Examining What Good Maintenance Planning Looks Like.

Disclaimer.

This article provides general information about maintenance planning principles and practices. It is intended for educational purposes and should not be considered professional advice specific to your organisation.

Maintenance planning requirements vary significantly across industries, regulatory environments and organisational contexts.

Readers should consult qualified maintenance professionals, reliability engineers and relevant industry standards when developing or modifying maintenance planning systems.

The examples provided are illustrative and may not reflect the specific requirements of your operations.

The thoughts, views, opinions and ideas expressed are those of the Author only.

Article Summary.

Maintenance planning is a disciplined, structured process that ensures maintenance work is executed safely, efficiently and with minimal disruption to operations.

Although industries differ widely in their assets, risks and regulatory environments, the foundational principles of planning remain remarkably consistent.

When applied well, planning shifts an organisation away from reactive firefighting and toward a predictable, optimised maintenance system that protects long‑term asset integrity.

This article explores the essential functions that underpin effective maintenance planning: preventive maintenance preparation, corrective work vetting, work pack development, materials and services coordination and financial oversight.

It illustrates how the maintenance planning equation varies across operational contexts, from simple, repeatable fleet maintenance tasks to highly complex, engineering‑controlled activities in critical industries.

The discussion highlights the planner’s role as the organisation’s primary readiness checkpoint, ensuring that by the time work reaches execution, every reasonable detail has been considered, validated and prepared.

Through this lens, maintenance planning emerges not as an administrative function, but as a strategic capability that directly influences safety, reliability and operational performance.

Top 5 Takeaways.

1. Maintenance planning is universal in principle but highly variable in practice, with the required depth, rigour and technical intensity shaped by each organisation’s unique combination of asset criticality, risk exposure, task complexity and operational impact.

2. Mature maintenance systems distinguish between approved and unapproved preventive maintenance tasks. Approved PM strategies require only readiness checks, while unapproved tasks demand detailed technical review, consultation with asset specialists and validation by a reliability engineer before execution.

3. Work packs are the planner’s signature output, providing technicians with the complete set of instructions, drawings, isolation requirements, inspection criteria, materials lists and safety notices needed for safe, efficient and error‑free execution. Work pack quality is a direct predictor of execution performance.

4. Standardising repeatable corrective tasks through controlled job plans and task lists eliminates redundant planning effort, ensures consistent execution across teams and applies the same discipline to corrective work that is traditionally reserved for preventive maintenance.

5. Proactive materials and services planning, especially early identification of long‑lead items, is essential to schedule adherence. Accurate specifications, timely procurement and close coordination with supply teams prevent delays, reduce downtime and eliminate procurement‑related bottlenecks.

Table of Contents.

- Introduction.

1.1 The “What Does Good Look Like Framing/Scale.

- The Maintenance Planning Equation.

2.1. Industry Variability in Planning Requirements.

2.2. Example 1: Courier Business.

2.3. Example 2: Satellite Launch Company.

2.4. Universal Principles Across Different Contexts.

- The Foundation of Maintenance Planning.

3.1. Clarity of Purpose.

3.2. The Planner as Readiness Checkpoint.

- Preventive Maintenance Planning.

4.1. PM Work Order Generation.

4.2. Forward Visibility and Early Preparation.

4.3. Approved PM Strategies and Readiness Checks.

4.4. Detailed Technical Review of Unapproved PMs.

4.5. Reliability Engineer Validation and Strategy Control.

- Corrective Work Planning.

5.1. Work Order Vetting and Prioritisation.

5.2. Bundling Tasks for Efficiency.

5.3. Capitalisation Considerations.

- Work Pack Development.

6.1. Components of a Comprehensive Work Pack.

6.2. Work Pack Quality Review and Approval.

6.3. Impact on Execution Efficiency.

- Standardisation of Repeatable Work.

7.1. Standard Job Plans and Task Lists.

7.2. Benefits of Standardised Corrective Work.

- Financial Oversight in Maintenance Planning.

8.1. Cost Estimation and Budget Alignment.

8.2. CAPEX versus OPEX Identification.

- Break In Work and Urgent Maintenance.

9.1. Balancing Urgency with Control.

9.2. Minimum Planning Requirements for Emergency Work.

- Long Term Forecasting and Strategic Planning.

10.1. Asset Plans and Major Maintenance Events.

10.2. Resource Coordination and Capital Planning.

- Materials and Services Planning.

11.1. Early Identification of Requirements.

11.2. Procurement Coordination.

- Conclusion.

- Bibliography.

1.0 Introduction.

Maintenance planning represents a fundamental discipline within asset intensive organisations. It serves as the structured process through which maintenance work is prepared for execution in a manner that prioritises safety, efficiency and minimal operational disruption.

The role extends beyond simple scheduling; it encompasses comprehensive preparation that ensures maintenance activities are clearly defined, properly resourced and aligned with operational needs.

In modern industrial operations, maintenance planning functions as a core reliability discipline rather than an administrative afterthought.

The quality of planning directly influences production continuity, cost control, workforce efficiency and risk management outcomes.

When executed effectively, planning transforms maintenance departments from reactive service providers into proactive reliability partners that support long term asset integrity.

This article examines the principles, processes and practical considerations that define effective maintenance planning across different operational contexts.

1.1 The “What Does Good Look Like Framing/Scale.

A useful way to frame the importance of maintenance planning is to consider the question of “What does good look like?”

Every organisation operates somewhere along a performance scale.

At one extreme lies the outcome of doing the worst possible job, where poor maintenance leads to uncontrolled risks, serious injuries, regulatory breaches, financial penalties and reputational damage that no responsible organisation would ever want.

At the opposite extreme sits the idealised version of excellence, where maintenance performance is so consistently outstanding that it becomes a benchmark for the industry and a source of organisational pride.

Most organisations will might not ever experience either extreme, yet the concept of the scale remains something worth remembering.

Leaders must determine where they expect their organisation to operate on that continuum, what level of performance is realistically achievable, what they are willing to invest and, critically, what outcomes must never be allowed to occur.

Maintenance planning is the discipline that anchors these expectations in day‑to‑day practice.

It provides the structure, foresight and control required to avoid unacceptable outcomes while steadily moving the organisation toward higher levels of reliability maturity.

