability.

Modern planners must be comfortable navigating CMMS platforms, interpreting digital data and working with technical drawings, engineering databases and supplier systems.

Digital fluency enhances accuracy, efficiency and the planner’s ability to make informed decisions.

14.0 Conclusion.

Maintenance planning is the bridge between intention and execution. It converts raw work requests into actionable, fully prepared jobs that technicians can perform confidently and safely. More than a procedural requirement, it is a core competency that underpins operational reliability, safety and cost-effectiveness in asset-intensive industries.

By embedding discipline, foresight and continuous improvement into every stage of the maintenance lifecycle, planning ensures that the organisation’s maintenance effort is not just reactive repair, but a proactive engine of performance, reliability and value.

14.1 Summary Table: The Core Elements of Maintenance Planning.

Category | What It Covers | Why It Matters |

Purpose of Maintenance Planning | Preparing work so it can be executed safely, efficiently and predictably. | Transforms maintenance from reactive firefighting into a proactive, reliable system. |

Planner’s Role | Validates requests, defines scope, challenges priority, ensures readiness. | Acts as the organisation’s readiness checkpoint; prevents waste and ambiguity. |

Work Request Verification | Confirms asset, problem, justification and clarity; removes duplicates. | Ensures only meaningful, well‑defined work enters the planning pipeline. |

Work Order Development | Defines what, why and how; identifies materials, tools, labour, skills and risks. | Eliminates uncertainty and enables technicians to execute without delays. |

Preventive Maintenance Planning | Validates PM tasks, updates strategies, maintains PM library. | Ensures consistency, reduces future planning effort and supports reliability goals. |

Corrective Maintenance Planning | Assesses urgency, risk and impact; scopes variable work; creates standard jobs. | Controls variability, prevents low‑value work and improves repeatability. |

Work Pack Creation | Sequenced instructions, safety documentation, drawings, materials lists, quality checks. | Provides technicians with a complete, trusted roadmap for safe, repeatable execution. |

Materials & Services Coordination | Identifies parts early, validates specs, manages long‑lead items, liaises with procurement. | Prevents delays caused by missing materials; improves schedule adherence. |

Backlog & Readiness Management | Reviews open work, defers unready jobs, ensures only executable work enters the schedule. | Protects schedule integrity and improves execution success rates. |

Continuous Improvement | Updates task lists and strategies based on execution feedback. | Strengthens system maturity and prevents recurring planning failures. |

Strategic Contribution | Provides insights for budgeting, forecasting, asset planning and reliability improvement. | Connects day‑to‑day planning with long‑term organisational performance. |

15.0 Bibliography.

1. Mobley, R.K., 2009. Maintenance Fundamentals. 2nd ed. Elsevier.

2. Kelly, A. and Harris, M.J., 2005. Management of Industrial Maintenance. Elsevier.

3. Moubray, J., 1997. Reliability-Centered Maintenance II. Industrial Press Inc.

5. Smith, R. and Hawkins, B., 2011. Lean Maintenance. Elsevier.

7. Wireman, T., 2013. Maintenance Planning and Scheduling Handbook. 3rd ed. McGraw-Hill Education.

8. Dekker, R. and Scarf, P.A., 1998. Maintenance Modelling and Optimization. Springer.

9. Higgins, L.R. and Mobley, R.K., 2002. Maintenance Engineering Handbook. McGraw-Hill.

10. Swanson, L., 2001. Linking Maintenance Strategies to Performance. Elsevier.

11. Levitt, J., 2011. Complete Guide to Preventive and Predictive Maintenance. Industrial Press.

12. Arnold, J.R.T. and Chapman, S.N., 2004. Introduction to Materials Management. Prentice Hall.

13. Kelly, A., 2006. Maintenance Strategy: Business-Centred Maintenance. Butterworth-Heinemann.

14. Nelson, C., 2020. Maintenance and Reliability Best Practices. 2nd ed. CRC Press.

15. Rausand, M., 2014. Reliability of Safety-Critical Systems: Theory and Applications. Wiley.

16. Plant Engineering, 2023. The Importance of Maintenance Planning and Scheduling.

17. Effco Solutions, 2022. What Does a Maintenance Planner Do?

18. ReliabilityWeb, 2021. Defining the Role of the Maintenance Planner.

19. Assetivity, 2022. What Is Effective Maintenance Planning and Scheduling?

20. Maintenance Journal, 2023. Maintenance Planning Explained: Key Steps and Practices.

21. Fiix, 2021. The Complete Guide to Maintenance Planning and Scheduling.

22. Plant Services, 2022. Why Maintenance Planning Fails (and How to Fix It).

23. ReliabilityConnect, 2020. Building Effective Maintenance Work Packs.

24. Industrial Maintenance & Plant Operation, 2023. Planner-Scheduler Best Practices.

25. CMMS Software Insights, 2024. Maintenance Backlog Management Guide.

26. UpKeep, 2023. How to Improve Maintenance Planning Efficiency.

27. SMRP, 2022. Best Practices in Maintenance Work Management.

28. Reliability Academy, 2020. Maintenance Planning – The Foundation of Reliability.

29. ABB, 2023. Digital Maintenance Planning for Industrial Assets.

30. SAP, 2022. Maintenance Planning and Scheduling in SAP PM.

16.0 Additional Maintenance Planning Resources On This Website.

If this article has sparked new ideas or helped clarify your approach to maintenance planning, you might be wondering what to explore next, then you’re in the right place.

This website hosts a deep library of articles that expand on the themes you’ve just read, covering planning, scheduling, asset management systems, work management maturity and the practical realities of building a reliable maintenance function.

To help you continue your learning journey, I’ve curated a selection of the most relevant next reads.

Each one builds on the concepts in this article and I hope you will find they strengthen your foundation for whatever challenge you’re tackling next.

Recommended Next Reads:

1. Develop A Full Understanding Of Maintenance Planning

2. Planning Maintenance Using SAP

3. Maintenance Work Scheduling

4. Ensuring CMMS Quality Work Orders

5. Thinking About Planning A Shutdown?

Each of these articles connects directly to the ideas you’ve just explored and will hopefully help you deepen your understanding.