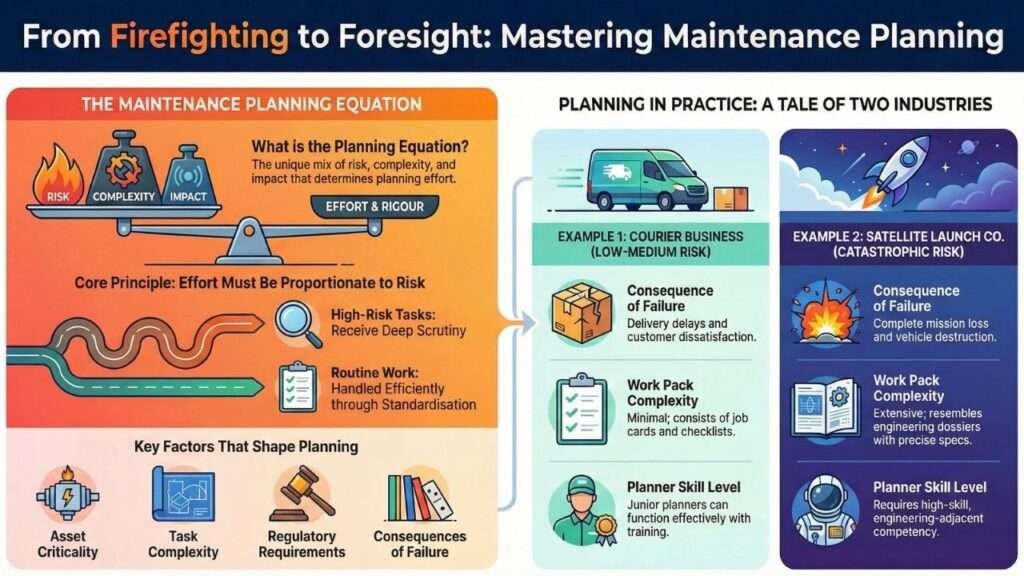

2.0 The Maintenance Planning Equation.

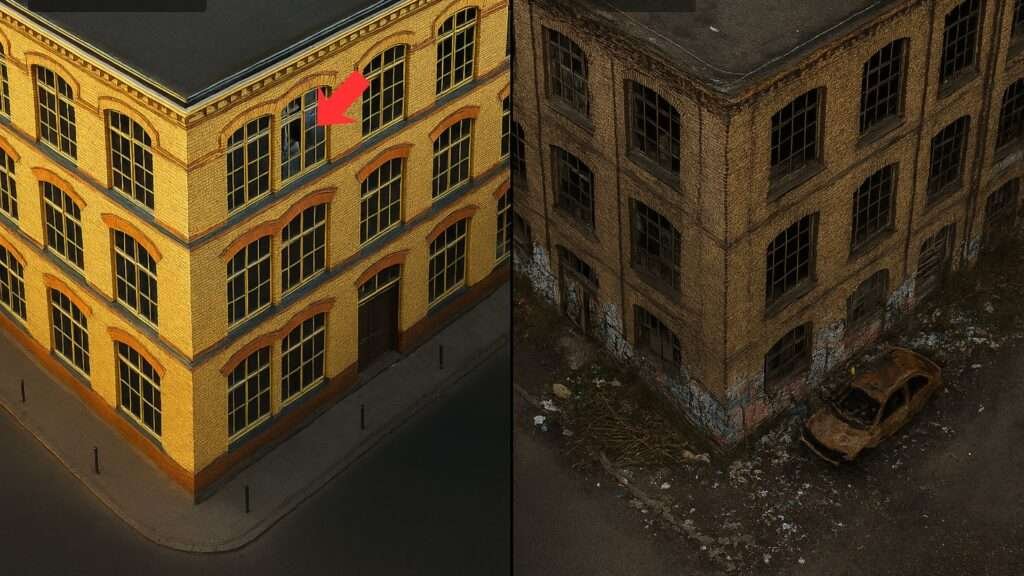

For an organisation aiming to operate at roughly 65–75% excellence on the “What does good look like?” scale, the maintenance planning equation becomes a deliberate tool for balancing risk, effort and operational impact.

At this level of maturity, the organisation is not striving for perfection or industry‑defining performance, but it is firmly committed to avoiding unacceptable outcomes and consistently delivering safe, reliable and predictable maintenance execution.

A 65–75% organisation understands that planning effort must be proportionate to risk. It applies structured thinking to determine how much detail, technical review and coordination each job requires.

High‑risk or complex tasks receive deeper scrutiny, while routine or low‑impact work is handled efficiently through standardisation.

Leaders at this level expect planning to be disciplined, repeatable and aligned with operational priorities, without imposing unnecessary administrative burden.

This section explains how the maintenance planning equation provides the framework for making those decisions, ensuring that planning effort is targeted, consistent and aligned with the organisation’s desired position on the excellence scale.

Category | Explanation |

What | The maintenance planning equation is the combination of asset criticality, risk exposure, task complexity, regulatory requirements and operational impact that determines the appropriate level of planning effort. It defines how much rigour is required for both preventive and corrective maintenance. |

Why | It ensures planning effort is proportionate to risk, prevents over‑ or under‑planning, supports safety and compliance and aligns maintenance activities with operational needs. It also ensures resources are used efficiently and consistently. |

Who | Maintenance Planners, Supervisors, Reliability Engineers, Operations, Procurement, Materials Management, Quality and Safety teams. Each group interacts with the planning equation, but planners and reliability engineers use it most directly. |

When | Applied continuously during PM generation, corrective work vetting, materials planning, work pack development, engineering review and long‑term strategy development. It is used whenever determining the level of detail required for a job. |

How | By adjusting the depth and rigour of planning based on context. Low‑criticality environments rely on standardisation and coordination; high‑criticality environments require engineering‑level planning, extensive documentation and long‑lead materials management. The equation determines planning effort, documentation complexity, skill requirements and review depth. |

2.1. Industry Variability in Planning Requirements.

Every organisation operates with a maintenance planning equation, a unique combination of asset criticality, risk exposure, task complexity and operational impact that determines the appropriate level of planning effort.

While the fundamental principles of maintenance planning remain constant, the weighting assigned to each variable changes significantly across industries and operational contexts.

The planning equation considers:

- Risk of equipment failure.

- Consequences of failure on operations, safety and compliance.

- Regulatory and statutory requirements.

- Technical complexity of maintenance tasks.

- Materials procurement lead times.

- Planning horizon requirements.

- Work package documentation complexity.

- Maturity level of maintenance strategies.

2.2. Example 1: Courier Business.

A courier business operating a fleet of 12 delivery vans, 2 flatbed trucks and 4 coupe utilities demonstrates maintenance planning in a low to medium criticality environment with high asset utilisation.

The maintenance planning equation for this operation includes:

- Risk of failure: Moderate.

- Consequence of failure: Delivery delays, customer dissatisfaction, overtime costs.

- Regulatory requirements: Roadworthiness certifications, emissions compliance, safety inspections.

- Complexity of tasks: Predominantly standardised activities such as oil changes, brake servicing, tyre replacements and belt inspections.

- Materials lead time: Low, with most parts available from local suppliers.

- Planning horizon: Weeks rather than months.

- Work pack complexity: Minimal, consisting primarily of job cards, checklists and standard task instructions.

- Strategy maturity: High potential for standardisation across the fleet.

In this environment, preventive maintenance tasks are simple, repetitive and readily standardised. Corrective tasks typically involve predictable component failures including alternators, batteries and tyres.

Planners rely extensively on pre built job plans and service checklists provided by manufacturers or developed internally.

Most maintenance work can be scheduled around delivery windows or conducted after operational hours. The planner’s primary function centres on coordination rather than deep technical review.

This operational context allows:

- Junior planners to function effectively with appropriate training.

- CMMS systems to automate preventive maintenance generation and readiness verification.

- Low planning effort per individual job.

- Substantial organisational benefit from investment in standard job plans.

This represents a classic repeatable maintenance environment where standardisation and systematic coordination deliver optimal results.

2.3. Example 2: Satellite Launch Company.

A satellite launch company managing launch vehicles, cryogenic fuel systems, guidance and telemetry equipment, high precision ground support equipment and mission critical infrastructure operates at the opposite end of the planning spectrum.

The maintenance planning equation for this operation includes:

- Risk of failure: Catastrophic.

- Consequence of failure: Complete mission loss, vehicle destruction, regulatory violations, safety incidents.

- Regulatory requirements: Aerospace standards, defence compliance frameworks, safety certifications.

- Complexity of tasks: Extremely high, requiring multidisciplinary coordination and engineering oversight.

- Materials lead time: Months to years for specialised components.

- Planning horizon: Multi year strategic planning cycles.

- Work pack complexity: Extensive documentation resembling engineering dossiers, including detailed drawings, precise torque specifications, comprehensive test procedures and quality assurance hold points.

- Strategy maturity: High, but continuously evolving with engineering modifications and configuration changes.

In this environment, preventive maintenance tasks are engineering controlled and subject to strict configuration management protocols.

Corrective work frequently requires root cause analysis completion before planning activities can commence.

Work packages resemble engineering dossiers rather than simple job cards. Every maintenance task carries safety, quality and regulatory implications that must be rigorously addressed.

Materials procurement may involve long lead times, custom fabrication or certification processes.

Planners work in close coordination with engineers, quality assurance teams, mission control personnel and safety specialists.

Planning functions as a high skill, engineering adjacent discipline requiring advanced technical knowledge and meticulous attention to detail.

This operational context requires:

- Planning as a high skill discipline with engineering competency.

- Planner involvement in risk assessment, configuration control and compliance verification.

- Extremely high planning effort per individual job.

- Engineering review for all tasks, including repeat activities.

This represents a zero defect tolerance environment where planning rigour directly correlates with mission success and safety outcomes.

2.4. Universal Principles Across Different Contexts.

Despite the substantial differences illustrated by the courier business and satellite launch company examples, both organisations execute the same core planning functions:

- Generate preventive maintenance work orders.

- Plan corrective maintenance activities.

- Build work packages with appropriate documentation.

- Manage materials procurement and inventory.

- Coordinate resources and labour allocation.

- Utilise CMMS or EAM systems for work management.

The depth, rigour and technical intensity applied to each function varies dramatically based on the organisation’s maintenance planning equation.

The examples demonstrate that planning requirements change across multiple dimensions:

- Planner workload and capacity requirements.

- Required skill levels and technical competency.

- Depth of technical review and validation.

- Work package complexity and documentation standards.

- Strategy maturity and governance requirements.

- Organisational risk tolerance thresholds.

Regardless of industry context, effective planning ensures maintenance activities are clearly defined, properly resourced and aligned with operational needs.

3.0 The Foundation of Maintenance Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, the foundation of maintenance planning must be solid, disciplined and consistently applied.

At this level, the organisation is committed to avoiding unacceptable outcomes, such as safety incidents, regulatory breaches or uncontrolled downtime, while also recognising that perfection is not the goal.

Instead, the focus is on building reliable, repeatable processes that ensure maintenance work is clearly defined, properly justified and fully prepared before it reaches execution.

A 65–75% organisation expects planners to bring clarity, structure and foresight to every task.

Ambiguity is minimised, reactive behaviour is reduced and maintenance activities are aligned with operational priorities rather than driven by urgency or convenience.

The foundation of planning at this maturity level is not about excessive documentation or gold‑plated processes; it is about ensuring that every job begins with a clear purpose, a defined scope and the essential information required for safe, efficient execution.

This section outlines the core principles that underpin effective maintenance planning and explains how clarity of purpose and readiness control form the bedrock of a reliable maintenance system.

Category | Explanation |

What | The foundational purpose of maintenance planning: defining what work must be done, why it is required and how it will be executed. It includes reviewing work orders, generating PM tasks, vetting corrective work and preparing complete work packages. |

Why | To eliminate ambiguity, prevent delays, reduce safety risks and ensure maintenance activities directly support asset reliability and operational objectives rather than reactive pressures. |

Who | Maintenance Planners (primary role), supported by Tradespeople, Supervisors, Reliability Engineers, Operations, Procurement and Safety teams. |

When | Applied continuously during backlog review, PM generation cycles, corrective work vetting and immediately before work is released for execution. |

How | Through structured review of work orders, readiness checks, job site validation, coordination with stakeholders, preparation of work packs and ensuring all materials, documentation and resources are in place before |

3.1. Clarity of Purpose.

Maintenance planning begins with clarity regarding what work must be done, why it is required and how it will be executed.

The planner’s foundational responsibilities include reviewing outstanding work orders, generating preventive maintenance tasks, vetting corrective work requests and preparing detailed work packages that technicians can rely upon during execution.

This clarity of purpose eliminates ambiguity and ensures that maintenance activities directly support asset reliability objectives rather than simply reacting to immediate pressures.

3.2. The Planner as Readiness Checkpoint.

The planner functions as the primary checkpoint for maintenance readiness within the organisation.

When a job reaches the execution phase, every reasonable detail should have been considered, documented and prepared.

This checkpoint function prevents incomplete work from entering the execution pipeline, where missing information, unavailable materials or unclear scope would result in delays, safety risks and inefficient resource utilisation.

The planner ensures that technicians can focus on value adding maintenance activities rather than searching for information, clarifying instructions or waiting for materials.

4.0 Preventive Maintenance Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, preventive maintenance planning becomes one of the most important levers for controlling risk and ensuring predictable asset performance.

At this maturity level, the organisation recognises that preventive maintenance is not simply a recurring task list, it is a structured reliability strategy that must be prepared, validated and executed with discipline.

The goal is not perfection, but consistent, dependable performance that prevents avoidable failures and keeps the business well clear of the unacceptable outcomes found at the lower end of the scale.

A 65–75% organisation expects preventive maintenance to be governed by clear strategies, accurate master data and a planning process that differentiates between mature, approved tasks and those requiring deeper technical review.

Planners apply readiness checks to well‑established PMs, while unapproved or ambiguous tasks trigger more detailed scrutiny, consultation with specialists and engineering validation.

This balance ensures that planning effort is proportional to risk, while still maintaining the efficiency needed to support a large volume of recurring work.

This section outlines how preventive maintenance planning functions within this performance band, demonstrating how structured preparation, forward visibility and strategy governance combine to deliver safe, reliable and repeatable maintenance execution.

Category | Explanation |

What | The structured preparation of recurring maintenance tasks defined in PM master records, including PM work order generation, readiness checks, technical review of unapproved PMs and strategy governance. |

Why | To ensure preventive tasks are executed safely, consistently and with adequate preparation time. Early visibility prevents reactive maintenance, reduces downtime, supports compliance and improves reliability. |

Who | Maintenance Planners (readiness and review), Reliability Engineers (strategy validation), Tradespeople and Engineers (scope clarification), Operations (schedule alignment), Procurement/Materials teams (lead times and availability). |

When | At each PM generation cycle , from days in advance for simple tasks to months ahead for shutdowns or major overhauls. Technical reviews occur when PMs lack approved strategy codes; engineering validation follows planner review. |

How | By generating PMs from master data, identifying long‑lead materials, coordinating with procurement and operations, applying readiness checks to approved PMs, conducting detailed technical reviews for unapproved PMs and submitting updates to Reliability Engineers for strategy approval and master data control. |

4.1. PM Work Order Generation.

A significant portion of maintenance planning effort revolves around preventive maintenance activities. PM work orders originate from approved PM master records stored within the CMMS, EAM or ERP system.

These master records define the recurring tasks required to maintain asset reliability based on manufacturer recommendations, regulatory requirements, engineering analysis or operational experience.

Work orders are generated automatically by the system a defined period before they fall due, creating a planning runway that allows adequate preparation time.

4.2. Forward Visibility and Early Preparation.

Early work order generation provides forward visibility that enables planners to identify long lead time materials, coordinate with procurement teams and align maintenance activities with production schedules.

Without this advance preparation window, maintenance operations quickly become reactive, resulting in increased costs, extended downtime and frequent delays.

The planning runway varies based on organisational requirements and may range from several days for simple tasks to several months for complex shutdowns or major overhauls.

4.3. Approved PM Strategies and Readiness Checks.

In organisations with mature, approved PM strategies, planners focus primarily on materials availability, resource allocation and overall readiness verification.

The scope and technical content of these PM work orders have already been validated through a strategy governance process involving reliability engineers, maintenance specialists and operational stakeholders.

Good practice involves applying a visible code or identifier to all approved PM strategies within the CMMS.

This coding system allows planners to immediately recognise which tasks require only a readiness check rather than detailed technical review.

This distinction prevents unnecessary duplication of effort and ensures planning resources are allocated where they add most value.

Readiness checks typically verify:

- Materials availability or procurement status.

- Labour resource allocation.

- Coordination with production schedules.

- Isolation and permit requirements.

- Special tooling or equipment needs.

4.4. Detailed Technical Review of Unapproved PMs.

When a planner encounters a PM that lacks the approved strategy identifier, the level of scrutiny must increase substantially.

These situations require a detailed technical review rather than a simple readiness check.

The technical review process includes:

- Walking the job site to understand physical conditions and access requirements.

- Consulting with tradespeople who will execute the work to validate scope and identify potential issues.

- Speaking with asset specialists or process engineers to clarify technical requirements.

- Identifying safety requirements including isolation procedures, confined space entry, work at height or hazardous materials handling.

- Determining inspection and test requirements with appropriate acceptance criteria.

- Documenting compliance obligations related to regulatory standards or manufacturer requirements.

Many planners are former tradespeople who have been promoted into planning roles. This background provides valuable hands on knowledge that enhances the technical review process. The detailed review transforms a generic PM task into a precise, executable plan that technicians can trust.

4.5. Reliability Engineer Validation and Strategy Control.

Once the planner completes a detailed technical review of an unapproved PM, the documented information should be passed to the Reliability Engineer for further evaluation.

The engineer’s role includes:

- Confirming technical validity of the proposed maintenance tasks.

- Ensuring alignment with broader asset management strategies.

- Incorporating improvements based on failure history, condition monitoring data or industry best practice.

- Updating PM master data to reflect validated requirements.

After this engineering review, the PM can be formally approved, added to the controlled strategy library and coded appropriately within the CMMS.

Future occurrences of this PM can then be treated as mature, validated tasks requiring only readiness checks rather than repeated technical review.

This governance process creates continuous improvement in PM quality while preventing planning effort waste on repeated evaluation of the same recurring tasks.

5.0 Corrective Work Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, corrective work planning must balance responsiveness with discipline.

At this maturity level, the organisation accepts that corrective work will always arise, but it refuses to let urgency or ambiguity drive poor decisions, unsafe actions or uncontrolled risk.

Instead, corrective tasks are channelled through a structured vetting and prioritisation process that ensures only necessary, clearly defined and properly justified work enters the planning pipeline.

A 65–75% organisation expects planners to validate the problem, assess urgency based on risk and operational impact and determine the appropriate level of planning effort.

Routine corrective tasks are handled efficiently, while higher‑risk or technically complex issues trigger deeper review, bundling opportunities or capitalisation assessment.

The goal is not to eliminate corrective work, but to ensure that every corrective task is prepared with enough clarity, control and foresight to prevent the kinds of failures that sit at the lower end of the performance scale.

This section outlines how corrective work is vetted, prioritised and prepared within this performance band, demonstrating how structured decision‑making and disciplined planning prevent reactive maintenance from undermining safety, reliability and operational stability.

Category | Explanation |

What | Corrective work planning ensures that faults, defects and breakdown‑related tasks are properly vetted, prioritised and prepared before execution. It includes validating work requests, assessing urgency and risk, bundling tasks for efficiency and identifying capitalisable work. |

Why | To prevent vague or low‑value tasks from entering the planning pipeline, reduce downtime through bundling, ensure safety and production risks are managed and support financial governance by identifying capital work early. |

Who | Maintenance Planners (vetting, prioritisation, bundling), Operators and Technicians (raising work requests), Reliability Engineers (capitalisation and technical review), Supervisors (scope confirmation), Production/Operations (schedule coordination). |

When | Applied immediately after a corrective work request is raised, during daily/weekly backlog review, when planning shutdowns or outages and whenever assessing whether work should be capitalised or bundled. |

How | By validating work requests, assessing urgency and risk, checking for duplicates, determining capitalisation requirements, grouping tasks around planned outages, coordinating with production and preparing work packs for execution. |

5.1. Work Order Vetting and Prioritisation.

Corrective work follows a similar planning path to preventive maintenance but with greater emphasis on urgency, clarity and risk assessment.

When a fault or defect is identified by operators, technicians or condition monitoring systems, a work request is raised and must be vetted to determine its validity, priority and required response.

The vetting process is critical because it ensures only necessary, well defined work enters the planning pipeline.

This prevents vague requests, duplicate notifications or low value tasks from consuming limited planning and execution resources.

During vetting, planners consider:

- Validity of the reported issue and whether investigation is required.

- Urgency based on safety risk, production impact and equipment condition.

- Whether the work should be capitalised rather than treated as routine maintenance.

- Opportunities to bundle the work with other planned activities.

5.2. Bundling Tasks for Efficiency.

Bundling represents a powerful planning technique, particularly in asset intensive environments where equipment shutdowns significantly impact production.

When multiple corrective tasks affect the same asset or system, grouping them around a planned outage or preventive maintenance window can substantially reduce cumulative downtime and improve labour efficiency.

Effective bundling requires forward visibility of both planned and corrective work, coordination with production schedules and clear communication with maintenance supervisors regarding the combined scope.

5.3. Capitalisation Considerations.

Some corrective work represents capital expenditure rather than operational expenditure due to its nature or scale.

Work that extends asset life, increases capacity, improves performance beyond original specifications or involves major component replacement may require capitalisation treatment.

Planners support financial oversight by identifying potential capital work during the vetting process and ensuring it receives appropriate review and approval before proceeding.

6.0 Work Pack Development.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, work pack development becomes one of the clearest indicators of planning maturity.

At this level, the organisation recognises that technicians can only perform safe, efficient and high‑quality work when they are equipped with complete, accurate and unambiguous information.

The goal is not to produce encyclopaedic documentation, but to ensure that every job is supported by a work pack that eliminates avoidable uncertainty and prevents the kinds of errors, delays and safety exposures found at the lower end of the scale.

A 65–75% organisation expects work packs to be consistent, structured and aligned with the complexity of the task.

Routine jobs receive streamlined, standardised packs, while higher‑risk or technically demanding work requires more detailed instructions, drawings, isolation requirements and inspection criteria.

The emphasis is on clarity, completeness and usability, providing technicians with everything they need to execute the job correctly the first time.

This section outlines how work packs are constructed, reviewed and approved within this performance band, demonstrating how high‑quality documentation directly drives execution efficiency, safety performance and overall maintenance reliability.

Category | Explanation |

What | Work pack development is the creation of a complete, structured bundle of information that technicians rely on to execute maintenance work safely, efficiently and correctly. It includes work instructions, drawings, isolation lists, inspection and test plans, materials lists, tooling requirements, OEM notices and applicable standards. |

Why | High‑quality work packs reduce delays, prevent rework, minimise safety risks and ensure technicians spend their time performing value‑adding work rather than searching for missing information. They directly influence execution efficiency, equipment uptime and maintenance cost control. |

Who | Maintenance Planners (primary authors), Work Pack Approvers such as Supervisors or Senior Technicians (quality review), Technicians (end users), Reliability Engineers (technical input when required), Safety and Compliance teams (verification of isolation and regulatory requirements). |

When | Developed during the planning phase before work is released for scheduling or execution. Reviewed and approved immediately prior to execution to ensure accuracy, completeness and readiness. |

How | By assembling all required documentation, writing clear step‑by‑step instructions, incorporating engineering drawings and specifications, preparing isolation and blind lists, defining inspection and test criteria, listing materials and tooling, referencing standards and OEM bulletins and submitting the pack for formal review and approval. |

6.1. Components of a Comprehensive Work Pack.

The work pack represents the planner’s signature deliverable and serves as the comprehensive bundle of information that technicians rely upon to execute work safely, efficiently and correctly.

A complete work pack typically includes:

- Work instructions with step by step procedures.

- Engineering drawings, diagrams and technical specifications.

- Isolation and blind lists detailing energy isolation requirements.

- Inspection and test plans with acceptance criteria.

- Materials lists with part numbers and quantities.

- Special technical instructions addressing critical steps or precautions.

- OEM safety notices and technical bulletins.

- Tooling requirements including specialised equipment.

- Applicable codes, standards and regulatory references.

The work pack quality directly reflects planning quality and serves as a key driver of execution efficiency.

Well constructed work packs reduce delays, prevent rework and ensure technicians spend time performing value adding maintenance rather than searching for information or clarifying ambiguous instructions.

6.2. Work Pack Quality Review and Approval.

Work packs often undergo formal review before release to execution.

The Work Pack Approver, frequently a maintenance supervisor or senior technician, verifies that all required documentation is present, instructions are clear and the job can be executed without ambiguity. If information is missing or unclear, the pack is returned to the planner for revision.

This review step maintains consistency across the maintenance department, supports compliance with safety and engineering standards and creates a feedback loop that helps planners continuously improve their output quality.

6.3. Impact on Execution Efficiency.

The correlation between work pack quality and execution efficiency cannot be overstated. Incomplete or poorly prepared work packs result in:

- Work delays while technicians search for missing information.

- Safety risks from unclear isolation or hazard identification.

- Rework when tasks are performed incorrectly due to inadequate instructions.

- Extended equipment downtime impacting production.

- Increased maintenance costs from inefficient labour utilisation.

Conversely, comprehensive work packs enable technicians to work confidently, safely and efficiently, maximising the value delivered from maintenance activities.

7.0 Standardisation of Repeatable Work.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, standardisation becomes a defining feature of maintenance maturity.

At this level, the organisation recognises that many corrective tasks occur frequently enough to justify controlled, repeatable planning.

The goal is not to create rigid, inflexible procedures, but to eliminate unnecessary variation, reduce planning effort and ensure that common tasks are executed safely and consistently every time.

A 65–75% organisation expects planners to identify repeatable work, capture the essential steps, safety requirements, materials and inspection criteria and store them in controlled job plans or task lists.

This approach ensures that routine corrective work receives the same discipline and reliability focus as preventive maintenance, without burdening planners with repetitive documentation.

Standardisation also strengthens training, improves cost predictability and reduces the risk of errors caused by inconsistent work practices.

This section outlines how standard job plans and task lists support efficient, reliable execution within this performance band, demonstrating how controlled repeatability becomes a practical lever for lifting overall maintenance performance.

Category | Explanation |

What | Standardisation involves creating controlled, reusable job plans, task lists and pre‑plans for corrective tasks that occur frequently. These standard plans capture typical steps, safety requirements, materials, tools and inspection criteria so they can be instantly applied to new work orders. |

Why | Standardisation reduces planning effort, ensures consistent execution, improves quality through engineering‑approved content, simplifies training and enhances cost and resource forecasting. It brings corrective work up to the same level of discipline and repeatability as preventive maintenance, reinforcing a culture of reliability and continuous improvement. |

Who | Maintenance Planners (primary users), Reliability Engineers (approvers and content owners), Technicians (end users), Supervisors (execution oversight) and Training/Competency teams (using standard plans for onboarding). |

When | Applied whenever a repeatable corrective task is identified, during strategy development, when reviewing historical work and when converting work requests into work orders. Standard plans are attached at the planning stage before execution. |

How | By analysing recurring corrective tasks, developing standard job plans with procedural steps, safety requirements, materials, tools and inspection criteria, storing them in a controlled library and attaching them to work orders during planning to eliminate rework and ensure consistency. |

7.1. Standard Job Plans and Task Lists.

In organisations with mature maintenance systems, many corrective tasks occur with sufficient frequency to justify standardisation.

Creating standard job plans, task lists or pre plans for these repeatable activities delivers substantial benefits.

Standardised plans contain the information that consistently applies to specific types of work:

- Typical procedural steps.

- Safety requirements and isolation procedures.

- Standard materials and quantities.

- Required tools and equipment.

- Inspection points and acceptance criteria.

When a planner converts a work request into a work order, these standard plans can often be attached instantly from the controlled library.

This eliminates the need to recreate planning documentation for common tasks.

7.2. Benefits of Standardised Corrective Work.

Standardisation of repeatable corrective work provides multiple advantages:

- Reduced planning time and effort.

- Consistent execution approach across different technicians.

- Engineering approved content that ensures quality.

- Simplified training for new planners and technicians.

- Improved cost estimation and resource forecasting.

Importantly, standardisation ensures corrective work receives the same discipline and repeatability as preventive maintenance.

This reinforces a culture of reliability and continuous improvement rather than treating corrective work as inherently unpredictable or chaotic.

8.0 Financial Oversight in Maintenance Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, financial oversight becomes a core component of disciplined maintenance planning.

At this level, the organisation recognises that maintenance decisions are not only technical and operational, they are also strategic financial commitments.

The goal is to ensure that every maintenance activity, from routine tasks to major interventions, is aligned with budget expectations, organisational priorities and long‑term asset strategies.

A 65–75% organisation does not tolerate uncontrolled spending, ambiguous cost estimates or reactive financial decisions that push it toward the lower end of the scale.

Instead, planners are expected to provide realistic cost estimates, identify capital‑eligible work early and ensure that approval pathways reflect both risk and financial impact.

High‑cost or high‑risk work receives appropriate scrutiny, while routine tasks flow efficiently through delegated authority limits.

This balance prevents financial surprises, supports transparent decision‑making and ensures that maintenance activities contribute to sustainable asset performance rather than creating hidden liabilities.

This section outlines how financial oversight functions within this performance band, demonstrating how structured cost estimation, CAPEX/OPEX clarity and disciplined approval processes help maintain control, predictability and alignment with organisational strategy.

Category | Explanation |

What | Financial oversight ensures that maintenance work is costed accurately, aligned with available budgets and correctly classified as operational expenditure (OPEX) or capital expenditure (CAPEX). It includes cost estimation, budget checks, delegated approval processes and early identification of capital‑eligible work. |

Why | To prevent budget overruns, ensure financial accountability, support organisational prioritisation and ensure capital projects follow proper governance. Accurate classification affects funding, reporting, project controls and long‑term asset management. |

Who | Maintenance Planners (cost estimation and CAPEX/OPEX identification), Supervisors and Superintendents (approval within delegated limits), Managers and Senior Leaders (review of high‑cost work), Reliability Engineers (technical input for capital work), Finance Teams (budget oversight and reporting). |

When | Applied before any work order is approved for execution, during planning and vetting, when estimating costs, when identifying capital work and during budget review cycles. Early identification is essential for governance and funding allocation. |

How | By estimating labour, materials and contractor costs; comparing estimates to available budgets; escalating high‑cost work for managerial review; identifying CAPEX‑eligible tasks based on asset life extension, performance improvement or major replacement; and ensuring capital work follows formal approval and project control processes. |

8.1. Cost Estimation and Budget Alignment.

Before a work order receives approval for execution, its estimated cost must be evaluated against available budgets and funding allocation.

Planners provide realistic cost estimates based on materials requirements, labour hours, contractor services and other anticipated expenses.

Smaller jobs may receive approval directly from planners or supervisors within delegated authority limits.

Larger work typically requires superintendent or manager review to ensure alignment with organisational priorities and budgetary constraints.

Even when formal approval is not required, senior management often appreciates awareness that high cost work is about to proceed.

8.2. CAPEX versus OPEX Identification.

Planners support financial discipline by identifying work that should be treated as capital expenditure rather than operational expenditure.

This distinction affects budgeting, approval processes, project oversight and financial reporting.

Capital work typically involves:

- Asset life extension beyond original design life.

- Performance improvements or capacity increases.

- Major component replacement or system upgrades.

- Regulatory compliance projects requiring significant investment.

Early identification ensures capital projects are properly justified, approved through appropriate governance channels and managed with suitable project controls.

9.0 Break In Work and Urgent Maintenance.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, break‑in work and urgent maintenance must be handled with a balance of rapid response discipline and controlled risk management.

At this maturity level, the organisation accepts that unplanned failures and urgent threats will occur, but it refuses to let urgency become an excuse for unsafe shortcuts, unclear scopes or uncontrolled decision‑making.

The goal is to respond quickly while maintaining enough structure to prevent the kinds of safety incidents, quality failures and escalation events that sit at the lower end of the performance scale.

A 65–75% organisation expects supervisors and planners to apply minimum planning controls even under time pressure, confirming the basic scope, identifying critical hazards, ensuring essential materials are available and verifying that the right skills are on hand.

This approach prevents emergency work from becoming chaotic or reactive, while still enabling the organisation to protect people, assets and production when time is limited.

This section outlines how urgent maintenance is managed within this performance band, demonstrating how disciplined responsiveness keeps the organisation safely above the unacceptable zone while maintaining operational stability.

Category | Explanation |

What | Break‑in work refers to urgent, unplanned maintenance tasks that must be executed immediately to address safety risks, environmental threats or imminent equipment failure. Although these tasks bypass normal planning and scheduling cycles, they still require minimum planning controls to ensure safe and effective execution. |

Why | To balance rapid response with essential planning discipline. Even in emergencies, inadequate preparation can lead to safety incidents, quality failures, extended downtime or escalation of the original problem. Minimum planning requirements ensure technicians understand the scope, hazards and resources needed before work begins. |

Who | Supervisors (primary decision‑makers and coordinators), Maintenance Planners (support where time allows), Technicians (executors of the work), Operations/Production (risk communication and access), Safety teams (verification of isolation and hazard controls). |

When | Applied immediately when a fault poses an urgent safety, environmental or operational risk and cannot wait for the standard planning and scheduling cycle. Minimum planning checks occur just before technicians are dispatched. |

How | By defining a basic job scope, confirming safety documentation and isolation requirements, ensuring critical materials are available, verifying appropriate labour skills, coordinating with operations and documenting the emergency work. Even under time pressure, supervisors maintain enough control to ensure safe, effective execution. |

9.1. Balancing Urgency with Control.

Break in work refers to urgent maintenance tasks that must be executed quickly to address immediate safety risks, environmental threats or imminent equipment failure.

These situations cannot wait for the normal planning and scheduling cycle.

However, urgency does not eliminate the need for planning discipline.

Even emergency work should not proceed without at least a basic understanding of what technicians are about to do, how they will do it safely and what resources are required.

9.2. Minimum Planning Requirements for Emergency Work.

Supervisors ensure that essential elements are in place before emergency work begins:

- Basic job plan or scope definition.

- Safety documentation including isolation requirements.

- Critical materials availability or procurement plan.

- Appropriate labour skills and availability.

Break in work may bypass the normal scheduling process but still requires documentation, approvals and coordination.

The objective is balancing urgent response with sufficient control to prevent safety incidents or quality failures that could worsen the original problem.

10.0 Long Term Forecasting and Strategic Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, long‑term forecasting and strategic planning become essential capabilities rather than optional administrative exercises.

At this maturity level, the organisation recognises that reliable maintenance performance depends on forward visibility, coordinated resource planning and structured alignment with production priorities.

The goal is to stay well ahead of emerging risks, major maintenance events and long‑lead resource requirements, ensuring the organisation never drifts toward the reactive, crisis‑driven behaviours found at the lower end of the scale.

A 65–75% organisation expects planners and leaders to maintain a rolling view of upcoming shutdowns, statutory inspections, overhauls and major interventions.

This includes anticipating specialist contractor needs, long‑lead materials and cross‑site scheduling conflicts, as well as supporting capital budgeting processes with accurate, future‑focused insights.

Long‑term planning at this level is not about predicting the future perfectly, it is about creating enough structured foresight to make informed decisions, negotiate effectively and ensure that critical resources are available when needed.

This section outlines how long‑term forecasting functions within this performance band, demonstrating how strategic visibility strengthens operational stability and supports sustainable asset performance.

Category | Explanation |

What | Long‑term forecasting provides a strategic view of major maintenance events such as shutdowns, turnarounds, overhauls and statutory inspections. It involves developing asset plans, reviewing PM requirements 12–36 months ahead and coordinating future resource needs including contractors, materials and specialist support. |

Why | To avoid scheduling conflicts, ensure resource availability, support capital budgeting, reduce procurement delays, negotiate favourable contractor rates and align major maintenance activities with production and organisational priorities. Long‑range planning reduces operational risk and improves cost efficiency. |

Who | Long‑Term Planners (primary role), Maintenance Planners, Reliability Engineers, Operations/Production teams, Engineering, Commercial/Finance departments, Procurement, Contractor Management and OEM technical support teams. |

When | Conducted continuously as part of rolling 12–36‑month planning cycles, during annual budgeting processes, ahead of major shutdowns or overhauls and whenever long‑lead materials or specialist contractors are required. |

How | By reviewing future PM requirements, mapping major maintenance events, aligning schedules with production plans, identifying long‑lead materials and specialist resources, coordinating across departments, supporting capital planning and updating long‑term asset plans to reflect operational and strategic needs. |

10.1. Asset Plans and Major Maintenance Events.

Maintenance planning extends beyond immediate work preparation into long term forecasting. Long term asset plans provide a strategic view of major maintenance events including shutdowns, turnarounds, overhauls and statutory inspections.

In some organisations, dedicated long term planners review preventive maintenance requirements projected over the next 12 to 36 months, align them with production schedules and coordinate with operations, engineering and commercial departments to avoid conflicts.

10.2. Resource Coordination and Capital Planning.

Long range visibility enables organisations to understand future resource demands well in advance. This includes identifying requirements for:

- Specialist contractors with specific technical capabilities.

- Overseas technical support from equipment manufacturers.

- Major materials with extended procurement cycles.

- Shutdown coordination across multiple facilities.

The further ahead an organisation can plan, the better it can support capital budgeting processes, negotiate favourable contractor rates and ensure that critical resources are available when needed.

11.0 Materials and Services Planning.

For an organisation aiming to operate at 65–75% excellence on the “What does good look like?” scale, materials and services planning becomes a critical safeguard against avoidable delays, cost overruns and execution failures.

At this maturity level, the organisation recognises that even the most well‑planned maintenance activity can collapse if the right parts, services or specialist support are not available when needed.

The goal is to maintain a level of proactive materials readiness that keeps the organisation well clear of the reactive, last‑minute scrambling found at the lower end of the scale.

A 65–75% organisation expects planners to identify material requirements early, validate technical specifications, confirm accurate part numbers, anticipate long‑lead procurement risks and coordinate closely with procurement and stores teams.

This approach ensures that materials arrive on time, meet quality expectations and are available before execution begins. It also strengthens cost predictability, reduces schedule disruptions and supports a stable, reliable maintenance workflow.

This section outlines how materials and services planning functions within this performance band, demonstrating how disciplined coordination and early identification of requirements directly support safe, efficient and interruption‑free maintenance execution.

Category | Explanation |

What | Materials and services planning ensures that all required parts, consumables and external services are identified, specified and procured in time to support scheduled maintenance execution. It includes early identification of materials, creation of requisitions and purchase orders and coordination with procurement to avoid delays. |

Why | To prevent one of the most common causes of maintenance disruption: materials unavailability. Accurate early identification and proactive procurement reduce delays, prevent incorrect orders, ensure quality compliance and support efficient execution. This directly improves schedule adherence and reduces downtime. |

Who | Maintenance Planners (requirements identification and accuracy checks), Procurement Teams (supplier engagement and purchasing), Supervisors (confirmation of needs), Technicians (technical input on specifications), Stores/Inventory Teams (receiving, inspection and stock control), Suppliers and Contractors (service delivery). |

When | Applied immediately after a work order is approved and throughout the planning phase. Long‑lead items must be identified early, emergency procurement is used when required and materials must be available before scheduled execution. Inventory forecasting occurs continuously. |

How | By identifying part numbers, specifications and quantities; aligning delivery timing with the schedule; raising requisitions and purchase orders; coordinating with procurement on long‑lead or urgent items; verifying materials on receipt; maintaining critical spares; and ensuring all materials and services are ready before work |

11.1. Early Identification of Requirements.

Once a work order receives approval, the maintenance system can generate requisitions and purchase orders for catalogued materials and external services.

These documents flow through procurement channels for supplier engagement and delivery coordination.

Planners play a crucial role in identifying material requirements early in the planning process and ensuring accuracy of:

- Part numbers and item codes.

- Technical specifications and quality requirements.

- Required quantities.

- Delivery timing aligned with scheduled execution.

11.2. Procurement Coordination.

Effective materials planning prevents execution delays caused by parts shortages, incorrect specifications or delivery failures.

Close coordination between planners and procurement teams ensures that:

- Long lead time items are identified and ordered promptly.

- Emergency procurement processes are used appropriately.

- Materials are received, inspected and made available before scheduled work commencement.

- Inventory levels for critical spares are maintained based on maintenance forecasts.

Materials delays represent one of the most common causes of maintenance schedule disruption. Proactive materials planning directly addresses this risk.

12.0 Conclusion.

Maintenance planning functions as a critical discipline that transforms maintenance operations from reactive firefighting into a predictable, optimised system supporting long term asset reliability.

While the specific application of planning principles varies across industries and operational contexts, the foundational elements remain consistent.

Effective planning creates readiness across multiple dimensions including scope clarity, risk understanding, materials availability, labour allocation and safety preparation.

When work reaches execution, technicians should be able to proceed confidently with comprehensive information and appropriate resources.

The maintenance planning equation, comprising asset criticality, risk, complexity and operational impact, determines the appropriate depth and rigour of planning effort. Organisations benefit from understanding where they sit on this spectrum and applying planning resources accordingly.

Quality maintenance planning reduces downtime, improves reliability, enhances safety performance and optimises maintenance costs.

It represents an investment that delivers returns through improved asset performance, extended equipment life and more efficient resource utilisation.

For asset intensive organisations, maintenance planning is not an optional administrative function but a core capability that directly enables operational success.

12.1 Operating at 65–75% Excellence on the Scale.

For organisations aiming to operate at 65–75% excellence on the “What does good look like?” scale, maintenance planning becomes the mechanism that consistently keeps performance above the threshold of unacceptable outcomes while steadily driving improvement.

This performance band reflects a mature, disciplined and reliable maintenance environment, one where reactive behaviour is controlled, risks are understood and planning processes are applied with intent rather than formality.

A 65–75% organisation does not pursue perfection at any cost, nor does it tolerate the systemic weaknesses that lead to safety incidents, uncontrolled downtime or regulatory exposure.

Instead, it focuses on building repeatable planning practices, strengthening cross‑functional coordination and ensuring that every job, whether preventive, corrective or urgent, receives the level of preparation appropriate to its risk and complexity. This balance allows the organisation to maintain operational stability while still being agile enough to respond to emerging issues.

Operating in this range also reflects a leadership mindset that values clarity of expectation, proportional planning effort and continuous improvement.

Leaders understand what must never be allowed to happen, what is realistically achievable and where investment in planning yields the greatest return.

The result is a maintenance function that is predictable, safe and aligned with organisational priorities, one that consistently delivers reliable asset performance without drifting toward the extremes of either complacency or over‑engineering.

This final perspective reinforces that maintenance planning is not merely a technical process but a strategic choice about where an organisation intends to position itself on the performance scale and how it ensures it stays there.

12.0 Bibliography.

1. Maintainability, Maintenance, and Reliability for Engineers by B.S. Dhillon

2. Maintenance Fundamentals, 2nd Edition by R. Keith Mobley

3. Engineering Reliability and Optimal Maintenance by Hoang Pham

4. Practical Reliability Engineering by Patrick D.T. O’Connor

5. Reliability Engineering Handbook by Hoang Pham and Myron L. Rhoades

6. Maintenance Engineering Handbook by Keith Mobley et al.

7. Reliability Engineering by Open Textbook BC

8. Engineering Maintenance: A Modern Approach by B.S. Dhillon

9. Reliability-Centered Maintenance by John Moubray

10. Uptime: Strategies for Excellence in Maintenance Management by John D. Campbell and James V. Reyes-Picasso

11. Maintenance and Reliability Best Practices by Ramesh Gulati

12. Rules of Thumb for Maintenance and Reliability Engineers by Ricky Smith and R. Keith Mobley

13. Reliability Engineering Handbook, Volume 1 by Dimitri B. Kececioglu

14. Physical Asset Management Handbook by John S. Mitchell

15. Lean Maintenance by Ricky Smith and Bruce D. Levitt

16. What makes good maintenance planning & scheduling? by Assetivity

17. Maintenance strategy: preventive or corrective? by Mobility Work

18. Work Management in CMMS: A Simple Guide for Maintenance by Reliable Plant

19. Corrective Maintenance vs. Preventive Maintenance by WorkTrek

20. Types of Maintenance Explained: Corrective, Preventive by F/T Maintenance

21. From Corrective to Predictive Maintenance—A Review by M. Molęda et al.

22. Preventive Maintenance Examples with a CMMS by ClickMaint

23. Preventive vs. Corrective Maintenance: Key Differences by UpKeep

24. Standard Job Plans by Maintenance World

25. Maintenance Plan: What Is It And How Does It Work by Process Navigation

26. Reliability Centered Maintenance (RCM) Guide by Reliable Plant

27. Work Packs in Maintenance Planning by Plant Maintenance

28. CMMS Best Practices for Planners by Uptime Institute

29. Bundling Maintenance Tasks for Efficiency by Assetivity

30. Preventive Maintenance Strategies in CMMS by Limble CMMS